Abstract

Mine collapse is a common geological hazard associated with mining areas. This study analyzes mine collapse above the Yongcheng mining area located on the Huanghuai Plain in eastern Henan Province, China. The aim is to predict surface subsidence and evaluate associated disaster risks in goaf with thick alluvial cover. The surface deformation above seven mined coalfields and six unmined coalfields was calculated using the probability integration method. The results showed that the final maximum ground subsidence would be 7.25 m for the Suburban mine and 5.3 m for the Xinzhuang mine. As part of a broader study, land subsidence was also measured over a 1-year period in 2012–2013 by interferometric point target analysis using Radarsat-2 satellite synthetic aperture radar. Interferometric displacement maps were validated with leveling data. Based on the principles of fuzzy mathematics and the analytical hierarchy process, a susceptibility assessment system was developed to define the risk from mine collapse for the coalfields across the mining area. A hazard-zoning map was also produced using the spatial analysis function of ArcGIS. These research results can serve as a reference for farmland reclamation, town planning, and the restoration of the natural environment in this area.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Land subsidence is a major constraint on development in many areas. Subsidence causes increased costs and delays for new developments, damages existing buildings and infrastructure, and, in the worst cases, leads to injury or loss of life. It may give rise to derelict land, loss of industrial production, and destruction of homes (Maker 2010). According to data from the China Geological Environment Bulletin, total ground subsidence hazards in China numbered 316 in 2009, 499 in 2010, and 360 in 2011 (Nie et al. 2013). Sinking or subsidence of the land surface may occur gradually, almost imperceptibly, or it may occur quite suddenly (Altun et al. 2010). Therefore, in the interests of disaster prevention and mitigation, it is important to study the physical features and mechanisms of mine-induced subsidence and collapse and explore the styles of deformation.

In general, there are two types of studies concerning subsidence around underground mines: one is aimed at predicting the total amount and/or rate of future ground subsidence at a given spot, and the other is focused mainly on the identification of areas with high subsidence risk (Choi et al. 2010). Approaches commonly employed in mine subsidence prediction can be classified into three groups:

-

1.

Methods that make use of long-term monitoring data, such as regression analysis (Lee et al. 2010), time series analysis (Zhang et al. 2015a), grey system theory (Cheng et al. 2011; Xu et al. 2014), and artificial neutral networks (Park et al. 2012);

-

2.

Physical and numerical simulations, such as finite element methods (Loupasakis et al. 2014), finite difference methods (Alejano et al. 1999; Zhu et al. 2014), and discrete element methods;

-

3.

Theoretical analysis methods, such as empirical equations, influence function methods (Brady and Brown 2011; Zhu et al. 2014), and probability integration methods (Song et al. 2012; Zhang et al. 2015b).

Among these methods, the probability integration method is one of the most widely used approaches to predict mine collapse. This method has sound theoretical foundations, offers the benefit of simple calculations, and is easy to apply (Wang et al. 2012).

Monitoring data can provide a reference for surface subsidence prediction. A number of methods have been proposed for the monitoring of ground subsidence due to underground mining (Table 1) (Bawden et al. 2005). The dominant monitoring methods currently rely on in situ measurements using traditional ground surveys, spirit levels, and GPS, but measurement points for all these methods are sparsely distributed (Ao et al. 2015). However, the interferometric synthetic aperture radar (InSAR) technique provides a new tool for ground subsidence surveillance (Zhang et al. 2015a). InSAR facilitates the acquisition of high-precision topographic and micro-deformation information (Massonnet et al. 1993, 1996; Zebker et al. 1994) through time series analyses of low-cost SAR images. These images are taken frequently (in all weather conditions) and have a vast spatial coverage (Tosi et al. 2010, 2012; Teatini et al. 2012a, b). The InSAR technique has been used extensively in geological and environmental monitoring contexts (Ouchi 2013; Saygin et al. 2014; Dong et al. 2015).

To avoid collapse disasters and thus reduce property loss and conceivably ensure people’s safety, relative collapse susceptibility levels and hazard should be assessed (Yilmaz et al. 2011). In recent years, a geographical information system has been used for spatial data management and manipulation aimed at obtaining information to assess collapse hazards and the probability of their occurrence (Yilmaz 2007). Collapse-related factors contribute a variety of control functions to susceptibility classes. Marschalko et al. (2008) and Marschalko and Duraj (2009) reported that their geo-factors (e.g., flood, slope deformation, and underground mining) and their evaluation by engineering geologists are very important for urban planning. In this study, geologic conditions (such as geological structure, seam dip, and types and thicknesses of Quaternary deposits), ground deformation conditions (such as collapse unit area ratio and ground fissure unit length ratio), and mining conditions were analyzed. The magnitudes (weights) assigned to each of these different conditions were established by use of an analytic hierarchy process (AHP), a process that will be described in more detail in “Susceptibility zonation”.

Mining under loose, deep overburden in flat areas commonly results in mined-out areas that present singular characteristics. For instance, the range of subsidence is generally large, the subsidence coefficient is greater than 1.0, and the horizontal displacement on the border of the subsidence basin is greater than the displacement in the vertical direction (Zhou et al. 2015). Marschalko et al. (2012) studied the relationships between strata and land subsidence above underground coal mines in the Czech Republic. They studied how individual geological engineering zones were represented spatially in relation to selected intervals of subsidence values.

Research on the Yongcheng coalfield is still far from being completed (Wang et al. 2008). The Yongcheng mining area, as one of the areas affected most severely by ground collapse, has subsided as much as 8 m since the coal was extracted. Therefore, it is vital to study the Yongcheng mining area to acquire data for land use planning and to gain insight into how farmland can be reclaimed and how the natural environment in this area can be restored.

Study area

Overview

The Yongcheng mining area is located in eastern Henan Province (Fig. 1). With 3 billion tons of identified reserves, it hosts one of the six largest anthracite reserves in China. The Yongcheng mining area is in a late Paleozoic coal sequence in North China. The coal-bearing strata range from Carboniferous to Permian in age. The main minable coal seams are the so-called II2 coal seam in the Permian Shanxi Formation and the III2 coal seam in the lower Shihezi Formation.

Coal seam thicknesses range from 1.36 to 2.84 m. The Shanxi Formation contains 1–4 coal seams with a total thickness of 2.63 m, whereas the lower Shihezi Formation contains 3–7 coal seams with a total thickness of 3.02 m. The coal is mined at depths of between 225 and 1000 m using long wall mining methods, a very efficient method that extracts almost 100 % of the coal (Brady and Brown 2011). The distribution of the coalfields within the Yongcheng mining area is shown in Fig. 2.

Engineering geological conditions

As shown in Fig. 3, the Yongcheng mining area is located on the southeastern edge of the North China plain at the junction of the Huanghuai alluvial plain and the Yellow River alluvial plain. In China, coal mining areas with more than 300 m of alluvium are known as mega thick alluvial mining areas (Zhou et al. 2015). The region discussed in this paper is considered to be such a region, because of its widely distributed loose Tertiary and Quaternary sediments with average and maximum thicknesses of 313 and 546 m, respectively. According to previous research, the lithologies of the strata have a significant influence on land subsidence (Marschalko et al. 2012).

The Yongcheng mining area is located in the eastern extension of the Qinling-Kunlun tectonic zone, which belongs to the third Neo-cathaysian subsidence zone and the North China hollow zone. As shown in Fig. 4, the structures are mainly aligned in a NNE–NE direction with some of them extending in an E–W direction. There are a few cross faults in the NW direction. The Yongcheng duplex anticline is a kind of high-grade fold structure with a length of 60 km and a dip of 10°–20°. The dip of the east limb is slightly greater, that of the west limb is relatively flat. Most faults in the area are high-angle normal faults. Many faults are almost vertical faults with a lesser number of oblique faults. There are only a few horizontal faults, but they are larger.

Ground subsidence features

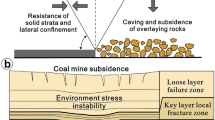

According to previous research by Zhou et al. (2015), ground deformation in the Yongcheng coalfields is typical for mined-out plain area deformation. Collapse is controlled by the following features: a relatively large area of ground subsidence (0.55 hectares per million tons of coal), rapid subsidence (over a short active period), and a high subsidence coefficient (up to 1.3). The collapsed areas have been fully mined out and ponds develop readily.

Many of the surface deformation features in this mining area appear as a large depression basin containing smaller dish-shaped depressions with funnel-shaped cross-sections. The outer edge of a typical depression basin is, obviously, higher in elevation than its center, and the depth of the center generally ranges from 0.5 to 8.0 m below the rim with an average depth of 5 m. The reason the maximum subsidence is 8 m when the coal seam was only 3 m thick is that mining developed good drainage channels and allowed the groundwater to drain from the coal belt. This dewatered the alluvium and soil above the coal belt. During the dewatering, the soil consolidated when the pore water pressure in the soil was reduced and the effective stress increased, thus increasing the subsidence.

The transition between subsidence zones and surrounding stable areas is generally gentle and not obvious. Most of the depression basins occur as long strips, and, less commonly, as squares or quasi-circles. The basins generally have lengths of 300–2000 m and widths of 200–800 m, and encompass an area larger than the actual mined-out area. The largest single subsidence depression in the Yongcheng mining area is 3.4 km2. When different mines are close enough to each other or are actually connected underground, a number of collapse pits may join and form a much larger collapse area. A lake-like feature may form if this area fills with water (Fig. 5a). In one instance, the lakes destroyed the homes of at least 45 families and what used to be a grain market became a paradise for ducks (Fig. 5b). The lakes also encroach on the scarce farmland (Fig. 5c) turning farmland into reedy marshes. At the same time, ground cracks (Fig. 5d) form on the borders of connected pits. These cracks run approximately parallel to each other with a maximum width of 60 cm and vertical offset of 55 cm, greatly decreasing the amount of arable land.

Control measures

Reclamation engineering involves a series of control measures including backfilling, digging, leveling, and building up low areas in accordance with the proposed use of the land being reclaimed. Reclamation must also take the local conditions and degree of collapse into account (Wu et al. 2014). Within the constraints of the local conditions and costs, measures that have been taken to reclaim areas that have subsided include excavating ditches to drain deep groundwater from areas of low subsidence and digging depressions in deep collapse zones. The material excavated from the deep zones is used to build peripheral areas up (Figs. 6, 7a). The ponds formed by dredging can promote the development of aquaculture and the built up areas can provide land for cultivation of crops or trees (Fig. 7b).

Surface subsidence prediction

Probability integration method

The probability integration method is currently widely used in predicting mining subsidence. This method treats the combined rock-soil mass as a stochastic medium and views the movement of the rock as a stochastic process (Litwiniszyn 1958; Fan et al. 2014). According to the superposition principle, a semi-infinite and completely mined surface subsidence W(x) can be modeled by computing the integral of the influence function f(x), namely

where x is the step length.

Furthermore, tilt and curvature estimates can be obtained via the derivation of surface subsidence value W(x). The relationship between horizontal movement and tilt is linear, and horizontal deformation is a derivative of horizontal movement. Thus, a series of parameters predicting surface deformation can be calculated. According to the influence function offered by Litwiniszyn (Zou et al. 2003):

where W 0 is the maximum surface subsidence; r is the main influence radius (r = H 0/tanβ); H 0 is the average mining depth, and β is the main influence angle.

Probability integration parameters

When it comes to the probability integration method, the selection of appropriate parameters is quite important. This selection is commonly determined by field surveys of nearby mines. Survey data are analyzed and parameters are selected accordingly (Song et al. 2012).

According to survey data from the Yongcheng study area, the subsidence factor calculated for the area is 0.75. Several major factors are considered to determine the parameters required for surface deformation prediction. These factors include, amongst others, the availability of existing ground subsidence monitoring data, physical layout of the mine, the mine plan and mining method, and the lithology of the strata overlying the mined-out area. With the aid of these data, the following parameters were calculated: subsidence coefficient q = 1.3, horizontal coefficient b = 0.35, tangent angle of major impact tgβ = 1.7, and transmission coefficient of mining impact k = 0.6. Other indicators such as the dips, depths and the number and thicknesses of the coal seams were also incorporated into the prediction calculations.

Results of surface deformation prediction

The computer program for surface deformation prediction has been developed based on the principles of probability integration. Surface deformation has thus been modeled using the aforementioned parameters for seven coalfields that have been mined and for six fields that have not yet been mined. For the mined fields, long-term monitoring of ground deformation has been carried out during mining operations. Three-dimensional projected surface depression patterns for three representative coalfields, namely the Suburban mine, the Xinzhuang mine and the Zhengdian mine, are shown in Fig. 8. The Suburban and the Xinzhuang mines have been mined for many years and their surface subsidence is nearly complete. The Zhengdian mine is a prospective mining field. According to the ground deformation monitoring data for the area, the maximum ground subsidence has been 7.25 m for the Suburban mine and 5.3 m for the Xinzhuang mine. As shown in Fig. 8a and b, prediction results agree with the measured results, indicating that the selected parameters and prediction methods are reasonably reliable.

As shown in Tables 2 and 3, calculated results indicate that the depth of ground subsidence caused by mining is in the range of 3.1–7.7 m. The subsidence area of the different coalfields in the Yongcheng mining area was also calculated with the aid of the spatial statistical analysis modules of ArcGIS. Furthermore, horizontal surface deformation and ground surface curvature deformation were also calculated using the proposed surface deformation model.

By analyzing the above results, it is clear that mine collapse in the Yongcheng mining area has certain special characteristics, such as an obviously excessive subsidence coefficient, severe surface deformation, and large-scale multi-depression basins. There is a layer of loose sediment 200–500 m thick overlying the coal seams. The groundwater table in this area would drop dramatically if the seams were mined and the water drained, significantly increasing the effective stress. In addition, there would be further consolidation of the overlying loose sediments increasing the amount of collapse. All of these factors would contribute to a large subsidence coefficient in the mining area.

Surface subsidence monitoring

Method

Interferometric point target analysis is a temporal InSAR method for calculating high-precision deformation with iterations based on PS points (Werner et al. 2003). This technique can measure relative changes in elevation of less than 1 cm (Wegmuller et al. 2010; Yang et al. 2015a; Yang and Peng 2015b), and has been used to study surface deformation resulting from landslides (Strozzi et al. 2005), earthquake and volcanic movements (Masato 2007).

Data

This study used 12 Radarsat-2 images of the Yongcheng mining area acquired between 4 February 2012 and 8 March 2013. The images were acquired with imaging mode wide, polarization mode VV, and resolution 11.85 m × 5.23 m. The terrain phase was removed based on a high-resolution digital elevation model (SRTM DEM; 90 m). To verify the satellite-based data, those data were compared with the ground-based leveling survey results. The level surveying was done in 2012–2013, the same general time frame in which the satellite scenes were imaged. Two leveling surveys were conducted between 2 and 9 May 2012 and 12 and 19 January 2013.

Time series analysis

Figure 9 shows cumulative deformation time series maps for the Yongcheng mining area for 2012–2013. Figure 10 is the deformation velocity map from 2012 to 2013 in the same area. From the results, it can be seen that the central region of the Yongcheng mining area underwent more intense deformation than other regions during the monitoring period. The maximum subsidence that occurred over the monitoring period was 50.9 mm, with widely varied subsidence values across the region.

InSAR interferometric displacement maps were compared with global positioning system (GPS) data available for two continuously operating GPS reference stations located in the study area. The results of the evaluation are shown in Table 4. There are seven points for which the absolute value of the difference is less than 5 mm, 70 % of the total points. Mean square error of the differences is 4.1 mm/a. The results demonstrate the high consistency of the local vertical motion measurements made by the two different surveying techniques.

Susceptibility zonation

Fuzzy AHP method

Analytic hierarchy process has become one of the most commonly used methods in environmental assessment over the past two decades. The AHP technique involves human subjectivity in pair-wise comparison. Fuzzy set theory was applied and evolved into the fuzzy AHP method in a bid to eliminate vagueness and uncertainty. The fuzzy AHP method addresses the criteria scoring and judgment processes by bringing triangulated fuzzy numbers to the pair-wise comparison matrix (Vanlaarhoven and Pedrycz 1983; Kwiesielewicz 1998).

Using the AHP method, the evaluation index weights were determined. Based on fuzzy mathematical theory, the uncertainty pertaining to mine collapse factors was transformed into abstract determinism through the membership function. In this way, the influence factors could be quantified and the associated hazard risks classified. Then a risk zoning map could be plotted with the aid of ArcGIS software.

Process and results of fuzzy AHP assessment

Mine hazard assessment is commonly undertaken on a site basis. Regional assessment, although less frequent, can provide an overview of the problems involved such that planners, for example, can determine the most difficult areas for development and avoid imposing unnecessarily rigorous conditions in areas where such restrictions are not warranted (Bell and Bruyn 1997).

Based on the map of the Yongcheng mining area, the research region (with a total area of approximately 1994 km2) was subdivided into 7616 square calculation units (each representing an area of 0.5 × 0.5 km) using ArcGIS. Afterwards, a risk assessment could be made step by step as follows:

-

1.

Collect spatial information for the mining area and create an attribute database.

-

2.

Assign each unit to a class using single-factor evaluation criteria.

-

3.

Determine an index weight for each influence factor by the AHP method.

-

4.

Carry out a comprehensive Fuzzy evaluation.

-

5.

Construct spatial attribute overlays.

-

6.

Determine the primary attribute of each unit and plot hazard zoning maps.

As shown in Fig. 11, the risk evaluation index employed in this study is based on the main factors influencing mine collapse. The hierarchical index system has three levels, namely the target layer, the criterion layer, and the index layer.

Grading standards pertaining to the index of single factors affecting the risk of mine collapse are presented in Table 5.

Based on the above methods, a mine collapse hazard zoning map was produced for the Yongcheng mining area (Fig. 12). The results are also summarized in Table 4. According to the risk grades of the different calculation units, the research region can be divided into four zones; namely, the serious risk zone (grade I), the medium risk zone (grade II), the minor risk zone (grade III), and the stable zone (grade IV) (Table 6). The research results could serve as a reference during farmland reclamation, town planning and the restoration of natural environmental conditions in this mining area.

Conclusion

In this paper, some factors influencing mine collapse, such as topography, stratigraphy, structural geology, hydro-geological conditions, coal seam characteristics, and control measures, have been presented and analyzed for the Yongcheng mining area. There are three major mine collapse risk factors: the goaf substrate, the high ground water level, and the deep overburden layer.

Methods for the prediction of ground subsidence and the evaluation of mine collapse risk in mined-out areas were developed during this study and are presented in this paper. Using the developed ground subsidence prediction model, the surface deformation of 13 coalfields in the Yongcheng mining area was calculated. The results indicate that the amount of ground subsidence caused by mining is in the range of 2–6 m and the maximum depth of possible collapse is in excess of 7 m. This means that cumulative subsidence at the Suburban mine will not halt until the maximum ground subsidence reaches 7.25 m.

Subsidence displacement and the subsidence rate for the study area were monitored using interferometric synthetic aperture radar from 4 February 2012 to 18 March 2013. Calculated maximum subsidence displacement was 50.9 mm and the calculated subsidence rate was 40.4 mm/a. The subsidence monitoring data were collected over a known time interval; therefore, a subsidence rate can be calculated. The subsidence prediction can have no time factors directly attached to it, but it is feasible to speculate about when the deformation in specific area will come to a halt and the area will become stable by contemplating the two research results.

Using an evaluation program for mine collapse risk, the risks for mine collapse in different coalfields across the study area were determined and a hazard zoning map was compiled using the spatial analysis function of ArcGIS. This information promises to provide a useful reference for use in land reclamation, town planning, and the restoration of natural environmental conditions in the Yongcheng mining area.

References

Alejano LR, Ramirez-Oyanguren P, Taboada J (1999) FDM predictive methodology for subsidence due to flat and inclined coal seam mining. Int J Rock Mech Min 36:475–491

Altun AO, Yilmaz I, Yildirim M (2010) A short review on the surficial impacts of underground mining. Sci Res Essays 5(21):3206–3212

Ao MS, Wang CC, Xie RA et al (2015) Monitoring the land subsidence with persistent scatterer interferometry in Nansha District, Guangdong, China. Nat Hazards 75:2947–2964

Bawden GW, Sneed M, Stork SV et al (2005) Measuring human-induced land subsidence from space, U.S. Geological Survey Fact Sheet FS-069-03, Sacramento

Bell FG, Bruyn IA (1997) Subsidence problems due to abandoned pillar workings in coal seams. Bull Eng Geol Environ 57:225–237

Brady BHG, Brown ET (2011) Rock Mechanics for Underground Mining, 3rd edn. Science Press, Beijing

Cheng AB, Wang XM, Liu HQ (2011) Application of grey hierarchy analysis in the stability evaluation of underground mined-out areas (in Chinese). Metal Mine 416(2):17–21

Choi JK, Kim KD, Lee S et al (2010) Application of a fuzzy operator to susceptibility estimations of coal mine subsidence in Taebaek City, Korea. Environ Earth Sci 59:1009–1022

Dong SC, Sergey S, Yin HW et al (2015) Spatio-temporal analysis of ground subsidence due to underground coal mining in Huainan coalfield, China. Environ Earth Sci 73:5523–5534

Fan HD, Gu W, Qin Y et al (2014) A model for extracting large deformation mining subsidence using D-InSAR technique and probability integral method. Trans Nonferrous Met Soc China 24:1242–1247

Kwiesielewicz M (1998) A note on the fuzzy extension of Saaty’s priority theory. Fuzzy Set Syst 95:161–172

Lee S, Oh HJ, Kim KD (2010) Statistical spatial modeling of ground subsidence hazard near an abandoned underground coal mine. Disaster Adv. 3:11–23

Litwiniszyn J (1958) Statistical methods in the mechanics of granular bodies. Rheol Acta 2–3:146–150

Loupasakis C, Angelitsa V, Rozos D et al (2014) Mining geohazards-land subsidence caused by the dewatering of opencast coal mines: the case study of the Amyntaio coal mine, Florina, Greece. Nat Hazards 70:675–691

Maker BR (2010) Review of approaches to mapping of hazards arising from subsidence into cavities. Bull Eng Geol Environ 69:159–183

Marschalko M, Duraj M (2009) Knowledge of engineering-geological conditions as decisive factor for good-quality and functional foundation of potential structures. In: SGEM 2009: 9th Internatıonal Multidisciplinary Scientific Geoconference, Vol I. Conference Proceeding-Modern Management of Mine Producing, Geology and Environmental Protection 261–269

Marschalko M, Juris P, Tomas P (2008) Selected geo-factors of flood land, radon risk, slope deformations and undermining as significant limiting conditions in land-use planning. In: SGEM 2008: 8th International Multidisciplinary Scientific Geoconference, Vol I. Conference Proceeding-Modern Management of Mine Producing, Geology and Environmental Protection, pp 201–210

Marschalko M, Bednarik M, Yilmaz I, Bouchal T, Kubecka K (2012) Evaluation of subsidence due to underground coal mining: an example from the Czech Republic. Bull Eng Geol Environ 71(1):105–111

Masato F (2007) Application of interferometric point target analysis to Izu-Oshima Volcano, Japan. In: Envisat symposium 2007, Montreux, 23–27 April 2007. European Space Agency

Massonnet D, Rossi M, Carmona C et al (1993) The displacement field of the Landers earthquake mapped by radar interferometry. Nature 364(6433):138–142

Massonnet D, Thatcher W, Vadon H (1996) Detection of postseismic fault-zone collapse following the Landers earthquake. Nature 382:612–616

Nie L, Zhang M, Jian H (2013) Analysis of surface subsidence mechanism and regularity under the influence of seism and fault. Nat Hazards 66:773–780

Ouchi K (2013) Recent trend and advance of Synthetic Aperture Radar with selected topics. Remote Sens 5(2):716–807

Park I, Choi J, Lee MJ et al (2012) Application of an adaptive neuro-fuzzy inference system to ground subsidence hazard mapping. Comput Geosci 48:228–238

Saygin A, Mahmut A, Fusun BS et al (2014) Monitoring of coal mining subsidence in peri-urban area of Zonguldak city (NW Turkey) with persistent scatterer interferometry using ALOS-PALSAR. Environ Earth Sci 71:4081–4089

Song JJ, Han CJ, Li P et al (2012) Quantitative prediction of mining subsidence and its impact on the environment. Int J Min Sci Technol 22:69–73

Strozzi T, Re L, Valenti G et al (2005) SAR interferometric point target analysis of slope instabilities in the community of Biasca, Switzerland. In: Fringe ATSR workshop 2005, European Space Agency

Teatini P, Tosi L, Strozzi T (2012a) Comment on “Recent subsidence of the Venice Lagoon from continuous GPS and interferometric synthetic aperture radar In: Bock Y, Wdowinski S, Ferretti A, Novali F, Fumagalli A. Geochem Geophys Geosyst 13:Q07008

Teatini P, Tosi L, Strozzi T et al (2012b) Resolving land subsidence within the Venice Lagoon by persistent scatterer SAR interferometry. Phys Chem Earth 40–41:72–79

Tosi L, Teatini P, Strozzi T et al (2010) Ground surface dynamics in the northern Adriatic coastland over the last two decades. Rend Fis Acc Lincei 21(1):115–129

Tosi L, Teatini P, Bincoletto L et al (2012) Integrating geotechnical and interferometric SAR measurements for secondary compressibility characterization of coastal soils. Surv Geophys 33(5):907–926

Vanlaarhoven PJM, Pedrycz W (1983) A fuzzy extension of Saaty’s priority theory. Fuzzy Set Syst 11:229–241

Wang H, Li Z, Yang WM et al (2008) Formation mechanism of the ground collapse in mined-out area of coalmine underlying loose loess deposit (in Chinese). Geosci 22(5):877–883

Wang N, Wu K, Qin ZF (2012) Prediction model of mining subsidence with probability integration method based on thickness influence of loose layer (in Chinese). Coal Sci Technol 40(7):10–16

Wegmuller U, Walter D, Spreckels V, Werner CL (2010) Nonuniform ground motion monitoring with Terra SAR-X persistent scatterer interferometry. IEEE Trans Geosci Remote Sens 48(2):89–904

Werner CL, Wegmuller U, Strozzi T, Wiesmann A (2003) Interferometric point target analysis for deformation mapping. In: Proceedings of international geoscience remote sensing symposium 2003, Toulouse, 21–25 July 2003, vol 7, pp 4362–364

Wu G, Wei D, Zhou ZD et al (2014) A summary of study on ecological restoration technology of large coal bases construction in China (in Chinese). Acta Ecol Sin 34(11):2812–2820

Xu HF, Liu B, Fang ZG (2014) New grey prediction model and its application in forecasting land subsidence in coal mine. Nat Hazards 71:1181–1194

Yang HL, Peng JH (2015) Monitoring urban subsidence with multi-master radar interferometry based on coherent targets. J Indian Soc Remote Sens 43(3):529–538

Yang HL, Peng JH, Wang BC et al (2015) Ground deformation monitoring of Zhengzhou city from 2012 to 2013 using an improved IPTA. Nat Hazards. doi:10.1007/s11069-015-1953-x

Yilmaz I (2007) GIS based susceptibility mapping of karst depression in gypsum: a case study from Sivas basin (Turkey). Eng Geol 90(1–2):89–103

Yilmaz I, Marschalko M, Bednarik M (2011) Gypsum collapse hazards and importance of hazard mapping. Carbonates Evaporites 26(2):193–209

Zebker HA, Rosen PA, Goldstein RM et al (1994) On the derivation of coseismic displacement fields using differential radar interferometry: the landers earthquake. J Geophys Res Solid Earth (1978–2012) 99(B10):1961–9634

Zhang JX, Zhang Q, Sun Q et al (2015a) Surface subsidence control theory and application to backfill coal mining technology. Environ Earth Sci. doi:10.1007/s12665-015-4133-0

Zhang JZ, Huang HJ, Bi HB (2015b) Land subsidence in the modern Yellow River Delta based on InSAR time series analysis. Nat Hazards 75:2385–2397

Zhou DW, Wu K, Cheng GL (2015) Mechanism of mining subsidence in coal coalfield with thick alluvium soil in China. Arab J Geosci 8:1855–1867

Zhu GY, Xu ZH, Xie C et al (2014) Study on influence functions of surface residual movement and deformation above old goaf (in Chinese). Chin J Rock Mech Eng 33(10):1962–1970

Zou YF, Deng KZ, Ma WM (2003) Mining subsidence engineering (in Chinese). China University of Mining and Technology Press

Acknowledgments

This project was supported by the National Natural Science Foundation of China (Grant Numbers 41572301, 61427802 and 41330634) and the Fundamental Research Funds for the Central Universities of China (Grant Number 2-9-2015-071). The authors appreciate the financial support of these organizations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, B., Zhang, L., Yang, H. et al. Subsidence prediction and susceptibility zonation for collapse above goaf with thick alluvial cover: a case study of the Yongcheng coalfield, Henan Province, China. Bull Eng Geol Environ 75, 1117–1132 (2016). https://doi.org/10.1007/s10064-015-0834-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-015-0834-6