Abstract

Surface roughness is one of the most important parameters governing the shear strength of rock discontinuities. Roughness types may vary based on genesis, physico-mechanical, and mineralogical properties of rocks. In this study, granite samples representing three different weathering degrees were selected to evaluate the effects of surface roughness and weathering degree on shear strength. To this aim, we determined the profile roughness coefficient (PRC), profile roughness angle (PRA), and joint roughness coefficient (JRC) for the selected fresh and weathered granite joint samples. Values of PRC were in the range of about 1.043–1.073, and PRA and JRC varied in the ranges of 16.67–21.45 and 12–18, respectively. Weathering led to the increment of joint surface roughness of the selected granitic joints due to the higher resistance of quartz crystals in the weathered matrix. However, the increment in surface roughness did not result in an increase in the shear strength. On the contrary, the shear strength of discontinuities dramatically decreased.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The determination of the shear strength of dominant discontinuities is an important aspect for rock mass stability calculations. The shear strength of discontinuities is controlled by different factors such as surface roughness, filling material, water pressure, and discontinuity wall compressive strength. Therefore, the above-mentioned factors should be precisely determined to reveal the shear strength of the discontinuities. In the literature, some discontinuity surface roughness parameters have been paid more attention compared to others. A number of studies were carried out by different researchers to determine the relationship between joint surface roughness and the shear strength of rock joints (Aydan et al. 1996a; Belem et al. 2000; Grasselli and Egger 2003; Ünal and Ünver 2004; Andrade and Saraiva 2008). The joint surface roughness was first evaluated by Barton (1973) using the joint roughness coefficient (JRC) parameter. The JRC and the roughness profiles developed by Barton and Choubey (1977) are the most common tools used in rock mechanics engineering. Many researchers have used tape line, profilometer, photography, and laser techniques to measure the surface roughness of discontinuities (Miller et al. 1989; Milne 1990; Yoshinaka et al. 1990; Aydan et al. 1996a; Ünal 2000; Du et al. 2009). Moreover, geo-statistical and fractal methods have also been employed numerically to evaluate roughness (Türk et al. 1987; Lee et al. 1990; Roko et al. 1997; Ünal 2000).

In the same way, effects of surface roughness on shear strength joints were investigated and considered by different studies (Barton and Choubey 1977; Saeb 1990; Denli 2004). In the majority of these studies, the lithological distinction of the discontinuity wall was not made. Even some artificial materials were used instead of natural rock samples to create standard test conditions. However, in reality, discontinuity type and weathering can form different surface roughness profiles based on the physico-mechanical and mineralogical properties of rock.

In our study, we attempted to assess the effect of weathering on roughness and, in particular, how this circumstance affects shear strength rather than how surface roughness should be described. Aydan et al. (1996a) stated that the description of surface morphology of rock discontinuities was only a geometric operation, in other words that it is the operation of describing discontinuity surface topography. This operation includes concepts such as height, shape, periodic ridges and the ratio of surface area to the main area. Many empirical and analytic studies have been conducted for this purpose. Since determining discontinuity surface topography is rather challenging, most of them were based on linear profiles (Myers 1962; Sayles and Thomas 1977; Tse and Cruden 1979; Thomas 1982; Türk et al. 1987; Gokhale and Drury 1990; Aydan and Shımızu 1995; Aydan et al. 1996b). While these methods take linear profiles, today with the help of new techniques (laser, photogrammetry), the topography of discontinuity surface area can be produced and more precise evaluations can be made (Grasselli and Egger 2003; Ünal and Ünver 2004; Belem et al. 2000; Sharifzadeh et al. 2008). Apparently, the determination of surface roughness of discontinuities is an aspect based on different grounds and is developing rapidly. When considering linear profiles, analytic methods outclass other methods in terms of being practical and easy. However, such methods may prove to be inadequate in evaluating the anisotropy of roughness (Ünal and Ünver 2004). It can be concluded that, when compared to each other, there are pros and cons of the above mentioned methods.

In order to avoid the aforementioned discussion, in this study we selected basic parameters to describe surface roughness. Therefore, analytic methods and empiric approaches, which are easy and practical and are based on linear profiles, were used. Analytically, profile roughness coefficient (PRC) and profile roughness angle (PRA) were calculated. Empirically, the JRC, which is practically the most commonly used method to describe the surface roughness of profiles (Barton and Choubey 1977), was evaluated. While the fact that JRC is determined as a result of comparisons with these suggested typical profiles provides superiority in terms of being an easy and practical method, it has some disadvantages due to being subjective. The most important reason for selecting these parameters is that they are easier and more practical when compared to other complex and difficult methods, and also widely used. Moreover, since the consideration of how surface roughness parameters should be determined was not one of the primary goals of this study, these parameters (which can be determined in the most practical way) were selected to investigate the influence of surface roughness and weathering on the shear strength of rock joints.

The granite samples of three different weathering degrees were selected to evaluate the effect of surface roughness and weathering on shear strength in the current study. Natural rock joints were collected from boreholes drilled in the granitic layers that crop out in northern Turkey (Fig. 1). The surface roughness of the samples was determined in accordance with the roughness profiles proposed by Barton and Choubey (1977) using a profilometer. Additionally, the profile roughness coefficient (PRC) and the profile roughness angle (PRA) were calculated based on the methods suggested by Gokhale and Drury (1990) and Türk et al. (1987), respectively. The shear strength of samples was measured by direct shear tests at the laboratory. Finally, the effects of weathering on surface roughness and the shear strength of granitic rock joints were evaluated based on the tests results, and the roughness parameters were correlated with the shear strength of the granitic rock joints under selected normal stress conditions.

Location map of the granite samples. Modified from MTA (2002)

Geological, petrographical, and physico-mechanical properties of granites

Granitic plutons, which outcrop in northern Turkey, were classified in three different phases by Yılmaz (1995). The first one consists of quartz monzonite, diorite, and granites. The second one consists of syenite and quartz syenite. The last one is represented by diorite and gabbros, which are Eocene aged. All granitic layers range in age from Cretaceous to lower Tertiary (Yılmaz 1995). Rock joint samples were obtained from three different boreholes that were drilled for geotechnical investigations in northern Turkey (Fig. 2a, b). The tectonic structures between the Upper Cretaceous and Miocene, such as E–W trending trust faults, NW–SE, NE–SW trending strike-slip faults, and discontinuity surfaces within the plutonic rocks comprise the main tectonic features of the study area (Yılmaz 1995).

The boreholes reveal different weathering degrees, consisting of fresh (G1), slightly weathered (G2), and moderately weathered (G3) granites. The weathering degrees were identified as grades I, II, and III based on Hencher and Martin (1982), categorizing the weathered granite into six degrees: fresh rock, slightly weathered, moderately weathered, highly weathered, completely weathered, and residual soil. In the study area, these weathering degrees were observed for the examined granitic rocks.

The thin sections of granite samples were examined under a polarizing microscope to identify average grain size, grain shape, grain contact type, and modal composition. Some thin section images of samples are shown in Fig. 3. Fresh granite samples mainly consist of subhedral to anhedral tabular plagioclase, anhedral quartz, and euhedral to subhedral biotite. A few micro-cracks were observed in quartz minerals with white color. Plagioclase minerals were detected in decomposed form. Slightly weathered granites consist of tabular plagioclase, anhedral quartz, and euhedral to subhedral biotite. The biotite is slightly chloritized and the orthoclase is partly altered. Moderately weathered granites mainly consist of subhedral to anhedral tabular plagioclase, quartz, biotite, orthoclase, chlorite, and hornblende. In the thin sections, the granites showed a hypidimorphic texture. Quartz minerals are highly cracked. Chlorite is partially or completely replaced by biotite, intensely observed in thin sections of moderately weathered granite. Orthoclase is partly altered.

The physico-mechanical properties of the granitic rocks were determined by means of laboratory tests in accordance with the ISRM Suggested Methods (2007). The median values of dry unit weight (γ d), uniaxial compressive strength (UCS), and P-wave velocity (V p) are presented in Table 1. The UCS of fresh, slightly, and moderately weathered granites are 172, 117, and 79 MPa, respectively. According to Deere and Miller (1966), they are classified as very strong, strong, and medium strong rock, respectively.

Joint surface roughness of granites

Aydan and Shimizu (1995) stated that the effect of roughness on the shear strength of discontinuities was dependent on the genesis of rock discontinuities. They also classified discontinuities into three categories based on the order of their occurrences, which were primary discontinuities (related with the genesis of rocks), secondary discontinuities (depending on desiccation, cooling, and freezing) and tertiary discontinuities (depending on tectonic forces). The discontinuities in the granites used in this study are generally primary and secondary discontinuities and can be defined as “flow plains”, “grain planes”, “sheeting planes”, and “hardway planes”, based on Aydan and Shimizu (1995). These discontinuities emerged as a result of tensile stress and show an undulated structure.

A total of nine joint samples were obtained from granite cores with three different weathering degrees. In the granite samples used in this study, the primary roughness of the discontinuity planes, which are related to the genesis of the rock and develop due to cooling, shows changes depending on weathering. In the samples, we have observed an increased roughness in the shape of ridges by quartz minerals as a result of feldspar weathering. In general, discontinuities can be stepped, undulated, or planar based on their occurrence. Surface roughness develops in different ways in each one of these. The highest shear strength is obtained in the stepped types. According to ISRM (2007), maximum shear strength depends on normal stress and the degree of surface roughness. Aydan and Shimizu (1995) stated that maximum shear stress would occur perpendicular to axes of the ridges causing roughness because of dilatation. It is clear that there is a strong relationship between surface roughness and shear strength; therefore, PRC and PRA were also selected in this study. The following processes were performed in order to determine these parameters.

The cross-sectional view of the roughness profiles for each sample was drawn. Eight profiling lines were selected for the evaluation of the joint surface roughness (Fig. 4). The roughness profiles of the granite joints were measured with the aid of a mechanical needle profilometer. Measured profiles of weathered and fresh granite joint surfaces were transformed into image files by digital scanning. The roughness profiles were digitized using software to measure the actual length (LA) and the length of profiles (LL). The profile roughness coefficient (PRC) and profile roughness angle (PRA) were calculated using the equations of Gokhale and Drury (1990) and Türk et al. (1987), respectively, as follows:

In addition, the joint roughness of the granitic samples was quantified as JRC, as suggested by Barton and Choubey (1977), with respect to the measurements of surface roughness amplitude from a straight edge (Barton 1973).

Aydan and Shimizu (1995) and Aydan et al. (1996b) stated that while one of the most significant problems of determining surface roughness was sampling interval, there were no guidelines regarding this issue until the these papers. The primary procedures and checks that are the most fundamental requirements in order to have representative values of surface roughness parameters were first suggested by Aydan and Shimizu (1995) and Aydan et al (1996b). These authors, who stated that this interval cannot be smaller than 1 mm, used 2 mm as a sampling interval in their studies.

In this study, a mechanic needle-type profilometer with 0.5-mm diameter needles was used, which is difficult to control manually for low sampling intervals such as 2 mm. Also, Aydan and Shimizu (1995) indicated that in some parameters (e.g., CLAH-Centre-line average height) the effect of the sampling interval was negligible. Therefore, in order to carry out a systematical sampling on the rock samples, the above mentioned roughness parameters were determined for eight different profiles that were parallel, perpendicular, and diagonal to the shear direction (Fig. 4) in this study. The distance between parallel profiles was chosen as 12 mm. In Fig. 5a, b, change of the roughness parameters is given based on the different directions. As it can be seen in the figure, the change of roughness parameters as per the directions is insignificant in the granite samples. This is because the system for defining joint surface roughness (sampling intervals, profile lengths, etc.) used to determine discontinuity is insufficient for evaluating the discontinuity based on the directions in this study. Therefore, joint roughness parameters based on direction are not set forth as explained by Aydan and Shimizu (1995) and Aydan et al. (1996b). Also, it should not be derived from Fig. 5a, b that the surface morphology parameters are unchanged based on directions. Additionally, maximum shear stress would occur perpendicularly to the axes of the ridges, causing roughness because of dilation (Aydan and Shımızu 1995). Because of this, evaluations towards shear strength were made using the roughness parameters obtained through the profiles parallel to the shear direction.

Surface roughness parameters of PRC, PRA, and JRC were obtained from the three profiles, parallel to the shear direction, and the median values of the roughness parameters were given for each sample (Table 2). Hencher et al. (2011) indicated that a series of shear tests on different samples of a joint will often yield very wide scatter, which is simply not interpretable without correcting for sample-specific dilation. Because of this reason, very similar surface roughness samples were selected for each weathered granite degree, as seen in Table 2. Accordingly, the PRC values vary between 1.043 and 1.073, whereas the PRA and JRC differ from 16.67 to 21.45 and 12 to 18, respectively. As seen from Fig. 5c, roughness coefficients and angle obviously rise with the increasing weathering degree. The moderately weathered granites have the highest roughness parameters. Weathering led to the increment of joint surface roughness of selected granitic rocks due to the resistance of quartz crystals in the weathered matrix. The effect of increasing roughness with weathering on the shear strength of discontinuities is discussed in the following sections.

Shear strength of granites

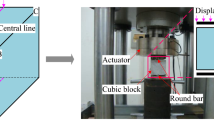

Direct shear tests were carried out according to the ISRM Suggested Method (2007) using the portable direct shear machine (Fig. 6) under three different normal stress conditions (0.33, 0.66, and 0.99 MPa). At least three samples were tested for each weathering class. Therefore, a total of nine natural granite joints were tested in this study to evaluate the effects of surface roughness on the shear strength. The samples were fixed into the moulds and were hardened with plaster. Subsequently, the shear boxes were set into the portable shear machine and were sheared until the residual stress was reached. Shear rates were selected as 0.1 and 0.3 mm/min. Total shear displacement ranged between 7.0 and 12.0 mm.

Shear stress-shear displacement curves under the normal stresses of 0.33, 0.66, and 0.99 MPa are plotted in Fig. 7. As expected, the shear strength of fresh granite was higher than that of moderately weathered granite after the tests. At the same time, shear stress and displacement curves attain steady-state conditions just after reaching peak stress for moderately weathered granite. But, shear stress and displacement curves do not show a similar behavior for fresh granite and slightly weathered granite even. In these cases some alterations can be observed. This point can be explained by the fact that effects of surface roughness on shear strength for moderately weathered granites are completely removed after reaching peak strength.

Figure 8a, b show the failure envelopes of peak and residual shear stress for differently weathered granite cores. As seen from Fig. 8, the failure envelope is strongly dependent on the weathering degree. The peak strength line has a slope of ϕ (friction angle) and an intercept of c (apparent cohesion) on the shear strength axis. The friction angles of fresh granite, slightly weathered granite, and moderately weathered granite are 36°, 30°, and 26°, respectively. The friction angles decrease with respect to the increment of the weathering degree. The same relationship was also observed for residual strength conditions (Fig. 8b). Also, some scatterings are observed in the test results presented in Fig. 8b. This effect is especially valid for slightly weathered granite and moderately weathered granite in this study. The selected rock joint samples for each weathering degree may display small differences in their surface roughness and wall strength. Since their shear behavior is very sensitive to these characteristics, small scattering of the test results may be observed, as displayed in Fig. 8b.

In the literature, the first non-linear strength criterion for rock joints was developed by Barton (1973). He used joint strength data reported in previous studies. The criterion was revised by Barton and Choubey (1977) based on their 130 direct shear test results. The shear strength equation was revised as:

where JRC is the joint roughness coefficient, JCS is the joint wall compressive strength, and ϕ r is the residual friction angle. JCS is equal to the unconfined compressive strength (UCS) of the rock if the joint is unweathered. However, JCS may be reduced up to 75 % when the walls of the joint are weathered (Bell 2007). Already, Barton (1973) had stated that a ratio of JCS/UCS equal to 1/4 could be used for weathered rocks when no direct measurements were available. In this study, JCS values were estimated from UCS (Table 2). Two cases were considered; in Fig. 9a, JCS values were considered equal to UCS, while in Fig. 9b, JCS values for the weathered granite joints were reduced by 75 % to 29 and 20 MPa. The residual friction angle was obtained via direct shear tests that were carried out in this study. Accordingly, the residual friction angle of the fresh granite, slightly weathered granite, and moderately weathered granite are 32°, 27°, and 22°, respectively. JRC values are taken from Table 2 for each sample. Fig. 9a, b shows the failure envelopes obtained by using both the UCS values directly and the decreased UCS values for weathered samples. As seen from Fig. 9a, the curves obtained by using UCS values directly are very different from the experimental results. Furthermore, the curve of the unweathered (fresh) sample is located between the slightly and moderately weathered samples, which create an anomalous situation. Figure 9b is established using reduced JCS values for the slightly and moderately weathered samples. It is clearly seen that the curves obtained in this form are more compatible with the experimental results.

At the same time, a different shear strength formula proposed by Aydan et al. (1996b) was used to evaluate the test results. The formula was suggested for rock discontinuities having rough surface topography, as follows:

where τ is shear stress, σ n is normal stress, c is the cohesion of wall rock, A 2, B 1, B 2 are coefficients, ϕ i is the friction angle of wall rock, and ϕ α is the base friction angle of discontinuity. If the normal stresses are not high enough to cause shearing of asperities, the shear strength of the discontinuities should be purely frictional. In this case, cohesion should be neglected and the shear strength of the discontinuities can be written as:

where, σ t is the tensile strength of hard rocks. More technical details of the formula are available from Aydan et al. (1996b). Input parameters and obtained curves are given in Fig. 9b. As seen in Fig. 9b, the failure envelope obtained by using the Barton and Choubey (1977) failure criterion is observed as above of the linear failure envelope that was obtained experimentally. However, the work of Aydan et al. (1996b) is substantially consistent with the experimental results and is also more compatible than that of Barton and Choubey (1977). The curvilinear criterion is seen to fit the data well at low normal stresses; the effect of the weathering is clearly seen in the figure. The failure envelope of the moderately weathered granite is seen as at the bottom. In addition to this, in weathered granites, discontinuity wall strength is more effective on the shear strength of discontinuity planes than on other parameters.

Evaluation of the effects of surface roughness on shear strength

In the previous sections, the joint surface roughness and shear strength of granitic rocks were evaluated for different weathering degrees. The peak and residual shear strengths evaluated from the shear tests under the selected normal stresses are depicted in Figs. 10 and 11. Moreover, the relationship between peak shear strength and joint surface roughness parameters (PRC, PRA and JRC) are also shown in the same figures. It is easily recognized that an inverse relationship exists between the shear strength and PRC, PRA, and JRC. Logarithmic trends are presented at all selected normal stresses (0.33, 0.66, and 0.99 MPa). The highest shear strength was obtained for fresh granites, which have the lowest joint surface roughness parameters. This relationship was similarly observed for all normal stress conditions. On the contrary, the highest shear strength was not obtained for the highest joint surface roughness in this study, showing that the weathering degree is much more relevant for the shear strength of granitic joints than the roughness parameters. The relationships between joint shear strength and physico-mechanical properties (UCS and P-wave velocity) for the 0.33, 0.66, and 0.99 MPa of normal stress are shown in Figs. 12 and 13. The shear strength increases with the increment of UCS and V p. Positive logarithmic trends are presented for all selected normal stress levels.

After the tests, serious degradation of the roughness was observed for the moderately weathered granite joint surfaces. However, similar deformations were not recognized for the fresh granites joints. This detail can be clearly observed in Fig. 14. Therefore, the joint surface roughness of the tested granite samples was re-evaluated due to the fact that the roughness parameters (PRC, PRA, and JRC) had changed after the tests. The correlations of the roughness parameters before and after the tests are presented in Fig. 15. After the test, the values of PRC range between 1.037 and 1.048; and PRA and JRC vary between 15.48 and 17.49 and between 10 and 12, respectively. The reduction in roughness parameters after the test may be up to 33 % when compared to the roughness parameters before the test.

Conclusions

Based on the results of the present study performed on granitic rock joints, the following conclusions are drawn.

The roughness coefficients and angle clearly increase with the weathering degree due to the higher resistance of the quartz crystals in the weathered matrix. The roughness parameters of weathered granite are higher than those of fresh granite. Weathering leads to the increment of joint surface roughness of selected granitic rocks.

Peak friction angle of joints of fresh, slightly weathered, and moderately weathered granite are 36°, 30°, and 26°, respectively. The friction angles decrease due to the increment of the weathering degree. While joint surface roughness increases, the shear strength decreases with respect to the increment of the weathering degree.

After the tests, serious degradation was observed on the joint surfaces of weathered granites. The reduction of the roughness parameters after the test may be up to a 33 % decrease when compared to the original roughness parameters.

The results indicate that the physico-mechanical parameters such as UCS and P-wave velocity are more effective than joints surface roughness parameters on the shear strength of weathered granitic rocks. An inverse relationship between surface roughness parameters and shear strength was observed for weathered granitic rocks, although weathering causes an increase in surface roughness. However, the increment in surface roughness did not result in an increase in shear strength. On the contrary, a significant decrease was identified. The effect of surface roughness on the shear strength was prevented by the decreasing wall strength of joints. Serious degradation and wear occurred at high shear and normal stress levels, especially in moderately weathered granites.

References

Andrade PS, Saraiva AA (2008) Estimating the joint roughness coefficient of discontinuities found in metamorphic rocks. Bull Eng Geol Environ 67:425–434

Aydan Ö, Shimizu Y (1995) Surface morphology characteristics of rock discontinuities with particular reference to their genesis. Fractography, Geological Society Special Publication No. 92, pp 11–26

Aydan Ö, Shimizu Y, Kawamoto T (1996a) The anisotropy of surface morphology characteristics of rock discontinuities. Rock Mech Rock Eng 29(1):47–59

Aydan Ö, Shimizu Y, Kawamoto T (1996b) The anisotropy of surface morphology and shear strength characteristics of rock discontinuities and its evaluation. NARMS’96, pp 1391–1398

Barton NR (1973) Review of a new shear strength criterion for rock joints. Eng Geol 7:287–332

Barton NR, Bandis SC (1982) Effects of block size on the shear behaviour of jointed rock. 23rd U.S. symposium on rock mechanics, Berkeley, pp 739–760

Barton NR, Choubey V (1977) The shear strength of rock joints in theory and practice. Rock Mech 10:1–54. Carr, 1989

Belem T, Homand-Etienne F, Souley M (2000) Quantitative parameters for rock joint surface roughness. Rock Mech Rock Eng 33(4):217–242

Bell FG (2007) Engineering geology, 2nd edn. Butterworth-Heinemann, London, p 581

Deere DU, Miller RP (1966) Engineering classification and index properties of the intact rock. Air Force Lab Tech Rep AFNLTR, Albuquerque, NM, pp 65–116

Denli AK (2004) Effect of discontinuity roughness and anisotropy on shear strength, M.Sc Thesis. METU. Ankara

Du SG, Hu YJ, Hu XF (2009) Measurement of joint roughness coefficient by using profilograph and roughness ruler. J Earth Sci 20(5):890–896

Gokhale AM, Drury WJ (1990) A general method for estimation of fracture surface roughness: part II. Theoretical aspects. Metall Trans A 21A:1193–1199

Grasselli G, Egger P (2003) Constitutive law for the shear strength of rock joints based on three-dimensional surface parameters. Int J Rock Mech Min Sci 40(1):25–40

Hencher SR, Martin RP (1982) The description and classification of weathered rocks in Hong Kong for engineering purposes. In: Proceedings of 7th South-east Asian geotechnical conference. Hong Kong, vol 1, pp 125–142

Hencher SR, Lee SG, Carter TG, Richards LR (2011) Sheeting joints: characterisation, shear strength and engineering. Rock Mech Rock Eng 44:1–22

ISRM (International Society For Rock Mechanics) (2007) The complete ISRM suggested methods for rock characterization, testing and monitoring: 1974–2006. Suggested Methods R Ulusay and JA Hudson (eds), Prepared by the commission on testing methods, international society for rock mechanics, compilation arranged by the ISRM Turkish National Group, Ankara, Turkey, p 628

Lee YH, Carr JR, Barr DJ, Haas CJ (1990) The fractal dimension as a measure of the roughness of rock discontinuity profiles. Int J Rock Mech Mining Sci Geomech Abstr 27(6):453–464

Miller SM, McWilliams PC, Kerkering JC (1989) Evaluation of stereo digitizing for measuring rock fracture. In: Rock mechanics as a guide for efficient utilization of natural resources. Proceedings of 30th US symposium on rock mechanics, West Virginia. Balkema, Rotterdam, pp 201–208

Milne D (1990) Standardized joint descriptions for improved rock classification. In: Hustrulid WA, Johnson GA (eds) Rock mechanics contributions and challenges. Proceedings of the 31st U.S. symposium on rock mechanics, Balkema, Rotterdam, pp 35–41

MTA (2002) 1/500000 Ölcekli Türkiye jeoloji haritaları, Samsun paftası. MTA Genel Müdürlüğü, Ankara (In Turkısh)

Myers MO (1962) Characterization of surface roughness. Wear 5:182–189

Roko RO, Daemen JJK, Myers DE (1997) Variogram characterization of joint surface morphology and asperity deformation during shearing. Int J Rock Mech Min Sci 34(1):71–78

Saeb S (1990) A variance on Ladanyi and Archambault’s shear strength criterion. In: Barton S (ed) Rock Joints. Balkema, Rotterdam, pp 701–705

Sayles RS, Thomas TR (1977) The spatial representation of surface roughness by means of the structure function: a practical alternative to correlation. Wear 42:263–276

Sharifzadeh M, Mitani Y, Esaki T (2008) Joint surfaces measurement and analysis of aperture distribution under different normal and shear loading using GIS. Rock Mech Rock Eng 41(2):299–323

Thomas TR (1982) Rough surfaces. Longman, Harlow

Tse R, Cruden DM (1979) Estimating joint roughness coefficients. Int J Rock Mech Min Sci 16:303–307

Türk N, Greig MJ, Dearman MR, Amin FF (1987) Characterisation of rock joint surfaces by fractal dimension. In: Proceedings, 28th US symposium on rock mechanics, Tucson, Arizona, pp 1223–1236

Ünal M (2000) Modelling of discontinuity surface roughness and investigation of its effects on shear strength. PhD thesis, Hacettepe University, Ankara, p 219

Ünal M, Ünver B (2004) Characterization of rock joint surface degradation under shear loads. Int J Rock Mech Min Sci 41(3):380–381

Yılmaz S (1995) Dereli-Şebinkarahisar (Giresun Güneyi) Arası Granitoyid Plütonlarının Karşılaştırmalı İncelemesi. Cumhuriyet Üniv., Fen Bilimleri Enst. Doktora Tezi, s 310 (unpublished, in Turkish)

Yoshinaka R, Yoshida J, Shimizu T, Arai H, Arisaka S (1990) The influence of roughness and degree of interlocking on strength characteristics. In: Proceedings of 22th symposium on rock mechanics, JSCE, pp 206–210

Acknowledgments

The authors are very grateful to Prof. Adem Ersoy (University of Çukurova) for his help and support during the experimental tests. Special thanks are due to Prof. Dr. Ömer Aydan (Tokai University) for his valuable suggestions. The authors also wish to thank Dr. Vural Oyan for his help in the petrographical studies, Dr. Mutluhan Akın and Dr. Mucip Tapan for their comments, suggestions, and review of the paper before publication, Bülent Aras for the supply of samples, and Didem Kuzu for grammatical corrections. We are grateful to the anonymous reviewers for their useful comments and contribution the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Özvan, A., Dinçer, İ., Acar, A. et al. The effects of discontinuity surface roughness on the shear strength of weathered granite joints. Bull Eng Geol Environ 73, 801–813 (2014). https://doi.org/10.1007/s10064-013-0560-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-013-0560-x