Abstract

A novel uric acid biosensor based on Fe3O4 nanoparticles (Fe3O4NPs) modified carbon paste electrode is described. Electron transfer characteristics of bare (CPE) and Fe3O4NP-modified carbon paste electrodes (Fe3O4/CPE) were studied by cyclic voltammetry and electrochemical impedance spectroscopy. The voltammetric study indicated that the incorporation of Fe3O4NPs into carbon paste increased the electroactive surface area of the electrode and improved electron transfer. Under the optimum working conditions, the purposed biosensor showed a linear response to uric acid from 0.16 mM to 2.11 mM with a detection limit of 0.08 mM. The biosensor exhibited high selectivity, good repeatability, reproducibility, and stability. Moreover, the construction and renewal procedure of the purposed biosensor is simple and inexpensive.

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Uric acid (C5H4N4O3) is one of the end products of purine metabolism in humans [1]. Normal level of uric acid in urine and serum is ranged from 1.4 to 4.4 mM and 0.24 to 0.52 mM, respectively [2]. Raised levels of uric acid in serum and urine are considered as a symptom of many diseases including gout, hyperuricemia, and kidney diseases. Thus, determination of uric acid levels in human physiological fluids is indispensable for the diagnosis of these disorders [3, 4]. Various techniques, including spectrophotometry, high-performance liquid chromatography, enzymatic test kits, capillary electrophoresis, and chemiluminescence were reported for uric acid determination in serum and urine [3, 5]. However, these techniques have disadvantages, such as long analysis times, time-consuming sample pretreatment steps, expensive equipment and they usually only focus on single detection [6]. Compared with these methods, electrochemical methods have advantages, such as simple instrumentation, high precision, direct measurement, and low cost [7].

One of the first electrochemical studies on uric acid, Wang and Freiha investigated electro-activity of pre-concentration uric acid. The electrode was immersed in uric acid solution for a given period time and then the differential pulse response was measured by taking it into the electrolytic solution. They said that the method can be used in the selective determination of uric acid with a flow injection system [8].

In recent years, modified electrodes have attracted great interest in electrochemistry [9]. Carbon paste electrodes are commonly used in electro-analysis due to their ease of fabrication and modification, low background current, chemical inertness, good reproducibility, and stability [10, 11]. Nanomaterial-modified CPEs have become an attractive field in biosensor research with their enhanced sensitivity, improved response signal, and better reproducibility [12, 13]. Metal oxide nanoparticles (MONPs), which are used to modify of electrode surface, have many advantages, such as a high ratio of surface area to volume, strong adsorption ability, and high surface reaction activity, and are also one of the most promising materials used in sensor design [14,15,16,17]. Among the various MONPs, magnetite nanoparticles (Fe3O4NPs) have become attractive because they possess unique catalytic, magnetic, and electrical properties and can be used in different fields, such as biomedical, environmental conversion, magnetic data storage [18, 19]. In literature, many studies have been reported based on the use of Fe3O4NPs for the fabrication of sensor and biosensors [12, 18, 20, 21].

Various study-based modified electrodes have been reported for uric acid detection in the literature [22,23,24]. Jirakunakorn et al. constructed amperometric biosensor using graphene incorporated chitosan on Prussia Blue layer-modified screen-printed electrode and determined uric acid in human serum samples [25]. Kanyong et al. modified the screen-printed electrode using uricase, polycarbonate membrane, and cobalt phthalocyanine and prepared a uric acid biosensor. They investigated the usability of the prepared biosensor by performing uric acid analysis in urine samples with chronoamperometric method [26]. Murugan et al. established the electrochemical determination of uric acid with exfoliated graphitic-like carbon nitride nanosheets modified glassy carbon electrode and have found used in food, medicine, and environmental applications [27].

Herein we report uric acid biosensor based on Fe3O4NPs and uricase (UOx)-modified CPE. UOx was immobilized using glutaraldehyde as cross-linking agent in Fe3O4NPs-modified carbon paste matrix. The morphology of Fe3O4/CPE was studied by scanning electron microscopy (SEM) and electrochemical properties of this electrode were characterized by CV and EIS. After the optimization of working conditions, performance characteristics of the resulting biosensor were determined.

Results and discussion

Characterization of bare and modified electrodes

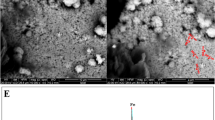

The morphology of electrode surfaces was evaluated by SEM. Figure 1 shows the SEM images of (A) CPE and (B) Fe3O4/CPE. As shown in Fig. 1a, an irregular structure was observed in SEM image of the CPE. On the SEM image of Fe3O4/CPE (Fig. 1b), Fe3O4NPs were completely mixed with graphite and a more homogeneous structure was observed compared to the bare carbon paste. However, any difference between the surface properties of the electrodes was not obviously visible. In addition to the SEM measurements, the energy-dispersive X-ray (EDX) spectra measurements of the modified and bare electrodes were also performed and compared (Fig. 1c and d). The presence of Fe3O4NPs in modified electrode was supported with the peaks of iron and oxygen in EDX spectra (Fig. 1d).

Electrochemistry of Fe(CN)64−/3− redox system is a suitable tool to observe the changes on electrode surface during the modification process [28]. Electrochemical characteristics of CPE and Fe3O4/CPE were investigated by CV and EIS in redox probe solution. Figure 2a shows that well-defined anodic and cathodic peaks were observed with CPE. After the modification process, peak currents of Fe3O4/CPE were significantly increased compared to CPE. Moreover, the presence of Fe3O4NPs increased current intensity and reduced peak-to-peak separation (Epa—Epc = ΔEp) for Fe(CN)6 4−/3− waves. ΔEp values of CPE and Fe3O4/CPE were found as − 0.290 V and − 0.221 V, respectively. The low ΔEp value of Fe3O4/CPE shows that the electron transfer at the electrode–solution interface is more rapid [29]. The Nyquist plots of EIS of CPE and Fe3O4/CPE surfaces are shown Fig. 2b. The diameter of the semi-circle portion observed at higher frequencies corresponds to the charge transfer resistance (Rct), that controls the electron transfer kinetics of the redox probe at the electrode interface [30, 31]. Our studies show that after the modification of carbon paste with Fe3O4NPs, the diameter of the semi-circle in Nyquist plot decreased (Fig. 2b), indicating that the Fe3O4NPs decrease the resistance of the electrode and possess higher electron transfer efficiency. EIS results confirmed what we obtained in CV.

Optimization of experimental variables and electrode composition

To find the best electrode response, the experimental variables and electrode composition were optimized in presence of 90.9 µM UA.

The amount of modification materials is an important factor on biosensor performance. To evaluate the influence of Fe3O4NPs amount on biosensor response, CPEs were prepared using different quantities of Fe3O4NPs ranging from 1.0 mg to 6.0 mg. The current difference increased as the Fe3O4NPs amount increased from 1.0 to 3.0 mg and then decreased (Fig. 3a). Maximum current difference was obtained with 3.0 mg Fe3O4NPs and this amount was used in all further experiments.

To determine the optimum enzyme loading for the fabrication of Fe3O4NPs-modified carbon paste uric acid biosensor, four different biosensors were fabricated using different enzyme amounts between 0.25 and 1.00 IU. Since maximum current difference was obtained at 0.75 IU (Fig. 3b), this amount was chosen as the optimum enzyme amount in all subsequent experiments.

The concentration of the buffer solution influences the response of a biosensor. Hence, the effect of buffer concentration was studied in various phosphate buffer concentrations (0.025 M—0.200 M) at + 0.50 V. Uric acid response of the biosensor increased gradually between 0.025 and 0.20 M and decreased after 0.10 M (Fig. 3c). The decrease in response currents at lower buffer concentrations than 0.10 M may be due to the poor buffering capacity of the solution. The decrease in the response currents observed above 0.10 M buffer concentrations can be attributed to the deterioration of carbon paste on the electrode surface. Best response was obtained at 0.10 M phosphate buffer and this value was selected as the optimum buffer concentration.

Enzyme activity is highly dependent on the pH of the sensing medium. Therefore, optimum working pH of a biosensor should be determined [30]. The pH dependence of the biosensor response was tested in the pH range of 6.5–8.5. Figure 3d indicates that the highest response was observed at pH 7.5. So, this value was selected as the optimum pH. Optimum pH for the free uricase was reported as 8.0 [28]. The optimum pH of the prepared biosensor is 0.5 unit less than the optimum pH of the free uricase. The change in optimum pH may be due to the immobilization method used or micro-environment of the enzyme.

The influence of working potential on biosensor response was studied at different potentials between + 0.10 V and + 0.70 V and maximum current difference was obtained at + 0.60 V. However, we have selected + 0.50 V as the working potential to minimize the interference effect of other species.

Performance parameters

The chronoamperometric response of UOx/Fe3O4/CPE was studied with successive addition of uric acid in 0.10 M pH 7.5 PBS (under stirring) at + 0.50 V (Fig. 4). The biosensor exhibited a linear response to uric acid in the range of 0.16–2.11 mM. The limit of detection (LOD) for the UOx/Fe3O4/CPE was calculated to be 0.08 mM (LOD = 3sb/m where sb is the standard deviation of the response and m is the slope of the calibration curve). The LOD of the UOx/Fe3O4/CPE is lower than that of the previously reported uric acid biosensors [32, 33].

The apparent Michaelis–Menten Constant (KM) which is a reflection of enzymatic affinity, can be evaluated using the Lineweaver–Burk equation:

where i corresponds to the current, imax corresponds to the maximum current obtained under saturated substrate condition and C corresponds to the substrate concentration [31]. The KM for UOx/Fe3O4/CPE was found as 6.31 mM.

The repeatability of the determination of using this biosensor was calculated by performing six consecutive measurements of 90 µM uric acid using the same biosensor and the relative standard deviation (RSD) of the current responses was found to be 4.94%. To investigate the selectivity of the UOx/Fe3O4/CPE, the effect of some common interfering substances, such as urea, glucose, and ascorbic acid, on biosensor response was studied at constant uric acid concentration. Urea, glucose, and ascorbic acid did not significantly change the current response of the biosensor. It can be concluded that the interfering effect of these substances is negligible and the biosensor exhibits high selectivity to uric acid.

Conclusion

In this study, we have developed an amperometric uric acid biosensor using Fe3O4 nanoparticles and uricase enzyme. The cost of the biosensor is low and its fabrication process is very simple. This uric acid biosensor has lower detection limit [33, 34] and high sensitivity [32, 34] when compared with other uric acid sensor previously reported in literature. Moreover, UOx/Fe3O4/CPE exhibits high performance for electrochemical uric acid determination and is promising for analytical applications in real samples. Hence, our future study will be focused on the use of the UOx/Fe3O4/CPE for uric acid determination in real samples.

Experimental

CHI 6032D electrochemical analyzer (CH Instruments, USA) was utilized for the electrochemical measurements. A traditional three-electrode system, comprising a modified CPE as the working electrode, a saturated Ag/AgCl electrode (CHI 111) as the reference electrode, and platinum wire (CHI 115) as the counter electrode, was used. VWR 1100L pH meter and VWR combined pH electrode were used to measure the pH values of the solutions. All aqueous solutions were prepared with deionized water obtained from Millipore Milli-Q Plus water purification system. UOx (E.C. 1.7.3.3 18 International Units/mg from Arthrobacter globiformis), uric acid (≥ 99%) and Fe3O4NPs were from Sigma-Aldrich. Sodium dihydrogen phosphate monohydrate (99–102%), disodium hydrogenphosphate dihydrate (99.5%), potassium hexacyanoferrate(III) (≥ 99%), and potassium hexacyanoferrate (II) trihydrate (≥ 99%) were bought from Merck. Ascorbic acid (99.9%), glucose, and urea were supplied from VWR BDH Prolabo. Standard uric acid solution was prepared daily by dissolving uric acid in 4% Li2CO3 aqueous solution.

Fabrication of bare and modified carbon paste electrodes

Fe3O4/CPE was prepared in a traditional way by hand-mixing 3.0 mg Fe3O4NPs with 27.0 mg graphite powder and 10 mm3 paraffin oil in a mortar. The bare carbon paste was prepared in the same way without adding Fe3O4NPs to the mixture. To fabricate the Fe3O4NPs and enzyme-modified electrode (UOx/Fe3O4/CPE), enzyme solution (10 mm3 UOx (0.75 U), 1.5 mg BSA, and 10 mm3 2.5% glutaraldehyde) was added to the Fe3O4NPs–graphite mixture and thoroughly hand-mixed for 20 min. 10 mm3 of paraffin oil was pipetted into the mixture and mixed well for 20 min to obtain a uniformly wetted paste. In all cases, carbon paste was packed into the electrode body (BAS MP 5023) and smoothed on a weighing paper until a shiny surface was obtained. CPEs were washed with distillated water between the measurements and stored at + 4 ℃ when not in use.

Electrochemical measurement

Electrochemical properties of the modified and bare CPEs were studied by CV and EIS in redox probe solution (Fe(CN)63−/4−) containing 0.1 M KCl. Under the optimum experimental conditions, uric acid response of the biosensor was measured by chronoamperometry at + 0.50 V. All measurements were carried out in pH 7.5, 0.10 M phosphate buffer solution (PBS) at room temperature (23 ± 2 ℃).

References

Huang SH, Shih YC, Wu CY, Yuan CJ, Yang YS, Li YK, Wu TK (2004) Biosens Bioelectron 19:1627

Lu HF, Li JY, Zhang MM, Wu D, Zhang QL (2017) Sens Actuators B 244:77

Erden PE, Kılıç E (2013) Talanta 107:312

Kannan A, Sivanesan A, Kalaivani G, Manivel A, Sevvel R (2016) RSC Adv 6:96898

Arora J, Nandwani S, Bhambi M, Pundir CS (2009) Anal Chim Acta 647:195

Yu H-W, Jiang J-H, Zhang Z, Wan G-C, Liu Z-Y, Chang D, Pan H-Z (2017) Anal Biochem 519:92

Nigovic B, Milanovic I (2017) Anal Sci 33:1219

Wang J, Freiha BA (1984) Bioelectrochem Bioenerg 12:225

Shahrokhian S, Hafezi-Kahnamouei M (2018) J Electroanal Chem 825:30

Jayaprakash GK, Swamy BEK, Sanchez JPM, Li X, Sharma SC, Lee SL (2020) J Mol Liq 315:113719

Sroysee W, Chairam S, Amatatongchai M, Jarujamrus P, Tamuang S, Pimmongkol S, Chaicharoenwimolkul L, Somsook E (2018) J Saudi Chem Soc 22:173

Jahanbani S, Benvidi A (2016) Biosens Bioelectron 85:553

Kingsley MP, Desai PB, Srivastava AK (2015) J Electroanal Chem 741:71

Hazer DB, Hazer B (2011) J Polym Res 18:251

Hazer DB, Hazer B, Dinçer N (2011) J Biomed Biotechnol 2011:7

Hazer DB, Mut M, Dinçer N, Saribas Z, Hazer B, Özgen T (2012) Child’s Nerv Syst 28:839

Kilic MS, Korkut S, Hazer B, Erhan E (2014) Biosens Bioelectron 61:500

Al-Zahrani E, Soomro MT, Bashami RM, Rehman AU, Danish E, Ismail IMI, Aslam M, Hameed A (2016) J Environ Chem Eng 4:4330

Dresco PA, Zaitsev VS, Gambino RJ, Chu B (1999) Langmuir 15:1945

Gholivand MB, Torkashvand M, Yavari E (2015) Mater Sci Eng C 48:235

Tammari E, Nezhadali A, Lotfi S, Veisi H (2017) Sens Actuators B 241:879

Niu X, Li X, Chen W, Li X, Weng W, Yin C, Dong R, Sun W, Li G (2018) Mater Sci Eng C 89:230

Sha R, Vishnu N, Badhulika S (2019) Sens Actuators B 279:53

Verma S, Choudhary J, Singh KP, Chandra P, Singh SP (2019) Int J Biol Macromol 130:333

Jirakunakorn R, Khumngern S, Choosang J, Thavarungkul P, Kanatharana P, Numnuam A (2020) Microchem J 154:104624

Kanyong P, Pemberton RM, Jackson SK, Hart JP (2012) Anal Biochem 428:36

Murugan N, Chan-Park MB, Sundramoorthy AK (2019) J Electrochem Sci 166:3163

Rawal R, Chawla S, Chauhan N, Dahiya T, Pundir CS (2012) Int J Biol Macromol 50:112

Erden PE, Zeybek B, Pekyardimci Ş, Kilic E (2013) Artif Cells Nanomed Biotechnol 41:165

Liu Y, Yuan M, Liu L, Guo R (2013) Sens Actuators B 176:592

Wang J (2000) Analytical Electrochemistry, 2nd edn. John Wiley and Sons Inc, New York

Pemberton RM, Jackson SK, Hart JP (2012) Anal Biochem 428:39

Azmi NE, Ramli NI, Abdullah J, Hamid MAA, Sidek H, Rahman SA, Ariffin N, Yusof NA (2015) Biosens Bioelectron 67:129

Ali M, Shah I, Kim SW, Sajid M, Lim JH, Choi KH (2018) Sens Actuators 283:282

Acknowledgements

This work is supported by Selcuk University Scientific Project (Project no: 12201026).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Erdogan, Z.O., Kucukkolbası, S. Fabrication of an electrochemical biosensor based on Fe3O4 nanoparticles and uricase modified carbon paste electrode for uric acid determination. Monatsh Chem 152, 309–314 (2021). https://doi.org/10.1007/s00706-021-02749-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-021-02749-z