Abstract

A new aminopeptidase (An-APa) was identified and biochemically characterized from Aspergillus niger CICIM F0215. It had maximal activity at 40 °C and pH 7.0 and exhibited a broad substrate specificity both on hydrophilic and hydrophobic amino acid residues at N-terminals. With An-APa hydrolysis for 1 h, the casein-pepsin and soybean protein isolates (SPI)-pepsin hydrolysates released both hydrophilic and hydrophobic amino acids and the hydrophobic amino acids having Q values (degree of hydrophobicity) greater than 1500 cal/mol were remarkably released. Leu, Ile, Phe, Tyr, Trp, Pro, Val and Lys in the casein hydrolysate after treatment with An-APa increased 18.61, 0.84, 11.35, 13.18, 3.34, 6.30, 7.46, and 8.19 mg/100 mL, respectively, and 19.72, 1.47, 18.37, 11.72, 4.61, 4.10, 8.13, and 5.85 mg/100 mL, respectively, in the SPI hydrolysate. Both accounted for 65.0% and 64.4% of total released free amino acids from casein and SPI hydrolysates, respectively. This indicated that An-APa could be potentially applicable in debittering protein hydrolysates.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The functional and application characteristics of protein products from either animal (meat, milk, and fish) or plant (soy, legume, and cereal) sources are improved or expanded when modified by certain proteolytic enzymes (Saha and Hayashi, 2001). These protein hydrolysates have been reported to show better processing characteristics due to improved solubility, hygroscopicity, foaming potency, gelatinisation ability, modified emulsifying capacity and reduced viscosity (Kodera et al., 2006). However, the enzymatic treatment of various food proteins generally results in undesirable characteristics like bitter taste due to formation of low molecular weight peptides containing hydrophobic amino acids. Thus, their applications are limited in food processing industry (Saha and Hayashi, 2001).

Various methods have been explored for debittering protein hydrolysates to increase their palatability (Saha and Hayashi, 2001). These include physical and chemical methods, such as activated carbon adsorption, organic solvent extraction and isoelectric precipitation (pH adjustment) which resulted in a substantial improvement in the taste of the preparations (Adler‐Nissen, 1984; Lalasidis and Sjoberg, 1978; Suh et al., 2000). These methods, however, have certain disadvantages such as significant reduction of certain amino acid residues from hydrolysates, introduction of chemical compounds into the product and loss of the target product (Cogan et al., 1981; Suh et al., 2000). Bitterness has been masked in hydrolysates via the addition of polyphosphates, specific amino acids, cyclodextrins, gelatin or glycine, or acidic phospholipids and lysophospholipids (Saha and Hayashi, 2001). However, this method requires an introduction of extra compounds and generally is costly. Hydrophobic chromatography was also used to reduce bitter peptides (Helbig et al., 1980; Roland et al., 1978), yet it required specific equipment and is time consuming and costly.

The alternative process for debittering protein hydrolysates is the enzymatic method using specific peptidases. Exopeptidases (aminopeptidases and carboxypeptidases) and endopeptidases have been widely exploited in protein hydrolysates debittering. Exopeptidases directly hydrolyze bitter peptides containing hydrophobic amino acids in the terminal region while endopeptidases degrade bitter peptides in protein hydrolysates by internal cleavage (Baankreis et al., 1995; Edens et al., 2005; Kanekanian et al., 2000). In both cases, the bitterness of the peptides was reduced by removal of these hydrophobic amino acids (Cheung et al., 2015; Mase et al., 2017; Stressler et al., 2013). Controlled enzymatic debittering using aminopeptidases can be both economic and effective (Saha and Hayashi, 2001). To date, bacterial and fungal aminopeptidases such as leucine aminopeptidases, prolyl aminopeptidase and alanyl aminopeptidase, have been used in protein hydrolysate debittering (FitzGerald and O'cuinn, 2006; Hiwatashi et al., 2004; Huang et al., 2015; Mane et al., 2010; Lin et al., 2004; Nampoothiri et al., 2005; Stressler et al., 2013).

In this study, a new aminopeptidase (nominated as An-APa) with potential debittering ability on protein hydrolysates was identified from Aspergillus niger. Its biochemical properties and substrate specificity were examined. Its probable mechanism for protein hydrolysate debittering was investigated.

Materials and methods

Strains, plasmids and growth conditions

Aspergillus niger CICIM F0215 strain was obtained from CICIM-CU, Jiangnan University, China. Escherichia coli JM109 and Pichia pastoris GS115 (Invitrogen, Carlsbad, CA, USA) were used as the host for plasmid amplification and gene expression, respectively. Plasmid pPIC9K (Invitrogen) was used for gene cloning and expression. The aminopeptidase was secreted into the supernatant with α-factor secretion signal peptide contained in the pPIC9K plasmid and the α-factor was removed during its translocation (Cereghino and Cregg, 2000). Potato dextrose agar (PDA) medium (Solarbio, Beijing, China) supplemented with 1% casein (Jiangsu Ruiyang Biotech, Wuxi, China) was used to cultivate A. niger F0215. E. coli JM109 was grown in Luria–Bertani (LB) medium (Solarbio). P. pastoris GS115 and its derived recombinant were cultivated in yeast extract peptone dextrose (YPD) medium (Solarbio). Minimal dextrose medium (MD), the buffered minimal glycerol-complex medium (BMGY), and the buffered minimal methanol-complex medium (BMMY) were prepared according to the Multi-Copy Pichia Expression Kit Instructions (Invitrogen).

Chemicals and reagents

Amino acid p-nitroanaline (pNA) substrates were purchased from GL Biochem (Shanghai, China). Phenylmethanesulphonyl fluoride (PMSF), 1,10-phenanthroline, ethylenediaminetetraacetic acid (EDTA), ethylene glycol-bis (2-aminoethylether)-N,N,N',N'-tetraacetic acid (EGTA), polyethylene glycol 8000 (PEG 8000) and tris (hydroxymethyl) aminomethane (Tris–HCl) were purchased from Sinopharm Reagent (Shanghai, China). L-3-Carboxy-trans-2,3-epoxy-propionyl-L-leucine-4-guanidinobutylamide (E-64) and puromycin were purchased from Amresco (Solon, OH, USA). Pepstatin and protein molecular weight standard were supplied by Roche Diagnostics (Mannheim, Germany) and Fermentas (Lithuania), respectively. SPI was supplied by Jiangsu Ruiyang Biotech. All other chemicals were used in high purity and purchased from Solarbio.

Sequence analysis

The theoretical molecular mass of the protein was calculated by the ProtParam tool (SIB, 2005). Conserved domain analysis was carried out with Conserved Domain Architecture Retrieval Tool (NCBI, 2002). Signal peptide was predicted using SignalP 4.1 Server (DTU Bioinformatics, 2011). Protease family designation was identified by reference to the peptidase database of MEROPS (EBI, 2018). Phylogenetic and molecular evolutionary analysis were conducted using MEGA version X (Kumar et al., 2018).

Construction of the recombinant P. pastoris

The general procedures for gene cloning and plasmids identification were carried out according to standard methods previously described (Sambrook and Russell, 2001). Total RNA sample was extracted with the High Pure RNA Isolation Kit (Roche Diagnostics) and cDNA was synthesized using Transcriptor High Fidelity cDNA Synthesis Kit (Roche Diagnostics) according to the manufacturer’s protocol, respectively. The target gene was amplified with Pfu DNA polymerase (Sigma-Aldrich, St Louis, MO, USA) with the following forward primer, 5′-GCATCTAAGGACAGAGATATCCTCCCG-3′ and reverse primer, 5′-TGCTCTAGATCAAGCGTAGCCATGGCCC-3′ (Bln I). The PCR product including the region encoding the original signal peptide was sequenced by Sanger sequencing for verification of the target ORF (Sanger and Coulson, 1975).

Preparation of recombinant aminopeptidase

Production of recombinant aminopeptidase from recombinant P. pastoris followed the instructions described in the Multi-Copy Pichia Expression Kit (Version F, Invitrogen). The supernatant was collected by centrifugation (8,000 × g 10 min) and analyzed by SDS-PAGE to detect the expression level of recombinant enzyme. The recombinant protein was first precipitated by ammonium sulfate between 30 and 85% saturation, and collected by centrifugation at 8000 × g for 20 min at 4 °C. Then the pellets were resuspended in 20 mM Tris–HCl buffer (pH 7.0) and dialyzed against the same buffer. Subsequently, the desalted protein was concentrated by PEG8000 and loaded onto a Sephacryl S-200 column (GE Healthcare, Waukesha, WI, USA). The active fractions were collected and concentrated using an ultrafiltration membrane (PALL Corporation, Ann Arbor, MI, USA) with a 30 kDa molecular weight cutoff value for further study.

Aminopeptidase activity assay

Aminopeptidase activity was determined according to Xi et al. (2015) using 2 mM Arg-pNA as substrate suspended in 50 mM Tris–HCl, pH 7.0 at 40 °C for 10 min. The concentration of released p-nitroaniline was calculated using absorbance readings at 405 nm in a microplate reader (TECAN, Männedorf, Netherland). One unit is defined as the amount of enzyme required to release 1 μmol p-nitroaniline in one minute at 40 °C. The protein concentration was assayed using the Bradford assay using bovine serum albumin fraction V (Sigma-Aldrich) as the standard (Bradford, 1976).

Effects of temperature, pH, cations and protease inhibitors on aminopeptidase activity

The optimal temperature and thermostability were analyzed between temperatures range from 20 to 50 °C in 50 mM Tris–HCl buffer (pH 7.0). The optimal pH and pH stability were measured at 40 °C under various pH conditions: pH 3.0–8.0 using phosphate-citrate buffer, pH 8.0–9.0 with phosphate buffer and pH 9.0–10.0 with glycine/NaOH buffer systems. For the determination of the effect of cations or protease inhibitors on the enzymatic activity, the enzyme was incubated with selected compounds for 60 min at optimum conditions and the residual activity was measured according to the method as described above.

Substrate specificity assay

The activity of the recombinant aminopeptidase on different amino acid-pNA (2 mM) substrates was assayed using the activity assay as described above.

Enzymatic hydrolysis of casein and SPI

Protein hydrolysates were prepared by controlled digestion of casein and SPI with pepsin according to Izawa et al. (1997). The protein hydrolysate solution was adjusted to pH 7.0 with 1 M NaOH, and incubated with a constant ratio (5 U of enzyme: 1 mg substrate) of the recombinant aminopeptidase at 40 °C for 60 min. The samples were further analyzed for amino acid profiles.

Amino acid profiling

The concentration of amino acids was monitored by the ninhydrin method (Troll and Cannan, 1953). The profiling and concentration of free amino acids were determined using amino acid analyzer (Model L-8900, Hitachi Co., Tokyo, Japan) after removal of undigested protein and large peptides by 1% sulfosalicylate precipitation.

Results and discussion

Molecular cloning, sequence analysis and expression of A. niger aminopeptidase

Sequence analysis of A. niger CBS 513.88 genome revealed a putative aminopeptidase ORF (An09g06800) of 2646 bp corresponding to a protein length of 881 amino acid with no putative signal peptide, which was renamed as An-APa. It had two conserved domains: M1 aminopeptidase N (M1_APN_2) at amino acid positions 16–475 and ERAP1-like C-terminus (ERAP1_C) at 544–858. The zinc-binding site (323H, 327H, 346E) was also detected using InterProScan. The deduced amino acid sequences of An09g06800 exhibited 81.95% identity with its orthologous ApsB, an identified lysine aminopeptidase from Aspergillus oryzae (Marui et al., 2012). These results strongly suggested that it is a putative aminopeptidase.

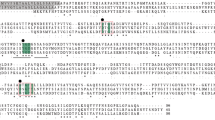

The encoding cDNA for An-APa was successfully cloned and sequenced from A. niger F0215 based on the genome sequence of CBS 513.88 and its deduced amino acid sequence exhibited 100% identity with An09g06800 of A. niger CBS 513.88. The phylogenetic analysis indicated that An-APa evolved from same ancestors with ApsB from Aspergillus oryzae but different ancestors with other aminopeptidases (Fig. 1). The gene was subsequently cloned and expressed in P. pastoris GS115 mediated by methanol-induced promoter, PAOX and purified to homogeneity by ammonium sulfate precipitation and gel filtration chromatography from the culture supernatant. The purified recombinant enzyme showed an apparent molecular mass of about 100 kDa on SDS-PAGE (Fig. 2) with the specific activity of 586.0 U/mg.

Phylogenetic analysis of An-APa amino acid sequence with reported aminopeptidases with debittering effect and biochemically characterized aminopeptidase Ns from UniProtKB (https://www.uniprot.org/). The analysis was done using the neighbour-joining method available with MEGA X software. The UniProtKB entry code of each aminopeptidases has been provided after the name of its biological source

SDS-PAGE analysis of the expression and purification of recombinant An-APa. Lane M, protein molecular weight markers; lane 1, a negative control clone that is transformed with empty vector alone; lane 2, culture supernatant of An-APa; lane 3, purified recombinant An-APa. The bands at about 100 kDa represent the target proteins

Enzymatic properties of An-APa

To test the temperature and pH optima, the activity of purified enzyme was determined at a temperature range from 20 to 50 °C and pHs from 3.0 to 10.0, respectively. The temperature optimum of the recombinant aminopeptidase was 40 °C and the activity rapidly decreased at temperatures above 45 °C and below 30 °C (Fig. 3A). The enzyme was stable at 20 to 40 °C and retained more than 50% of its activity after incubation for 60 min at the above range (Fig. 3B). The enzyme was found to be active in the pH range of 5.0 to 9.0 with the optimal activity at pH 7.0. The enzyme retained more than 80% of its residual activity at pH 5.5 and 8.0 (Fig. 3C). The enzyme showed excellent stability over a wide pH ranges from acidic to alkaline and retained more than 90% activity between pH 5.0 and 8.0 after incubation at 37 °C for 60 min (Fig. 3D). The effect of the different cations on its activity was also examined (Table 1). Cu2+ and Fe2+ severely inhibited the activity of the enzyme by 97.3 and 88.4%, whereas Co2+ and Na+ significantly stimulated the activity.

Enzyme activity and stability profiles of purified An-APa at various pH and temperatures using Arg-pNA as substrate. (A) Effect of temperature on the activity; (B) Effect of temperature on the stability; (C) Effects of pH on the activity; (D) Effects of pH on the stability. Data represents the mean ± standard deviation or triplicate determinations

The activity was severely inhibited by metallopeptidase inhibitor 1,10-phenanthroline, EDTA and EGTA, whereas serine protease inhibitor (PMSF), aspartic protease inhibitor (pepstatin) and cysteine protease inhibitor (E-64) only slightly suppressed the activity. In addition, as the typical and effective inhibitors of aminopeptidases, both bestatin and puromycin severely inhibited its activity (Table 1). These results strongly indicated that An-APa is a metallo-aminopeptidase.

Substrate specificity of the purified An-APa

To analyze the ability of An-APa to release free amino acids from N-terminus, 20 types of chemically synthesized amino acid-pNA substrates were used to detect its activity (Fig. 4). The purified An-APa could release 17 types of amino acids from amino acid-pNA substrates except Asp-pNA, Gln-pNA and Cys-pNA. The enzyme showed the highest activity towards Arg-pNA, followed by Tyr-pNA (82.5%), Trp-pNA (67.3%), Lys-pNA (54.3%), Phe-pNA (50.5%), His-pNA (42.7%), Ser-pNA (31.2%) and Leu-pNA (26.4%), and weak activity (less than 20%) on Thr-pNA, Val-pNA, Met-pNA, Asn-pNA, Glu-pNA, Ala-pNA, Pro-pNA, Gly-pNA and Ile-pNA (Fig. 4). These results indicated that An-APa could be an arginine aminopeptidase with broad substrate specificity and a preference for hydrolyzing hydrophilic N-terminal Arg, Lys, His and Ser and hydrophobic N-terminal Tyr, Trp, Phe and Leu. These results strongly suggested that it may be useful in debittering protein hydrolysates.

Hydrolysis of protein hydrolysates with An-APa

To test the hydrolysis of An-APa on protein hydrolysates, casein and SPI hydrolysates prepared by controlled digestion with pepsin were used as substrates. Pepsin is well-known for the endohydrolysis of polypeptides and has little effect on terminal residues (Powers et al., 1977). After treatment with An-APa, both free hydrophilic and hydrophobic amino acids were significantly released from the casein and SPI hydrolysates (Fig. 5), meanwhile only trace amounts of free amino acids were detected in the hydrolysates digested by pepsin (Data not shown). The hydrophobic amino acids especially having Q values (degree of hydrophobicity) greater than 1500 cal/mol were remarkably released. Leu, Ile, Phe, Tyr, Trp, Pro, Val and Lys in the casein hydrolysate after treatment with An-APa increased 18.61, 0.84, 11.35, 13.18, 3.34, 6.30, 7.46, and 8.19 mg/100 mL, respectively, and 19.72, 1.47, 18.37, 11.72, 4.61, 4.10, 8.13, and 5.85 mg/100 mL, respectively, in the SPI hydrolysate. The sum of them accounted for 65.0 and 64.4% of the total released free amino acids from casein and SPI hydrolysates, respectively. This indicated that An-APa could be potentially applicable in debittering protein hydrolysates.

The hydrolysis of protein is usually employed to improve the homogeneity of the solution. However, this is frequently accompanied with increased bitterness due to release of bitter peptides. These peptides are characterized by containing hydrophobic amino acid residues, or amino acid residues having Q values above 1500 cal/mol, such as Leu, Ile, Phe, Tyr, Trp, Pro, Val, and Lys (Nishiwaki et al., 2002). According to Matoba and Hata (1972) the internal hydrophobic amino acids resulted in most intensive bitterness of protein hydrolysate, while those at N- or C-terminus resulted in less bitter products, and in the free state made the least contribution to bitterness.

The probable debittering mechanism of An-APa on the protein hydrolysates was deduced (Fig. 6). When the hydrophobic amino acids were in the internal part of a peptide, An-APa could first hydrolyze hydrophilic amino acids (except Asp, Gln, and Cys) from N-terminus and continue hydrolyzing the peptide until an Asp, Gln or Cys residue appeared (Fig. 6A). When the hydrophobic amino acids were in the N-terminus of the peptides, An-APa continuously released the amino acids efficiently until termination upon which the hydrophilic amino acid residues (Asp, Gln or Cys) appears (Fig. 6B).

In the present study, a novel intracellular aminopeptidase, An-APa, was identified, from A. niger genome. A broad substrate specificity was characterized along with preferred hydrolysis of peptides with Arg, Tyr, Trp, Lys, Phe, His, Ser, and Leu at the N-terminus. When tested on casein and SPI hydrolysates prepared by pepsin digestion, An-APa was able to release a high percentage of free hydrophobic amino acids.

Some reported aminopeptidases with debittering effect have exhibited different N-terminal amino acid preferences. The aminopeptidase rLap1 from Aspergillus sojae showed the highest activity against Arg-pNA, followed by Leu-, Lys-, Met-, and Phe-pNA (Huang et al., 2015). However, the aminopeptidase II from Penicillium caseicolum has better cleaving activity on N-terminal of Leu and Phe residues present in dipeptides and oligopeptides (Matsuoka et al., 1991). An aminopeptidase N from chicken intestine preferentially hydrolyzed Leu-β-NA followed by Ala, Phe, Tyr, and Gly at N-terminus (Mane et al., 2010). Aminopeptidase T from Thermus aquaticus mainly released amino acids such as Ala, Val, Met, Ile, Leu, and Phe from bitter peptides (from milk casein) (Minagawa et al., 1989). Aminopeptidase from Aeromonas caviae T-64 significantly reduced milk casein and SPI by removing N-terminal hydrophobic amino acids (Val, Ile, Leu, Tyr, and Phe) (Izawa et al., 1997). Aminopeptidase from Grifola frondosa debittered the bitter peptides from soy protein and casein milk by preferentially releasing hydrophobic amino acids such as Val, Leu, Phe, Tyr, and Ile (Nishiwaki et al., 2002). However, all aminopeptidases preferentially released one or several hydrophobic amino acids. An-APa in this study was identified to possess broad substrate specificity. Efficient hydrolysis of hydrophobic amino acids at the N-terminus of Try-, Trp-, Lys-, Phe-, and Leu-pNA was identified, along with weak activity on Val-, Pro-, and Ile-pNA. Therefore, protein hydrolysates treated with combinational An-APa and aminopeptidases highly active on Val-, Pro-, and Ile-pNA were possible to achieve higher elimination of bitterness.

In conclusion, a novel aminopeptidase with broad substrate specificity and potential debittering properties in the protein hydrolysates was identified and characterized from A. niger and offered a potential application in oligopeptides preparation.

References

Adler‐Nissen J. Control of the proteolytic reaction and of the level of bitterness in protein hydrolysis processes. J. Chem. Technol. Biotechnol. 34: 215-222 (1984)

Baankreis R, van Schalkwijk S, Alting AC, Exterkate, FA. The occurrence of two intracellular oligoendopeptidases in Lactococcus lactis and their significance for peptide conversion in cheese. Appl. Microbiol. Biotechnol. 44: 386-392 (1995)

Bradford MM. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Biochem. 72: 248-254 (1976)

Cereghino JL, Cregg JM. Heterologous protein expression in the methylotrophic yeast Pichia pastoris. FEMS Microbiol. Rev. 24: 45-66 (2000)

Cheung LK, Aluko RE, Cliff MA, Li-Chan EC. Effects of exopeptidase treatment on antihypertensive activity and taste attributes of enzymatic whey protein hydrolysates. J. Funct. Foods. 13: 262-275 (2015)

Cogan U, Moshe M, Mokady S. Debittering and nutritional upgrading of enzymic casein hydrolysates. J. Sci. Food Agric. 32: 459-466 (1981)

DTU Bioinformatics (Bioinformatic Unit at Technical University of Denmark). SignalP 4.1 Server. Available from: https://www.cbs.dtu.dk/services/SignalP. Accessed Nov. 25, 2017 (2011)

EBI (European Bioinformatics Institute). MEROPS-the Peptidase Database. Available from: https://merops.sanger.ac.uk. Accessed Jan. 12, 2019 (2018)

Edens L, Dekker P, van der Hoeven R, Deen F, de Roos A, Floris R. Extracellular prolyl endoprotease from Aspergillus niger and its use in the debittering of protein hydrolysates. J. Agric. Food Chem. 53: 7950-7957 (2005)

FitzGerald R, O'cuinn G. Enzymatic debittering of food protein hydrolysates. Biotechnol. Adv. 24: 234-237 (2006)

Helbig N, Ho L, Christy G, Nakai S. Debittering of skim milk hydrolysates by adsorption for incorporation into acidic beverages. J. Food Sci. 45: 331-335 (1980)

Hiwatashi K, Hori K, Takahashi K, Kagaya A, Inoue S, Sugiyama T, Takahashi S. Purification and characterization of a novel prolyl aminopeptidase from Maitake (Grifola frondosa). Biosci. Biotechnol. Biochem. 68: 1395-1397 (2004)

Huang WQ, Zhong LF, Meng ZZ, You ZJ, Li JZ, Luo XC. The structure and enzyme characteristics of a recombinant leucine aminopeptidase rlap1 from Aspergillus sojae and its application in debittering. Appl. Biochem. Biotechnol. 177: 190-206 (2015)

Izawa N, Tokuyasu K, Hayashi K. Debittering of protein hydrolysates using Aeromonas caviae aminopeptidase. J. Agric. Food Chem. 45: 543-545 (1997)

Kanekanian A, Gallagher J, Evans EP. Casein hydrolysis and peptide mapping. Int. J. Dairy Technol.53: 1-5 (2000)

Kodera T, Asano M, Nio N. Characteristic property of low bitterness in protein hydrolysates by a novel soybean protease D3. J. Food Sci. 71: S609-S614 (2006)

Kumar S, Stecher G, Li M, Knyaz C, Tamura K. MEGA X: Molecular Evolutionary Genetics Analysis across computing platforms. Mol. Biol. Evol. 35: 1547-1549 (2018)

Lalasidis G, Sjoberg LB. Two new methods of debittering protein hydrolysates and a fraction of hydrolysates with exceptionally high content of essential amino acids. J. Agric. Food Chem. 26: 742-749 (1978)

Lin LL, Hsu WH, Wu CP, Chi MC, Chou WM, Hu HY. A thermostable leucine aminopeptidase from Bacillus kaustophilus CCRC 11223. Extremophiles. 8: 79-87 (2004)

Mane S, Damle M, Harikumar P, Jamdar S, Gade W. Purification and characterization of aminopeptidase N from chicken intestine with potential application in debittering. Process Biochem. 45: 1011-1016 (2010)

Marui J, Matsushita-Morita M, Tada S, Hattori R, Suzuki S, Amano H, Ishida H, Yamagata Y, Takeuchi M, Kusumoto KI. Comparison of expression and enzymatic properties of Aspergillus oryzae lysine aminopeptidases ApsA and ApsB. World J. Microbiol. Biotechnol. 28: 2643-2650 (2012)

Mase T, Shitasue S, Kondo T, Tanaka M, Takada R, Hiwatashi M, Isshiki S, Kawai J. Purification of an extracellular carboxypeptidase from Pseudozyma hubeiensis 31-B and its characterization as a food additive. Jpn. J. Food Chem. Saf. 24: 39-43 (2017)

Matoba T, Hata T. Relationship between bitterness of peptides and their chemical structures. Agric. Biol. Chem. 36: 1423-1431 (1972)

Matsuoka H, Fuke Y, Kaminogawa S, Yamauchi K. Purification and debittering effect of aminopeptidase II from Penicillium caseicolum. J. Agric. Food Chem. 39: 1392-1395 (1991)

Minagawa E, Kaminogawa S, Tsukasaki F, Yamauchi K. Debittering mechanism in bitter peptides of enzymatic hydrolysates from milk casein by aminopeptidase T. J. Food Sci. 54: 1225-1229 (1989)

Nampoothiri KM, Nagy V, Kovacs K, Szakacs G, Pandey A. L-leucine aminopeptidase production by filamentous Aspergillus fungi. Lett. Appl. Microbiol. 41: 498-504 (2005)

NCBI (National Center for Biotechnology Information). Conserved Domain Architecture Retrieval Tool. Available from: https://www.ncbi.nlm.nih.gov/Structure/lexington/lexington.cgi. Accessed Dec. 02, 2018 (2002)

Nishiwaki T, Yoshimizu S, Furuta M, Hayashi K. Debittering of enzymatic hydrolysates using an aminopeptidase from the edible basidiomycete Grifola frondosa. J. Biosci. Bioeng. 93: 60-63 (2002)

Powers JC, Harley AD, Myers DV. Subsite specificity of porcine pepsin. Adv. Exp. Med. Biol. 95: 141-157 (1977)

Roland JF, Mattis DL, Kiang S, Alm WL. Hydrophobic chromatography: debittering protein hydrolysates. J. Food Sci. 43: 1491-1493 (1978)

Saha BC, Hayashi K. Debittering of protein hydrolyzates. Biotechnol. Adv. 19: 355-370 (2001)

Sambrook J, Russell DW. Molecular cloning: a laboratory manual. 3rd ed, Cold Spring Harbor Laboratory Press, Cold Spring Harbor, NY, USA. pp. 895–909 (2001)

Sanger F, Coulson AR. A rapid method for determining sequences in DNA by primed synthesis with DNA polymerase. J. Mol. Biol. 94: 441-448 (1975)

SIB (Swiss Institute of Bioinformatics). ProtParam tool. Available from: https://us.expasy.org/tools/protparam.html. Accessed Oct. 11, 2018 (2005)

Stressler T, Eisele T, Schlayer M, Lutz-Wahl S, Fischer L. Characterization of the recombinant exopeptidases PepX and PepN from Lactobacillus helveticus ATCC 12046 important for food protein hydrolysis. Plos One 8: e70055 (2013)

Suh HJ, Bae SH, Noh DO. Debittering of corn gluten hydrolysate with active carbon. J. Sci. Food Agric. 80: 614-618 (2000)

Troll W, Cannan RK. A modified photometric ninhydrin method for the analysis of amino and imino acids. J. Biol. Chem. 200: 803-811 (1953)

Xi H, Tian Y, Zhou N, Zhou Z, Shen W. Characterization of an N-glycosylated Bacillus subtilis leucine aminopeptidase expressed in Pichia pastoris. J. Basic Microbiol. 55: 236-246 (2015)

Acknowledgements

This work was kindly supported by the Intergovernmental International Scientific and Technological Innovation Cooperation program, MOST, China (Grant No.: 2018YFE0100400), the Raising Program of Innovation Team for Tianjin Universities, Tianjin, China (Grant No.: TD13-5009), and the Tianjin Key R&D Projects Supported by Science and Technology, TMSTB, Tianjin, China (Grant No.: 19YFZCSN00560).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Song, P., Cheng, L., Tian, K. et al. A novel aminopeptidase with potential debittering properties in casein and soybean protein hydrolysates. Food Sci Biotechnol 29, 1491–1499 (2020). https://doi.org/10.1007/s10068-020-00813-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-020-00813-8