Abstract

Focused ion beam scanning electron microscopy (FIB-SEM), X-ray photoelectron spectroscopy (XPS) and Brunauer–Emmett–Teller gas adsorption methods have been used for the characterisation of physical properties of microporous carbide-derived carbon electrodes, prepared from Mo2C at 600 °C (noted as Mo2C-CDC) before and after electrochemical tests conducted within a very wide two-electrode cell potential region. Cyclic voltammetry, constant current charge/discharge and impedance data have been analysed to establish the electrochemical characteristics of the hybrid devices consisting of the 1 M Na2SO4 and 1 M Rb2SO4 aqueous electrolytes and Mo2C-CDC electrodes within the very wide cell potential region (ΔE ≤ 2.4 V). The influence of cation chemical composition on the electrochemical characteristics of supercapacitors/electrochemical hybrid devices has been analysed. The complex kinetics behaviour of completed devices (adsorption, blocking adsorption and intercalation of Na+ and Rb+ ions; faradic and mass transfer; gas adsorption; etc.) has been established at ΔE ≥ 1.5 V. At least three different characteristic time constants dependent on the electrolyte cation composition and cell potential applied have been established.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nowadays, mainly four types of electrochemical energy storage/conversion devices are under development: supercapacitors (SCs), batteries, electrolysers (ELs) and fuel cells (FCs) [1–6]. Batteries have higher specific energy than supercapacitors but lower specific power, and a very limited number of charging/discharging cycles can be applied [1–12]. Fuel cells and electrolysers [13–15] are characterised with high energy but moderate power density, and differently from supercapacitors, they are working in the stationary regime. Regardless of low energy density, the high power density supercapacitors are important energy storage systems, which can be used in various areas of modern technology, starting from the pulse energy generation/accumulation systems and finishing with the consumer goods [16–21]. For the high specific energy–specific power density application, the microporous carbon material [22, 23] and electrolyte characteristics have to be optimised [1–6, 8–11, 19–22]. Based on the results obtained [8–11, 19–23], the electrolyte chemical composition has a big influence on the electrochemical behaviour of aqueous and non-aqueous SCs [7–12, 23–26]. The potential advantages of H2O-based supercapacitors would be the very cheap electrolyte applicable for SCs, regardless of the narrower region of ideal polarisability compared with that for non-aqueous SCs [8–11, 19–27]. For neutral Na2SO4 solution in H2O and microporous and mesoporous carbons, the cell potential operation region from 1.0 up to 1.6 V [23–25], and even 1.9 V, has been demonstrated [26]. Of course, at ΔE ≥ 1.6 V, these systems are non-ideally polarisable and more detailed electrochemical analysis including impedance is inevitable, being the main aim of this paper.

Historically, SCs have been divided into two main groups: electrical double-layer capacitors and so-called hybrid supercapacitors [1–4, 8–11, 16–18]. However, based on our earlier studies [8–11, 19–21], there is no rigid border between these types of SCs as some faradic reactions, including gas evolution (H2 or surface oxidation and O2 formation and evolution), can be observed outside of the low current density cell potential region (so-called electrical double-layer charging/discharging region, known as the region of ideal polarisability ΔE ideal) observed for carbon | H2O + x M Na2SO4 neutral electrolyte systems usually at ΔE ≥ 1.4 V. Thus, if the cell potential ΔE > ΔE ideal, the nearly exponential increase of current density with cell potential is usually observed, where the faradic reduction reactions (reduction of H3O+ to H2 and adsorption or intercalation of Li+, Na+, etc., cations as neutral atoms) at a negatively charged surface are main processes. H2O decomposition or surface oxidation in a neutral medium at a positively charged surface is limited by the activation energy, strongly dependent on the pH of the solution, as well as on the electrode material used. For graphite electrodes, the H2 evolution overvoltages η H2 as well as the surface oxidation/O2 evolution overpotentials η ox are usually very high [1, 8, 23].

Using the electrochemical kinetics data for metal electrodes [28], it was demonstrated that H2 evolution overpotential η depends strongly on the cation adsorption energy, being highest for Cs+-containing electrolytes (η H2 ∼40 mV, compared with H+ cations containing salts) due to the shift of ψ1 potential toward more positive values (ψ1 potential is the so-called Frumkin or double-layer correction potential, usually fixed/assumed for the plane (position in the Helmholtz layer)), where the electrochemical reaction takes place [28–32]. Thus, usually, it is assumed that the Frumkin correction depends on the chemical composition of the surface active cation used. However, for microporous–mesoporous electrodes, there are some objective complications connected with the establishment of the outer Helmholtz plane position due to the surface roughness and microporosity–mesoporosity, as well as macroscopic non-homogeneity of the electrode surface [31–36].

This paper reports the results of the systematic studies of the electrochemical devices based on mainly microporous with a small amount of mesopores carbide-derived carbon (CDC) electrodes, prepared from Mo2C (−325 mesh powder, Sigma-Aldrich) at T synt = 600 °C, noted as Mo2C-CDC, and 1 M Rb2SO4 or 1 M Na2SO4 aqueous electrolyte within the very wide two-electrode cell potential ΔE. The very high ΔE values have been applied to activate the faradic reactions at Mo2C-CDC electrodes followed by the adsorption/absorption of formed H2 and O2 inside of the microporous Mo2C-CDC electrode, as well as carbon electrode surface oxidation at very positive electrode potentials, increasing the faradic capacitance component.

Experimental

The SC electrodes were prepared from Mo2C-CDC powder and from the mixture of binder (polytetrafluoroethylene, PTFE, 60 % solution in H2O). The mixture received was laminated and roll pressed (HS-160N, Hohsen Corporation) to form a flexible layer of an active electrode material with thickness L = 100 ± 5 μm.

The crystallinity and macroscopic structure of the Mo2C-CDC electrodes were evaluated by focused ion beam scanning electron microscopy (FIB-SEM)–energy-dispersive X-ray spectroscopy (EDX) and X-ray diffraction (XRD) (with a Cu anode to generate CuKα radiation (λ = 1.5406 Å)). XRD data were collected in the 2θ range from 15° to 70° with the step size of 0.05°.

The FIB-SEM data have been obtained using Helios™ NanoLab 600. The X-ray photoelectron spectroscopy (XPS) experiments were carried out with a SCIEHTA SES-100 spectrometer by using an unmonochromated MgKα X-ray source with power of 300 W. The SES-100 system was calibrated using Au 4f photolines. The pressure in the analysis XPS chamber was within the range from 2 × 10−10 to 5 × 10−10 mbar.

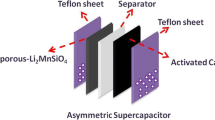

The two-electrode standard stainless steel test cell (HS Test Cell, Hohsen Corporation) with two identical electrodes (flat cross-sectional area of one electrode ∼2.0 cm2) was completed with a manometer (Migishita Seiki Co.) for analysis of pressure inside of the cell. All electrochemical experiments were carried out at fixed temperature T = 20 ± 5 °C. A 25-μm-thick Celgard® 2400 separator sheet was used for mechanical separation of the working Mo2C-CDC electrodes from each other. One molar Rb2SO4 and Na2SO4 aqueous electrolytes were used.

Results and discussion

Adsorption measurement data

Nitrogen adsorption measurements at liquid nitrogen temperature have been conducted using the Micromeritics ASAP 2020 surface area and porosity analysis measurement system. Based on the N2 adsorption data for Mo2C-CDC at T synt = 600 °C, the multipoint Brunauer–Emmett–Teller (BET) surface area S BET = 1855 m2 g−1, micropore area (obtained using the t-plot method) S micro = 1823 m2 g−1, total pore volume V tot = 1.139 cm3 g−1 and micropore volume V micro = 1.077 cm3 g−1 were calculated. The pore size distribution function vs. pore width plots, obtained using non-local density functional theory, shows two main peaks at d 1 = 1.04 nm and d 2 = 2.64 nm, respectively. Thus, in addition to the micropores (d 1 lower than 2 nm according to IUPAC classification), there are some amount of mesopores (2 nm < d 2 < 50 nm, IUPAC) at/inside of the Mo2C-CDC, synthesised at T = 600 °C. More detailed gas adsorption analysis has been given in our previous paper [18]. Thus, based on the N2 sorption data and our previous SC studies [16–18], Mo2C-CDC with hierarchical structure is an interesting material containing micropores for adsorption of charged ions and adsorption/absorption of gaseous H2 or O2 into micropores and mesopores. It should be mentioned that mesopores are needed for the quick mass transfer of reactants (H3O+ ions (or H2O molecules)) into the micropores [22] as well for desorption of gaseous H2 and O2 from micropores into the neutral electrolyte solution.

FIB-SEM–EDX, Raman and XPS measurements

Focused ion beam scanning electron microscopy combined with the EDX (FIB-SEM–EDX) analysis method was used for the quantitative analysis of SC electrodes (Fig. 1a–d, Table 1). Similarly to the high-resolution transmission electron microscopy (HRTEM) data, discussed in [18], it was shown that the small amount of graphite-like carbon layers at the top (core level) of mainly amorphous carbon particles was observed. The Raman spectra were recorded using a Renishaw micro-Raman spectrometer equipped with a ×50 objective and 488 nm Ar+ ion laser with maximum radiation power of 15 mW on the sample. XRD and Raman data, in agreement with HRTEM data, show that Mo2C-CDC carbon has mainly an amorphous structure and only very slightly graphitized regions were found at the surface of some particles of Mo2C-CDC material [11]. It was found that before electrochemical tests, the porous Mo2C-CDC structure consists of particles with variable linear dimensions (from 10 to 100 nm). PTFE wires and lumps were observed between CDC particles, connecting the carbon particles into the flexible electrode layer (not shown for shortness). After electrochemical analysis (after 10, 100, 1000 and 10,000 charge/discharge cycles), the SC cells were opened and electrodes were washed many times with clean Milli-Q+ H2O, dried under vacuum and analysed again using the FIB-SEM and XPS methods. It was demonstrated that in agreement with HRTEM data [18], there is no Cl− or Cl2 and/or other contaminants in electrode materials under testing.

Results of FIB-SEM analysis for Mo2C-CDC electrodes in 1 M Rb2SO4 (a), 1 M Na2SO4 (b–d) and aqueous solutions for negatively (a–c) and positively (d) charged supercapacitor electrodes. Image b is taken from the membrane side and c from the current collector side Mo2C-CDC electrode, tested in Na2SO4 + H2O solution, respectively

A lot of signals connected with Rb (Fig. 1a, Table 1a) and Na (Fig. 1b, c, Table 1b, c) absorbed/deposited/intercalated into the negatively charged Mo2C-CDC were found after 10,000 galvanostatic cycles in Rb2SO4 or Na2SO4 aqueous electrolyte, differently from the carbon electrodes measured after ten cycles (not shown for shortness) have been observed. Somewhat lower concentrations of Na+ and Rb+ have been observed in CDC after 1000 charge/discharge cycles (not shown for shortness). It should be noted that for positively charged Mo2C-CDC, the concentration of Na was very low (Fig. 1d, Table 1d) indicating that the electrochemically activated accumulation of Na+ ions (Na intercalation) has been taking place in the negatively charged electrode only.

Thus, during electrochemical potential cycling in the wide cell potential region, adsorption/absorption of Rb+ and Na+ ions and the intercalation (or chemisorption) of Rb and Na onto/into the Mo2C-CDC electrode structure have been taking place. It should be mentioned that there is no big difference in amount of Rb or Na accumulated (data in Fig. 1a, b, Table 1a, b). It is surprising that a small amount of S (probably from SO4 2− ions), especially from the Rb2SO4 solution, has been observed as well.

The XPS analysis data (Fig. 2) confirm the existence of adsorbed/intercalated Rb and Na (binding energy peak from 235 to 248 eV for Rb and at 498 eV for Na) onto/into the Mo2C-CDC structure. Based on these results, the amount of the strongly covalently bonded Rb for Mo2C-CDC electrodes observed after 10,000 galvanostatic cycles is remarkable. For electrodes studied after 100 cycles, the amount of covalently bonded Rb is smaller. For electrodes analysed after ten cycles, it was impossible to verify the existence of the Rb-C surface compound at all. It should be noted that the FIB-SEM–EDX and XPS are ex situ methods and, for more detailed studies, electrochemical in situ synchrotron radiation-based X-ray absorption spectroscopy [37] must be applied.

Cyclic voltammetry data

Cyclic voltammetry (CV) curves, expressed as capacitance for a symmetrical two-electrode system in 1 M Na2SO4, as well as in 1 M Rb2SO4 aqueous solutions, are given in panels a and b, respectively, of Fig. 3. The current density, j, measured at fixed cell potential scan rate v, has been used for calculation of the medium capacitance values according to Eq. 1:

Equation 1 is correct if the capacitance C CV is constant (C CV ≠ f(E)) [8, 19, 20] and/or the current density applied is small. In a symmetrical two-electrode system, the gravimetric capacitance C m;CV (F g−1) for one activated carbon electrode can be obtained as follows:

where m is the weight per one activated carbon electrode assuming that the positively and negatively charged electrodes have the same capacitance at fixed ΔE applied. The cyclic voltammetry curves expressed as capacitance vs. cell potential curves up to 1.3 V for 1 M Rb2SO4 and 1.2 V for Na2SO4, obtained at small voltage scan rates v = d(E) / /dt, have nearly mirror image symmetry of the current responses about the zero current line (t is potential scanning time) characteristic of the ideal polarizability of the system under study. However, the discharging current densities, i.e. capacitance values for Rb2SO4 as well as for Na2SO4, depend on the final ΔE applied, indicating that the desorption of Rb+ as well as Na+ ions is slower than the adsorption step. At 1.3 ≤ ΔE ≤1.5 V, for both electrodes, a small increase in faradic current density has been observed, indicating that the hydrogen evolution and H2O decomposition (or surface oxidation) at Mo2C-CDC is a slow process due to the very high H3O+ electroreduction overvoltages [33–36].

However, for 1 M Rb2SO4 solution, the quick nearly exponential increase of j can be seen at ΔE ≥ 1.3 V. Surprisingly, there is nearly linear dependence of ΔE on log i (at ΔE ≥ 1.3 V) (Fig. 4), known as the Tafel plot, if the individual electrode has been analysed. However, for the two-electrode system, ΔE vs. log i dependence characterises the behaviour of two different (or even more) electrode processes (or the behaviour of one electrode with the rate-limiting reaction kinetics). Therefore, the slope values of b and Tafel constant value a in the Tafel equation ΔE = a + b log i calculated cannot be used for detailed and correct reaction mechanism analysis. The slope b value, characterising the complex electrochemical behaviour of the system, including the electroreduction step of hydrated protons (H3O+ + e− → H2O + Hads) and interaction of Rb through reaction (Rb+ + e−) and negatively charge electrode as well as the surface oxidation and O2 evolution (H2O oxidation) reaction at the positively charged Mo2C-CDC | electrode interface, is very high for the Rb2SO4-based electrolyte.

For 1 M Na2SO4 solution, the intensive increase of current density starts already only at ΔE ≥ 1.5 V (Fig. 3). Differently from the Rb2SO4 electrolyte, there is no linear dependence of ΔE on log i (Fig. 4) within the 1.3 < ΔE ≤ 1.5 V region. Thus, only at ΔE ≥ 1.5 V the linear dependence of ΔE on log i has been observed with a noticeably lower slope value. Considerably different slope values (Fig. 4) for these two systems indicate that in addition to H2 evolution and surface oxidation, the adsorption and reduction (intercalation) of cations play a probably important role. The intensive increase of the faradic process(es), i.e. hydrogen and O2 (surface oxidation) evolution, is shifted ∼150 ± 5 mV toward higher ΔE values for the Rb2SO4 solution, indicating that the hydrogen and oxygen evolution overvoltages at Mo2C-CDC from 1 M Na2SO4 solution are somewhat lower than that for 1 M Rb2SO4. This is in very good agreement with H2 evolution data established for Hg and other metal electrodes [28], indicating that the Na+ or Rb+ adsorption influences the ψ1 potential similarly to high hydrogen overvoltages measured for metals (Hg, Pb, Bi, Cd). Thus, the adsorption of Rb+ (similarly to Cs+) cations increases the hydrogen as well as the oxygen evolution overvoltages [28, 33–36]. It is surprising that during the first very wide cell voltage cycles (ΔE = 2.0 V), the charging (reduction/oxidation) curve is very well reproducible and only a weak increase of discharging currents (reoxidation of H2 and reduction of oxygen containing surface functionalities) can be seen after 100 or 1000 cycles but especially after 10,000 cycles (not shown for shortness).

After the polarisation of electrodes at cell ΔE ≥ 2.4 V in the discharging curve at ΔE < 1.0 V, only a very small and very wide current peak (plateau) (Fig. 5) has been observed, indicating the reoxidation of H2 adsorbed/absorbed in porous Mo2C-CDC, as well as the reduction of the oxygenated functional groups at the electrode surface. Faradic hydrogen reoxidation (ionisation) and surface reduction processes at the Mo2C-CDC electrode surface, within the region of ΔE studied, are very slow and irreversible processes as there are no clearly visible current peaks in the discharging curve at lower cell potentials and wide potential scan rates, v, applied.

Cyclic voltammetry curves expressed as capacitance C vs. cell potential curves in 1 M Na2SO4 (a) and in 1 M Rb2SO4 (b) at different cell potentials and at different potential scan rates, noted in the figure. Hybrid electrochemical device cell pressure vs. time dependence in 1 M Rb2SO4 (c) and at cell potential 2.4 V

A comparison of current densities measured in 1 M Na2SO4 and 1 M Rb2SO4 solutions indicates that both electrodes can be applied within the very wide ΔE region; however, for the Rb2SO4-based electrolyte, the faradic current densities are clearly lower (Figs. 3 and 5) due to the blocking adsorption of Rb+ at the negatively charged Mo2C-CDC electrode (Figs. 1 and 2).

The activation of microporous and mesoporous Mo2C-CDC electrodes takes place only at ΔE ≥ 1.5 V. Thus, C m;CV increases with the decrease of the potential sweep rate applied, indicating a slow rate of reduction and oxidation reactions occurring at negatively and positively charged electrodes. Data in Fig. 5a, b show that the high capacitance values have been calculated in the high-current-density (hydrogen/oxygen evolution/surface oxidation) region, explained by the high faradic process capacitance values for hydrogen and oxygen evolution reactions.

At v > 5 mV s−1 and ΔE > 1.7 V, the C values are lower for the Rb2SO4 electrolyte-based SC explained by the higher hydrogen overvoltage for 1 M Rb2SO4 solution than that for Na2SO4. Thus, the adsorption/reduction/intercalation of Rb+ cations onto the Mo2C-CDC surface causing the shift of the zero total charge potential (and the ψ1 potential) toward the less negative electrode potential increases the hydrogen and oxygen evolution overpotential (∼0.04 V).

For the verification of hydrogen and oxygen evolution processes, the pressure inside of the hermetic test cell was monitored. It is surprising that during the first 10–20 min, there was no big increase of pressure inside of the cell during the first cycles or even during short-time holding (t < 3 min) of the cell at ΔE = 2.4 V (Fig. 5c). Only during long-lasting holding (1–1.5 h) of the two-electrode cell at 2.4 V the small overpressure in cells has been observed, as demonstrated in Fig. 5c. As can be seen in Fig. 5c, during 50 to 500 min polarisation at ΔE = 2.4 V, the pressure inside of the cell increases nearly exponentially and, after polarisation during 1000–1500 min (at ΔE = 2.4 V), the increase in Δp practically stopped. To the first very rough approximation, this surprising result can be explained by the adsorption/absorption of generated hydrogen/oxygen onto/into the porous Mo2C-CDC electrode [28–30, 33–35].

Surface charge density potential curves (at potential scan rate 10 mV s−1) have been integrated to obtain the surface charge density Q, ΔE curves (Fig. 6). A comparison on Q, ΔE curves for charging and discharging cycles indicates that the electrochemical coulombic efficiency η noticeably decreases with the increase of ΔE applied, if ΔE ≥ 1.5 V. A somewhat lower η has been calculated for the Rb2SO4-based system, explained by the blocking adsorption of Rb+ cations into the negatively charged Mo2C-CDC electrode. The cyclic voltammetry and coulombic efficiency data show that systems under discussion can be used as combined electricity storage, i.e. H2/O2 generation/storage systems however with quite low efficiency at ΔE ≥ 1.5 V. However, it is very interesting to mention that even at ΔE = 1.8 V, the electrochemical reversibility of the Mo2C-CDC | 1 M Na2SO4 system is higher (η ≥ 85 %) than that for lead accumulators (η ≤ 80 %) [1]. A very quick decrease of η has been established for the Rb2SO4-based system at ΔE ≥ 1.5 V.

Constant current charge/discharge data

The SC cells were tested at constant current (CC) charge/discharge regimes (from 1 to 50 mA cm−2) within the different voltage range from 0 to 1.2, from 0 to 1.5 and from 0 to 2.0 V (Fig. 7a), and from 1.0 to 2.0 V (Fig. 7b). CC curves obtained for the normal ΔE region (0–1.2 V) have a very nice traditional shape [23] characteristic of ideally polarisable systems (not shown for shortness). However, Fig. 7a, b shows that the very complicated charging/discharging curves have been measured if the wider ΔE region has been applied: 0 V < ΔE < 2.0 V or 1.0 V < ΔE < 2.0 V. In principle, the two nearly linear charging regions have been observed: first at lower cell potentials (0.5 < ΔE < 1.0 V, double-layer charging) and second from 1.3 V < ΔE < 1.8 V (probably mainly H3O+ reduction and Na+ or Rb+ adsorption). In discharging CC curve, the linear regions have been observed at 1.2 V < ΔE < 1.9 V and 0.1 V < ΔE < 1.0 V. Interestingly, if these cells have been cycled within the limited cell potential region (1.0 V < ΔE < 2.0 V), the discharging curves are non-linear within the all potential region (1.0 < ΔE < 2.0 V) applied, indicating that after the gas (H2, O2) formation/adsorption step at ΔE > 1.2 V, the gas desorption and ionisation is only possible at lower cell potentials than ΔE < 1.0 V due to the very high activation energy of H2 or O2 ionisation step(s). Thus, the H2 and/or O2 ionisation and surface oxide reduction and cation desorption have very high overvoltages at Mo2C-CDC electrodes.

Usually, the capacitance of the cell (C CC) at ΔE ≤ 1.2 V will be obtained from the slope of the discharge curve according to Eq. 3:

where dt/d(E) is the slope of the discharge or charging curve with corresponding current density j.

From the constant current charge/discharge curves, the value of internal resistance, R CC, from the IR-drop is observable after the changing of the charging or discharging current direction has been calculated (R CC = dE 1/2j, where dE 1 is the value of cell potential for 10 ms). The lowest R CC value has been calculated for the 1 M Rb2SO4 + H2O-based cell compared with the Na2SO4 + H2O-based cell, explained by the higher molar conductivity of the Rb2SO4 aqueous solution in agreement with the analysis of impedance data (next chapter) and limiting ionic (molar) conductivity values λ (S cm2 mol−1: Na+ 50.10, Rb+ 77.8, SO4 2− 160). At ΔE ≤ 1.5 V, where the gas formation is slow and unimportant, the IR-drop is practically independent of the cycle number applied. However, the R CC value slightly increases with the cell potential applied at ΔE ≥ 1.5 V, explained by the accumulation of H2 and O2 (or surface oxides) inside of the porous carbon matrix and squeezing out of some electrolytes from the microporous matrix, and/or by blocking adsorption/intercalation of Na or Rb atoms into the porous matrix, decreasing the linear dimensions of the pore.

For the Mo2C-CDC | 1 M Na2SO4 or Mo2C-CDC | 1 M Rb2SO4 aqueous interface, there is no remarkable dependence of the relative capacitance, C rel = C in / C x , or relative resistance, R rel = R in / R x , on the galvanostatic cycle number applied (C in and C x are the capacitance values of the third and x number cycle, respectively, and R in and R x are the corresponding series resistance values, calculated from the IR-drop), if ΔE < 1.3 V. Hence, for 1 M Na2SO4 and 1 M Rb2SO4 | Mo2C-CDC interfaces, C rel and R rel are quite stable and these salts can be used as aqueous electrolytes for SCs at ΔE ≤ 1.3 V.

The coulombic cycling efficiency, i.e. the so-called round trip efficiency (RTE) has been calculated as a ratio of capacitances measured during discharging and charging of SCs, if ΔE ≤ 1.3 V. The highest RTE ≥98 % at ΔE < 1.3 V has been calculated for 1 M Rb2SO4 aqueous supercapacitors and RTE ≥96 % for 1 M Na2SO4, demonstrating the reasonable dependence of RTE on the electrolyte conductivity discussed before. This effect can be explained by the influence of the IR-drop as well as the mass transfer and partial charge transfer resistances on the total charge accumulation efficiency, because the solvation (standard molar hydration enthalpy ΔH) of Rb+ ions in H2O is somewhat lower than that for Na+ ions (ΔH (kJ mol−1) Na+ = −321 and Rb+ = −300, respectively). Thus, the adsorption/absorption kinetics of ions (reversibility of charging/discharging of the system) depends on the hydration of cations applied as an electrolyte for SC. Formation of H2 and O2 gases or surface compounds as adsorbed/intercalated reaction products or surface oxides onto/into some places of electrode material at higher ΔE is possible, but a weak influence on the RTE of supercapacitors based on the 1 M Na2SO4 or 1 M Rb2SO4 electrolyte indicates that this effect is quite unimportant at lower ΔE ≤ 1.3 V. In addition, the physical adsorption/intercalation of Rb+ ions at/into the Mo2C-CDC electrode shifts the zero charge potential toward more positive values (∼30 mV), thus increasing the ψ1 potential values at the outer Helmholtz plane and therefore increasing the H2 evolution overpotential.

However, for systems tested at ΔE > 1.3 V, Eq. 3 cannot be applied as the charging/discharging curves are non-linear. Therefore, for the more detailed analysis, the charging/discharging curves have been integrated to obtain the charge densities accumulated during charging Q ch and discharging Q disch steps. The calculations show that in agreement with CV data, the coulombic efficiency is quite low (η ≤ 0.8) at ΔE > 2.3 V. The very quick decrease of Q ch and Q disch takes place after application of a comparatively small number of charging/discharging cycles (N cyc > 1000 at ΔE > 1.5 V), explained by the quick electrode degradation process after/during gas evolution, adsorption/deionisation steps or by the adsorption/absorption/intercalation of Na+ or Rb+ ions (thus Na or Rb atoms) into the microporous Mo2C-CDC electrodes.

Analysis of Nyquist and Bode plots

The Nyquist plots [19–21, 38–44], given in Fig. 8a, b for SCs completed from Mo2C-CDC electrodes in 1 M Rb2SO4 or 1 M Na2SO4 aqueous solutions, have been measured within the wide range of ac frequency, f (from 1 × 10−3 to 1 × 105 Hz), and at fixed cell potentials from ΔE = 1.2 to 2.0 V. At the very beginning of the experiments, if ΔE ≤ 1.2 V, the Nyquist plot has a traditional shape (not shown for shortness) [8–11, 19–21, 23] and they consist mainly of three parts: (1) the very small and noticeably depressed semicircle at higher ac frequency (f ≥ 3 Hz) with a characteristic frequency, f max (obtained as the frequency at the maximum in the Nyquist plot) (the semicircle shape depends on the adsorption kinetics of ions at the microporous electrode and on the series resistance of a material, mass transfer resistance inside the meso/macroporous carbon structure as well as on the mass transfer resistance in the micropores); (2) the so-called double-layer capacitance region (“knee” at low frequencies f < 0.01 Hz), obtained by the finite-length adsorption effect; and (3) the not very-well-expressed so-called “porous” region with a slope of α ≈ 45°, characteristic of the mass transfer-limited processes in the microporous–mesoporous matrix of an electrode.

At ΔE ≥ 1.3 V, the Nyquist plots for the Na2SO4-based SC have a very complicated shape and at least five different areas in Z″, Z′ plots have been established (shown in Fig. 8a, b). With the increase of ΔE ≥ 1.5 V applied, the role of faradic processes rises quickly (formation of the semicircle in Nyquist plots at f < 10 mHz). Differently from data measured at ΔE ≤ 1.3 V, Nyquist plots at a lower region of ac f < 1 Hz and at 2.0 V are non-linear and deviate strongly from a nearly vertical line explained by the deviation of the Na2SO4 | Mo2C-CDC interface from the simple adsorption-limited step (ideal capacitive) behaviour.

According to the experimental data given in Fig. 8b, the Nyquist plots at ΔE = 2.0 V for the Rb2SO4 solution have an even more complicated shape, compared with the Na2SO4-based SC, explained by the strong specific adsorption and intercalation of Rb+ being possible at ΔE ≥ 2.0 V (Fig. 8b). The shape of the Nyquist plot depends on the number of cycle analysed more pronounced for the Rb2SO4-based system. The relaxation frequency for the kinetically mixed so-called very-low-frequency process (f < 4 mHz) depends noticeably on the electrolyte studied, and f low increases from 1.9 mHz (1 M Rb2SO4) to 3.8 mHz for 1 M Na2SO4. Thus, the characteristic relaxation time τ max = (2πf max)−1 decreases from 0.1 s (1 M Rb2SO4) to 0.04 s (1 M Na2SO4), explained by the stronger chemical interaction of Rb+ cations with the Mo2C-CDC surface caused by the lower hydration energy values for Rb+ ions compared with Na+ ions [31, 32]. In addition, the stronger adsorption bond for Rb+-containing systems is caused by the smaller hydration number for Rb+ (∼4) compared with that for Na+ (∼6) as well as explained by the shorter effective Debye length values (shorter distance of the closest approach of Rb+ to the surface for weakly solvated Rb+ ions compared with strongly hydrated Na+ ions) [31, 32].

Thus, probably, dependency of the shape and the slope for the Nyquist plot in the low-frequency region on the SC cell voltage is mainly caused by the rate of the electrical double-layer formation and Rb+ adsorption/intercalation processes inside of the mesoporous and microporous carbide-derived carbon electrodes. However, mainly the adsorption-limited step for 1 M Na2SO4 and 1 M Rb2SO4 electrolyte-based systems has been established only at ΔE ≤ 1.3 V (not shown for shortness). The dependence of the shape of the Nyquist plots on the cell voltage at f < 0.01 Hz (so-called finite-length effect region) is mainly caused by the decrease of the effective screening length, well visible for the 1 M Rb2SO4 and 1 M Na2SO4 electrolytes with increasing cell potential. The effective diffuse layer thickness as a function of the electrode rational potential E R is given as κ eff(E R ) = 2/κ cos(eβE R ), where κ eff(E R) and κ are the effective and usual Gouy lengths and E R is a potential with respect to the zero charge potential, β = (R B T)−1, where T is the absolute temperature and R B is the Boltzmann constant [39, 40]. Thus, the dependence of the shape of the Nyquist plot within the very-low-frequency region on cell voltage, to a first approximation, indicates that the pore dimension is in the same order of magnitude as the effective Debye length for the 1 M electrolyte solutions, i.e. the pore dimension is comparable to the effective diameter of the partially desolvated Rb+ or Na+ ions absorbed [38–40]. A similar dependence of the screening length and effective diffuse layer thickness has been established for specifically adsorbed anions [38].

Preliminary non-linear least squares fitting data show that in addition to the slow adsorption and faradic charge transfer steps (f ≥ 100 mHz) as well as the finite-length Warburg-like mass limited transfer steps (5 mHz < f ≤ 50 mHz), the inductive behaviour (f < 2.4 mHz, Fig. 8b), initiated by the so-called corrosion of electrode material or irreversible blocking adsorption, surface oxide layer formation process, etc., are involved. In addition, accumulation of the gases (H2 and O2) into the microporous volume of Mo2C-CDC at ΔE > 1.5 V and reionisation ΔE < 1.0 V occur in agreement with the rise of high-frequency series resistance of the system under discussion (Fig. 8a, b). It should be noted that the exact fitting of Nyquist plots at ΔE > 1.5 V and f < 100 mHz was impossible due to very many processes involved.

The analysis of the Bode phase angle θ, log f plots and log (−Z″), log f plots (Fig. 9a–c) shows that differently from the Mo2C-CDC | 1 M (C2H5)3CH3NBF4 + acetonitrile (non-aqueous) interface (ΔE ≤ 3.0 V) for aqueous Na2SO4 and Rb2SO4 solutions at ΔE < 1.0 V, at ΔE ≥ 1.3 V, there are noticeable deviations from the ideally polarisable interface model for Rb2SO4 and Na2SO4 solutions within all ac frequency region studied. For the Mo2C-CDC | 1 M Na2SO4 or 1 M Rb2SO4 + H2O system, at least four different regions characterised by different time constants can be calculated. At ΔE = 2.0 V, the data in Figs. 8 and 9 show that the very-high-frequency region f high ≥ 10 kHz is noticeably shorter for the Rb2SO4-based system compared with Na2SO4. The high-frequency minimum (i.e. maximum with negative δ values) in δ, log f plot is shifted nearly one order toward lower f values for the Na2SO4-based system compared with that for Rb2SO4. The |δ| values are higher (|δ| = 40°) for the Na2SO4-based system than for the Rb2SO4-based SC (|δ| = 20°), indicating the more pronounced mixed kinetics for Rb2SO4 and lower ratio adsorption but more pronounced mass transfer processes for the Na2SO4-based SC.

Bode phase angle, log f and log (−Z″), log f plots for hybrid electrochemical devices in 1 M Na2SO4 (a) and in 1 M Rb2SO4 (b) at ΔE = 2.0 V in aqueous electrolyte after 1000 (rhombs), 2000 (triangles) and 5000 cycles (circles) at current charging/discharging test from 0 to 2.0 V. Open symbols correspond to the Bode phase angle (expressing the magnitude of the frequency response gain), and filled symbols correspond to the log (−Z″), log f plots. Corresponding Bode phase angle, log f plots (1–4) and log (−Z″), log f plots (5–8) in 1 M Na2SO4 (1, 3, 6, 8) and in 1 M Rb2SO4 (2, 4, 5, 7) at ΔE = 2.0 V (1, 2, 7, 8) at ΔE = 1.0 V (3, 4, 5, 6) (c), noted in the figure

Phase angle absolute values are nearly comparable with the so-called medium-frequency ac (from 0.2 to 10 Hz for Na2SO4 and from 1.0 to 500 Hz or Rb2SO4) region, indicating that the faradic processes are mainly occurring at the Mo2C-CDC electrode surfaces. Within the low-frequency ac region f low < 1 Hz for Rb2SO4 and f low < 2 Hz for Na2SO4, the second minimum in δ, log f plots can be seen indicating the slow mixed kinetics processes (faradic mass transfer and adsorption step-limited processes) at the Mo2C-CDC | electrolyte interface. Within the very-low-frequency ac region, f < 2.4 mHz, the phase angle values increase to zero, indicating that the very slow faradic reaction(s) determine(s) the Na2SO4 or Rb2SO4 aqueous solution | Mo2C-CDC interface behaviour.

The relaxation frequency for the high-frequency process f high from 100 to 500 Hz for the Na2SO4-based system depends noticeably on the cycle number applied. With the increase of cycle number applied from 1 to 1000, there is no big shift of f high values, but f high decreases very remarkably after 2000 or 5000 cycles (f high = 120 Hz). Surprisingly, f high = 8000 Hz is noticeably higher for the Rb2SO4-based SC and there is no remarkable shift of f high with the cycle number (material degradation step) studied.

Interestingly, the low-frequency processes f med = 0.3 Hz have systematically lower values for the Na2SO4-based SC compared with f med = 5 Hz for the Rb2SO4-based supercapacitor. At very low frequency, there are no clearly visible maxima in phase angle absolute value, log f plots, and the |δ| are approaching zero, indicating that the very slow faradic processes are rate-determining processes for the Na2SO4- and Rb2SO4-based SC (Fig. 9a, b). At f med and f high frequency regions, the mixed kinetics processes take place at mesoporous–macroporous regions of Mo2C-CDC electrodes, respectively. Thus, a comparison of data with our previous work [23] and data in Fig. 9c shows that the ΔE has very noticeable influence on the medium- and low-frequency process parameters.

Based on the Orazem et al. model [42] within the high-frequency region, the slope of log |−Z″|, log f plot is nearly −0.85, indicating the mixed kinetics adsorption, mass transfer step and faradic processes at the Rb2SO4 | Mo2C-CDC or Na2SO4 | Mo2C-CDC interfaces. More detailed analysis of log |−Z″|, log f plots demonstrates that the slope value of log |−Z″|, log f plot for the Rb2SO4-based system is somewhat less negative (−0.92) compared with the Na2SO4-based system, indicating the more pronounced deviation of the Rb2SO4 + H2O | Mo2C-CDC supercapacitor system from the ideally polarisable electrode model. Within the medium-frequency region 1.0 < f < 100 Hz, there are linear areas in log |−Z″|, log f plots with the slope nearly zero, indicating that within this frequency region, the slow faradic processes determine the kinetics behaviour of the SC under study.

The absolute values of the imaginary part of impedance strongly depend on ΔE applied and at fixed ΔE = 2.0 V are lower for the Rb2SO4-based SC compared with the Na2SO4-based system. With the increase of ΔE from 1.0 to 2.0 V, |−Z″| values increase, indicating that capacitance values increase with ΔE applied. At very low ac frequency and very high ΔE = 2.0 V, the limiting rate-determining process is the very slow faradic charge transfer step (the slope of log |−Z″|, log f plots is nearly zero for both systems under study [42–44], but at ΔE = 1.0 V, nearly ideal capacitive behaviour has been established (slope −0.95) [23].

The values of gravimetric series (C s) and parallel (C p) capacitances (Figs. 10a, b), calculated from the Nyquist plots (Z″ = −1/(j2πfC s; C p = C s / (1 + tan2 δ); tan δ = Z′ / Z″), are in a good agreement with the values of C m;CV and C CC only at very low ac frequency (f ≤ 1 mHz). C s weakly increases in the order 1 M Na2SO4 ≤ 1 M Rb2SO4 aqueous electrolyte-based supercapacitors. At higher frequency, there is a well-expressed dependence of C s or C p on f for the all electrolyte systems studied, caused by the faradic reactions as well as by the small ac penetration depth compared with the pore length.

It should be mentioned that the essential increase of the IR-drop inside of the microporous carbide-derived carbon electrode matrix, expressed as R s and R p (R s = Z′) and R p = R s (1 + 1/tan2 δ), with the increase of cycle number analysed, explained by the accumulation of gaseous products and electrodeposited non-conducting intermediates onto/into the electrode surface, has been observed for both electrolytes. However, the less-pronounced dependence of C s and R s on f (as well as C p and R p) and C p/C s ≈ 1.0 at f → 0 Hz for 1 M Rb2SO4 at ΔE = 1.0 V (Fig. 11a, b) indicates that for this electrolyte, the distances of the maximal approach of cations onto the Mo2C-CDC porous system are shorter and the quicker establishment of the adsorption equilibrium has been established at relatively moderate ac frequency (f low = 10 mHz). At f ≤ 1 mHz, the ratio of C p/C s is very close to unity which indicates that the blocking adsorption step-limited processes at Mo2C-CDC | 1 M Na2SO4 or 1 M Rb2SO4 + H2O interface are taking place at ΔE = 1.0 V. At ΔE = 2.0 V and f ≤ 1 mHz, C p/C s for the Na2SO4-based system is nearly 0.8 and, for Rb2SO4, lower R p/R s values at ΔE = 2.0 V differently from ΔE = 1.0 V have been calculated at f → 0, indicating that adsorption-limited faradic reduction processes are prevailing at the Rb2SO4-based supercapacitor. At f → 0, for the Rb2SO4-based system, somewhat higher increase of R p/R s has been observed explained by more effective surface blocking compared with the Na2SO4-based SC. However, more detailed time stability tests are inevitable for SC applications under development.

Conclusions

The analysis of impedance data demonstrates very complex kinetics behaviour of completed devices (adsorption and blocking adsorption, faradic, mass transfer, reduction of Na+ and Rb+ ions and intercalation, surface oxidation, gas adsorption, ionisation, etc.) at ΔE ≥ 1.5 V. At least four different characteristic time constants dependent on the electrolyte cation composition and cell potential applied have been calculated and discussed. Preliminary non-linear least squared fitting data show that low and high Rb2SO4-based system frequency inductive effect (characteristic of the decomposition of cell components) must be taken into account to have a reasonable fitting of calculated Nyquist plots with experimental data.

References

Conway BE (1999) Electrochemical supercapacitors: scientific fundamentals and technological applications. Kluwer Academic/Plenum Publishers, New York

Burke A (2000) J Power Sources 91:37–50

Kötz R, Carlen M (2000) Electrochim Acta 45:2483–2498

Chmiola J, Yushin G, Gogotsi Y, Portet C, Simon P, Taberna PL (2006) Science 313:1760–1763

Miller JR, Simon P (2008) Science 321:651–654

Simon P, Gogotsi Y (2008) Nat Mater 7:845–854

Salitra G, Soffer A, Eliad L, Cohen Y, Aurbach D (2000) J Electrochem Soc 147:2486–2493

Jänes A, Permann L, Arulepp M, Lust E (2004) Electrochem Commun 6:313–318

Jänes A, Kurig H, Lust E (2007) Carbon 45:1226–1233

Jänes A, Thomberg T, Lust E (2007) Carbon 45:2717–2722

Jänes A, Thomberg T, Kurig H, Lust E (2009) Carbon 47:23–29

Eliad, Salitra G, Soffer A, Aurbach D (2005) Langmuir 21:3198–3202

Wang Y, Chen KS, Mishler J, Cho SC, Adroher XC (2011) Appl Energy 88:981–1007

Carmo M, Fritz DL, Mergel J, Stolten D (2013) Int J Hydrogen Energy 38:4901–4934

Härk E, Nerut J, Vaarmets K, Tallo I, Kurig H, Eskusson J, Kontturi K, Lust E (2013) J Electroanal Chem 689:176–184

Lee HY, Goodenough JB (1999) J Solid State Chem 144:220–223

Portet C, Lillo-Ródenas MÁ, Linares-Solano A, Gogotsi Y (2009) Phys Chem Chem Phys 11:4943–4945

Roldan S, Villar I, Ruiz V, Blanco C, Granda M, Menendez R, Santamaria R (2010) Energy Fuels 24:3422–3428

Jänes A, Lust E (2006) J Electroanal Chem 588:285–295

Jänes A, Lust E (2006) J Electrochem Soc 153:A113–A116

Thomberg T, Jänes A, Lust E (2009) J Electroanal Chem 630:55–62

Lota G, Frackowiak E (2009) Electrochem Commun 11:87–90

Eskusson J, Jänes A, Kikas A, Matisen L, Lust E (2011) J Power Sources 196:4109–4116

Khomenko V, Raymundo-Piñero E, Béguin F (2010) J Power Sources 195:4234–4241

Bichat MP, Raymundo-Piñero E, Béguin F (2010) Carbon 48:4351–4361

Demarconnay L, Raymundo-Piñero E, Béguin F (2010) Electrochem Commun 12:1275–1278

Gao Q, Demarconnay L, Raymundo-Piñero E, Béguin F (2012) Energy Environ Sci 5:9611–9617

Damaskin BB, Petrii OA, Tsirlina G (2006) Electrochemistry. Khimia, Moscow

Frumkin AN (1987) Elektrodnye protsessy (The electrode processes). Nauka, Moscow

Conway BE (1965) Theory and principles of electrode processes. Ronald, New York

Trasatti S, Lust E, in White RE, Bockris J O’M, Conway BE (eds) (1999) Modern aspects of electrochemistry. vol 33 Kluwer Academic/Plenum Publishers, New York, p 1

Lust E, in: Bard JA, Stratman M (eds) (2002) Encyclopedia of electrochemistry, Wiley–VCH, Weinheim, pp 188–224

Frumkin AN, in: Yeager E (ed) (1961) Advances in electrochemistry and electrochemical engineering. New York, Wiley, pp 1-15

Frumkin AN (1965) J Electroanal Chem 9:173–183

Bian X, Scanlon MD, Wang S, Liao L, Tang Y, Liu B, Girault HH (2013) Chem Sci 4:1432–1441

Chizmadzhev YA, Chirkov YG, in: (Yaeger E, Bockris JOM, Conway BE . Sarangapani S (eds) (1983) Comprehensive treatise of electrochemistry. Plenum Press, New York, pp 317-91

Tõnisoo A, Kruusma J, Pärna R, Kikas A, Hirsimäki M, Nõmmiste E, Lust E (2013) J Electrochem Soc 160:A1084–A1093

Lust E, Jänes A, Sammelselg V, Miidla P (2000) Electrochim Acta 46:185–191

Lust E, Jänes A, Arulepp M (2004) J Solid State Electrochem 8:488–496

Jänes A, Permann L, Arulepp M, Lust E (2004) J Electroanal Chem 569:257–269

Nurk G, Jänes A, Lust K, Lust E (2001) J Electroanal Chem 515:17–32

Orazem ME, Pébère N, Tribollet B (2006) J Electrochem Soc 153:B129–B136

Lasia A (2006) J Electroanal Chem 593:159–166

Macdonald JR, Johnson WB (1987) Fundamentals of impedance spectroscopy. In: Macdonald JR (ed) Impedance spectroscopy. Wiley, New York, pp 1–26

Acknowledgments

This work was supported by the Estonian Science Foundation under Project No. 9184, Estonian Ministry of Education and Research project SF0180002s08, European Regional Development Fund Project SLOKT10209T, Estonian Centre of Excellence in Research Project TK117T “High-technology Materials for Sustainable Development” and Project IUT20-13.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jänes, A., Eskusson, J., Mattisen, L. et al. Electrochemical behaviour of hybrid devices based on Na2SO4 and Rb2SO4 neutral aqueous electrolytes and carbon electrodes within wide cell potential region. J Solid State Electrochem 19, 769–783 (2015). https://doi.org/10.1007/s10008-014-2668-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-014-2668-8