Abstract

An eco-friendly and efficient synthesis of substituted 1,3,4-thiadiazole derivatives has been developed. This aqueous heterogeneous approach proceeds smoothly and quickly under combined microwave and ultrasound irradiation in the presence of FeCl3.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The concept of “ideal chemistry” has been widely adopted to meet the fundamental scientific principles of protecting human health and the environment while simultaneously achieving commercial value [1]. In this regard, the replacement of organic solvents is one of the most important goals. Although an ideal and universal green solvent for all problems does not exist, water is a widely explored green solvent [2–4]. Clearly, the development of a sustainable approach for synthesizing biologically active molecules is very important. In this field, combined microwave and ultrasound irradiation has proven to be a powerful tool for both speeding up chemical optimizations and for efficiently preparing new compounds [5–10].

Over the years, heterocycles have become important synthetic intermediates that have found a variety of applications in medicinal, agricultural, and materials chemistry [11–13]. Although many important types of heterocyclic compounds have been synthesized in aqueous media [14–20], the synthesis of new and important types of heterocyclic compounds in water still attracts wide attention. 1,3,4-Thiadiazoles are very important heterocycles with great applicability in medicinal chemistry, agrochemistry, and so on. This core structure can be found in compounds with wide-ranging biological applications [21–27]. The literature reveals that most traditional synthetic methods for the synthesis of 1,3,4-thiadiazole derivatives suffer from one or more drawbacks, such as laborious work-up, strongly acidic conditions, low yields, and the use of organic solvents [28–32]. As part of our continued interest in the application of combined microwave and ultrasound irradiation (CMUI)-assisted heterogeneous reactions [33–35], we here report a mild, efficient, and environmentally benign approach for the synthesis of substituted 1,3,4-thiadiazoles via intramolecular cyclization or the three-component reaction of an aldehyde, a phenylisothiocyanate, and hydrazine hydrate under CMUI in a heterogeneous aqueous medium.

Results and discussion

In our initial study, we employed 1-benzylidenethiosemicarbazide (1a) as a model substrate in combination with 3 equiv. of FeCl3 to evaluate the efficiency of microwave and ultrasound irradiation (Table 1, entries 1–3). The results showed that a combination of microwave irradiation at 200 W and ultrasound irradiation at 50 W gave the highest yield after 3 min (Table 1, entry 1). Several control experiments were carried out in order to demonstrate the superiority of CMUI over other methods (Table 1, entries 1, 4–6). The results clearly show that CMUI achieved the best results in terms of both reaction time and yield. This drastic acceleration effect may be attributed to a combination of enforced heat transfer due to microwave irradiation and intensive mass transfer at phase interfaces caused by sonication. Regarding the concentrations of FeCl3, we found that lower yields were obtained when using less than 3 equiv. of FeCl3 (Table 1, entries 7, 8). As a compromise between eco-efficiency and yield, 2 equiv. of FeCl3 were adopted for further elaboration. The desired 5-phenyl-1,3,4-thiadiazol-2-amine (2a) was obtained in 82 % yield after an increased irradiation time of 4 min (Table 1, entry 9), while reducing the irradiation time to 2 min resulted in a decreased yield of 56 % (Table 1, entry 10).

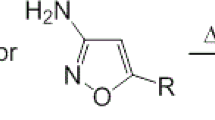

Having identified the optimal conditions (Table 1, entry 7), we next investigated the scope and limitation of the process with variously substituted 1-benzylidenethiosemicarbazides 1 (Table 2). Both electron-withdrawing (Table 2, entries 2–5) and electron-donating (Table 2, entries 6–8) groups were well tolerated, although a slightly lower yield was obtained with a para-methyl substituent (Table 2, entry 6).

Considering that Schiff bases with heterocycles express biological activities [36, 37], we next evaluated the scope of the CMUI technology for the synthesis of 5-aryl-N-arylidene-1,3,4-thiadiazol-2-amines 4 employing a variety of 5-substituted 1,3,4-thiadiazol-2-amines 2 in combination with 4-hydroxybenzaldehyde (3, Table 3). The result showed that the 1,3,4-thiadiazol-2-amines 2 with electron-donating groups reacted rapidly and gave a high yield of 4 (Table 3, entries 6–8), while those with electron-withdrawing groups required longer reaction times and gave lower yields (Table 3, entries 2–5). Interestingly, when the 1,3,4-thiadiazol-2-amines 2c and 2e were used, increased yields of the desired compounds 4c and 4e were obtained when 2 mol % of concentrated hydrochloric acid was added as a catalyst.

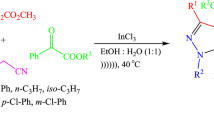

Encouraged by these results, we tried to explore the CMUI approach for synthesizing other substituted 1,3,4-thiadiazoles. Based on the literature [38–41], we found that 1,3,4-thiadiazoles could be obtained via a one-pot three-component reaction of an aldehyde, a phenylisothiocyanate, and hydrazine hydrate in water under CMUI (Table 4). Therefore, we next investigated the application of our previous protocol applying a variety of aldehydes 5 containing electron-withdrawing (Table 4, entries 2–5) or electron-donating (Table 4, entries 6–13) substituents. To our satisfaction, all reactions worked well and provided the desired products 8a–8m in good yields.

In conclusion, we have developed an efficient, simple, and green procedure for the synthesis of 5-aryl-N-arylidene-1,3,4-thiadiazol-2-amines and 5-aryl-N-phenyl-1,3,4-thiadiazol-2-amines employing a FeCl3-promoted process under combined microwave and ultrasound irradiation (CMUI) in water. The CMUI provides extremely efficient dielectric heating along with intensive mass transport in these heterogeneous systems, making it an excellent approach for achieving environmentally friendly and efficient organic synthesis.

Experimental

All solvents and reagents were purchased from commercial sources and were used without prior purification. All combined microwave and ultrasound irradiation experiments were carried out in a professional TCMC-102 microwave apparatus (Nanjing Lingjiang Technological Development Company, Nanjing, China) operating at a frequency of 2.45 GHz with continuous irradiation power from 0.0 to 500 W, and a FS-250 professional ultrasound apparatus (Shanghai S.X. Ultrasonics, Shanghai, China) operating at a frequency of 20 kHz with controllable irradiation power from 10 to 100 W. The reactions were carried out in a 15 cm3 two-necked Pyrex flask placed in the microwave cavity with the tip of the detachable horn immersed just under the liquid surface. TLC analysis was performed on aluminum-backed plates SIL G/UV254. The products were purified by filtration and were identified by 1H NMR (DMSO-d 6, 400 MHz) and MS (EI). All new products were identified by 1H and 13C NMR (DMSO-d 6, 400 MHz) and high-resolution mass spectra (EI). Melting points were measured with a digital melting-point apparatus (WRR, Shanghai Precision and Scientific Instruments, Shanghai, China).

General experimental procedure for the synthesis of 5-aryl-1,3,4-thiadiazol-2-amines 2

A mixture of 1-arylidenethiosemicarbazide 1 (1 mmol), FeCl3 (2 mmol), and 6 cm3 water was subjected to microwave–ultrasound activation conditions. The ultrasound and microwave sources were switched on successively (power levels: ultrasound 50 W, microwave 200 W). The mixture was irradiated simultaneously with microwaves and ultrasound for 3 min. The suspension was filtered and the residue was washed with water and ethanol, after which the residue was recrystallized from ethanol and dried under vacuum to obtain the products 2.

General experimental procedure for the synthesis of 5-aryl-N-arylidene-1,3,4-thiadiazol-2-amines 4

A mixture of 5-aryl-1,3,4-thiadiazol-2-amines 2 (1 mmol), 4-hydroxy-benzaldehyde 3 (1 mmol), and 6 cm3 water was subjected to microwave-ultrasound activation conditions. The ultrasound and microwave sources were switched on successively (power level: ultrasound 50 W, microwave 200 W). The mixture was irradiated simultaneously with microwaves and ultrasound for 3 min. The suspension was filtered and the residue was washed with water and ethanol, after which the residue was recrystallized from ethanol and dried under vacuum to obtain the products 4.

4-[[5-(4-Fluorophenyl)-1,3,4-thiadiazol-2-ylimino]methyl]phenol (4b, C15H10FN3OS)

Yellow solid; m.p.: 261.2–262.0 °C; 1H NMR (400 MHz, DMSO-d 6): δ = 6.94 (d, J = 8.4 Hz, 2H), 7.41 (t, J = 8.4 Hz, 2H), 7.93 (d, J = 8.8 Hz, 2H), 8.00–8.03 (m, 2H), 8.88 (s, 1H), 10.63 (s, 1H) ppm; 13C NMR (100 MHz, DMSO-d 6): δ = 116.7, 117.2, 126.2, 127.3, 130.2, 133.2, 163.5, 164.5, 165.4, 169.1, 174.8 ppm; HRMS (EI): m/z calc’d for C15H10FN3OS (M + H) 299.0529, found 299.0529.

4-[[5-(4-Chlorophenyl)-1,3,4-thiadiazol-2-ylimino]methyl]phenol (4d, C15H10ClN3OS)

Yellow solid; m.p.: 251.3–252.4 °C; 1H NMR (400 MHz, DMSO-d 6): δ = 6.94 (d, J = 8.4 Hz, 2H), 7.63 (d, J = 8.4 Hz, 2H), 7.93 (d, J = 8.8 Hz, 2H), 7.98 (d, J = 8.4 Hz, 2H), 8.89 (s, 1H), 10.65 (s, 1H) ppm; 13C NMR (100 MHz, DMSO-d 6): δ = 116.3, 126.2, 128.4, 130.0, 133.3, 134.4, 136.3, 163.8, 164.5, 169.2, 175.0 ppm; HRMS (EI): m/z calc’d for C15H10ClN3OS (M + H) 315.0233, found 315.0236.

4-[[5-(2,4-Dichlorophenyl)-1,3,4-thiadiazol-2-ylimino]methyl]phenol (4e, C15H9Cl2N3OS)

Yellow solid; m.p.: 255.1–256.6 °C; 1H NMR (400 MHz, DMSO-d 6): δ = 6.95 (d, J = 8.8 Hz, 2H), 7.65 (m, 1H), 7.92–7.95 (m, 3H), 8.21 (d, J = 8.4 Hz, 1H), 8.96 (s, 1H), 10.64 (s, 1H) ppm; 13C NMR (100 MHz, DMSO-d 6): δ = 116.7, 126.3, 128.8, 130.7, 132.7, 132.3, 133.3, 135.0, 136.6, 156.0, 163.6, 169.4, 176.3 ppm; HRMS (EI): m/z calc’d for C15H9Cl2N3OS (M + H) 348.9842, found 348.9848.

4-[[5-(4-Methylphenyl)-1,3,4-thiadiazol-2-ylimino]methyl]phenol (4f, C16H13N3OS)

Yellow solid; m.p.: 249.7–250.8 °C; 1H NMR (400 MHz, DMSO-d 6): δ = 2.38 (s, 3H), 6.94 (d, J = 8.4 Hz, 2H), 7.37 (d, J = 8.0 Hz, 2H), 7.84 (d, J = 8.0 Hz, 2H), 7.92 (d, J = 8.4 Hz, 2H), 8.87 (s, 1H), 10.62 (s, 1H) ppm; 13C NMR (100 MHz, DMSO-d 6): δ = 21.8, 116.7, 126.3, 127.6, 127.9, 130.5, 133.1, 141.8, 163.4, 165.7, 168.9, 174.3 ppm; HRMS (EI): m/z calc’d for C16H13N3OS (M + H) 295.0779, found 295.0760.

4-[[5-(Benzo[d][1,3]dioxol-5-yl)-1,3,4-thiadiazol-2-ylimino]methyl]phenol (4 h, C16H11N3O3S)

Yellow solid; m.p.: 250.2–251.1 °C; 1H NMR (400 MHz, DMSO-d 6): δ = 6.15 (s, 2H), 6.94 (d, J = 8.8 Hz, 2H), 7.09 (d, J = 8.0 Hz, 1H), 7.46 (m, 1H), 7.51 (d, J = 8.2 Hz, 1H), 7.92 (d, J = 8.4 Hz, 2H), 8.85 (s, 1H), 10.60 (s, 1H) ppm; 13C NMR (100 MHz, DMSO-d 6): δ = 102.5, 107.1, 109.5, 116.7, 123.0, 124.6, 126.3, 133.1, 148.7, 150.3, 163.4, 165.3, 168.7, 174.1 ppm; HRMS (EI): m/z calc’d for C16H11N3O3S (M + H) 325.0521, found 325.0513.

General experimental procedure for the synthesis of 5-aryl-N-phenyl-1,3,4-thiadiazol-2-amines 8

A mixture of aldehyde 5 (1 mmol), hydrazine hydrate 6 (1 mmol), phenylisothiocyanate 7 (1 mmol), FeCl3 (2 mmol), and 6 cm3 water was subjected to microwave–ultrasound activation conditions. The ultrasound and microwave sources were switched on successively (power levels: ultrasound 50 W, microwave 200 W). The mixture was irradiated simultaneously by microwaves and ultrasound for 3 min. The suspension was filtered and the residue was washed with water and ethanol, after which the residue was recrystallized from ethanol and dried under vacuum to obtain the products 8.

4-[5-(Phenylamino)-1,3,4-thiadiazol-2-yl]benzonitrile (8b, C15H10N4S)

Light yellow solid; m.p.: 242.3– 243.5 °C; 1H NMR (400 MHz, DMSO-d 6): δ = 7.06 (t, J = 7.2 Hz, 1H), 7.39 (t, J = 7.6 Hz, 2H), 7.67 (d, J = 7.9 Hz, 2H), 7.98 (d, J = 8.7 Hz, 2H), 8.05 (d, J = 8.3 Hz, 2H), 10.71 (br s, 1H) ppm; 13C NMR (100 MHz, DMSO-d 6): δ = 112.6, 118.1, 122.8, 127.8, 129.6, 133.6, 140.6, 156.4, 165.5 ppm; HRMS (EI): m/z calc’d for C15H10N4S (M + H) 278.0626, found 278.0623.

5-(3-Fluorophenyl)-N-phenyl-1,3,4-thiadiazol-2-amine (8e, C14H10FN3S)

White solid; m.p.: 212.2–213.8 °C; 1H NMR (400 MHz, DMSO-d 6): δ = 7.03 (t, J = 7.0 Hz, 1H), 7.34–7.37 (m, 4H), 7.65 (d, J = 8.1 Hz, 2H), 7.93 (t, J = 6.4 Hz, 2H), 10.54 (br s, 1H) ppm; 13C NMR (100 MHz, DMSO-d 6): δ = 117.0, 117.9, 122.6, 127.4, 129.6, 140.8, 156.9, 162.2, 164.5 ppm; HRMS (EI): m/z calc’d for C14H10FN3S (M + H) 271.0579, found 271.0577.

N-Phenyl-5-[3-(trifluoromethoxy)phenyl]-1,3,4-thiadiazol-2-amine (8f, C15H10F3N3OS)

White solid; m.p.: 193.8–195.6 °C; 1H NMR (400 MHz, DMSO-d 6): δ = 7.04 (t, J = 7.0 Hz, 1H), 7.38 (t, J = 7.6 Hz, 2H), 7.51 (d, J = 9.3 Hz, 2H), 7.66 (d, J = 8.1 Hz, 2H), 8.01 (d, J = 9.3 Hz, 2H), 10.58 (br s, 1H) ppm; 13C NMR (100 MHz, DMSO-d 6): δ = 118.1, 122.2, 122.7, 129.2, 129.6, 130.0, 140.8, 149.7, 156.5, 164.9 ppm; HRMS (EI): m/z calc’d for C15H10F3N3OS (M + H) 337.0497, found 337.0490.

5-(3,5-Dimethoxyphenyl)-N-phenyl-1,3,4-thiadiazol-2-amine (8 h, C16H15N3O2S)

White solid; m.p.: 192.3–194.2 °C; 1H NMR (400 MHz, DMSO-d 6): δ = 3.82 (s, 6H), 6.64 (s, 1H), 6.98–7.05 (m, 3H), 7.37 (t, J = 7.0 Hz, 2H), 7.64 (d, J = 8.1 Hz, 2H) ppm; 13C NMR (100 MHz, DMSO-d 6): δ = 56.0, 102.6, 105.2, 117.9, 122.6, 129.6, 132.5, 140.8, 157.9, 161.3, 164.5 ppm; HRMS (EI): m/z calc’d for C16H15N3O2S (M + H) 313.0885, found 313.0880.

5-(4-Isopropylphenyl)-N-phenyl-1,3,4-thiadiazol-2-amine (8k, C17H17N3S)

White solid; m.p.: 178.2–180.0 °C; 1H NMR (400 MHz, DMSO-d 6): δ = 1.23 (d, J = 6.8 Hz, 6H), 2.91–2.98 (m, 1H), 7.02 (t, J = 7.2 Hz, 1H), 7.37 (t, J = 8.6 Hz, 4H), 7.66 (d, J = 8.0 Hz, 2H), 7.77 (d, J = 8.0 Hz, 2H), 10.50 (br s, 1H) ppm; 13C NMR (100 MHz, DMSO-d 6): δ = 24.1, 33.6, 117.9, 122.4, 127.3, 127.6, 128.5, 129.6, 140.8, 151.2, 158.1, 164.1 ppm; HRMS (EI): m/z calc’d for C17H17N3S (M + H) 295.1143, found 295.1140.

References

Anastas PT, Warner JC (1998) Green chemistry: theory and practice. Oxford University Press, Oxford

Li CJ (2005) Chem Rev 105:3095

Li CJ (2008) Green Chem 10:151

Sheldon RA (2005) Green Chem 7:267

Dallinger D, Kappe CO (2007) Chem Rev 107:2563

Appukkuttan P, Mehta VP, Van der Eycken EV (2010) Chem Soc Rev 39:1467

Kappe CO, Van der Eycken EV (2010) Chem Soc Rev 39:1280

Cravotto G, Cintas P (2006) Chem Soc Rev 35:180

Cravotto G, Cintas P (2007) Chem Eur J 13:1902

Mason TJ (1997) Chem Soc Rev 26:443

Martins MAP, Frizzo CP, Moreira DN, Zanatta N, Bonacorso HG (2008) Chem Rev 108:2015

Candeias NR, Branco LC, Gois PMP, Afonso CAM, Trindade AF (2009) Chem Rev 109:2703

Martins MAP, Frizzo CP, Moreira DN, Buriol L, Machado P (2009) Chem Rev 109:4140

Peng YQ, Dou RL, Song GH (2006) Green Chem 8:573

Molteni V, Hamilton MM, Mao L, Crane CM, Termin AP, Wilson DM (2002) Synthesis 1669

Tu SJ, Zhang Y, Jiang H, Jiang B, Zhang JU, Zhang JY, Jia RH, Shi F (2007) Eur J Org Chem 73:1522

Cho CS, Kim JS, Oh BH, Kim TJ, Shim SC, Yoon NS (2000) Tetrahedron 56:7747

Cao H, Wang X, Jiang H, Zhu Q, Zhang M, Liu H (2008) Chem Eur J 14:11623

Totlani VM, Peterson DG (2005) J Agric Food Chem 53:4130

Bose DS, Fatima L, Mereyala HB (2003) J Org Chem 68:587

Rajak H, Agarawal A, Parmar P, Thakur BS, Veerasamy R, Sharma PC, Kharya MD (2011) Bioorg Med Chem Lett 21:5735

Han F, Wan R, Wang Y, Wang P, Wang JT (2010) Youji Huaxue 30:132

Chai B, Cao S, Wu Q, Song GH, Qian XH (2003) Yingyong Huaxue 20:811

Rollas S, Kandemirli K, Shvets N, Dimoglo AS (2004) J Med Chem 47:6760

Carvalho SA, Silva EFD, Santa-Rita RM, Castrod SLD, Fraga CAM (2004) Bioorg Med Chem Lett 14:5967

Jatav V, Mishra P, Kashaw S, Stables JP (2008) Eur J Med Chem 43:135

T Nalan, G Aysel (2004) J Med Chem 47:6760

Pattan SR, Kittur BS, Sastry BS, Jadav SG, Thakur DK, Madamwar SA, Shinde HV (2011) Indian J Chem Section B 50B:615

Bernstein J, Yale HL, Losee K, Holsing M, Martins J, Lott WA (1951) J Am Chem Soc 73:906

Kumar D, Vaddula BR, Chang KH, Shah K (2011) Bioorg Med Chem Lett 21:2320

Kumar V, Singh P (2010) Asian J Chem 22:6829

Mishra RM, Singh DV, Wahab A, Mishra AR (2004) Pestic Res J 16:7

Giri S, Singh H (1966) J Indian Chem Soc 43:281

Peng YQ, Song GH (2002) Green Chem 4:349

Peng YQ, Song GH (2003) Green Chem 5:704

Feng HD, Li Y, Van der Eycken EV, Peng YQ, Song GH (2012) Tetrahedron Lett 53:1160

Supuranl CT, Popescu A, Ilisiu M, Costandachez A, Banciuz MD (1996) Eur J Med Chem 31:439

Chohan ZH, Pervez H, Rauf A, Andrea S, Supuran CT (2002) J Enzym Inhib Med Chem 17:117

Bonizzoni M, Fabbrizzi L, Taglietti A (2006) Eur J Org Chem 3567

Rostamizadeh S, Aryan R, Ghaieni HR (2008) Heteroatom Chem 19:320

Shelke S, Mhaske G, Gadakh S, Gill C (2010) Bioorg Med Chem Lett 20:7200

Hussein AQ, El-Abadelah MM, Nazer MZ, Awadallah AM, Rademacher P, Bandmann H (1994) Heterocycles 38:981

Dutta MM, Goswami BN, Kataky JCS (1987) J Indian Chem Soc 64:195

Efimova YA, Karabanovich GG, Artamonova TV, Koldobskii GI (2009) Russ J Org Chem 45:631

Liu ZX, Song ZS, Zhao JL, Zheng JY (2010) Phosphorus Sulfur Silicon Relat Elem 185:2375

Sharabasappa S, Bhat KI, Jalihal PC, Kilarimath B (2009) J Chem Pharm Sci 2:141

Acknowledgments

Financial support for this work from the NSFC (grant 20972052), the National Basic Research Program of China (973 Program) (grant 2010CB126101), and the Shanghai Leading Academic Discipline Project (project number: B507) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feng, H., Ying, X., Peng, Y. et al. FeCl3-promoted synthesis of 1,3,4-thiadiazoles under combined microwave and ultrasound irradiation in water. Monatsh Chem 144, 681–686 (2013). https://doi.org/10.1007/s00706-012-0846-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-012-0846-x