Abstract

Concerning the pollution-free and eco-friendly materials, the prospect of using biopolymer as ion conducting matrix has been investigated in this study. Biopolymer electrolyte based on agar with different concentrations of NH4Br has been prepared by solution casting technique using water as solvent. The prepared electrolytes are characterized by X-ray diffraction analysis, Fourier-transform infrared spectroscopy, AC impedance spectroscopy, and electrochemical stability. X-ray diffraction is done to study the nature (amorphous/crystalline) of the polymer membranes. The complexation of the prepared polymer electrolytes has been studied using Fourier-transform infrared (FTIR) spectroscopy. The maximum ionic conductivity of 1.33 × 10−4 S cm−1 has been obtained for 50 M.wt% NH4Br with agar polymer electrolyte. The temperature dependence of ionic conductivity of the prepared polymer electrolytes obeys Arrhenius law. The ionic transference numbers of mobile ions have been estimated by Wagner’s dc polarization method and the results reveal that the conducting species are predominantly ions. The electrochemical stability is studied by linear sweep voltammetry. A battery has been constructed using the highest conductivity sample and its output voltage is found to be 1.80 V. A proton-exchange membrane fuel cell fabricated with the 50 M.wt% NH4Br-doped agar polymer electrolyte exhibited an output voltage of 500 mV. These results of 50 M.wt% NH4Br-doped agar have been compared with 50 M.wt% agar:50 M.wt% NH4I biopolymer electrolyte.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The term “Solid State Ionics” was first coined by Prof. Takehiko Takahashi, Nagoya University in 1970. This science focuses mostly on solid electrolytes in which conduction takes place predominantly due to ions. The seed of the technological achievements in this field has been sowed by the end of nineteenth century by Faraday. A further development has been contributed by Nernst in 1897 with the development of a solid electrolyte stabilized zirconia which was used in Nernst Glower. Hence, with the efforts of the researchers, the sowed seed of this field has flourished with the branches of various types of solid electrolytes such as solid polymer electrolytes (SPEs), crystals, glasses, and biopolymer electrolytes. In recent years, it has bloomed as blossoms with flourishing fragrance in batteries [1, 2], sensors [3, 4], super-capacitors [5], electrochromic displays [6], fuel cells [7], solar cells [8], and other applications.

Owing to the depletion of fossil fuels and growing energy demand, there arises a necessity to find an alternate energy-producing resource which means to be eco-friendly. Recently, biopolymer materials, such as chitosan, corn starch, and carrageenan, have been used extensively as electrolytes [9,10,11]. S. C. Nunes et al. [12] have reported a conductivity value of 8.47 × 10−4 S cm−1 at room temperature for κ-carrageenan with 1-butyl-3-methyl-1H-imidazolium chloride ionic liquid and glycerol. Maximum conductivity value of 3.56 × 10−3 S cm−1 at room temperature for i-carrageenan with ammonium thiocyanate has been reported recently [13]. Biopolymer electrolyte based on tamarind seed polysaccharide and lithium chloride exhibited maximum conductivity of 6.7 × 10−3 S cm−1 at room temperature [14]. By merely becoming more environmentally aware, agar, a biopolymer, has been chosen as the host polymer for the production of solid polymer electrolyte which finds application in energy storage devices and solid-state devices. Agar which is extracted from seaweed has good film-forming capability and mechanical strength. Although agar is not a new material, the early use of agar in electrochemical studies was limited to preparation of salt bridges and in construction of some reference electrodes [15]. Recently agar has been used in some electrochemical cells [16], dye sensitized solar cells [17], and for several industrial uses. Agar is used in tissue engineering and pharmaceutical for potential use in bone replacement [18]. L. An et al. [19] have reported the synthesis and application of a novel, cost-effective, and environmentally friendly agar chemical hydrogel (ACH) electrode binder in fuel-electrolyte-fed fuel cells. Ellen Raphael et al. [20] have reported a conductivity value of 1.1 × 10−4 S cm−1 at room temperature for agar with acetic acid. Nwanya et al. [21] has reported the values of the ion conductivity obtained for the agar-based polymer films are 6.54 × 10−8, 9.12 × 10−8, 3.53 × 10−8, and 2.24 × 10−8 S cm−1 for the agar/acetic acid, agar/lactic acid, agar/LiClO4, and agar/KClO4 polymer films, respectively. Selvalakshmi et al. [22] has reported the conductivity of agar with NH4SCN as 1.03 × 10−3 S cm−1, 1.17 × 10−4 S cm−1 for agar with NH4I [23]. Hence in the present study, biopolymer electrolyte with agar and NH4Br has been prepared with water as solvent. The prepared samples were then subjected to XRD, Fourier-transform infrared spectroscopic analysis, AC impedance spectroscopic analysis, and linear sweep voltammetry. The highest conductivity sample was used to fabricate a battery and a fuel cell. The obtained results have been compared with the reported values of agar with NH4I [23].

Materials and method

Materials

Agar of average molecular weight 120,000 Da (purity, 95%, Condo-Forja) and NH4Br (purity, 99%, Spectrum) have been used in the present work.

Preparation of electrolyte

The simplest technique called solution casting technique has been employed in the synthesis of the biopolymer electrolytes. The M.wt% of agar ranging from 100 to 40% and M.wt% of NH4Br ranging from 10 to 60% was dissolved in hot double distilled water. The solution was magnetically stirred for 3 h. The homogeneous clear solution was casted in clean glass petri dish and allowed to evaporate in a hot air oven at 40 °C. After 48 h, free standing transparent films were obtained with thickness in the range 7–19 μm.

Electrolyte characterization

X-ray diffraction analysis

X-ray diffraction patterns of the prepared samples were recorded at room temperature on a Philips X’ Pert PRO diffractometer using Cu-Kα radiation in the range of 2θ = 10° to 90° at the rate of 2° min−1 to determine the nature (crystalline/amorphous) of the electrolytes.

Fourier-transform infrared spectroscopy

FTIR spectra were recorded for the proton-conducting polymer electrolyte films in the range of 400–4000 cm−1 with resolution 1 cm−1 at room temperature using a SHIMADZU-IR Affinity-1 Spectrometer to investigate the complex formation between the polymer and the salt.

AC impedance spectroscopic analysis

Electrical measurements were performed on the polymer electrolyte films in the frequency range 42–1 MHz, at an operating voltage of 1.1 V, over the temperature range 303–343 K by sandwiching them between aluminum-blocking electrodes using HIOKI 3532 LCR meter interfaced with a computer.

Transference number measurement

Wagner’s dc polarization method was employed to determine the transference number. The prepared biopolymer electrolyte was sandwiched between two aluminum-blocking electrodes which were connected in series to a dc power supply of 12 V through an ammeter. The polarization current is monitored as a function of time for different voltages (1–2.5 V).

Linear sweep voltammetry

The electrochemical stability window of the polymer electrolyte was determined by means of linear sweep voltammetry technique which was performed on a Bio-Logic VSP-300 multichannel workstation (France). LSV of the membranes were carried out using stainless steel electrodes at a scan rate of 0.1 mVs−1 scan rate at room temperature from 0 to 5 V.

Fabrication of proton battery

A proton battery was constructed using the highest conductivity sample which is sandwiched between cathode and anode. The cathode material contains lead oxide (PbO2), vanadium pentaoxide (V2O5), graphite, and the highest conductivity electrolyte in the ratio 8:2:1:0.5. The anodic compartment consists of zinc powder, zinc sulfate, and graphite in the ratio 3:1:1. The cathode and anode are constructed in the form of thin pellets.

Fabrication of fuel cell

The highest conductivity membrane was sandwiched between two platinized carbon electrodes to form a membrane assembly. The membrane assembly was then sealed tightly using silicon gaskets between two bipolar graphite plates which has flow channels. The hydrogen with a flow rate of 10 ml/min and oxygen with a flow rate of 8 ml/min were supplied to the single fuel cell with an electrolyser operated at a voltage of 3 V.

Results and discussions

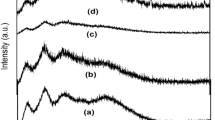

X-ray diffraction analysis

The X-ray diffraction patterns obtained for the agar-based polymer film electrolyte samples are shown in Fig. 1. The diffraction pattern of pure agar shows peaks at 2θ = 13°, 20°, and 30° which have already been reported by Raphael et al. [20]. On the addition of NH4Br, the broadness of the peaks increases which indicates the increase in amorphous nature of the biopolymer electrolytes. It is obvious from the figures that the biopolymer electrolyte of compositions 50 M.wt% agar with 50 M.wt% NH4Br is more amorphous than other composition which is revealed by the decrease of intensity and the increase of broadness of the diffraction peak of agar. This result is interpreted in terms of the Hodge criterion which establishes a correlation between the intensity of the peak and the degree of crystallinity [24]. This change of intensity and broad nature of peaks in the polymer electrolyte suggest the amorphous nature of the polymer electrolytes [25]. No peaks corresponding to pure NH4Br are observed in complexed polymers up to 50 M.wt% NH4Br-doped agar polymer electrolytes. This indicates the complete dissociation of the salt in the polymer matrix [26, 27].

The sharp peaks at 2θ = 30°, 38°, 44°, 49°, and 55° (JCPDS file no. 85-099) in 40 M.wt% agar with 60 M.wt% NH4Br are attributed to NH4Br. The occurrence of these peaks may be due to the presence of undissociated salt in the polymer matrix. This is because the polymer host is unable to accommodate the salt which leads to the aggregation of ions. In the case of agar with NH4I polymer electrolyte, 50 M.wt% agar:50 M.wt% NH4I is more amorphous than other ratios [23].

Fourier-transform infrared analysis

Figure 2 shows the absorption peaks for agar and various ratios of agar doped with NH4Br polymer electrolytes film.

The small peak at 1642 cm−1 observed in Fig. 2 for pure agar is attributed to the O–H bending. The band at 2925 cm−1 in pure agar is due to CH stretching. The absorption band at about 3400 cm−1 is associated with O–H stretching [28]. When NH4Br is added to agar, the polar group (O–H) in agar will attract the salt molecules to be attached to it. Hence, the peak at 1642 cm−1 due to O–H bending is observed to have wave shift decrease up to 24 cm−1. The band at around 1642 cm−1 is found almost in all natural polymers which may be due to the stretching vibration of the conjugated peptide bond formed by amine (NH) and acetone (CO) groups [29]. In NH4Br, the hydrogen bonding occurs with the N–H bond within the tetrahedral ion, NH4+, pointing towards Br− ion and forming an N–H–Br hydrogen bond. Two of the four hydrogen atoms of NH4+ ions are bound identically, one hydrogen is bound more rigidly and the fourth more weakly. The weakly bound hydrogen can easily be dissociated by applying a dc electric field [30]. These H+ ions can hop via each coordinating site at the band 1642 cm−1 of the host polymer (agar) and thus conduction takes place. The conduction is due to the interaction of ions between coordinate sites (Grotthus mechanism) [31]. The possible interaction between the biopolymer agar and NH4Br is shown in Fig. 3.

In Fig. 2, the peak at 1373 cm−1 in pure agar is assigned to ester sulfate [32] and the bands at 1039 cm−1 and 934 cm−1 in pure agar are associated with the 3,6-anhydro-galactose bridges [33]. A summary of characteristic bands of agar with NH4Br films are presented in Table 1. It is observed that with the addition of NH4Br, a new peak has been formed at 1437 cm−1 in 60 M.wt% agar:40 M.wt% NH4Br. The increase in salt content caused an increase in the intensity of absorbance band at 1437 cm−1. This is due to the fact that mixing a polymer and a salt leads to shift in characteristic peaks as a reflection of the physical and chemical interactions. These observations indicate the complex formation between agar and NH4Br.

AC impedance spectroscopic analysis

Impedance spectroscopy has been employed to determine the conductivity of the prepared biopolymer electrolytes. The ionic conductivity depends on several factors, such as ionic conducting species concentration, mobility of charge carriers, and the temperature [34]. Figure 4 shows the Nyquist plot of agar doped with different ratios of NH4Br.

The Nyquist plots of agar doped with different concentrations of NH4Br show a low frequency spike and that of pure agar shows a depressed high-frequency semicircle followed by a low-frequency spike. The high-frequency semi-circle can be related to the parallel combination of bulk resistance (Rb) and bulk capacitance (Cb) of the material and the linearly rising pattern (spike) reveals the adsorption of ions at the electrode-electrolyte interface and it could be represented as a constant phase element (CPE) [35]. With the addition of NH4Br to pure agar, the semicircle disappears representing that only resistive component prevails in the polymer matrix. The bulk resistance can be retrieved using Boukamp software [36].

The ionic conductivity values for all ratios of agar with NH4Br polymer electrolyte at 303 K and 343 K have been listed in Table 2. The highest conductivity has been found to be 1.33 × 10−4 S cm−1 at ambient temperature for 50 M.wt% NH4Br:50 M.wt% agar. Samsudin AS and Isa MIN [37] have reported a conductivity value of 1.12 × 10−4 S cm−1 for carboxymethyl cellulose (CMC) with NH4Br based biopolymer electrolytes. Maximum conductivity value of 3.61 × 10−4 S cm−1 for hydroxyethyl cellulose (HEC) with NH4Br based biopolymer electrolytes by Sit YK et al. [38]. Cornstarch-based electrolytes doped with NH4Br exhibited conductivity value of 5.57 ± 1.88 × 10−5 S cm−1 [39]. The obtained conductivity value for 50% NH4Br:50% agar is slightly greater than the value reported for CMC with NH4Br and cornstarch with NH4Br but less than that of HEC with NH4Br. Boopathi et al. [40] have obtained a maximum conductivity of 6.57 × 10−4 S cm−1 for agar with NH4NO3 which is slightly greater than the value reported in the present study. A conductivity value of 1.17 × 10−4 S cm−1 is observed for 50 M.wt% agar with 50 M.wt% NH4I. The conductivity value obtained for agar doped with NH4Br is slightly greater than that obtained for NH4I which may be due to the impact of ionic radius. The ionic radius of bromide ion (1.96 Ǻ) is less than that of iodide ion (2.2 Ǻ). Hence, more free volume is produced for agar with bromide membrane. This increased free volume helps the free movement of protons and hence the conductivity increases.

Temperature-dependent conductivity

Ionic conductivity of pure agar and NH4Br doped agar polymer electrolytes fitted with Arrhenius relationship ranging from ambient temperature until 343 K. It was observed that the ionic conductivity of the prepared biopolymer electrolytes increases with increase in temperature for all the ratios. The regression values were found to be close to unity, suggesting that the conductivity values of agar-based polymer electrolytes at different temperatures follow the Arrhenius equation,

where σo is the pre-exponential factor, Ea is the activation energy, and k is the Boltzman constant.

According to Druger et al. [41], the increase in conductivity with temperature in polymer electrolytes may be attributed to increase in free volume of the system and segmental mobility of the polymer matrix. Ionic transportation is enhanced with increasing temperature. The activation energy values for ionic conduction in different ratios of the polymer electrolyte calculated from the Arrhenius plots are shown in Table 2. It has been observed that 50 M.wt% NH4Br-doped agar membrane shows the highest conductivity, but bears the low activation energy of 0.23 eV in the system. This reveals that 50 M.wt% NH4Br-doped agar membrane manifests higher flexibility of polymer backbone coupled with increased segmental mobility within the polymer chains. Hence, this highest conductivity membrane requires the lowest activation energy for the hopping process. For further increase of salt content (60 M.wt% NH4Br), the activation energy increases due to aggregation of ions, thus decreasing the number of mobile charge carriers. Similar condition prevails in agar with NH4I biopolymer electrolytes. The highest conductivity sample 50 M.wt% agar with 50% NH4I exhibits low activation energy of 0.43 eV. The increase in activation energy of 50% agar with 50 M.wt% NH4I than that of 50 M.wt% agar with 50 M.wt% NH4Br may be attributed to the increase in ionic radius and it is found to be consistent with the conductivity values. The activation energy of 0.04 eV has been reported for agar with NH4NO3 [40] which is less than that of agar with NH4Br and NH4I.

Transference number measurement

Ionic transference number is one of the most important parameter for the characterization of polymer electrolyte materials. Transference numbers were evaluated using Wagner’s dc polarizing technique [42] using blocking electrodes. To determine the ionic contribution to the total conductivity of the polymer electrolyte films, the highest conductivity membrane (50 M.wt% agar:50 M.wt% NH4Br) was sandwiched between two aluminum-blocking electrodes. The Al/(agar+NH4Br)/Al cell was polarized at 303 K by a dc power supply of 12 V. The schematic diagram of the experimental setup is shown in Scheme 1. Three trials have been performed on the highest conductivity sample (50 M.wt% agar:50 M.wt% NH4Br) and the average values have been given in Table 3. The polarization measurements have been performed at 1 V, 1.5 V, 2 V, and 2.5 V for the highest conductivity sample (50 M.wt% agar:50 M.wt% NH4Br) and the polarization curves have been shown in Fig. 5.

The appearance of initial polarization current on application of the different potential was proportional to the dc applied field but subsequently it starts decreasing with time. The transference numbers (tion, tele) were calculated using the equations

where Ii is the initial current and If is the final current. The ionic transference number (tion) values are in the range 0.95 ± 0.01 to 0.98 ± 0.01. This suggests that the charge transport in these polymer electrolytes are predominately due to ions. The electronic contribution to the total current is negligible in all the polymer electrolyte films [43]. The ionic transference number (tion) of the present polymer electrolyte films is close to unity and hence these electrolytes are suitable for solid-state electrochemical cells. Hema et al. [31] have reported that the values of tion lie between 0.93–0.96 for PVA-NH4Br polymer electrolytes.

Linear sweep voltammetry

In order to fabricate polymer electrolyte for electrochemical devices, it is essential to determine the electrochemical stability window of the membrane where no oxidation or reduction take place in the polymer matrix. Concerning this point of view, the highest conducting biopolymer membrane (50 M.wt% agar:50 M.wt% NH4Br) was subjected to linear sweep voltammetry. The linear sweep voltammetry experiment employed inert stainless steel disc as working electrode and stainless steel plate as reference and counter electrodes. The stainless steel/50 M.wt% agar:50 M.wt% NH4Br polymer electrolyte/stainless steel cell was constructed and utilized at a scan rate of 1 mV/s from 0 to 5 V. Figure 6 shows the linear sweep voltammogram of the highest conducting (50 M.wt% agar:50 M.wt% NH4Br) polymer electrolyte as a function of voltage. The linear sweep voltammogram revealed that the electrochemical stability window for 50 M.wt% agar–50 M.wt% NH4Br system is up to 2.5 V. The electrochemical stability window for 50 M.wt% agar–50 M.wt% NH4I is up to 2.4 V which is slightly less than the value obtained for 50 M.wt% agar–50 M.wt% NH4Br films. Electrochemical stability window of 2.46 V has been reported for iota-carrageenan (Ι-carrageenan) with ammonium nitrate (NH4NO3) membrane [13] which lies between the value obtained for agar:NH4I and agar:NH4Br. Shukur MF et al. [39] has reported electrochemical stability window of 1.66 V for starch:NH4Br:glycerol. From the reported works, it is obvious that agar:NH4Br has electrochemical stability which is suitable for electrochemical devices.

Battery characterization

For a successful proton battery, an anode capable of supplying or injecting H+ ions into the battery electrolyte, a proton-conducting polymer electrolyte, and a cathode are needed. K. Singh et al. [44] showed that ZnSO4.7H2O is a potential candidate for solid state, proton-conducting batteries. Metallic zinc is preferred in the anode compartment due to its superiority than other metals [45]. Kamlesh Pandey et al. [46] reported the best performance of the battery is achieved when the intercalating cathodes such as PbO2 and V2O5 are used as mixture.

In the present investigation, the highest conducting polymer electrolyte (50 M.wt% agar:50 M.wt% NH4Br ) is sandwiched between the prepared cathode (V2O5 + PbO2 + C) and anode (Zn + ZnSO4.7H2O + C + polymer electrolyte) and placed in the battery holder (Fig. 7A), which is connected to a multimeter to measure the open circuit voltage (OCV).

The prepared cell exhibited an open-circuit voltage of 1.80 V (Fig.7B) and it endured for 63 h. When a load of 1 MΩ is connected, the cell exhibited a closed-circuit voltage of 1.71 V which retained for 12 h. Figure 7 C shows the discharge characteristics of the constructed cell. Parameswaran et al. [47] have reported an OCV of 1.2 V for PVA/PVP/NH4Br-based polymer electrolytes. The cell constructed with 50% agar:50% NH4I exhibited open-circuit voltage of 1.73 V and with a load of 1 MΩ, it exhibited 1.61 V. During discharge with 1 MΩ load, 0.78 V has been observed by Parameswaran et al. [47].

Table 4 exhibits the cell parameters of the constructed cell which show that the developed solid-state electrochemical cell is simple, economical, and eco-friendly.

Construction of single PEM fuel cell

Fuel cells have attracted attention due to their potential as a promising alternative to traditional power sources. They are eco-friendly zero-emission power sources. A proton-exchange membrane (PEM) fuel cell transforms the chemical energy liberated during the redox reaction of hydrogen and oxygen directly to electrical energy. In the present study, a PEM fuel cell was constructed as designed by Monisha et al. [7] using the highest proton conducting membrane (50 M.wt% agar:50 M.wt% NH4Br) which was sandwiched between the electrodes. The PEM fuel cell was constructed with bipolar graphite plates etched with parallel flow channel of size 7.4 cm2 and sealed by silicon gaskets. These plates are mounted on two acrylic base plates. Over the flow channels of either graphite plates, platinized carbon cloths of area 8.4 cm2 coated with Pt at a uniform rate of 0.15 mg/cm were placed. These platinized carbon cloths act as cathode and anode. The platinum layer acts as a catalyst. A voltage of 3 V was supplied to a small electrolyser to produce hydrogen and oxygen separately which are the fuels for the constructed single PEM fuel cell at a flow rate of 10 ml/min and 8 ml/min respectively.

The anode and the cathode reaction for a PEM fuel cell are given in below equations:

The newly constructed PEM fuel cell with 50% agar:50% NH4Br biopolymer electrolyte exhibited a voltage of 500 mV and is shown in Fig. 8.

Similarly, we have already reported an OCV of 408 mV for PEM fuel cell constructed with agar and NH4I [48]. Literature survey show that fuel cell has been constructed with biopolymer electrolytes cellulose acetate with NH4NO3 [7] and NH4SCN [49] which exhibited an output voltage of 656 mV and 685 mV respectively. Boopathi et al. [40] has reported an output voltage of 558 mV for a single PEM fuel cell fabricated with a biopolymer membrane agar-agar with NH4NO3. The obtained output voltage for the PEMFC in present study is less than the values reported by Monisha et al. [7] and Boopathi et al. [40] but greater than the value obtained for agar with NH4I. Yet the value can be enhanced by doping either fillers or plasticizers with agar-agar:NH4Br in future. The obtained voltage suggests that the biopolymer membrane with a combination of agar and NH4Br is a worthy candidate for fuel cell applications than a combination of agar and NH4I.

From the comparative chart (Table 5), it is obvious that the biopolymer electrolyte based on agar with NH4Br is more efficient than agar with NH4I which may be due to the impact of ionic radius. Since the ionic radius value of bromide (1.96 Ǻ) is slightly less than the ionic radius value of iodide (2.2 Ǻ), the pathway for proton hopping is free in agar with NH4Br electrolytes. The greater ionic radius of iodide may hinder the proton migration and thus the overall parameters are found to be less for agar with NH4I than that obtained for agar with NH4Br.

Conclusions

Agar-based proton-conducting polymer electrolytes with NH4Br in different ratios have been prepared by solution-casting technique using double distilled water as solvent. X-ray diffraction reveals the amorphousness of the polymer electrolytes. The FTIR analysis confirms the complex formation between the polymer and the salt. From the impedance analysis, it has been observed that the 50 M.wt% NH4Br-doped agar polymer complex has the highest conductivity of 1.33 × 10−4 S cm−1 at ambient temperature. The temperature-dependent conductivity of polymer electrolytes obeys Arrhenius behavior. The activation energy estimated from the Arrhenius plot has been found to be 0.24 eV for 50 M.wt% NH4Br-doped agar polymer electrolyte. The 50 M.wt% NH4Br-doped agar polymer electrolyte has the highest dielectric constant indicating high-storage capacity. The ionic transference number and other transport parameters were determined which revealed that the conducting species are predominantly H+ ions. The battery that has been fabricated by using the highest conducting composition 50 M.wt% agar:50 M.wt% NH4Br polymer electrolyte film is found to perform with an OCV of 1.80 V and the constructed PEMFC exhibited an open-circuit potential of 500 mV. From the results obtained, it is clear that the biopolymer electrolyte based on agar with NH4Br is more efficient than agar with NH4I for the application in solid-state devices.

References

Christie AM, Lilley SJ, Staunton E, Andreev YG, Bruce PG (2005) Increasing the conductivity of crystalline polymer electrolytes. Nature 433(7021):50–53

Tarascon JM, Armand M (2001) Issues and challenges facing rechargeable lithium batteries. Nature 414(6861):359–367

Armand M (1994) The history of polymer electrolytes. Solid State Ionics 69(3-4):309–319

Gray FM (1991) Solid Polymer Electrolytes: Fundamentals and Technological Applications, VCH-Verlag-Ges, Wiley, New York, pp 1-30

Hashmi SA, Latham RJ, Linford RG, Schlindwein WS (1997) Studies on all solid state electric double layer capactors using proton and lithium ion conducting polymer electrolytes. J Chem Soc Faraday Trans 93(23):4177–4182

Tatsumisago M, Shinkuma Y, Minami T (1991) Stabilization of superionic α-AgI at room temperature in a glass matrix. Nature 354(6350):217–218

Monisha S, Mathavan T, Selvasekarapandian S, Milton Franklin Benial A, Aristatil G, Mani N, Premalatha M, Vinoth pandi D (2016) Investigation of bio polymer electrolyte based on cellulose acetate-ammonium nitrate for potential use in electrochemical devices. Carbohydr Polym 157:38–47

singh PK, Jadhav NA, Mishra SK, Singh UP, Bhattacharya B (2010) Application of ionic liquid doped solid polymer electrolyte. Ionics 16(7):645–648

Khiar ASA, Arof AK (2011) Electrical properties of starch/chitosan-NH4NO3Polymer electrolyte. WASET 59:23–27

Liew CW, Ramesh S (2015) Electrical, structural, thermal and electrochemical properties of corn starch–based biopolymer electrolyte. Carbohydr Polym 124:222–228

Rhim JW (2012) Physical-mechanical properties of agar/κ-carrageenan blend film and derived clay nanocomposite film. J Food Sci 77(12):66–73

Nunes SC, Pereira RFP, Sousa N, Silva MM, Almeida P, FML F, de Zea Bermudez V (2017) Eco-friendly red seaweed-derived electrolytes for elecrochemical devices. AdvSustainable Syst 1700070:1–17

Moniha V, Alagar M, Selvasekarapandian S, Sundaresan B, Hemalatha R, Boopathi G (2018) Synthesis and characterization of bio-polymer electrolyte based on iota-carrageenan with ammonium thiocyanate and its applications. JSolid State Electrochem 22:1–15

Sampath Kumar L, Christopher Selvin P, Selvasekarapandian S, Manjuladevi R, Monisha S, Perumal P (2018) Tamarind seed polysaccharide biopolymer membrane for lithium-ion conducting battery. Ionics 24(12):3793–3803

Hassel AW, Fushimi K, Masahiro S (1999) An agar-based silver/silver chloride reference electrode for use in micro-electrochemistry. Electrochem Commun 1(5):180–183

Othaman R, Yahaya AH, Arof AK (2002) Zinc-air cell with OH-treated agar layer between electrode and electrolyte containing hydroponics gel. J New Mat Electrochem Systems 5:177–182

Alias SS, Mohamad AA (2013) Effect of NH4I and I2 concentration on agar gel polymer electrolyte properties for a dye-sensitized solar cell. Ionics 19(8):1185–1194

Senthilarasan K, Ragu A, Sakthivel P (2014) Synthesis and characterization of nano hydroxyapatite with agar-agar bio-polymer. IJERA 4:55–59

An L, Zhao TS, Zeng L (2013) Agar chemical hydrogel electrode binder for fuel-electrolyte-fed fuel cells. Appl Energy 109:67–71

Raphael E, Avellaneda CO, Manzolli B, Pawlicka A (2010) Agar-based films for application as polymer electrolytes. Electrochim Acta 55(4):1455–1459

Nwanya AC, Amaechi CI, Udounwa AE, Osuji RU, Maaza M, Ezema FI (2015) Complex impedance and conductivity of agar-based ion-conducting polymer electrolytes. Appl Phys A Mater Sci Process 119(1):387–396

Selvalakshmi S, Vijaya N, Selvasekarapandian S, Premalatha M (2017) Biopolymer agar-agar doped with NH4SCN as solid polymer electrolyte for electrochemical cell application. J Appl Polym Sci 134:44702 1–44702 4470210

Selvalakshmi S, Mathavan T, Selvasekarapandian S, Premalatha M (2017) Study on NH4I composition effect in agar–agar-based biopolymer electrolyte. Ionics 23(10):2791–2797

Ramya CS, Selvasekarapandian S, Savitha T, Hirankumar G, Angelo PC (2007) Vibrational and impedance spectroscopic study on PVP-NH4SCN based polymer electrolytes. Physica B 393(1-2):11–17

Nithya S, Selvasekarapandian S, Karthikeyan S, Inbavalli D, Sikkinthar S, Sanjeeviraja C (2014) AC impedance studies on proton-conducting PAN:NH4SCN polymer electrolytes. Ionics 20(10):1391–1398

Ramya CS, Selvasekarapandian S, Savitha T, Hirankumar G, Angelo PC (2008) Investigation on dielectric relaxations of PVP-NH4SCN polymer electrolyte. J Non-Cryst Solids 354:1949–1502

Yusof YM, Illias HA, Kadir MFZ (2014) Incorporation of NH4Br in PVA-chitosan blend-based polymer electrolyte and its effect on the conductivity and other electrical properties. Ionics 20(9):1235–1245

Robitzer M, Tourrette A, Horga R, Valentin R, BoissièreM DJM, Di Renzo F, Quignard F (2011) Nitrogen sorption as a tool for the characterisation of polysaccharide aerogels. Carbohydr Polym 85(1):44–53

El-Hefian E, Nasef MM, Yahaya AH (2012) Preparation and characterization of chitosan/agar blended films: part 1. Chemical structure and morphology. E-journal of Chemistry 9(3):1431–1439

Hema M, Selvasekarapandian S, Sakunthala A and Arunkumar (2008) Structural, vibrational and electrical characterization of PVA-NH4Br polymer electrolyte system. Phys B, 403:2740-2747, 17

Hashmi SA, Kumar A, Maurya KK, Chandra S (1990) Proton conducting polymer electrolyte 1.The Polyethyelene oxide + NH4ClO4 system. J PhysD Applied Phys 23(10):1307–1314

Armise’n R, Galatas F (1987) Production, properties and uses of agar. FAO Fish Tech Pap 288(1)

Chirapart A, Ohno M, Ukeda H, Sawamura M, Kusunose H (1995) Chemical composition of agars from a newly reported Japanese agarophyte, Gracilariopsis lemaneiformis. Appl Phycol 7(4):359–365

Schantz S, Torell LM (1993) Evidence of dissolved ions and ion pairs in dilute poly (propylene oxide)-salt solutions. Solid State Ionics 60(1-3):47–53

Selvalakshmi S, Mathavan T, Selvasekarapandian S, Premalatha M (2018) Effect of ethylene carbonate plasticizer on agar-agar: NH4Br based solid polymer electrolytes. Ionics 24(8):2209–2217

Boukamp BA (1986) A nonlinear least square fit procedure for analysis of immitance data of electrochemical systems. Solid State Ionics 20(1):31–44

Samsudin AS, Isa MIN (2012) Structural and Ionic transport study on CMC doped NH4Br: a new type of biopolymer electrolytes. J Appl Sci 12:174–179

Sit YK, Samsudin AS, Isa MIN (2012) Ionic conductivity study on hydroxyethyl cellulose (HEC) doped with NH4Br based biopolymer electrolytes. ResJRecent Sci 1:16–21

Shukur MF, Kadir MFZ (2014) Electrical and transport properties of NH4Br doped cornstarch-based solid biopolymer electrolyte. Ionics 21:111–124

Boopathi G, Pugalendhi S, Selvasekarapandian S, Premalatha S, Monisha S, Aristatil G (2016) Development of proton conducting biopolymer membrane based on agar–agar for fuel cell. Ionics 23:2775–2780

Druger SD, Nitzam A, Ratner MA (1983) Dynamic bond percolation theory, a microscopic model for diffusion in dynamically disordered systems. I. Definition and one dimensional case. J Chem Phys 79(6):3133–3142

Weppner W, Huggins RA (1978) Electrochemical methods for determining kinetic properties of solids. Annu Rev Mater Sci 8(1):269–311

Atkins PW (1994) Physical Chemistry, 5th edn. Oxford Univ. Press, Oxford

Singh K, Tiwari RU, Deshpande VK (1993) Performance of a solid state battery with a proton-conducting electrolyte. J Power Sources 46(1):65–71

De Bruin HJ, Badwal SPS (1978) Faradaic impedance dispersion of the noble metal/ceramic electrolyte interface. J Aus Ceramic Soc 14:20-28

Pandey K, Lakshmi N, Chandra S (1998) A rechargeable solid state proton battery with an intercalating cathode and an anode containing a hydrogen storage- material. J Power Sources 76(1):116–123

Parameswaran V, Nallamuthu N, Devendran P, Manikandan A, Nagarajan ER (2018) Assimilation of NH4Br in polyvinyl alcohol/poly(N-vinyl pyrrolidone) polymer blend base electrolyte and its effect on ionic conductivity. J Nanosci Nanotechnol 18(6):3944–3953

Selvalakshmi S, Mathavan T, Selvasekarapandian S, Premalatha M (2018) A Study of electrochemical devices based on agar-agar-NH4I biopolymer electrolytes. AIP Proceedings 1942:140019

Monisha S, Mathavan T, Selvasekarapandian S, Milton Franklin Benial A, Manoharan S, Karthikeyan S (2016) Preparation and characterization of biopolymer electrolyte based on cellulose acetate for potential applications in energy storage devices. J Mater Sci Mater Electron 27:9314–9324

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Selvalakshmi, S., Mathavan, T., Selvasekarapandian, S. et al. Characterization of biodegradable solid polymer electrolyte system based on agar-NH4Br and its comparison with NH4I. J Solid State Electrochem 23, 1727–1737 (2019). https://doi.org/10.1007/s10008-019-04262-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-019-04262-0