Abstract

A reliable estimation of the groutability of the target geomaterial is an essential part of any grouting project. An artificial neural network (ANN) model has been developed for the estimation of groutability of granular soils by cement-based grouts, using a database of 87 laboratory results. The proposed model used the water:cement ratio of the grout, relative density of the soil, grouting pressure, and diameter of the sieves through which 15% of the soil particles and 85% of the grout pass. A very good correlation was obtained between the ANN predictions and the laboratory experiments. Comparison of these results with those obtained using traditional methods for groutability prediction confirmed the viability of using ANN to estimate groutability.

Résumé

Une estimation fiable de l’injectabilité de géomatériaux constitue une question essentielle de tout projet d’injection. Dans ce contexte, un modèle de réseau de neurones artificiel (ANN) a été développé pour l’estimation de l’injectabilité de sols granulaires par des coulis à base de ciment, en utilisant une base de données établie à partir de 87 résultats d’essais en laboratoire. Le modèle proposé considère comme paramètres d’entrée: le rapport eau-ciment du coulis, la densité relative du sol, la pression d’injection, la taille de particule du sol correspondant au passant à 15% et la taille de particule du coulis correspondant au passant à 85%. Un très bon accord a été obtenu à partir de la comparaison des résultats de l’analyse ANN avec ceux obtenus à partir des expérimentations. La comparaison de ces résultats avec ceux obtenus avec les méthodes traditionnelles pour les prévisions d’injectabilité confirment la possibilité d’utiliser le modèle ANN pour les estimations d’injectabilité.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Permeation grouting is a widely used ground improvement technique that involves the injection of suitable particulate grouts and chemical solutions into soil and rock with the aim of reducing the permeability and/or improving the mechanical properties (Jessberger 1983; Krizek 1985; Welsh 1986; Welsh and Burke 1991; Gouvenot 1998; Dupla et al. 2004. The properties and behaviour of cement grouts have been a major research focus in recent years (e.g. Zebovitz et al. 1989; Akbulut 1999; Kim et al. 2009) as, despite its advantages, there can be some adverse effects with the use of chemical solutions.

One of the main challenges in the utilization of cement-based grouts is the reliable estimation of the groutability (N) of the target geomaterial. The grouting process is based on the complex time-dependent transport process of cement grains through the soil matrix. This involves the grain size distribution of the soil and grout, the concentration and viscosity of the grout suspension, the pore size and hydraulic conductivity of the soil, the injection pressure etc. As a result, there is no agreement on a universal set of criteria or a methodology.

Because of their heuristic problem-solving capabilities, artificial neural networks (ANNs) have been applied successfully to many geotechnical engineering problems (Shahin et al. 2008). Within foundation design, ANNs have been used in predicting the settlement and bearing capacity of shallow foundations (e.g. Chen et al. 2006; Shahin et al. 2005; Padmini et al. 2008) and the axial and lateral load capacity of pile foundations, drilled shafts, and ground anchors (e.g. Abu-Kiefa 1998; Goh et al. 2005; Rahman et al. 2001). ANNs have also been employed in applications concerning earth retaining structures (e.g. Kung et al. 2007), site characterization (e.g. Najjar and Basheer 1996), mining (Rankine and Sivakugan 2005), dams (Kim and Kim 2008), tunnels (Yoo and Kim 2007), slope stability (e.g. Goh and Kulhawy 2003), blasting (Lu 2005) and geoenvironmental engineering (Shang et al. 2004). A comprehensive overview of ANN applications in geotechnical engineering is given by Shahin et al. (2008).

ANNs are particularly useful for constitutive modeling of soils, in which the complexity of the soil formation and excessive number of required empirical factors (Adeli 2001) prohibit the use of traditional theories to properly simulate the soil behavior. They are also valuable in soil property estimation, which is usually controlled by many interacting parameters that are difficult to handle by statistics alone. ANNs have been used in the estimation of pre-consolidation pressure and stress history (Celik and Tan 2005), swell pressure (Erzin 2007), liquefaction potential (e.g. Hanna et al. 2007), density (Goh 1995), shear strength (e.g. Lee et al. 2003), compaction and permeability (e.g. Sinha and Wang 2008). Interestingly, no studies have been performed on estimating the groutability of soils using ANNs.

Within this context, in this paper an ANN model was developed to estimate the groutability of granular soils with cement grouts. To achieve this, results from a database consisting of 87 laboratory grouting tests were used. The performance of the ANN model is compared with the most commonly used existing groutability estimation methods.

Existing methods for the estimation of groutability

Early studies on the estimation of groutability of granular soils involved only a comparison of the grain size of the host soils with that of the cement grout. Burwell (1958) and Mitchell (1981) defined groutability with the following simple and practical equation:

in which D 15 = the diameter of a sieve through which 15% of the soil passes and d 85 = the diameter of a sieve through which 85% of the cement grout passes. According to this equation, if N is larger than 25, then the grout can be successfully injected into the soil while if N is smaller than 11, sufficient grout will not be injected into the soil formation. For values of N between 25 and 11, in situ tests should be performed to determine if the grouting is possible.

According to Burwell (1958), even if N obtained from Eq. 1 is greater than 25, the following additional equation should be used to determine if grouting is possible:

in which D 10 = the diameter of a sieve through which 10% of the soil passes and d 95 = the diameter of a sieve through which 95% of the cement grout passes. If the N value calculated using Eq. 2 is greater than 11, then grouting is possible. For values of N smaller than 5, the soil is not groutable with the particular cement type considered. Again, in situ tests are recommended for N values in between 5 and 11.

Another similar equation that considers the grain size of host soils and that of cement was developed by Incecik and Ceren (1995):

in which d 90 = the diameter of a sieve through which 90% of the cement grout passes. According to this approach, if the N value obtained by Eq. 3 is greater than 10, grouting is possible.

The permeability of soil has also been used to estimate groutability. Starting from the Hazen Formula, DeBeer (1970) developed the following equation to predict groutability:

in which k = hydraulic conductivity in cm/s, and t = temperature in °C. Note that the unit of D 10 is cm. According to Landry et al. (2000), if the k value obtained using Eq. 4 is greater than 1 × 10−1 cm/s, the host soil is groutable by cement. For 1 × 10−1 cm/s > k > 5 × 10−3 cm/s, fine grained cement is required for grouting. If 5 × 10−3 cm/s > k > 1 × 10−4 cm/s, special chemical solutions are needed to ensure groutability.

Recent studies (e.g. Akbulut and Saglamer 2002; Tekin 2004; Kim et al. 2009) indicated the need for the consideration of additional parameters for a more reliable estimation of groutability. Based on a series of laboratory experiments on grouted sand samples prepared at various relative densities and grain size distributions, Akbulut and Saglamer (2002) developed the following empirical formula for the estimation of groutability of granular soils:

in which w/c = water/cement ratio of the grout, FC = content of soil passing through a 0.6 mm sieve, P = grouting pressure in kPa, and D r = relative density of the host soil. k 1 = 0.5 (unitless) and k 2 = 0.01 in 1/kPa are the constants based on experimental observations to normalize the N values.

If the N value obtained from Eq. 5 is greater than 28, the granular soil can be grouted effectively by cement-based grouts. For N values smaller than 28, injection by cement-based grouts is not possible, and groutability using chemical grouts should be investigated. Note that Eq. 5 is most applicable for conditions where FC is smaller than 6%, water:cement ratio is between 0.8 and 2, and grouting pressure is between 50 and 200 kPa.

Modeling with artificial neural networks

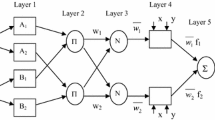

An ANN is a collection of interconnected processing elements called neurons with performance characteristics similar to the biological neurons (Fausett 1994). These processing elements are organized in layers: an input layer, an output layer, and one or multiple intermediate layers, which are also called hidden layers. A typical ANN structure with five neurons in the input layer, three neurons in the hidden layer, and a single neuron in the output layer is shown in Fig. 1. Each neuron in a specific layer is connected to many other neurons with weighted connections; a zero weight implying no connection and a negative weight indicating a prohibitive relationship.

The simulation problem with an ANN consists of finding a satisfactory relationship between a set of neurons representing the input data and the associated outputs (Erzin 2007). The learning phase of ANN consists of using the input and output data for a specific problem and changing the weighting of among the neurons until the error is minimized. There are several learning algorithms; the most popular one is the feed-forward back-propagation algorithm, which is also used in the current study. The trained network is then tested in the validation phase based on the predictions it makes using a completely new set of data. Details of artificial neural networks have been widely reported elsewhere; see for example Flood and Kartam (1994) and Zurada (1992).

ANN model for estimation of groutability

Identification and collection of data

As discussed previously, in the literature the simplified techniques for the prediction of groutability are based on a comparison between the grain size of the host soils and that of the cement grout, or the permeability of host soil. However, as shown in more recent studies (e.g. Akbulut and Saglamer 2002; Tekin 2004) various other parameters affect the groutability. It is believed that better predictions of groutability can be achieved by including as many influential soil and grout input parameters as possible in one model. In this way, the high parameter recognition capacity of ANN can be utilized to improve the prediction capability of the model. Accordingly, a database that consists of case records, each of which carry information at least on w/c, D r, P, FC, as well as the grain size distribution of the host soil and the grout is used to develop a robust ANN model.

Using the test setup shown in Figs. 2 and 3, Tekin (2004) investigated the penetrability of the microfine cement Rheocem 900 into sand specimens with a variety of grain size distributions. A total of fifteen tests were conducted under 100 kPa grouting pressure for sands prepared at a D r of about 30%. These are presented as case records 57 to 71 in Table 1. To obtain a database that includes case records with more diverse properties, the same experimental setup was utilized to perform sixteen additional tests for the current study, numbered 72 to 87 in Table 1. The new tests were conducted at a higher grouting pressure and with different grain size distributions and FC for the host soil, using a finer cement grout, and with various values of D r, as summarized in Table 1. These results were supplemented with data compiled from the literature: case records numbered from 1 to 38 in Table 1 being from Akbulut and Saglamer (2002), and 39 to 56 from Zebovitz et al. (1989). As seen in Table 1, the ANN was based on a total of 87 case records including w/c, D r, P, FC, D 10 and D 15 of soil, and d 85, d 90, and d 95 of grout and the experimental results of the grouting.

Implementation of the ANN model

The neural network toolbox of MATLAB was used to develop the ANN model, which comprised five neurons in the input layer (i.e., w/c, D r, P, FC, and (D 15)base soil/(d 85)cement grout), and one neuron in the output layer (groutability decision), where the binary number 1 represents successful grouting and 0 represents unsuccessful grouting. The range of the model input and output parameters are given in Table 2. As suggested by Demuth et al. (2009), for a more effective learning phase, the input and output data were normalized to a range of −1.0 to 1.0 using the pre-processing functions:

in which, for a N x Q sized matrix X, where N = number of ANN model parameters, and Q = number of samples, x = actual value, y max = maximum value for each row of X, y min = minimum value for each row of X, x min = minimum value of matrix X, and x max = maximum value of matrix X.

Division of data is another aspect of ANN modeling which requires careful attention. To divide the data into two subsets, namely training and testing, can result in overfitting, i.e., memorization rather than generalization, especially if the training data are noisy (Shahin et al. 2008). Consequently, a separate validation set is needed to ensure that the model can generalize within the range of the data used during training. For the current study, the dataset given in Table 1 was randomly categorized into three subsets of training, testing and validation. In the literature, there are no hard and fast rules concerning the relative ratios of these subsets. Hammerstrom (1993) suggested two-thirds of the data should be used for model training and testing and one-third for model validation. Shahin et al. (2004)investigated the impact of the proportion of data used in the various subsets in a study on estimating the settlement of shallow foundations, and found that there is no clear relationship between the proportion of data for training, testing and validation and model performance. However, they observed that the model performed best when 20% of the data were used for validation and the remaining data were divided into 70% for training and 30% for testing. For the model developed in this study, about 60% of the data, i.e., 53 of the case records, were used for training with the remaining data divided equally into testing and validation sets. The cross-validation technique proposed by Stone (1974) was used as the stopping criteria in order to overcome premature model stopping or over-training.

There is no unified approach regarding determination of an optimal ANN architecture. For multilayer perceptrons (MLPs), also used in the current study, the number of layers representing the input and output variables are each fixed at one. It has been shown that one hidden layer is sufficient to approximate any continuous function provided that sufficient connection weights are given. Accordingly, for the MLP feedback ANN model in the current study, a single hidden layer was used. After many trials, the number of neurons within the hidden layer was selected to be fifteen. As a result, the model consists of three layers (input, hidden, and output) with 5, 15 and 1 neurons, respectively. For obtaining the best performance in the learning phase, tangent-sigmoid (Orbani and Fajdiga 2003) and logistic sigmoid (Sakellariou and Ferentinou 2005) transfer functions are used in the hidden and output layers, respectively. A shortened version of the ANN code prepared in Matlab is given in “Appendix”.

Performance assessment of ANN model and comparison with existing methods

The accuracy of the ANN model is examined by comparing the model predictions with the groutability results obtained in the experimental programs (Table 1). These results are also summarized in Fig. 4 for all data, including the training, testing and validation data sets. It can be seen that, overall, the ANN model correctly predicted the groutability for 83 of the 87 cases. For the validation data set (17 cases), all the ANN predictions were successful. Note that the validation data set can be regarded as the real test for the performance of the model, because it is used for applying the trained algorithm to a separate dataset which has not been introduced to the network previously (Hanna et al. 2007). In general, the results shown in Table 1 and Fig. 4 indicate the significant potential of the proposed ANN model in successfully predicting the groutability of granular soils by cement grouts.

The overall comparison of the performance of the ANN model with that of the commonly-used empirical methods for estimating groutability is shown in Table 3. Note that the number of cases that could be considered by each empirical model varies, as no definite groutability prediction can be performed for borderline situations. For example, with case number 23, using the Burwell (1958) method, the numerical value of N obtained by Eq. 1 is greater than 25, which means that Eq. 2 should subsequently be applied. As the value given by Eq. 2 is ten, the method requires that in situ tests should be performed to determine if the soil is groutable with cement-based grouts. In addition, the performance of the Akbulut and Saglamer (2002) method is assessed twice, using all the data and a subset of it. As this method was originally developed using 38 of the cases in Table 1, to avoid any bias a separate performance analysis should be performed excluding these data, as given in Table 3.

The Burwell (1958) and Akbulut and Saglamer (2002) methods have high success rates exceeding 90%. However, the Burwell (1958) method could only give predictions for 62% of the cases and the success rate of the Akbulut and Saglamer (2002) method was only 86% when the 38 cases used to develop the model are excluded from the analysis. As seen in Table 3, the highest ratio of successful predictions to the total number of case records considered (95.4%) is obtained by the ANN model.

Summary and conclusions

In this study, an ANN model was developed to predict the groutability of granular soils using cement-based grouts. A total of 87 laboratory case records were used to develop, test and validate the model. Sixteen of these experiments were specifically performed for this study. The proposed model uses w/c, D r, P, FC, and (D 15)base soil/(d 85)cement grout as input parameters.

The results obtained using the proposed ANN model compared very well with the groutability results determined experimentally. For 95% of the cases in the compiled database, the model correctly predicted the groutability result, with no error for the validation data set. Furthermore, a comparison of the performance of the ANN model with the results using empirical methods from the literature indicated the relative superiority of the proposed ANN model.

It is concluded that the proposed ANN model provides a viable groutability assessment tool that can assist the geo-professionals in making accurate and reliable predictions.

Appendix

Matlab 7.8.0 source code for ANN

-

clear all % clear all data

-

p = […]; %5 × 87 sized input matrix (not shown)

-

t = […]; %1 × 87 sized target matrix (not shown)

-

% input layer: 5 neurons

-

% hidden layer: 15 neurons

-

% output layer: 1 neuron

-

net = newff(p, t, [15,1], {‘tansig’,’logsig’},’trainlm’);

-

net.trainParam.epochs = 10000;

-

net.trainParam.mu = 1;

-

net.trainParam.mu_dec = 0.8;

-

net.trainParam.mu_inc = 1.5;

-

net = train(net, p, t);

-

Y = sim(net, p);

References

Abu-Kiefa MA (1998) General regression neural networks for driven piles in cohesionless soils. J Geotech Geoenviron Eng ASCE 124(12):1177–1185

Adeli H (2001) Neural networks in civil engineering: 1989–2000. Comput Aided Civ Infrastructure Eng 16(2):126–142

Akbulut S (1999) The improvement of geotechnical properties in granular soils by grouting. Dissertation, Istanbul Technical University

Akbulut S, Saglamer A (2002) Estimating the groutability of granular soils: a new approach. Tunn Undergr Space Technol 17(4):371–380

Burwell EB (1958) Cement and clay grouting of foundations: practice of the corps of engineers. J Soil Mech Foundations Div ASCE 84:1551/1–1551/22

Celik S, Tan O (2005) Determination of pre-consolidation pressure with artificial neural network. Civil Eng Environ Sys 22(4):217–231

Chen Y, Azzam R, Zhang F (2006) The displacement computation and construction pre-control of a foundation pit in Shanghai utilizing FEM and intelligent methods. Geotech Geol Eng 24(6):1781–1801

DeBeer EE (1970) Grondmechanica 2, Standard Scientific Publishers

Demuth H, Beale M, Hagan M (2009) MATLAB neural network toolboxTM 6 user’s guide. The Mathworks Inc, pp 5–52

Dupla J-C, Canou J, Gouvenot D (2004) An advanced experimental set-up for studying a monodirectional grout injection process. Ground Improv 8(3):91–99

Erzin Y (2007) Artificial neural networks approach for swell pressure versus soil suction behavior. Can Geotech J 44(10):1215–1223

Fausett LV (1994) Fundamentals neural networks: architecture, algorithms, and applications. Prentice-Hall, Englewood Cliffs

Flood I, Kartam N (1994) Neural networks in civil engineering I: principles and understanding. J Comput Civ Eng 8(2):131–148

Goh ATC (1995) Modeling soil correlations using neural networks. J Comput Civil Eng ASCE 9(4):275–278

Goh ATC, Kulhawy FH (2003) Neural network approach to model the limit state surface for reliability analysis. Can Geotech J 40(6):1235–1244

Goh ATC, Kulhawy FH, Chua CG (2005) Bayesian neural network analysis of undrained side resistance of drilled shafts. J Geotech Geoenviron Eng ASCE 131(1):84–93

Gouvenot D (1998) State of the art in European grouting. Ground Improv 2(2):51–67

Hammerstrom D (1993) Working with neural networks. IEEE Spectrum 30(7):46–53

Hanna AM, Ural D, Saygili G (2007) Neural network model for liquefaction potential in soil deposits using Turkey and Taiwan earthquake data. Soil Dyn Earthq Eng 27(6):521–540

Incecik M, Ceren I (1995) Cement grouting model tests. Bull Tech Univ Istanbul 48(2):305–317

Kim J-S, Lee I-M, Jang J-H, Choi H (2009) Groutability of cement-based grout with consideration of viscosity and penetration phenomenon. Int J Numer Analyt Methods Geomech. doi:10.1002/nag.785

Jessberger HL (1983) Soil grouting general report: improvement of ground. Proceedings of 8th European conference on soil mechanics and foundation engineering, Helsinki, pp 1069–1078

Kim Y, Kim B (2008) Prediction of relative crest settlement of concrete-faced rockfill dams analyzed using an artificial neural network model. Comput Geotech 35(3):313–322

Krizek RJ (1985) Chemical grouting in soils permeated by water. J Geotech Eng Div ASCE 111(7):898–915

Kung GT, Hsiao EC, Schuster M, Juang CH (2007) A neural network approach to estimating deflection of diaphram walls caused by excavation in clays. Comput Geotech 34(5):385–396

Landry E, Lees D, Naudts A (2000) New developments in rock and soil grouting: design and evaluation. Geotech News 18(3):38–44

Lee SJ, Lee SR, Kim YS (2003) An approach to estimate unsaturated shear strength using artificial neural network and hyperbolic formulation. Comput Geotech 30(6):489–503

Lu Y (2005) Underground blast induced ground shock and its modeling using artificial neural network. Comput Geotech 32(3):164–178

Mitchell JK (1981) Soil improvement: state-of-the-art. Proceedings of 10th international conference on soil mechanics and foundation engineering. Stockholm 4, pp 509–565

Najjar YM, Basheer IA (1996) Neural network approach for site characterization and uncertainty prediction. In: ASCE Geotechnical Special Publication 58(1):134–148

Orbani P, Fajdiga M (2003) A neural network approach to describing the fretting fatigue in aluminum steel couplings. Int J Fatigue 25:201–207

Padmini D, Ilamparuthi K, Sudheer KP (2008) Ultimate bearing capacity prediction of shallow foundations on cohesionless soils using neurofuzzy models. Comput Geotech 35(1):33–46

Rahman MS, Wang J, Deng W, Carter JP (2001) A neural network model for the uplift capacity of suction cassions. Comput Geotech 28(4):269–287

Rankine R, Sivakugan N (2005) Prediction of paste backfill performance using artificial neural networks. Proceedings of 16th international society for soil mechanics and foundation engineering, Osaka, pp 1107–1110

Sakellariou MG, Ferentinou MD (2005) A study of slope stability prediction using neural networks. Geotech Geol Eng 23:419–445

Shahin MA, Maier HR, Jaksa MB (2004) Data division for developing neural networks applied to geotechnical engineering. J Comput Civil Eng ASCE 18(2):105–114

Shahin MA, Jaksa MB, Maier HR (2005) Neural network based stochastic design charts for settlement prediction. Can Geotech J 42(1):110–120

Shahin MA, Jaksa MB, Maier HR (2008) State of the art of artificial neural networks in geotechnical engineering. Electron J Geotech Eng Bouquet 08:1–26

Shang JQ, Ding W, Rowe RK, Josic L (2004) Detecting heavy metal contamination in soil using complex permittivity and artificial neural networks. Can Geotech J 41(6):1054–1067

Sinha SK, Wang MC (2008) Artificial neural network prediction models for soil compaction and permeability. Geotech Eng J 26(1):47–64

Stone M (1974) Cross-validatory choice and assessment of statistical predictions. J R Stat Soc B 36:111–147

Tekin E (2004) Experimental studies on the groutability of microfine cement (Rheocem 900) grouts to sands having various gradations. Dissertation, Gazi University

Welsh JP (1986) In situ testing for ground modification techniques. In: ASCE Geotechnical Special Publication No. 6. New York, pp 322–335

Welsh JP, Burke GK (1991) Jet grouting: uses for soil improvement. Proceedings of geotechnical engineering congress. University of Colorado at Boulder, pp 334–345

Yoo C, Kim J (2007) Tunneling performance prediction using an integrated GIS and neural network. Comput Geotech 34(1):19–30

Zebovitz S, Krizek RJ, Atmazidis DK (1989) Injection of fine sands with very fine cement grout. J Geotech Eng Div ASCE 115(12):1717–1733

Zurada JM (1992) Introduction to artificial neural systems. West Publishing Company, St. Paul

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tekin, E., Akbas, S.O. Artificial neural networks approach for estimating the groutability of granular soils with cement-based grouts. Bull Eng Geol Environ 70, 153–161 (2011). https://doi.org/10.1007/s10064-010-0295-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-010-0295-x