Abstract

The electrochemical behavior of Sn(II) was studied at 25 °C in three different room temperature ionic liquids (1-ethyl-3-methylimidazolium dicyanamide (EMI-DCA), 1-butyl-1-methylpyrrolidium bis-(trifluoromethanesulfonyl)imide (BMP-NTf2), 1-ethyl-3-methylimidazolium bis-(trifluoromethanesulfonyl)imide (EMI-NTf2)). The Sn(II) was introduced into EMI-NTf2 by anodic dissolution with a current efficiency of almost 100 %. The diffusion coefficient of Sn(II) was compared in three ionic liquids at different temperatures. In addition, the morphology of Sn deposits on the inert substrate Mo obtained from three ionic liquids at 25 °C was characterized. This study also shows that the copper–tin alloy could be achieved in EMI-NTf2 by the electrodeposition method and subsequent thermal treatment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Room temperature ionic liquids (ILs or RTILs) [1–4] are widely used in various electrochemical domains notably as electrolyte for electrodeposition of various metals including noble metals [5–14], for batteries [15–21] and for dye-sensitized solar cells [16, 22], etc. Compared with conventional aqueous electrolytes, RTILs offer several advantages for practical uses such as negligible vapor pressure, higher thermal stability, higher ionic conductivity, and wider electrochemical windows allowing deposition of metals [17, 23–29]. Moreover, aprotic RTILs prevent the problem linked to the hydrogen evolution, which usually occurs in aqueous solutions and results in a decrease of the current efficiency. Depending on the nature of cations and anions, the physico-chemical properties in RTILs such as conductivity, solubility, deposition potential, etc. could differ drastically. Electrodeposition of M Sn alloys (with M = Ni, Cu, Co), which are usually obtained at high temperature (≥400 °C) for instance in molten LiCl-KCl as published recently [30, 31], could also be obtained in RTILs in milder conditions. It could also lead to different electrodeposition mechanisms and stripping processes as reported by Martindale et al. [18] when the anion of the RTIL varied. Furthermore, one of the specific properties of RTILs is their relatively high viscosity since it may have important drawbacks especially in electrochemistry. Viscosity greatly influences the diffusion of metal ions and conductivity of the salts. The size, shape, and molar mass of the anion are also known to contribute to the viscosity of RTILs, and it was reported that the more viscous RTILs were observed for RTILs having the smaller, lighter, and more symmetric anions [1, 32, 33]. It was also reported [1] that other parameters could have significant effects on the viscosity, notably the relative basicity of the anions and their ability to form hydrogen bonds or to allow van der Waals attractions [34, 35]. Higher viscosities of RTILs can also be observed depending on the nature of the cation types as the increase of the length of alkyl substituents leads to stronger van der Waals interactions between larger cations [32, 34, 36–38]. Finally, the nature of the anion also influences significantly the viscosity of the ionic liquid, notably through their ability to participate in hydrogen bonding.

Aqueous electrolytes exhibit usually higher conductivity due to proton-hopping mechanism and also lower viscosity. The viscosity is the most decisive factor for the conductivity of RTILs as a simple inversely proportional relationship between the molar conductivities and viscosities of RTILs called Walden’s law is observed.

Several RTILs have already been investigated for the electrodeposition of tin on an inert substrate such as Pt or glassy carbon, i.e., substrates avoiding the formation of alloys. Sn(II)/Sn and Sn(IV)/Sn(II) redox couples have also been investigated by cyclic voltammetry on different electrodes in aluminum chloride-1-ethyl-3-methylimidazolium chloride (AlCl3-EMICl) at 40 °C [23]. They showed that the electrodeposition process of tin deposition depended on the nature of the substrate and that the reduction process of Sn(II) on Pt electrode gave rise to the electrodeposition of Sn metal. The corresponding diffusion coefficient was in the order of magnitude of approximately 10−7 cm2 s−1. It was shown that the oxidation of Sn(II) to Sn(IV) is hindered in the voltammogram by the weak adsorption of Sn(II) [23]. Similar results were obtained in zinc chloride-1-ethyl-3-methylimidazolium chloride (ZnCl2-EMICl) [29]. However, haloaluminate-anion-based ionic liquids are very sensitive to water and air, and their uses for industrial applications are restricted. Less-reactive anions were explored, such as tetrafluoroborate (BF4 −), hexafluorophosphate (PF6 −), dicyanamide (DCA−), bis-(trifluoromethylsulfonyl)imide (NTf2 −), and so on. For example, Yang et al. [26] studied the electrodeposition of tin from Sn(II) in the EMIBF4 and showed that the reduction of Sn(II) on Pt electrode was electrochemically irreversible. Morimitsu et al. [6] studied the electrochemistry of Sn(II) in 1-ethyl-3-methylimidazolium tetrafluoroborate containing free chloride ions (EMI-BF4-Cl) originated from the mixture of EMICl and NaBF4 and showed that the electrodeposition of tin proceeded through a quasi-reversible step with two electron transfers. Nevertheless, BF4 −- and PF6 −-based ionic liquids are considered as undesirable due to the formation of corrosive HF in presence of water. Katayama et al. [10] investigated the electrochemical reduction of Sn(II) with Pt electrode in 1-butyl-1-methylpyrrolidinium bis-(trifluoromethylsulfonyl)imide (BMP-NTf2) at 25 °C. They introduced Sn(II) by the anodic dissolution of Sn and found that the current efficiency relative to the electrodeposition of Sn was close to 100 %. The voltammetric oxidation of Sn(II) to Sn(IV) was not observed due to the limitation of the explored potential window. In addition, the electrodeposition of Sn on a reactive substrate as copper was achieved in BMP-NTf2 containing Sn(II) [38] and should give rise to Cu–Sn alloys. Leong et al. [38] studied the electrochemical reaction of Sn(II) in 1-ethyl-3-methylimidazolium dicyanamide (EMI-DCA) on Pt electrode at 40 °C. Sn deposits produced by potentiostatic electrolysis on Cu substrate showed various morphologies depending on the deposition potentials.

Although DCA−- and NTf2 −-based ionic liquids are considered as one of the most promising electrolytes for the electrodeposition of metal, only few information is available in the literature to compare their specific properties for instance using 1-ethyl-3-methylimidazolium cation. Therefore, this paper is devoted to study the electrochemical behavior of Sn in three different RTILs: EMI-DCA, BMP-NTf2, and 1-ethyl-3-methylimidazolium bis-(trifluoromethanesulfonyl)imide (EMI-NTf2). At first, the physico-chemical properties (viscosity, conductivity, and density) of the RTILs were investigated. Then, the electrochemical deposition mechanisms of Sn were presented, and the influence of the nature of the anion/cation of the RTILs on the deposition process was discussed. Finally, Cu–Sn alloys were prepared by reduction of Sn(II) ions using a reactive Cu working electrode. The deposits were characterized by X-ray diffraction (XRD) and scanning electron microscopy (SEM), and the composition of the alloys was obtained by energy-dispersive X-ray spectroscopy (EDS) analyses.

Experimental section

EMI-DCA (≥98.5 %), BMP-NTf2 (99.9 %), and EMI-NTf2 (99.5 %) were obtained from Fluka and Solvionic and stored in a glove box filled by argon (water content, ≤5 ppm). The water content was estimated from Karl–Fischer measurements and was found to be 1066 ppm for EMI-DCA, 79 ppm for BMP-NTf2, and 204 ppm for EMI-NTf2. These values were close to those announced by suppliers (5000, 2, and 500 ppm, respectively).

The density of RTILs was measured using an Anton Paar DSA-5000 digital densimeter at atmospheric pressure with experimental uncertainty less than ±4 × 10−5 g cm−3. Dynamic viscosities of RTILs were determined with an Anton Paar Automated Micro-viscometer (AMVn). The automated micro-viscometer is based on the rolling ball principle. The sample to be measured is introduced into a glass capillary in which a steel ball rolls. The viscosity of the tested fluid can be determined by measuring the rolling time of the steel ball. A built-in Pt100 thermometer measures and controls the exact temperature. The experimental uncertainty was lower than ±2 mPa s for viscosity range in between 300 and 700 mPa s and ±0.3 mPa s for viscosities values lower than 300 mPa s.

All the experiments including the electrolyte preparation and handling were performed in the glove box filled by Ar using a three electrodes cell. A Pt disk electrode (S Pt = 0.03 cm2) was used as inert working electrode to avoid the formation of any Sn-based alloys during the electroreduction step for the study of the electrochemical behaviors of Sn(II)/Sn. Before each experiment, the Pt working electrode was mechanically polished and the last step being performed in an aqueous alumina suspension (0.05 μm) to obtain a mirror-like surface. Then the electrodes were rinsed with distilled water to remove traces of alumina using an ultrasonic treatment. Finally, the samples were dried under vacuum at around 120 °C before introduction in the glove box.

The counter electrode was a Sn bar prepared by fusing Sn powder (prolabo; purity, 99.97 %), and then cooling the fused tin in a molder to obtain a bar. Well-known tin contents were introduced in the electrolyte by anodic dissolution of the prepared Sn bar electrodes using a two-compartment cell presented in Fig. 1. To succeed, a tin bar used as working electrode was placed in the first compartment. The counter electrode was also a Sn bar placed in the second compartment separated from the first compartment with a G4 glass frit to avoid any pollution of the Sn(II)-containing solution. For the measurement of the standard potential of Sn(II)/Sn and the electrodeposition of Cu–Sn alloy, an Ag wire was immersed in EMI-NTf2 containing 0.1 M AgNTf2 (solvionic, 99.5 %) and used as reference electrode; for the other experiments, a Pt wire was used as a quasi-reference electrode as described in the literature [39–44]. These two different reference electrodes were tested periodically in 0.05 M ferrocene in EMI-NTf2 to be sure that no potential drift of the reference occurred over the experiments.. All the electrochemical experiments were carried out using a Biologic VMP3 potentiotat/galvanostat.

Finally, the electrodeposition experiments were carried out on molybdenum or copper foils and characterized by the techniques as follows: XRD patterns were collected using a Rigaku Ultima IV diffractometer and SEM images were obtained by a Jeol JEM 100 CX II scanning electron microscope equipped with a Jeol high-resolution scanning attachment (SEM-FEG).

Results

Physico-chemical properties of RTILs

Before studying the electrochemical behaviors of Sn(II)/Sn on inert substrate, the main characteristics of the RTILs used in this study, such as viscosity and conductivity were measured depending on the RTIL chemistry and the temperature between 25 and 100 °C, which corresponds to the range used in the electrochemical section for the deposition of Sn and Sn alloys. Data collected at 25 °C are summarized in Table 1.

The RTILs were selected in order to study both the influence of the anion (DCA− or NTf2 −) and the cation (EMI+ or BMP+) on the electrodeposition mechanism. Whatever was the RTIL, values obtained are in the same order of magnitude of the literature (http://www.solvionic.com) [45]. The influence of the temperature on the density of the RTIL is presented in Fig. 2. The variation of ρ vs. T is evidenced, but this variation is small. The decomposition temperature of these three RTILs is higher than 360 °C [34], giving rise to a large temperature window for the preparation of the tin-based materials.

The temperature dependences of the conductivities and viscosities of three RTILs from 25 to 100 °C are given in Fig. 3a, b.

As shown in these figures, significant decrease of viscosity is observed with increasing temperature. Whatever was the RTIL, the variation of the viscosity vs. 1/T obeys the Arrhenius’ law and the data allowed calculating the activation energy (E a) for viscous flow. It is found that the viscosity of BMP-NTf2 (76.6 mPa s) measured at 25 °C is larger than that of EMI-NTf2 (33.3 mPa s) or EMI-DCA (14.7 mPa s). Consequently, this should have a great influence on the electrodeposition process since the diffusion coefficient is related to the viscosity. Therefore, the diffusion coefficient of tin species in BMP-NTf2 should be the smallest among the three RTILs.

According to the basic studies on viscosity of non-haloaluminate ionic liquids with the same anion, reported in the literature [46, 47], the viscosities of the ionic liquids composed of the imidazolium cation are relatively low, and the larger the alkyl substituent on the imidazolium cation is, the more viscous the fluids tend to be. It is also well known that the viscosity is related to the nature of anions. Moreover, the size, shape, and molar mass of the anion contribute to the viscosity. Thus, RTIL with the smaller, lighter, and more symmetric anions leads to more viscous electrolyte. For ionic liquids with the same cation, the lowest viscosity is observed for the one having the large NTf2 − anions, according to the literature [48]. However, it can be added that, in the case of DCA− ionic liquids, the viscosity is about two times lower. It is probably because the delocalized charge weakens the ion–ion interactions in these ionic liquids.

Finally, it is worth to mention that the viscosity is not only dependent on both the nature of the cations and anions but also on the presence of impurities, especially water. This explains why the interpretation of data reported in literature is not always consistent.

Determination of the electroactive domains

Before studying the Sn(II)/Sn redox couple in RTILs, the electroactive domains of the three RTILs were investigated at room temperature with a Pt electrode (0.03 cm2) by cyclic voltammetry (v = 50 mV s−1) without the presence of tin ions in solution. This provided blank curves which allowed the determination of the electroactive domains (Fig. 4).

Whatever was the RTIL, the curves (Fig. 4) recorded in a wide potential range (about 3 V) do not reveal any significant currents (of the order of 100 nA), indicating a very good electrochemical stability of the selected RTILs and the absence of high content of impurities. Neither oxidation nor reduction peak is pointed out, indicating the absence of electroactive impurities, i.e., no side reactions are detected during the anodic and the cathodic scans. The electrolyte resistances measured by impedance measurements at 25 °C are equal to 80 Ω for EMI-DCA, 680 Ω for BMP-NTf2, and 270 Ω for EMI-NTf2.

Preparation of the Sn-containing solution

Because of the too low solubility of chlorinated tin salts in RTILs and with regard to the hydrated state of the available salts, tin was introduced in the RTIL by anodization of Sn electrode. The benefits of the anodic dissolution were a better control of the Sn(II) content in the solution and the absence of water or other anions which usually lead to uncontrolled complexation state of the ionic species.

In the case of EMI-DCA, Sn(II) ions were introduced into the solution by anodic dissolution of a Sn bar in galvanostatic mode using the two compartments cell described previously (Fig. 1). A constant current was applied to the Sn electrode, and the Sn(II) content in solution obviously increased with time according to Faraday’s law (Eq. 1):

where I is the current applied to the electrode, t the duration of the galvanostatic pulse, M Sn the molar mass of tin, Δm Sn the weight loss of the tin electrode, n e the number of electron exchanged in the reaction, and F the Faraday constant. In a first approximation, we considered that the yield of the reaction Sn → Sn(II) + 2e− was almost 100 %.

In the case of EMI-NTf2 and BMP-NTf2, the potentiostatic anodisation is preferred due to the too high resistivity of the solutions. A constant dissolution potential of +0.5 V vs. Pt was applied to the tin working electrode. The electrolysis was stopped after reaching the required Sn(II) content. Whatever was the RTIL, the number of electrons also deduced from the Faraday’s law is found to be 1.99 ± 0.01, indicating that the anodic reaction leads to the formation of divalent Sn(II) as described above.

Determination of the standard potential of the Sn(II)/Sn redox couple in RTILs

At first, the evolution of the free potential for different Sn(II) contents for the three RTILs was studied. The first measurement was done with the highest concentrated solution and the next ones after dilution. As expected according to the Nernst’s equation, a linear variation of the free potential vs. log (Sn(II)) was observed whatever was the RTIL (Fig. 5) containing Sn(II) initial concentration of 0.1 mol L−1. The slopes of the curves recorded at 25 °C lead to the number of exchanged electrons. Whatever was the RTIL, the experimental values 1.97 ± 0.05 are very close to the theoretical value (n = 2). The extrapolation to the origin of the curves leads to the value of the standard potential. It was found that E 0Sn(II)/Sn is : −0.54 ± 0.01 V vs. Ag/Ag(I) in EMI-NTf2, −0.53 ± 0.01 V vs. Ag/Ag(I) in BMP-NTf2, and −1.43 ± 0.01 V vs. Ag/Ag(I) in EMI-DCA. These values clearly show the influence of the RTIL on the standard potential of the Sn(II)/Sn redox couple.

In particular, these data reveal a strong influence of the nature of the anions (NTf2 − or DCA−) on E 0. This influence is probably due to the donor ability of the anions. Gutmann showed that the potential of M n+/M tended to be more negative with an increase in the donor property of solvent [49]. According to the order of the donor ability of the anions DCA− > Cl− > NTf2 − [50, 51], the standard potential of Sn(II)/Sn in EMI-DCA is much more negative than that in both ionic liquids with the anion NTf2 −.

Study of tin redox system by cyclic voltammetry

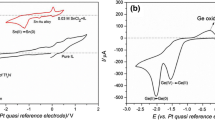

A typical voltammogram recorded between −0.8 and +0.5 V vs. Pt (v = 50 mV/s) with a non-reactive Pt electrode in EMI-NTf2 containing 0.01 mol L−1 Sn(II) ions at 25 °C is given in Fig. 6a. Potentials were scanned from the equilibrium to the cathodic side until −0.8 V vs. Pt, and then to +0.5 V vs. Pt in the oxidation side.

a Cyclic voltamogramm obtained with a Pt working electrode in 0.01 mol L−1 Sn(II) in EMI-NTf2 at 25 °C. Reference electrode, Pt wire. Scan rate, 50 mV s−1. b Cyclic voltamogramms obtained with a Pt working electrode in 0.01 mol L−1 Sn(II) in EMI-NTf2 at various scan rates. T = 25 °C. Reference electrode, Pt wire

A cathodic peak is observed at around −0.30 V vs. Pt due to the reduction of Sn(II) to Sn. This peak is associated to the anodic peak observed during the reverse scan at around −0.07 V vs. Pt, which corresponds to the oxidation of Sn formed during the cathodic scan. The shape of the reduction and oxidation peaks are characteristic of the deposition of an insoluble metal (Sn in the present case) and its dissolution during the reverse scan, respectively.

As shown in the inset of Fig. 6a, the anodic stripping overtakes the cathodic deposition at −0.22 V. Thus, the current crossed to the anodic side and the overpotential is related to nucleation and growth process. The latter was needed before bulk deposition of Sn. In other words, the reduction potential of Sn(II) ions is more negative than expected due to this electrocrystallisation overpotential. Obviously, an increase of the scan rate should have a great influence on the potential of a diffusion-controlled process such as the reduction of Sn(II). The cyclic voltammograms obtained for increasing scan rates are presented in Fig. 6b. As expected, the oxidation peak was unchanged whatever was the scan rate; in contrast, the overpotential due to electrocrystallisation phenomenon during the reduction step increased with the scan rate (i.e., the reduction peak was observed at more negative potential).

One may notice that the oxidation of Sn(II) to Sn(IV) was not observed in the explored potential window.

The difference in potential (Fig. 6a) between the anodic and the cathodic peaks (ΔE a–c) was different depending on the RTIL, but no obvious correlation could be pointed out between the variation of ΔE a–c and the parameters given in Table 2. Moreover, due to the overpotential electrocrystallisation, it was difficult to compare and to interpret the variation of ΔE a–c in terms of reversibility or irreversibility of the reaction. The influence of the ohmic drop was also an important factor which has to be taken into account for a good interpretation of our results. The studies carried out on this subject will be published in a next coming paper.

The same curve shape was observed in BMP-NTf2 in presence of Sn(II) involving a nucleation and growth process. In that case, the difference in potential, ΔE a–c was higher than that observed in EMI-NTf2 and was about 350 mV.

As shown in Fig. 7, if the reduction scan was stopped and maintained at −0.9 V vs. Pt for a few seconds (from 0 to 10 s with a potential step of 2 s), the intensity of the oxidation peak related to Sn dissolution increased with increasing potential stop time. It means that during the potential stop, Sn accumulated onto the electrode, giving rise to higher oxidation peak intensity. The variation of the capacity (Q a) deduced from the area under the oxidation peak vs. the duration of the stop is given in Fig. 8. A linear variation of Q a vs. t is obtained, and the slope of the curve gives rise to the deposition rate of Sn in this electrolyte: 2.6 × 10−6 C s−1, i.e., 1.6 × 10−6 mg s−1 in our experimental conditions. The deposition rate can be expressed in current density of which the value is 0.08 mA/cm2 in this case. This deposition rate is very slow comparing with that for the metal deposition in ionic liquids [52, 53].

Determination of the diffusion coefficient of Sn(II)

Reaction rates are usually related to the mass transportation of chemical species. This is more pronounced in ionic liquids due to their specific viscosity compared with aqueous solutions. Moreover, the charge on the electroactive species (Sn(II) in the present case) must also be considered due to strong interaction between the charged species and the constituted ions of the ionic liquids. The shape of the curves with a sharp decrease of the current is a feature of solid deposition. In our case, this decrease occurs at around −0.23 V with the compensation of IR drop. Thus, small diffusion coefficient should be preferable to obtain smooth and homogeneous Sn deposits.

The diffusion coefficient of Sn(II) ions (D Sn(II)) was determined from hydrodynamic voltammetry, i.e., using a Pt rotating disk electrode (RDE). With such an experiment, the current related to mass transfer tends to a limit value (I L), given by the Levich equation. The variation of the limited current I L vs. ω 1/2, the rotating speed, gave rise to the number of exchanged electrons if D Sn(II) is known. A straight line should be observed according to Eq. (2):

where S is the surface of the Pt working rotating disk electrode (0.03 cm2), D Sn(II) the diffusion coefficient of Sn(II), υ, the kinematic viscosity (0.219 cm2 s−1), C Sn(II) the concentration of Sn(II) ions, and ω, the rotating electrode speed.

Typical hydrodynamic voltamogramms recorded (scan rate, v = 5 mV s−1) on the cathodic side with a Pt working electrode (0.03 cm2) in 0.01 M Sn(II) in EMI-NTf2 for increasing ω values are given in Fig. 9. In these steady-state I–E curves, the potential values were IR drop compensated.

Whatever was the RTIL, the curves exhibited well-defined plateau for each ω value, i.e., the current tended to a constant I L value. In addition, and as expected from relation (2), a linear variation of I L vs. ω 1/2 is observed (Fig. 10), meaning the reduction of Sn(II) was controlled by the mass transport. An increase of I L with increasing ω values was observed (Fig. 10), i.e., the kinetics rate became faster and faster. In other words, the higher the ω values were, the higher the concentration of electroactive species at the electrode/electrolyte interface was and the higher the I L values were. The values of the diffusion coefficient D Sn(II) were determined from the slope of the curve I L vs. ω 1/2.

The values of the diffusion coefficient of Sn(II) deduced from the slope of the curve I L = ƒ(ω 1/2) with the three RTILs are reported in Table 2. These values confirmed that the higher the viscosity, the smaller the diffusion coefficient. Thus, the highest D Sn(II) value of 8.7 × 10−7 cm2 s−1 was obtained in EMI-DCA which has the lowest viscosity (μ = 14.7 mPa s). On the opposite side, the lowest D Sn(II) value was observed in BMP-NTf2 having the highest viscosity. Moreover, our results showed the influence of the nature of the anion on the D Sn(II) values. From Table 2, we found a good correlation of the diffusion coefficient D Sn(II) with the viscosity of the ionic liquids which contains the same anion NTf2 −. D Sn(II) being inversely proportional to the viscosity, D Sn(II) in EMI-NTf2 was two times bigger than that in BMP-NTf2 with a twice smaller viscosity. Even if the viscosity of EMI-DCA is twice smaller than that of EMI-NTf2, the D Sn(II) value obtained in EMI-DCA was almost five times higher than the one obtained in EMI-NTf2. The D Sn(II) depended mainly on the viscosity of ionic liquid. In fact, according to the Stokes–Einstein equation \( D=\frac{RT}{6\pi {N}_{\mathrm{A}}\eta r} \), the hydrodynamic radius of the Sn(II) in the ionic liquids could also affect the value of D Sn(II). Since the anion size of NTf2 − was bigger than that of DCA−, the hydrodynamic radius of Sn(II) with NTf2 − should be bigger than that of Sn(II) with DCA−. Consequently, it was reasonable to get a D Sn(II) in EMI-DCA almost five times bigger than that of D Sn(II) in EMI-NTf2.

Then, the effect of the temperature of the RTILs on the kinetics rate was investigated. The diffusion coefficients D Sn(II) determined in the RTILs with 0.01 mol L−1 Sn(II) at different temperatures are presented hereafter (Table 3). For instance, in EMI-NTf2, a rapid decrease of the resistance of the electrolyte with increasing temperature was pointed out: 270 Ω at 25 °C and 115 Ω at 100 °C. The conductivity increases (i.e., the resistance decreases) with temperature, because higher temperature results in the decrease of viscosity which improves the mobility of ions. Cyclic voltammograms were carried out at various temperatures (Fig. 11). Thus, the discrepancy of the electrolyte resistance and the increase of D Sn(II) occurred with increasing temperature. As expected, the diffusion coefficient D Sn(II) increases with temperature from 1.9 × 10−7 cm2 s−1 at 25 °C to 5.2 × 10−7 cm2 s−1 at 100 ° C in the case of EMI-NTf2 containing 0.01 mol L−1 Sn(II) electroactive species. However, this coefficient did not seem to be strongly influenced by the variation of the temperature.

The variation of ln (D Sn(II)) vs. the reverse of the absolute temperature given in Fig. 12 obeyed the Arrhenius’ law: D Sn(II) = D 0 exp (−E a/RT). As shown in this figure, a linear variation of ln (D Sn(II)) vs. 1/T (T expressed in K) was observed. It was found that E a = 11.6 kJ mol−1 and D 0 = 2.17 × 10−5 cm2 s−1 for EMI-NTF2 and E a = 7.6 kJ mol−1 and D o = 0.15 × 10−5 cm2 s−1 for BMP-NTF2. D 0 and E a values are given in Table 4.

Electrochemical deposition of Sn, Cu, and Cu–Sn alloys

Electrodeposition of Sn onto an inert Mo substrate

Tin was deposited by electroreduction of Sn(II) ions onto a non-reactive molybdenum substrate. The SEM images obtained for a deposit at 25 °C under overpotential conditions by applying a constant potential just before the occurrence of the reduction peak in the cyclic voltammogram of Fig. 6a are given in Fig. 13. SEM images reveal clear differences depending on the nature of the RTILs. The most adhesive, dense, and homogeneous electrodeposit film was obtained in EMI-NTf2 containing Sn(II) (Fig. 13 (c1 and c2)). Indeed, the films prepared in EMI-DCA and BMP-NTf2 were not homogeneous and did not cover all the surface; thus, large cavities were clearly evidenced. In EMI-DCA and BMP-NTf2, large particles of 1–2 μm were observed (Fig. 13 (b2)). In contrast, the films prepared in EMI-NTf2 were more homogeneous and composed of smaller particles (about 200 nm). Note that in EMI-DCA, the structure of the deposited tin was macroporous with the presence of some tin nanowires (Fig. 13 (b2)).

The XRD patterns corresponding to the three deposited films given in Fig. 13 are presented in Fig. 14. Whatever was the electrolyte used for the preparation of the films, the XRD patterns revealed only the presence of Sn in addition with those relative to Mo substrate.

From these results, we decided to focus our attention on the compounds prepared in EMI-NTf2 with 0.01 mol L−1 Sn(II) henceforth.

Electrodeposition of Sn onto a reactive Cu substrate

The behavior of copper as reactive working electrode was investigated by cyclic voltammetry in EMI-NTf2 containing 0.02 mol L−1 Cu(I) at 25 °C (scan rate: 50 mV s−1). The cyclic voltammogram recorded with a Pt working electrode (0.03 cm2) at 25 °C is given in Fig. 15 (v = 50 mV s−1).

Copper cations were introduced by anodic dissolution of a copper bar. It is well known that in ionic liquids Cu(II) are often unstable and dismutation reaction involving Cu(II) and Cu occurs according to: Cu(II) + Cu → 2 Cu(I) [22, 54]. This could explain why the number of exchanged electrons deduced from the analysis of the curves using a rotating disk electrode as discussed above was found to be close to 1. The well-defined waves observed in EMI-NTf2 in the presence of copper ions are attributed to the Cu(I)/Cu couple: the reduction peak observed at −0.2 V vs. Pt is related to the reduction of Cu(I) → Cu, whereas the oxidation peak detected at +0.2 V vs. Pt during the reverse scan is due to the reoxidation of Cu.

The diffusion coefficient of Cu(I) ions (DCu(I)) was also determined from hydrodynamic voltammetry, i.e., using a rotating disk electrode (RDE) in 0.02 mol L−1 Cu(I)-EMI-NTf2 for various rotating speed. It was found that D Cu(I) = 2.48 × 10−7 cm2/s−1 at 25 °C. In the same conditions, D Sn(II) = 1.9 × 10−7 cm2 s−1 was previously obtained.

Electrodeposition of Cu–Sn alloys

Let us consider now the formation of Sn-based alloys. As revealed from the binary phase diagram of Cu–Sn (http://www.metallurgy.nist.gov/phase/solder/cusn.html) reproduced in Fig. 16, ε-Cu3Sn and η′-Cu6Sn5 phases could be obtained at temperatures below 180 °C, depending on the operating conditions. The experimental enthalpies of formation of binary Cu–Sn alloys (Δf H) were reported in the literature [55, 56]. The averages Δf H values reported at 298 K are the following: −8.22 ± 1 kJ mol−1 for Cu3Sn (ε phase) and -6.11 ± 1 kJ mol−1 for Cu6Sn5 (η′ phase).

Potentiostatic electroformation of Cu–Sn alloys was carried out in RTILs. According to the Cu–Sn phase diagram (Fig. 16), CuSn, Cu3Sn, or Cu6Sn5 could be obtained in our experimental conditions.

As reported in the literature, the redox couples potentials of two metals M 1 and M 2 with their respective M 1 n1+ and M 2 n2+ ions in solution are given by the Nernst’s equation. In such conditions, there are three main electrochemical routes for the electrodeposition of M 1-M 2 alloys called method 1, 2 and 3, hereafter.

-

Method 1: the first route consists in performing the reduction of M 1 n1+ ions using a reactive electrode composed of M 2 (i.e., reduction of Sn(II) on Cu in the present study).

-

Method 2: this method is the most popular one and is based on the co-deposition of the two metals M 1 and M 2 from electroreduction of M 1 n1+ and M 2 n2+ ions (Sn(II) and Cu(I) in the present case) onto an inert working electrode. It is important to note that if the standard potentials of the two redox couples are very different, the co-deposition of the two metals is somewhat difficult. However, one solution to overcome this problem is to reduce the potential difference between the first metal to the second one. Thus, according to the Nernst’s law, the modification of the concentration allows reducing the potential difference between these two redox couples. Thus, Cu–Sn alloys deposition can be favored if the concentration of the more noble metal (copper) is the lowest while keeping the second one (tin) constant. Thus, by adjusting the concentration ratio between Cu(I) and Sn(II), a shift of the reduction potential of copper towards the reduction potential of tin is expected, allowing the co-deposition of Cu and Sn and the formation of alloys.

-

Method 3: to favor the formation of Cu–Sn-based alloys, a third method (method 3) was investigated in this study. It consisted in combining methods 1 and 2 described above. Thus, the electrodeposition of the Sn-based alloys was performed in EMI-NTf2 containing Sn(II) and Cu(I) ions with a concentration ratio of ions of Cu(I)/Sn(II) equals to 1/1 or 1/10. Finally, the working electrode was in copper to active the germination phenomena.

A first set of experiments (according to method 1) was performed using a Cu working electrode in presence of 0.01 mol L−1 Sn(II) ions only in EMI-NTf2. For this series, the influence of the temperature of the electrolyte on the deposits was investigated. The SEM images and the corresponding XRD patterns are given in Fig. 17a, b, respectively. The lowest temperature leads to the smallest particles size. Nevertheless, whatever was the temperature of the RTIL, the XRD patterns (Fig. 17b) do not exhibit any difference and all the diffraction lines are indexed with those of Sn in addition to those relative to the copper substrate.

Cross-section images and EDX quantitative analysis of the deposit obtained at 25 °C are presented in Fig. 17c. As shown here, the film electrodeposited at 25 °C is very thin (less than 1 μm), rather compact but its homogeneity is doubtful even if a clear distinction between the Cu substrate and the electrodeposited Sn is observed. This observation is in good agreement with results deduced from XRD showing that the film prepared in such conditions is composed of Sn and that no trace of Cu–Sn alloy could be detected.

A second set of experiments was achieved according to the method 3 that was described above. A positive influence of the concentration ratio Cu(I)/Sn(II) on the deposition potential of the Cu–Sn alloys was expected. The alloys were prepared in potentiostatic mode in EMI-NTf2 with 0.01 mol L−1 concentration for both Sn(II) and Cu(I), i.e., concentration ratio (Cu(I))/(Sn(II)) = 1. As discussed above, the formation of alloys for this concentration ratio should be difficult due to the huge potential difference between the two involved redox couples.

The XRD patterns of deposits obtained in EMI-NTf2 in presence of Sn(II) and Cu(I) with a concentration ratio equal to 1 before and after heat treatment are given in Fig. 18. As clearly shown in this figure, the deposited film is only composed of tin and does not evidence the presence of Cu–Sn alloys. The effect of a post heat treatment at moderate temperatures (≤200 °C) under vacuum is also investigated in order to study the influence of a moderate temperature on the crystallinity and the composition of the alloys but this does not show any positive effect on the crystallinity of the deposited film. Again, as discussed above, the potential difference is too high for generating alloys. In that case, the same experiments were performed in EMI-NTf2 with a concentration ratio (Cu(I))/(Sn(II)) = 1/10

The XRD obtained for example in potentiostatic mode with an applied potential of −0.8 V vs. Ag(I)/Ag considering the concentration ratio (Cu(I))/(Sn(II)) = 1/10 is given in Fig. 19a. All diffraction lines could be indexed based on the Cu3Sn phase (JCPDS card 65-4653 space group P6/mmm) in addition to those relative to Cu substrate. This composition is confirmed using energy dispersive X-ray analysis.

a XRD patterns of Sn–Cu deposited onto Cu substrate in EMI-NTf2 at 25 °C, then annealing at 200 °C under vacuum. b SEM images of Sn–Cu deposited onto Cu substrate in EMI-NTf2 containing 0.01 mol L−1 of Sn(II) and 0.001 M Cu(I) at 25 °C, then annealing at 200 °C under vacuum. The ratio of (Cu(I))/(Sn(II)) = 1/10. c BEI and EDS of cross section of deposited Sn–Cu after annealing

The SEM image is given in Fig. 19b. The obtained alloys are composed of very small particles, leading to a satisfactory coverage of the surface. The compactness and the homogeneity of the film are good without any trace of cracks. EDS quantitative analysis of the Cu–Sn alloy cross-section is presented in Fig. 19c. The cross-section image confirms the homogeneity of the electrodeposited film. Moreover, a clear distinction between the Cu substrate and the electrodeposited Cu–Sn alloy could be done. Quantitative analysis of Cu and Sn content within the film reveals a homogeneous distribution of each element within the film: the average content of Sn in the film is about 24 at.% (atomic percentage), in good accordance with results deduced from XRD. Finally, it must be noticed that the EDS spectrum clearly evidences the presence of Cu3Sn in agreement with the XRD analysis.

Conclusions

The electrochemical behaviors of Sn were studied in the EMI-NTf2 ionic liquid at room temperature. Sn(II) was introduced by the anodic dissolution of Sn with a current efficiency of nearly 100 %. The morphology of the Sn deposited from the EMI-NTf2, EMI-DCA and BMPN-Tf2 were compared. The dense and homogenous Sn particles with size around 200 nm were only obtained from EMI-NTf2. The diffusion coefficient of Sn(II) in EMI-NTf2 was found to be in the same order of magnitude as those reported for Sn(II) in BMP-NTf2 and EMI-DCA. Furthermore, a dense and adherent Cu–Sn alloy film could be obtained on the Cu substrate from EMI-NTf2 by the electrochemical technique followed by thermal treatment. The composition of Sn–Cu alloy was evidenced by XDR and EDS analysis and corresponded to Cu3Sn deposit. The Sn–Cu film from EMI-NTf2 may be suitable to be used as anode material in lithium rechargeable batteries.

References

Hapiot P, Lagrost C (2008) Chem Rev 108:2238–2264

Ohno H (2005) In: Ohno H (ed) Electrochemical aspects of ionic liquids. Wiley, New Jersey

Barrosse-Antle LE, Bond AM, Compton RG, O’Mahony AM, Rogers RI, Silvester DS (2010) Chem Asian J 5:202–230

Hagiwara R, Tamaki K, Kubota K, Goto T, Nohira T (2008) J Chem Eng Data 53:355–358

Pitner WR, Hussey CL (1997) J Electrochem Soc 144:3095–3103

Morimitsu M, Nakahara Y, Iwaki Y, Matsunaga M (2003) J Mining and Metall 39:59–67

Zein El-Abedin S, Borissenko N, Endres F (2004) Electrochem Commun 6:510–514

Endres F, Abbott AP, MacFarlane DR (eds) Electrodeposition from ionic liquids. Wiley-VCH, Weinheim

Garcia B, Lavallée S, Perron G, Michot C, Armand M (2004) Electrochim Acta 49:4583–4588

Katayama Y, Dan S, Miura T, Kishi T (2001) J Electrochem Soc 148:C102–C105

He P, Liu HT, Li ZY, Liu Y, Xu XD, Li JH (2004) Langmuir 20:10260–10267

He P, Liu H, Li Z, Li H (2005) J Electrochem Soc 152:E146–E153

Huang J-F, Sun I-W (2004) Electrochim Acta 49:3251–3258

MacFarlane DR, Tachikawa N, Forsyth M, Pringle JM, Howlett PC, Elliott GD, Davis JH, Watanabe M, Simon P, Angell CA (2014) Energy Environ Sci 7:232–250

Matsumoto K, Takini R, Nohira T, Hagiwara R (2014) ECS Transaction 64(4):433–438

Marszalek M, Fei Z, Zhu DR, Scopelliti R, Dyson PJ, Zakeeruddin SM, Grätzel M (2011) Inorg Chem 50:11561–11567

Gasparotto LHS, Borisenko N, Bocchi N, Zein S, Abedin E, Endres F (2009) Phys Chem Chem Phys 11:11140–11145

Martindale BCM, Ward Jones SE, Compton RG (2010) Phys Chem Chem Phys 12:1827–1833

Buzzeo MC, Evans RG, Compton RG (2004) Chem Phys Chem 5:1106–1120

Chen PY, Hussey CL (2007) Electrochim Acta 52:1857–1862

Chen Y, Davoisne C, Tarascon J-M, Guéry C (2012) J Mater Chem 22:5295–5299

Katase T, Murase K, Hirato T, Awakura Y (2007) J Appl Electrochem 37:339–344

Xu X, Hussey CL (1993) J Electrochem Soc 140:618–626

Huang JF, Sun I-W (2003) J Electrochem Soc 150:E299–E306

Seddon KR, Stark A, Torres MJ (2000) Pure Appl Chem 72:2275–2287

Yang W, Cang H, Tang Y, Wang J, Shi Y (2008) J Appl Electrochem 38:537–542

Chen PY, Hussey CL (2001) Electrochim Acta 46:1169–1177

Abbott AP, Capper G, McKenzie KJ, Ryder KS (2007) J Electroanal Chem 599:288–294

Huang J-F, Sun I-W (2002) J Electrochem Soc 149:E348–E352

Groult H, El-Ghallali H, Bahoun A, Briot E, Hernandovena S, Lantelme F (2010) Electrochim Acta 55:1926–1932

El-Ghallali H, Groult H, Bahoun A, Draoui K, Krulic D, Lantelme F (2009) Electrochim Acta 54:3152–3160

Dzyuba SV, Bartsch RA (2002) Chem Phys Chem 3:161–166

Every HA, Bishop AG, MacFarlane D, Orädd G, Forsyth M (2004) Phys Chem Chem Phys 6:1758–1765

Bonhôte P, Dias A-P, Papageorgiou N, Kalyanasundaram K, Grätzel M (1996) Inorg Chem 35:1168–1178

Fitchett BD, Knepp TN, Conboy JC (2004) J Electrochem Soc 151:E219–E225

Tokuda H, Hayamizu K, Ishii K, Susan MABH, Watanabe J (2005) J Phys Chem B 109:6103–6110

Huddleston JG, Visser AE, Reichert WM, Willauer HD, Broker GA, Rogers RD (2001) Green Chem 3:156–164

Leong T-I, Hsieh Y-T, Sun I-W (2011) Electrochim Acta 56:3941–3946

Suarez PAZ, Selbach VM, Dullius JEL, Einloft S, Piatnicki CMS, Azambuja DS, de Souza RF, Dupont J (1997) Electrchim Acta 42:2533–2535

Schröder U, Wadhawan D, Compton RG, Marken F, Suarez PAZ, Consorti CS, de Souza RF, Dupont J (2000) New J Chem 24:1009–1015

Endres F, Schrodt C (2000) Phys Chem Chem Phys 2:5517–5520

Brown RJC, Dyson PJ, Ellis DJ, Welton T (2001) Chem. Commun:1862–1863

Caban K, Donten M, Stojek Z (2004) J Phys Chem B108:1153–1159

Zein El Abedin S, Saad AY, Farag HK, Borisenko N, Liu QX, Endres F (2007) Electrochim Acta 52:2746–2754

Isobel Fletcher S, Sillars FB, Hudson NE, Hall PJ (2010) J Chem Eng Data 55:778–782

Trulove P, Mantz R (2003) In: Wasserscheid P, Welton T (eds) Ionic liquids in synthesis. Wiley-VCH, Weinheim

Seddon KR, Stark A, Torres MJ (2002) Am Chem Soc Symp Ser 819:34–49

Leong T-L, Sun I-W, Deng M-J, Wu C-M, Chen P-Y (2008) J Electrochem Soc 155:F55–F60

Gutmann V (1978) The donor-accepter approach to molecular interactions. Plenum Press, New York

Yamagata M, Katayama Y, Miura T (2006) J Electrochem Soc 153:E5–E9

Zawodzinski TA Jr, Osteryoung RA (1989) Inorg Chem 28:1710–1715

Paunovic M, Schlesinger M (2006) Fundamentals of electrochemical deposition, 2nd edn. Wiley, New Jersey

Schubert T, Zein S, Abedin E, Abbott A, McKenzie KJ, Ryder KS, Endres F (2008) In: Endres F, Abbott AP, MacFarlane DR (eds) Electrodeposition from ionic liquids. Wiley-VCH, Weinheim

Murase K, Nitta K, Hirato T, Awakura Y (2011) J Appl Electrochem 31:1089–1094

Biltz W (1924) Z Anorg Allg Chem 134:25–36

Li D, Franke P, Fürtauer S, Cupid D, Flandorfer H (2013) Intermetallics 34:148–158

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, D., Groult, H., Gaillon, L. et al. Tunable electrodeposition of Sn and Sn-based alloys using ionic liquids. J Solid State Electrochem 19, 2517–2532 (2015). https://doi.org/10.1007/s10008-015-2809-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-015-2809-8