Abstract

A star-shaped molecularly imprinted coating was prepared starting from octavinyl-modified polyhedral oligomeric silsesquioxanes (Ov-POSS). It possesses a relatively open structure and has good site accessibility and a larger capacity even at lower cross-linking. The imprinted coating was prepared from S-amlodipine (S-AML) as the template and analyte, Ov-POSS as the cross-linker, and methacrylic acid as the functional monomer. The preparation and chromatographic parameters were optimized, including ratio of template to functional monomer, apparent cross-linking degree, pH value, ACN content and salt concentration in the mobile phase. The best resolution in enantiomer separation by means of capillary electrochromatography reaches a value of 33. A good recognition ability (α = 2.60) was obtained and the column efficiency for S-AML was 54,000 plates m−1. The use of Ov-POSS as a cross-linker significantly improves the column capacity and thus the detection sensitivity. The results show that Ov-POSS is an effective cross-linker for the preparation of imprinted polymers with good accessibility and large capacity.

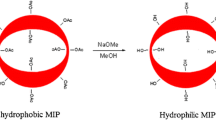

Schematic presentation of the preparation of star-shaped imprinted polymer using octavinyl-modified polyhedral oligomeric silsesquioxanes (Ov-POSS) and by using methacrylic acid (MAA) as functional monomer. The best enantiometric resolution (33) for amlodipine (AML) can be achieved in capillary chromatography (CEC).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

A molecularly imprinted polymer (MIP) is a synthetic host system that can recognize and bind the target molecule specifically [1, 2]. However, one of the limitations of MIP is broad guest affinities and selectivities. As a result, considerable attention has been focused on moulding desired recognition sites, including the use of a metal ion as self-assembly pivot [3], auxiliary monomers [4] and high pressure [5], optimization of polymerization temperature [6], as well as the strategy of molecular crowding [7].

Dendrimers are attractive candidates for material design because of a significant degree of cross-linking derived from the large number of end-groups [8, 9]. Due to their well-defined branched structures, as well as controlled functionality and composition, dendrimers have unique properties which are superior in comparison with their linear counterparts [10,11,12]. When used in the preparation of MIP, dendrimer structure with vast space made the template molecule elute and recombine to the polymer matrix easily. As a result, dendrimer MIP can give faster mass transfer, better capacity and selectivity [13]. For example, Pan et al. reported a kind of molecularly imprinted biomimetic sensor with incorporating poly(amidoamine) dendrimer as functional monomer [14]. Prasad et al. used a trifunctional monomer to prepare doubly imprinted dendrimer for the electrochemical determination of uric acid, norepinephrine [15] and folic acid [16]. In addition, hierarchical porous dendrimer-like amino-functionalized silica nanoparticles-based MIP has also been reported [17]. The need for multi-step synthesis of the dendrimers, as well as the high dilution conditions required for the reaction is the limitations of this approach.

Star polymers are alternative broad class of branched macro-molecular architectures and typically referred to as the “core”. They have linear “arms” radiating from a central branching point [18]. They represent one of the most simple deviations from one-dimensional linear polymers due to their spatially defined yet compact three-dimensional structure. By precise control of structure and function, such as core architecture, chain end composition and molecular weight, the properties of star-shaped polymers can be controlled.

Polyhedral oligomeric silsesquioxanes (POSS) are organic-inorganic hybrid composite based on a cage-like structure [19, 20], with general formula of (RSiO1.5)n. POSS have framework like silica and multiple reactive functionalities, thus can be used as building blocks frequently. For example, Bagheri et al. reported a method to prepare POSS-epoxy-based 3D nanoscaled materials with high surface area, uniform pore structure and hydrophobicity. The materials was used for solid phase microextraction of polycyclic aromatic hydrocarbons [22]. When POSS monomers containing eight reactive arms at the vertex of the core are used in polymerization, hybrid star-shaped polymers with well-defined branched structures can be formed [21]. Such strategy can be used to mediate polymer chain-chain interactions by use of well-defined nanoparticles. In addition, it provides the bottom-up approach to the control of the chemical functionalities and the structure is desired in the situations where the highly branched architecture is needed. As a result, star-shaped polymers have superior properties in comparison with their linear counter-parts. In the field of molecular imprinting, it was found that the use of POSS monomer of reactive site can improve imprinting effect by suppressing nonselective binding sites [23, 24]. However, the nature of the resulting POSS-based MIP is still linear counterparts.

Inspired of the advantage of the branched macro-molecular architectures, POSS macromonomer with eight reactive groups, PSS-octavinyl substituted (Ov-POSS) was first used as a cross-linker to prepare star MIP for improvement in imprinting capacity in the present work. The Ov-POSS MIPs were synthesized in a form of capillary coating column. The effect of introduction of branched macro-molecular architectures into MIP was evaluated by enantiomer separation using capillary electrochromatography (CEC). The resulting Ov-POSS MIPs can form good imprinting even at a lower cross-linking level since Ov-POSS as cross-linker can provide highly branched structure. The well-designed Ov-POSS-based star MIPs possess the following attractive features: (1) open structure of polymer network derived from the low cross-linking level; (2) good accessibility of sites and larger capacity; (3) greater imprinting effect than conventional non-star-based MIPs (Fig. 1). The effect of preparation parameters of the Ov-POSS-based MIP on the enantiomer separation ability was studied in CEC mode.

Experimental

Materials

S-AML and rac-amlodipine (rac-AML) were purchased from Hengshuo Sci. & Tech. Corp. (Hubei, China, www.hengshuochem.com). Azobisisobutyronitrile (AIBN) was purchased from J&K Scientific Ltd. (Beijing, China, www.jkchemical.com). PSS-Octavinyl substituted (Ov-POSS) was purchased from Aladdin (Shanghai, China, www.aladdin-e.com). Methacrylic acid (MAA) was supplied by Tianjin Kemiou Chemical Reagent (Tianjin, China, www.chemreagent.com). 3-(Trimethoxysilyl)propylmethacrylate (γ-MPS) was supplied by Acros (Geel, Belgium, www.acros.com). Acetonitrile (ACN) was HPLC grade (Fisher, NJ, USA, www.thermofisher.com). Other analytical reagents were supplied by Tianjin Chemical Reagent Co. Ltd. (Tianjin, China, www.2121853.atobo.com.cn). Bare fused-silica capillaries with 100 μm I.D. and 375 μm O.D. were supplied from Xinnuo Optic Fiber Plant (Hebei, China, www.11467.com/handan/co/68426.htm).

Preparation of octavinyl substituted polyhedral oligomeric silsesquioxanes (Ov-POSS) based dendrimer MIP capillary

Firstly, the bare fused-silica capillary was rinsed using 1 mol L−1 sodium hydroxide solution for approximately 30 min and then followed by double distilled water about 30 min. Next, a solution of 0.4% γ-MPS/ acetic acid (HAc) was prepared by adding 4 μl of γ-MPS into 1 mL of HAc solution (6 mmol L−1) and used to wash the capillary at least 90 min. Then the double distilled water and acetone were pumped into column respectively and kept for 30 min each. Lastly, the capillary was dried under nitrogen atmosphere. A pre-polymerization mixture consisting of AIBN (4 mg), S-AML (0.053 mmol), MAA (0.16 mmol) and Ov-POSS (0.08 mmol) were dissolved in 854 μL chloroform (CHCl3) (Table 1). After sonicating and mixing for 10 min, the pre-polymerization solution was injected into the column by syringe. Two ends of column were sealed with the rubber stoppers and painted with Vaseline, then kept at a 53 °C water bath for polymerization. After polymerization, the resultant coating column was instantly washed with ACN and methanol/acetic acid (90:10, v/v) using the hand-held pump, respectively. At a distance of 10.5 cm away from the exit end of the MIP coating column, a 2–3 mm segment detection window was created by burning out of the polyimide outer coating.

Capillary electrochromatography

Evaluation of the MIP coating column were performed on a K1050 system (Kaiao, Beijing, China) consisting of CXTH-3000 chromatographic workstation and UV detector. The mobile phase was prepared with different proportions of acetonitrile and buffer. The buffer was a mixture of acetic acid and sodium acetate solution, in which pH and salt concentration varied. All the mobile phase were prepared with double distilled water and filtered through a 0.2 μm microporous membrane. The column was washed with mobile phase for 10 min before CEC running. The voltage for separation was performed at 15 kV and ultraviolet detection wavelength was 238 nm.

In this experiment, separation factor (α) was calculated by α = tR2/tR1 since some of detected substances were eluted prior to electroosmotic flow (EOF) [24], where tR2 and tR1 are the retention time of the template molecule and its enantiomer, respectively. The separation degree of analyte was evaluated by normalized separation index (ΔtR/tR1) [25], where ΔtR is the difference between the two enantiomers retention times at peak maximum and tR1 is the retention time of the first eluted enantiomer.

The resolution (RS) was calculated by the equation RS = (tR2 - tR1)/0.5(W2 + W1) and the column efficiency (N) was calculated as N = 16 (tR/W)2, where W is the width at the baseline between tangents drawn to inflection points for the peak.

Results and discussion

Choice of materials

Traditionally, the MIPs are prepared by using high content of cross-linker, e.g., 80% ethylene glycol dimethacrylate (EDMA) (two polymerizable groups), to provide high rigidity for the preservation of the structure of the imprinted sites [2]. However, this may be lead to the excessively embedded imprinting sites thus decreased imprinting effect. It was found that increasing the number of polymerizable groups of cross-linker can reduce the content of cross-linker used while still maintain high rigidity of the MIP. For example, using trimethylolpropane trimethacrylate (TRIM) containing three polymerizable groups as cross-linker to prepare MIP can reduce the level of cross-linker to 67% effectively [6]. Thus, to use the POSS with eight vinyl groups as cross-linker (ov-POSS) is expected to reduce the level of cross-linker further in this work. Previously, POSS with one polymerizable groups has been used to prepare organic-inorganic hybrid MIPs [23, 24] with enhanced imprinting effect. However, the POSS can not maintain high rigidity of the polymer, and high content of cross-linker is still needed.

Synthesis of octavinyl substituted polyhedral oligomeric silsesquioxanes (ov-POSS) based star imprinted coatings

For fast evaluation, the Ov-POSS MIPs were synthesized in the form of capillary column since CEC can produce higher column efficiency and shorter analysis time. MAA is ionizable monomer which can provide EOF for CEC, thus selected as functional monomer to prepare star MIP. The reaction temperature and time are also vital factors affecting the performance of the polymer. The higher temperature will lead to the column occluded while the lower temperature needs longer reaction time [26]. Hence 53 °C was the optimum reaction temperature. In addition, the column may also be occluded if reaction time was too long. However, shorter time will make the MIP coating too thin thus lower loading. 1.75 h was considered as the optimum reaction time.

Figure 2 shows scanning electron microscopy images of capillary segments, indicating the microstructure of Ov-POSS-based coating. It can be seen that the thickness of the polymer coating on the inner surface of the capillary was around 0.1–0.2 μm. The MIP coating was fairly dense with a much looser amorphous and highly irregular layer.

Imprinting effect of the star molecularly imprinted coating was evaluated by means of CEC. Figure 3 illustrated the separation of rac-AML on the star molecularly imprinted coating, depicting the characteristic elution order, time of electroosmotic flow (EOF), and the selective retention of S-AML. The resolution of rac-AML was 14.27 (Fig. 3) and the higher number of theoretical plate of the template (44,200 plates m−1) can be achieved. Compared to the conventional MIP coating with AML imprints reported previously [24, 26], the column performance of the star imprinted coatings improved significantly, i.e., about 1.9 and 1.5 times.

Electrochromatograms of rac-AML, S-AML on S-AML imprinted capillary and EOF demonstrating the imprinting effect. Conditions: capillary, 100 μm inner diameter, 47.5 cm total length, and 37.0 cm effective length; separation voltage, 15 kV; UV detector, 238 nm; acetonitrile/10 mM acetate (pH 3.6) (80/20, v/v). Elution order of two enantiomers was identificated by injecting S-AML on the imprinted capillary

Optimization of method

To obtain a MIP coating with better separation characteristics, the following parameters were optimized: (a) the ratio of template to functional monomer; (b) the apparent cross-linking degree; (c) the pH of the mobile phase; (d) the ACN content of the mobile phase; (e) the salt concentration of the mobile phase. Corresponding data and figures are given in the Electronic Supporting Material (ESM). In short, the following experimental conditions were found to give the best results: (a) T/M ratio of 1:3 resulted in faster chiral separation and T/M ratio of 1:4 in the highest resolution and separation factor; (b) optimal value: 33.3%; (c) optimal pH value: 3.6; (d) optimal ACN content: 80%; (e) optimal salt concentration: 10 mM.

Capacity of the MIP

It was found that using Ov-POSS as cross-linker can significantly improve the column capacity thus detection sensitivity. The effect of sample loading on the Ov-POSS-based star MIP coating was studied by injecting different concentrations of template ranging from 0.3 to 30 μg mL−1. As shown in Fig. 4, when the concentration of rac-AML is 0.008 mg mL−1, overloading is observed while the separation efficiency is not declined. Detection sensitivity, the minimum concentration of sample that can be detected was 0.3 μg mL−1 at S/N = 5, 10 times higher than that obtained by Wei et al. [27]. The column capacity was up to 30 μg mL−1 for S-AML, which was 10 times greater than that of Ov-POSS-free MIP coating [24]. This improvement in performance of molecular imprinting may be attributed to the unique structure of POSS-based polymers different from conventional MIP: the POSS cages have typical diameters of 1.2 to 1.5 nm, thus each monomer occupies a substantial volume. As a result, the average cross-linking density of star POSS-based MIP will be lowered. In this case, the embedding of imprinted sites due to the need of highly cross-linking to keep the memory of the template molecule can be improved thus limited loading capacity of drug template would increase.

Reproducibility of the MIPg

The reproducibility of various CEC separation parameters is important for the synthesis and application of star molecularly imprinted coatings. The mobile phase used for the investigation of reproducibility was a mixture of ACN and acetate buffer (80/20, v/v) with pH value of 3.6 and salt concentration of 10 mM. The column performance, retention time of two enantiomers, separation factor and resolution from identical capillary and different batches reproducibility of Ov-POSS-based MIP column were investigated (Fig. S6, Fig. S7 and Table 2). There was no significant difference in the chromatograms after 200 injections. The relative standard deviation (RSD) of resolution for run-to-run and batch-to-batch was less than 3%, demonstrating better reproducibility of the MIP coatings based on Ov-POSS.

Comparison with related reference

In order to further evaluate the performance of Ov-POSS-based imprinted coating, some characteristic features were compared to other report on chiral separation [28]. Table 3 represents the comparison results in terms of the analytes, resolution and RSD. Although the reproducibility of selective factor was not as good as the Tang’s group, other separation parameters in our work were significantly better than the reference. Especially, the resolution of our method was 11 times grater than that of Tang’s group. In summary, using Ov-POSS as a cross-linker to prepare MIP stationary phase is an effective method to chiral separation.

The major limitation of this method was the difficulty to accurately find the position of the MIP ending in the capillary after polymerization. Since the synthesized polymer was a coating column, the position of the MIP ending after drying the capillary was not obvious. If the detection window was made at the location containing polymer by mistake, the detection in CEC run can not be realized. On the other hand, if the detection window was was made at the location too far, the peak will be broadened. Hence, the exact position of the MIP coating had to be observed with the help of optical microscope.

Conclusion

A novel MIP coating column was successfully fabricated by using octavinyl substituted polyhedral oligomeric silsesquioxanes (Ov-POSS) as cross-linker and can be employed for enantiomer separation of amlodipine. In addition, Ov-POSS was also used as dendrimer core and form the open three-dimensional structure by polymer chain-chain interactions. The resulting MIP had a lower cross-linking degree, thus the number of active sites was increased. As a result, the separation performance was significantly improved. At the same time, Ov-POSS-based MIP coating had better batch-to-batch and run-to-run reproducibility, demonstrating the good stability of the coating polymer. This finding may be helpful in preparation of MIP sensor, in which fast response is expected due to lower cross-linking polymer network. Other MIP formats rather than capillary coating need to be developed in the future for expanding the application of the MIP studied here. We convince that the outstanding features of the star MIP would open up new horizons to the imprints with good accessibility of sites and greater capacity.

References

Cieplak M, Kutner W (2016) Artificial biosensors: how can molecular imprinting mimic biorecognition? Trends Biotechnol 34:922–941

Chen L, Wang X, Lu W, Wu X, Li J (2016) Molecular imprinting: perspectives and applications. Chem Soc Rev 45(8):2137–2211

Bai LH, Chen XX, Huang YP, Zhang QW, Liu ZS (2013) Chiral separation of racemic mandelic acids by use of an ionic liquid-mediated imprinted monolith with a metal ion as self-assembly pivot. Anal Bioanal Chem 405(27):8935–8943

Li ZY, Liu ZS, Zhang QW, Duan HQ (2007) Chiral separation by (S)-naproxen imprinted monolithic column with mixed functional monomers. Chin Chem Lett 18(3):322–324

Sellergren B, Dauwe C, Schneider T (1997) Pressure-induced binding sites in molecularly imprinted network polymers. Macromolecules 30(8):2454–2459

Sellergren B (1989) Molecular imprinting by noncovalent interactions. Enantioselectivity and binding capacity of polymers prepared under conditions favoring the formation of template complexes. Macromol Chem Phys 190:2703–2711

Ban L, Zhao L, Deng BL, Huang YP, Liu ZS (2013) Preparation and characterization of imprinted monolith by atom transfer radical polymerization assisted with crowding agents. Anal Bioanal Chem 405(7):2245–2253

Mignani S, Rodrigues J, Tomas H, Zablocka M, Shi X, Caminade AM, Majoral JP (2018) Dendrimers in combination with natural products and analogues as anti-cancer agents. Chem Soc Rev 47(2):514–532

Gorain B, Tekade M, Kesharwani P, Iyer AK, Kalia K, Tekade RK (2017) The use of nanoscaffolds and dendrimers in tissue engineering. Drug Discov Today 22(4):652–664

Tang R, Li Z (2017) Second-order nonlinear optical dendrimers and dendronized hyperbranched polymers. Chem Rec 17(1):71–89

Wan J, Alewood PF (2016) Peptide-decorated dendrimers and their bioapplications. Angew Chem Int Ed Engl 55(17):5124–5134

Caminade AM (2016) Inorganic dendrimers: recent advances for catalysis, nanomaterials, and nanomedicine. Chem Soc Rev 45(19):5174–5186

Wang HM, Xu Q, Wang J, Du W, Liu FP, Hu XY (2018) Dendrimer-like amino-functionalized hierarchical porous silica nanoparticle: a host material for 2,4-dichlorophenoxyacetic acid imprinting and sensing. Biosens Bioelectron 100:105–114

Pan MF, Fang GZ, Lu Y, Kong LJ, Yang YK, Wang S (2015) Molecularly imprinted biomimetic QCM sensor involving a poly(amidoamine) dendrimer as a functional monomer for the highly selective and sensitive determination of methimazole. Sens Actuators B Chem 207:588–595

Prasad BB, Fatma S (2017) One monomer doubly imprinted dendrimer nanofilm modified pencil graphite electrode for simultaneouselectrochemical determination of norepinephrine and uric acid. Electrochim Acta 232:474–483

Prasad BB, Madhuri R, Tiwari MP, Sharma PS (2010) Electrochemical sensor for folic acid based on a hyperbranched molecularly imprinted polymer-immobilized sol-gel-modified pencil graphite electrode. Sens Actuators B Chem 146(1):321–330

Zimmerman SC, Wendland MS, Rakow NA, Zharov I, Suslick KS (2002) Synthetic hosts by monomolecular imprinting inside dendrimers. Nature 418(6896):399–403

Ren JM, McKenzie TG, Fu Q, Wong EHH, Xu J, An Z, Shanmugam S, Davis TP, Boyer C, Qiao GG (2016) Star polymers. Chem Rev 116:6743–6836

Ye Q, Zhou H, Xu J (2016) Cubic polyhedral oligomeric silsesquioxane based functional materials: synthesis, assembly, and applications. Chem Asian J 11(9):1322–1337

Ghanbari H, Cousins BG, Seifalian AM (2011) A nanocage for nanomedicine: polyhedral oligomeric silsesquioxane (POSS). Macromol Rapid Commun 32(14):1032–1046

Xu J, Song J (2010) High performance shape memory polymer networks based on rigid nanoparticle cores. PNAS 107:7652–7657

Bagheri H, Soofi G, Javanmardi H, Karimi M (2018) A 3D nanoscale polyhedral oligomeric silsesquioxanes network for microextraction of polycyclic aromatic hydrocarbons. Microchim Acta 185(9):418

Li F, Chen XX, Huang YP, Liu ZS (2015) Preparation of polyhedral oligomeric silsesquioxane based imprinted monolith. J Chromatogr A 1425:180–188

Zhao QL, Zhou J, Zhang LS, Huang YP, Liu ZS (2016) Coatings of molecularly imprinted polymers based on polyhedral oligomeric silsesquioxane for open tubular capillary electrochromatography. Talanta 152:277–282

Liu X, Zhong HY, Huang YP, Liu ZS (2013) Liquid crystal-based molecularly imprinted nanoparticles with low crosslinking for capillary electrochro- matography. J Chromatogr A 1309:84–89

Wei ZH, Mu LN, Huang YP, Liu ZS (2012) Low crosslinking imprinted coatings based on liquid crystal for capillary electrochromatography. J Chromatogr A 1237:115–121

Wei ZH, Wu X, Zhang B, Li R, Huang YP, Liu ZS (2011) Coatings of one monomer molecularly imprinted polymers for open tubular capillary electrochromatography. J Chromatogr A 1218(37):6498–6504

Gong ZS, Duan LP, Tang AN (2015) Amino-functionalized silica nanoparticles for improved enantiomeric separation in capillary electrophoresis using carboxymethyl-β-cyclodextrin (CM-β-CD) as a chiral selector. Microchim Acta 182(7–8):1297–1304

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 21775109).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The author(s) declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOC 10.6 MB)

Rights and permissions

About this article

Cite this article

Song, WF., Zhao, QL., Zhou, XJ. et al. A star-shaped molecularly imprinted polymer derived from polyhedral oligomeric silsesquioxanes with improved site accessibility and capacity for enantiomeric separation via capillary electrochromatography. Microchim Acta 186, 22 (2019). https://doi.org/10.1007/s00604-018-3151-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00604-018-3151-5