Abstract

HBF4/SiO2 was used as an efficient, green, and inexpensive catalytic system for synthesis of 12-aryl or 12-alkyl-8,9,10,12-tetrahydro-11H-benzo[a]xanthen-11-one derivatives via a one-pot three-component reaction of aldehydes, 2-naphthol, and cyclic 1,3-dicarbonyl compounds. The reactions proceeded rapidly at 80 °C under solvent-free conditions and the desired products were obtained in good to excellent yields.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

With increasing environmental concerns, the development of clean synthetic procedures has become crucial and demanding research. In this sense, heterogeneous organic reactions have many advantages, for example ease of handling, separation, and recycling, low corrosion, and environmentally safe disposal [1]. Multi-component reactions enable the creation of complicated molecules using only one process in a very fast, efficient, and raw materials and time-saving manner [2]. In addition, solvent-free conditions make synthesis simpler, save energy, and prevent solvent waste, hazards, and toxicity [3–5]. It therefore remains a challenge to develop multi-component reactions with a suitable heterogeneous catalysts and the use of solvent-free conditions.

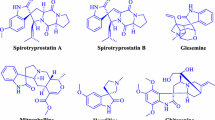

Xanthenes are an important class of compounds with remarkable biological and medicinal properties, for example antibacterial, antiviral, and anti-inflammatory activity [6–9]. Furthermore, they are used as dyes, pH-sensitive fluorescent materials, and in laser technologies [10–12]. Among this class of molecules, xanthone is a prominent structural motif found in numerous natural products and synthetic compounds with important biological activity [13–17]. Recently, methodology for synthesis of 12-aryl- or 12-alkyl-8,9,10,12-tetrahydro-11H-benzo[a]xanthen-11-one derivatives by condensation of aldehydes, 2-naphthol, and cyclic 1,3-dicarbonyl compounds in the presence of NaHSO4·SiO2 in 1,2-dichloroethane under reflux has been described [18]. However, this procedure also is limited in scope, because of relatively long reaction times and the use of a harmful volatile organic solvent. As a consequence, the development of an environmentally benign practical procedure for accessing these xanthones remains an elusive goal.

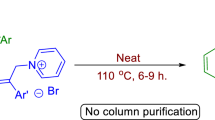

The use of silica-supported HBF4 (HBF4/SiO2) as a heterogeneous catalytic system to promote various transformations is well documented in the literature [19–24]. In particular, HBF4/SiO2 has been found to catalyze efficiently thia-Michael additions to α,β-unsaturated carbonyl compounds [25], Mannich-type reactions [26], and the synthesis of 1,5-benzodiazepines [27] and 14-aryl-14H-dibenzo[a,j]xanthene derivatives [28]. Considering these topics and our ongoing project on developing several catalytic systems for organic reactions [29–39], we now report a highly efficient procedure for preparation of 12-aryl- or 12-alkyl-8,9,10,12-tetrahydro-11H-benzo[a]xanthen-11-one derivatives via a one-pot three-component reaction of aldehydes, 2-naphthol, and cyclic 1,3-dicarbonyl compounds in the presence of HBF4/SiO2 under solvent-free conditions (Scheme 1).

Results and discussion

We started our study by examining the reaction of 4-chlorobenzaldehyde (2m), 2-naphthol (1), and 5,5-dimethyl-1,3-cyclohexanedione. After initial screening of amounts of HBF4/SiO2, solvents, and reaction temperatures, we found that use of 10 mol% HBF4/SiO2 at 80 °C under solvent-free conditions produced 12-(4-chlorophenyl)-9,9-dimethyl-8,9,10,12-tetrahydro-11H-benzo[a]xanthen-11-one (4m), after 1 h, in 95% yield. Notably, the desired product could not be obtained under similar reaction conditions, even after a long time (2 h) in the absence of the catalyst. This method is superior to available methods with regard to yield and reaction time [18].

To explore the scope and limitations of the procedure, a number of aldehydes were examined under the optimized conditions. As shown in Table 1, aromatic aldehydes substituted with an electron-withdrawing group or an electron-donating group were transformed into the corresponding xanthones in good to excellent yields. Moreover, it was observed that aliphatic aldehydes were viable substrates, although long reaction times were required for slightly lower yields. The products obtained were characterized by IR and 1H NMR spectroscopy; the results were in agreement with those published in the literature [18, 41].

In order to check the recyclability of the catalyst after completion of the reaction, the reaction mixture was dissolved in ethyl acetate and the catalyst was recovered after filtration. The recovered catalyst was reused again for the synthesis of 4m. The reaction was found to proceed smoothly and afforded comparable yields of 93, 92, 92, and 90%, confirming the recyclability and reusability of the catalyst in this reaction.

In conclusion, we have introduced a new catalyst system for synthesis of various xanthone derivatives via one-pot three-component reaction of aldehydes, 2-naphthol, and cyclic 1,3-dicarbonyl compounds. Advantages of our procedure include simplicity of operation, high yields of products, short reaction time, solvent-free conditions, and the use of an inexpensive and readily available catalyst.

Experimental

Melting points were determined on an X-4 apparatus. IR spectra were obtained using a Shimadzu FTIR-8900 spectrometer. 1H NMR spectra were recorded with a Varian Mercury Plus 400 spectrometer using TMS as internal standard. Elemental analysis was performed on a Vario EL III CHNOS elemental analyzer and the results obtained agreed favorably with calculated values.

Representative procedure for the synthesis of xanthones

A mixture of 281 mg 2m (2 mmol), 288 mg 1 (2 mmol), 350 mg 5,5-dimethyl-1,3-cyclohexanedione (2.5 mmol), and 0.4 g HBF4/SiO2 (0.2 mmol) was heated at 80 °C for the appropriate time according to Table 1. After completion of reaction, as indicated by TLC, the mixture was washed with ethyl acetate and filtered to recover the catalyst. The organic filtrate was separated and concentrated under reduced pressure. The crude product was recrystallized from EtOH to afford 737 mg 4m (95%).

12-Cyclohexyl-8,9,10,12-tetrahydro-11H-benzo[a]xanthen-11-one (4i, C23H24O2)

White solid; m.p.: 186–187 °C; IR (KBr): \( \bar{v} = 2,931, \) 2,860, 2,848, 1,643, 1,618, 1,595, 1,514, 1,391, 1,256, 1,234, 1,188, 1,134, 993, 949, 833 cm−1; 1H NMR (400 MHz, CDCl3): δ = 0.97–1.10 (m, 6H, cyclohexane), 1.26–1.81 (m, 5H, cyclohexane), 2.10–2.15 (m, 2H, CH2), 2.32–2.41 (m, 2H, CH2), 2.57–2.78 (m, 2H, CH2), 4.68 (d, J = 4.0 Hz, 1H, CH), 7.24 (d, J = 8.8 Hz, 1H, Ar–H), 7.45 (d, J = 7.6 Hz, 1H, Ar–H), 7.56 (d, J = 7.6 Hz, 1H, Ar–H), 7.71 (d, J = 8.8 Hz, 1H, Ar–H), 7.83 (d, J = 8.0 Hz, 1H, Ar–H), 8.12 (d, J = 8.0 Hz, 1H, Ar–H) ppm; 13C NMR (100 MHz, CDCl3): δ = 20.2, 26.3, 28.0, 28.5, 31.2, 32.6, 37.2, 45.6, 113.4, 116.8, 119.0, 123.8, 124.8, 126.6, 127.8, 128.5, 131.5, 131.6, 149.2, 168.6, 197.8 ppm.

References

Zolfigol MA, Chehardoli G, Ghaemi E, Madrakian E, Zare R, Azadbakht T, Niknam K, Mallakpour S (2008) Monatsh Chem 139:261

Shaabani A, Soleimani E, Sarvary A (2008) Monatsh Chem 139:629

Ren YM, Cai C (2009) Monatsh Chem 140:49

Bondock S, El-Azap H, Kandeel EEM, Metwally MA (2008) Monatsh Chem 139:1329

Liu L, Ji LY, Wei YY (2008) Monatsh Chem 139:901

Karimi-Jaberi Z, Hashemi MM (2008) Monatsh Chem 139:605

Li J-J, Tao X-Y, Zhang Z-H (2008) Phosphorus Sulfur Silicon Relat Elem 183:1672

Kesel AJ (2005) Curr Med Chem 12:2095

Zhang Z-H, Tao X-Y (2008) Aust J Chem 61:77

Griffiths J, Lee WJ (2003) Dyes Pigm 57:107

Ahmad M, King TA, Ko D-K, Cha BH, Lee J (2002) J Phys D Appl Phys 35:1473

Knight CG, Stephens T (1989) Biochem J 258:683

Sato N, Jitsuoka M, Shibata T, Hirohashi T, Nonoshita K, Moriya M, Haga Y, Sakuraba A, Ando M, Ohe T, Iwaasa H, Gomori A, Ishihara A, Kanatani A, Fukami T (2008) J Med Chem 51:4765

Lu Z-Y, Lin Z-J, Wang W-L, Du L, Zhu T-J, Fang Y-C, Gu Q-Q, Zhu W-M (2008) J Nat Prod 71:543

Carroll AR, Lamb J, Moni R, Guymer GP, Forster PI, Quinn RJ (2008) J Nat Prod 71:1564

Shaheen F, Ahmad M, Khan SN, Hussain SS, Anjum S, Tashkhodjaev B, Turgunov K, Sultankhodzhaev MN, Choudhary MI, Atta-ur-Rahman (2006) Eur J Org Chem 2371

Makino M, Fujimoto Y (1999) Phytochemistry 50:273

Das B, Laxminarayana K, Krishnaiah M, Srinivas Y (2007) Synlett 3107

Chakraborti AK, Gulhane R (2003) Tetrahedron Lett 44:3521

Bandgar BP, Patil AV (2007) Tetrahedron Lett 48:173

Kumar D, Kumar R, Chakraborti AK (2008) Synthesis 1249

Kamble VT, Bandgar BP, Joshi NS, Jamode VS (2006) Synlett 2719

Kamble VT, Bandgar BP, Muley DB, Joshi NS (2007) J Mol Catal A Chem 268:70

Bandgar BP, Patil AV, Kamble VT, Totre JV (2007) J Mol Catal A Chem 273:114

Sharma G, Kumar R, Chakraborti AK (2008) Tetrahedron Lett 49:4272

Chen WY, Li XS, Lu J (2008) Synth Commun 38:54

Bandgar BP, Patil AV, Chavan OS (2006) J Mol Catal A Chem 256:99

Liu Y-H, Tao X-Y, Lei L-Q, Zhang Z-H (2009) Synth Commun 39:580

Liu Y-H, Liu Q-S, Zhang Z-H (2008) J Mol Catal A Chem 296:42

Liu Y-H, Zhang Z-H, Li T-S (2008) Synthesis 3314

Zhang P, Yu Y-D, Zhang Z-H (2008) Synth Commun 38:4474

Liu Y-H, Liu Q-S, Zhang Z-H (2009) Tetrahedron Lett 50:916

Zhang Z-H (2005) Monatsh Chem 136:1191

Zhang Z-H, Li T-S, Li J-J (2007) Monatsh Chem 138:89

Mo L-P, Ma Z-C, Zhang Z-H (2005) Synth Commun 35:1997

Zhang Z-H, Li J-J, Gao Y-Z, Liu Y-H (2007) J Heterocycl Chem 44:1509

Zhang Z-H, Yang S-T, Lin J (2006) Synth Commun 36:1645

Zhang Z-H, Lin J (2007) Synth Commun 37:209

Zhang P, Zhang Z-H (2009) Monatsh Chem 140:199

von Hellmann H, Schröder M (1961) Liebigs Ann Chem 641:78

Wang R-Z, Zhang L-F, Cui Z-S (2009) Synth Commun 39:2101

Acknowledgments

We are grateful for financial support from the National Natural Science Foundation of China (20872025), the Nature Science Foundation of Hebei Province (B2008000149), the Natural Science Foundation of Hebei Education Department (2006318), and the Science Foundation of Hebei Normal University (L20061314).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, ZH., Wang, HJ., Ren, XQ. et al. A facile and efficient method for synthesis of xanthone derivatives catalyzed by HBF4/SiO2 under solvent-free conditions. Monatsh Chem 140, 1481–1483 (2009). https://doi.org/10.1007/s00706-009-0204-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-009-0204-9