Abstract

A carbon paste electrode was modified with a Ce(III)-imprinted polymer (Ce-IP) and used for voltammetric determination of Ce(III) ions in real water samples. Precipitation polymerization was used for synthesis of the nano-sized Ce-IP from vinylpyridine and methacrylic acid (acting as the complexing ligands and functional monomers), divinylbenzene (cross-linker) and AIBN as the radical starter. The Ce-IP was characterized by scanning electron microscopy and zeta potentials. A carbon paste electrode (CPE) was then impregnated with the Ce-IP and used for the extraction and subsequent determination of Ce(III). Oxidative square wave voltammetry showed the electrode to give a significantly better response than an electrode modified with the non-imprinted polymer. The addition of multiwalled carbon nanotubes to the Ce-IP-modified electrode further improves the signal, thereby increasing the sensitivity of the method. The effects of electrode composition, extraction pH value, volume and time were optimized. The electrode, if operated at a voltage of 1.05 V (vs. Ag/AgCl), displays a linear response to Ce(III) in the 1.0 μM to 25 pM concentration range, and the detection limit is 10 pM (at an S/N ratio of 3). The relative standard deviation of 5 separate determinations is 3.1 %. The method was successfully applied to the determination of Ce(III) in the spiked samples of drinking water and sea water.

A carbon paste electrode was modified with Ce-imprinted polymer and multiwalled carbon nanotube (Ce-IP-CNT-CP), and then utilized for the extraction of Ce(III) prior to its electroanalysis by square wave voltammety (SWV).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cerium is the most abundant among the rare earth elements. This metal is used as a core for the carbon electrodes of arc lamps and for the incandescent mantles in gas lighting. Cerium is used in aluminum and iron alloys, in stainless steels and in some rare-earth alloys [1]. The biological effects of lanthanides, arisen from their similarity to calcium, have stimulated deep studies about their therapeutic applications and one of the earliest therapeutic uses of a lanthanide was the use of cerium oxalate as an anti-emetic [2]. Because of widely usage of cerium, it is increasingly getting into the environment, accumulating in organisms, and finally entering in the food chains. Therefore, the development of monitoring techniques for cerium is of most importance. The spectrophotometric determination [3] is a general method for the measurement of Ce(III). Other instrumental techniques including inductively coupled plasma atomic emission spectrometry (ICP-AES) [4], chemiluminescence [5], fluorimetry [6], ion-selective electrodes [7, 8] and neutron activation analysis (NAA) [9] have been applied to the cerium determination.

Electrochemical sensors have been regarded as analytical tools for Ce (III) determination because of their favorable portability, ease of operation procedure and low-cost. Wang and co-workers have been determined cerium on mercury electrode using Adsorption Stripping Voltammetry (ASV) [10]. Nevertheless, carbon paste electrode (CPE) has attracted increasing attention in voltammetry due to its nonpoisonous, easy preparation, wide operational potential window, renewable surface and variability in which carbon pastes electrode can be simply modified [11].

In molecular imprinting, a molecule that is called template, is imprinted in the polymer by the use of monomers and cross linker. Removal of the template molecule from the polymer leads to molecularly imprinted polymers (MIPs), capable of recognizing and rebinding the desired molecular target with a high affinity and selectivity [12]. Ion imprinting polymers (CE-IPs) are similar to MIPs, but they can recognize metal ions after imprinting and hold all the virtues of MIPs [13]. Up to now, a number of ion imprinted polymers have been synthesized for various kinds of metal ions such as: lead (Pb2+) [14], cadmium (Cd2+) [15],mercury (Hg2+) [16] gadolinium (Gd3+) [17, 18], neodymium (Nd3+) [19], samarium (Sm3+) [20], dysprosium (Dy3+) [21] and erbium (Er3+) [22], europium (Eu3+) [23] and cerium (Ce3+) [13, 24].

We synthesized nano-sized imprinted polymer, containing Ce3+ selective sites, by the simple precipitation polymerization procedure. The polymer was then mixed with graphite and multiwalled carbon nanotubes (MWCNTs) in the presence of n-eicosane, as the binder, to fabricate the Ce (III) sensor. In this case, the Ce-IP modifier functioned as both selective recognition element and pre-concentrator at the same time. Also, this determination protocol did not need a separate extraction step with different condition, meaning that both extraction and determination steps were carried out at the same solution. This is an advantage of this sensor because of decreasing of the complexity of the determination procedure.

Experimental

Instrument and reagents

Electrochemical data were obtained with a three-electrode system using a potentiostat/galvanostat model PGSTAT302, Metrohm. Carbon paste electrodes, modified with Ce-IP (or non- imprinted polymer (NIP)) and MWCNTs, were used as the working electrodes. Platinum and Ag/AgCl electrodes were used as the counter and reference electrodes, respectively. Zeta potentials of the polymeric materials were measured using (particlemetrix PMX 200C StabiSizer). For the measurement of zeta potential, each sample of polymer (0.1 g) was dispersed in 10 mL of acetic acid (1 1 mol L−1). This mixture was sonicated for 5 min. Afterwards, the mixture was pipetted into a scintillation vial of apparatus and the pH was adjusted using aqueous sodium hydroxide (1 mol L−1) to record the zeta potential values. In fact, pH adjustment was done manually such that in each addition of NaOH, the pH and its related zeta potential was recorded, simultaneously.

Electrochemical impedance spectroscopy was performed using AUTOLAB PGSTAT302 electrochemical analysis system and GPES 4.9 software package. Impedance measurements were carried out at frequency range of 5 mHz-10 MHz, ΔEac = 50 mV and dc potential of 1.1 V (in the presence of 0.1 mM Ce3+) via a three-electrode system including counter electrode (platinum), reference electrode (Ag/AgCl) and working electrode (investigated electrodes). The pH of this solution was adjusted to 3 by acetate buffer (0.3 mol L−1).

Methacrylic acid (MAA), (Merck, Germany, http://www.merckgroup.com/), vinylpyridine (VP) and divinylbenzene (DVB) (Sigma-Aldrich, USA http://www.sigmaaldrich.com/united-states.html) were purified by distillation under reduced pressure. 2,2′-azobisisobutyronitrile (AIBN) was obtained from Acros Organic, Belgium http://www.exportersindia.com/acrosorganics/) and used as an initiator. Cerium nitrate (Ce(NO3)3) was from (Merck, Germany). Other chemicals were of analytical grade and were purchased from (Merck, Germany).

Preparation of Ce-IP nanoparticles by precipitation polymerization

In order to synthesis the Ce-IP by the precipitation polymerization, 0.5 mmol of Ce(NO3)3 (template), was dissolved in 10 mL of methanol (porogen). Then, 2 mmol of vinylpyridine (as both functional monomer and complexing ligand) and 1 mmol of MAA (as both functional monomer and complexing ligand) were slowly added to the mixture, while stirring. Then, 13 mmol of DVB (as cross-linker) and 50 mL of methanol were added to the mixture. Finally, 0.05 g of AIBN (dissolved in 1 mL of ethanol) was transferred to the mixture. The pre-polymerization mixture was purged with a stream of nitrogen gas for 10 min. The vessel was then sealed precisely and transferred to a water bath, fixed at temperature of 60 °C, to start the polymerization reaction. The polymerization reaction lasted 12 h. After completion of the reaction, the polymer powder was separated from the solvent and washed several times with water, hot ethanol and HCl solution (1 mol L−1) in order to remove non-reacted monomers as well as cerium species from the polymer. The NIP was also synthesized similar to the imprinted polymer; except that Ce3+ was absent in non-imprinted polymer synthesis.

Preparation and activation of the modified electrodes

Carbon paste electrodes, modified with the Ce-IP and NIP nanoparticles (nano-Ce-IP-CNT-CP) and nano-NIP-CNT-CP) were fabricated via mixing of graphite (0.094 g), MWCNTs (0.01 g) and nano-sized Ce-IP or the relevant NIP (0.004 g) for 10 min in a mortar. Subsequently, n-eicosane (0.03 g) was melted in a dish, heated a t45–50 °C. The previously prepared Ce-IP/MWCNT/graphite (or NIP/MWCNT/graphite) blend was then added to the melted n-eicosane and mixed further with a stainless steel spatula. The final paste was used to fill a hole (2.0 mm in diameter, 3 mm in depth) at the end of an electrode body, previously heated at 45 °C. After cooling of the electrode (at room temperature), the excess of solidified material on top of the electrode was removed via a clean paper sheet.

Determination of cerium(III)

In order to determine Ce3+ in an aqueous sample, the Ce-IP-modified electrode was inserted into the solution, containing undetermined concentration of Ce3+. The pH of this solution was adjusted to 3 by acetic acid (0.3 mol L−1). Furthermore, the solution was stirred (300 rpm) during extraction. After 15 min, the auxiliary and reference electrodes were placed in the vessel, including the solution and the square wave voltammetry was performed in the potential range of 0.7 to 1.4 V, while the frequency and amplitude were set on 30 Hz and 200 mV, respectively. The current response obtained was used for the estimation of Ce3+ concentration with respect to the calibration graph.

Determination of Ce (III) in real sample

Two real samples including spiked drinking water and sea water samples were analyzed by the sensor. Sea water samples were collected from Caspian Sea (coastal zone). The samples were tested before addition of Ce(III) with the optimized sensor and it was found that the drinking and sea water samples were Cerium free. 50 mL of the mentioned samples was spiked with different concentrations of Ce(III). Then, the pH of the sample was adjusted to the optimal pH with acetic acid.

The sensor was then immersed into the sample, meanwhile, the solution was stirred continuously at 300 rpm for 15 min. Reference and counter electrodes were immersed in the solution immediately and SWV analysis was performed in the optimum conditions at the same solution. In order to analyze the Ce3+ in the spiked drinking water, the same procedure was also applied.

Results and discussion

Choice of materials

Cerium ion is an electroactive cation among lanthanides which can be electrochemically detected using carbon paste electrode. The utilization of modern voltammetric method such as square wave voltammetry can improve the sensitivity and detection limit of Ce(III) detection. However, two main problems are observed when the determination of Ce(III) by the voltammetric method. The first problem is the small signal of Ce(III), produced in the carbon paste electrode even applying the square wave voltammetry. The second problem is the low selectivity of the detection method. This is arisen mainly because of higher oxidation potential of Ce(III). We tried to overcome these problems by the modification of the carbon paste electrode with highly selective Ce-IP and carbon nanotube. A well-designed Ce-IP can extract selectively the target ion of Ce(III) to the electrode surface. This strategy, not only increases the selectivity of the determination method, but also improves the sensitivity of the method via the pre-concentration of Ce(III) on the electrode surface, increasing thus the e(III) signal. It is well-known that the nano-sized imprinted polymers are better than the bulky imprinted polymers, regarding template rebinding kinetic and affinity. This is because of the situation of the selective sites of the nano-sized imprinted polymer in its surface. Regarding the obvious advantages of nano-sized imprinted polymers over the bulky imprinted polymers, we decided to synthesis IP nanoparticles.

It has been previously shown that addition of even small amount of CNTs in the electrode composition resulted in significant change in the conductance of the electrode and improve the analytical signal of the aimed compound [25]. Therefore, in order to improve further the sensitivity and detection limit of Ce(III) determination, the utilization of MWCNTs in the composition of the carbon paste electrode was also tested.

Synthesis of Ce (III)-imprinted polymer and its characterization

The synthesis procedure is briefly illustrated in Fig. 1(I). According to this method, MAA and VP were mixed with Ce3+ (mole ratio, 2:4:1). The monomers of MAA and VP acted as both functional monomer and complexing agent. No additional complexing ligand was required in this recipe. Divinyl benzene was also functioned as the cross-linker agent to fix the formed Ce(III) selective sites within the final polymer. Relative proportion of the functional monomers and Ce(III) involved in the Ce-IP synthesis was found to influence significantly the final recognition efficiency of the Ce-IP. For example the Ce-IP, synthesized from MAA, VP and Ce(III) in the mole ratios of 2:6:1 and 2:2:1 led to the Ce-IP, having no appropriate affinity to Ce(III). However, the polymer, prepared by MAA, VP and Ce(III) in molar ratio of 2:4:1 resulted in the material with the best recognition capability among the tested mole ratios.

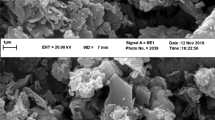

Scanning electron microscopy images (SEM) of the polymer particles (including Ce-IP and NIP) are shown in Fig. 1(II). As can be seen, the nano-sized polymeric particles (about 35 nm) have been resulted by performing the precipitation polymerization procedure.

Zeta potentials of different polymeric samples including, unleached Ce-IP, leached Ce-IP, non-imprinted polymers (NIP), and Ce(III) loaded Ce-IP (re-adsorbed Ce-IP) were recorded as a function of pH (Fig. 2). The zeta potentials of the imprinted polymeric particles depends on the pH of the medium, as, it affects the extent of ionization and protonation of the functional groups of the Ce-IP [26]. At a low pH, Ce-IP and re-adsorbed Ce-IP systems show higher zeta potentials, caused by the electrostatic repulsion, associated with the protonation of the carboxylate anions. The zeta potential is decreased with increasing of pH due to the ionization of carboxylic acid groups. The Ce-IP and NIP particles, however, tends to lie in the lower potentials at all tested pHs. The zeta potentials of Ce-IP and re-absorbed Ce-IP were much higher than those of Ce-IP and NIP, which clearly demonstrates the sorption of cerium ions. Moreover, the similar tendency in the zeta potential behavior, between the Ce-IP and re-absorbed Ce-IP, indicates that the adsorption of cerium ions is taken place in a reversible way. According to the described results, it seems that all binding sites on the Ce-IP particle surface are partially in a “working state”.

Application of the nano-sized Ce-IP particles for voltammetric sensor preparation

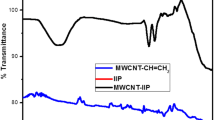

Figure 3 (I) show the voltammetric responses of different CP electrodes, modified with the Ce-IP, NIP and MWCNTs. Comparison of curve “a” and curve “c”, related to the NIP and Ce-IP containing CP electrodes, respectively, indicates that replacement of the NIP with the Ce-IP nanoparticles in the CP electrode, increases hugely the voltammetric signal of Ce(III). This is attributed to the high affinity of the Ce(III) selective sites of the Ce-IP, situated on the CP-IP electrode, to Ce(III)

Square wave voltammetry response of the carbon paste electrode, modified with the Ce-IP, NIP, Ce-IP/MWCNT and NIP/MWCNT to Ce3+(I); Conditions: 0.3 mol L−1, solution pH = 3, Ce3+ concentration = 10−6 mol L−1, extraction time = 15 min, frequency = 30 Hz and amplitude =100 mV; evaluation of the electrodes by electrochemical impedance spectroscopy, represented as Nyquist plots (II); the magnified zone of the Nyquist plots at high frequency regions (inset)

The effect of the addition of MWCNT in CP electrode on the voltammetric signal of Ce(III) was also tested. As can be seen in Fig 3 (comparison of curve “b” with curve “d”), the addition of MWCNTs to the NIP- and Ce-IP- modified electrodes enhances the Ce(III) signals in both electrodes. However, one can clearly see that such a signal enhancement effect of MWCNTs is very bigger in the Ce-IP-based electrode, compared to that in the NIP-based electrode. This phenomenon gives rise to appear huge difference between the signal of the nano-Ce-IP-CNT-CP and that of nano-NIP-CNT-CP. It is well established fact that as the signal difference between the IP- and NIP- based electrodes increases the selectivity of the Ce-IP-based electrode is guaranteed, because of diminishing of the role of non-specific adsorption on the analytical signal.

Figure 3 (II) illustrates the results of electrochemical impedance spectroscopy experiment as Nyquist plots, which was conducted for the evaluation of the effect of MWCNTs on the performance of the Ce-IP-modified electrode. It can be seen that the insertion of MWCNTs in the carbon paste electrode enhances considerably the charge transfer rate on the electrode surface, since, the diameter of the highly depressed semicircle in the Nyquist plot of the Ce-IP-CP is decreased greatly in the presence of MWCNTs. Therefore, the increase in the Ce-IP based electrode signal to Ce(III), in the presence of CNT, can be assigned to the positive effect of CNT in the acceleration of the electron transfer on the electrode surface. Furthermore, it is evident that there is no considerable difference between the NIP and IIP included electrodes in the presence of MWCNTs, suggesting that carbon nanotube improves the charge transfer in the electrodes, regardless of the kind of the polymer, used for the electrode modification. This, confirms our previous conclusion that higher affinity of Ce-IP toward Ce3+ ion is the main reason for bigger signal of Ce-IP-CNT-CP in comparison with that of NIP-CNT-CP.

Optimization of determination technique

The effect of different factors, influencing the sensor response (S1a (ESM)) was examined. Square wave voltammetry was found to be a sensitive method for the determination of Ce(III) on the nano-Ce-IP-CNT-CP electrode. Therefore, the frequency and amplitude of the applied potential in the SWV were optimized in order to improve the sensitivity of the final determination method. The optimum frequency and amplitude of the applied potential were found to be 30 Hz and 200 mV, respectively. It was found that at least 22 % (w/w) of whole composition of electrode had to be binder (n-eicosane) in order to achieve the electrode with suitable physical property. It was also observed that when 7 % (w/w) of whole composition of the electrode was CNT, the highest signal of the sensor to Ce(III) was obtained. The optimal Ce-IP content of the electrode was found to be 3 % (w/w). It was observed that Ce(III) extraction at pH = 3, fixed with acetic acid solution, resulted in the best response for the Ce(III). Increasing of extraction time up to 15 min led to increase in extraction efficiency, however, further increase in the extraction time did not improve the extraction efficiency. The effect of extraction solution volume on the response of Ce3+ sensor was also checked. It must be mentioned that the extraction and electroanalysis solution were the same. The current signal of the electrode increased sharply as the extraction volume was enhanced; however, after a definite volume (30 mL) the signal starts to descend strongly. Therefore, the volume of 30 mL was chosen as the optimum amount regarding this factor.

Evaluation of the selectivity and interference effect

In order to study the selectivity of the Ce-IP sites of the nano-Ce-IP-CNT-CP electrode to Ce3+ions the electrode was used for the determination of Ce(III) in the presence of 50-fold excess of some other lantanide ions. The results are depicted in Fig.4 (I). It can be seen that the response of the nano-Ce-IP-CNT-CP electrode to Ce(III) is not affected in the presence of 50-fold excess of La(III), Sm(III), Tb(III) and Nd(III). However, the electrode signal to Ce(III) is significantly influenced by the presence of 50-fold excess of Eu(III) and Dy(III).

Evaluation of the effect of potential interfering ions on the square wave voltammetry response of the Ce3+ sensor (I); Ce3+ concentration = 1 × 10−7 mol L−1, interfering ion concentration = 5 × 10−6 mol L−1; calibration curve of the Ce3+ sensor in the optimized conditions (II) in which every point is the average of three replicated determination of Ce3+ at potential of 1.05 V vs Ag/AgCl electrode; inset: the linear range of the calibration curve and the voltammetric responses of the sensor (from (a) 10−3 mol L−1 to (i) 2.5 × 10−11 mol L−1)

In addition to the lanthanide ions the interference effects of some transition metal ions in the determination of Ce(III) (10−7 mol L−1) were also investigated. The results are summarized in Table 1. The tolerance limit was established as the maximum concentration of the potentially interfering species that caused a relative error of 5 % in the analytical signal of Ce(III). The results shown in the table are clear indications for the high selectivity of the electrode to Ce(III) which makes it to resist strongly against the interference effect of lanthanide ions as well as other metal ions.

Analytical characterization

The calibration graph (shown in Fig.4 (II)) of the sensor showed a linear relationship over Ce3+ concentration in the range of 1.0 × 10−6 to 2.5 × 10−11 mol L−1 with a detection limit of 1.0 × 10−11 mol L−1 (S/N = 3). Each point of the calibration graph is the average of three replications. These results indicate that the sensor shows very wide determination range as well as excellent detection limit for Ce(III) determination. The relative standard deviation of 5 separate determinations was found to be 3.1 %.

It was also observed that there was no significant variation (confidence level = 95 %) in the nano-Ce-IP based electrode response to the Ce(III) after about 6 months, compared to the initial responses of the electrodes prepared with the same nano-Ce-IP. This observation suggests that the nano-Ce-IP material maintains its initial affinity and adsorption capacity for Ce(III) even after 6 months.

Determination of Ce3+ in real samples by the sensor

Determination of Ce(III) was carried out in real water samples. The samples were tested before addition of Ce(III) with the optimized sensor and it was found that the drinking and sea water samples were Ce(III) free. Thus, 50 mL of those samples was spiked with different concentrations of Ce(III) and then the method was employed for analysis of the samples. The results of the analysis, summarized in Table 2, certify clearly the applicability of this method for determination of Ce3+ in various real samples.

Determination of rare earths in sea water at ultratrace levels has always been a difficult task, because seawater is high saline complex matrix that causes both spectral interferences and matrix effects for powerful techniques such as ICP-MS. Therefore in such methods, a separation of the matrix components and preconcentration of the analytes are prerequisites. Nevertheless, our nano-Ce-IP-modified voltammetric sensor allowed us to successfully determine ultratrace levels of Ce3+ in sea water samples without pretreatment of the sample.

Comparison of this sensor with some previously reported sensors

Several analytical characteristics of this sensor were compared with those of other previously reported Ce(III) sensors. The comparison results are summarized in Table 3. It is evident that the present sensor exhibits better linear range and lower detection limit, compared to other represented sensors. These results might be attributed to the presence of both MWCNTs and Ce(III) imprinted polymer nanoparticles in the carbon paste electrode composition. The high affinity of the Ce-IP to the target ions has undeniable effect on the observed superiorities of this sensor. However, the positive effect of MWCNTs in the enhancement of the charge transfer rate, in the Ce-IP-modified electrode, is other reason for the improvement of the detection limit of the sensor.

Conclusion

The modification of a carbon paste electrode with the nano-sized Ce(III)-imprinted polymer and MWCNTs led to a voltammetric sensor, capable of Ce3+ determination at ultratrace levels. The nano-sized Ce-IP acted as the selectivity inducing agent and pre-concentrator in the carbon paste electrode, enabling thus the electrode to exhibit higher selectivity and lower detection limit. Also, it was shown that the presence of MWCNTs in the electrode composition could improve the charge transfer rate and thus enhance Ce3+ signal in the Ce-IP based electrode. The sensor showed considerably better analytical characteristics, compared to the previously reported counterparts. The sensor was also found reproducible, rugged, renewable, and cost-effective for in-field study.

References

Wilson CL, Wilson DW (1962) 477 Comprehensive analytical chemistry, vol 1C. Elsevier, Amsterdam

Fricker SP (2006) The therapeutic application of lanthanides. Chem Soc Rev 35:524–533

Rao CK, Reddy VK, Reddy TS (1994) Rapid and sensitive spectrophotometric determination of cerium (IV) with 2, 4-dihydroxy benzophenone benzoic hydrazone. Talanta 41:237–241

Gupta VK, Singh AK, Gupta B (2006) A cerium (III) selective polyvinyl chloride membrane sensor based on a schiff base complex of N, N-bis [2-(salicylideneamino) ethyl] ethane-1, 2-diamine. Anal Chim Acta 575:198–204

Osman AM, Hilhorst R, Laane C (2000) Chemiluminescent determination of Ce (IV) using cypridina luciferin analog. Anal Chim Acta 422:81–87

Akseli A, Rakicioğlu Y (1996) Fluorimetric trace determination of cerium (III) with sodium triphosphate. Talanta 43:1983–1988

Singh AK, Singh P (2010) Determination of cerium ion by polymeric membrane and coated graphite electrode based on novel pendant armed macrocycle. Anal Chim Acta 675:170–180

Afkhami A, Madrakian T, Shirzadmehr A, Tabatabaee M, Bagheri H (2012) New schiff base-carbon nanotube-nanosilica-ionic liquid as a high performance sensing material of a potentiometric sensor for nanomolar determination of cerium (III) ions. Sensors Actuators B Chem 174:237–244

Hamajima Y, Koba M, Endo K, Nakahara H (1985) Determination of lanthanoids in Japanese standard rocks by radiochemical neutron activation method. J Radioanal Nucl Chem 89:315–321

Wang J, Farias PA, Mahmoud JS (1985) Trace determination of lanthanum, cerium, and praseodymium based on adsorptive stripping voltammetry. Anal Chim Acta 171:215–223

Svancara I, Vytras K, Barek J, Zima J (2001) Carbon paste electrodes in modern electroanalysis. Crit Rev Anal Chem 31:311–345

Alizadeh T, Fard LA (2013) Synthesis of Cu2+-mediated nano-sized salbutamol-imprinted polymer and its use for indirect recognition of ultra-trace levels of salbutamol. Anal Chim Acta 769:100–107

Zhang X, Li C, Yan Y, Pan J, Xu P, Zhao X (2010) A Ce3+-imprinted functionalized potassium tetratitanate whisker sorbent prepared by surface molecularly imprinting technique for selective separation and determination of Ce3 +. Microchim Acta 169:289–296

Alizadeh T, Amjadi S (2011) Preparation of nano-sized Pb 2+ imprinted polymer and its application as the chemical interface of an electrochemical sensor for toxic lead determination in different real samples. J Hazard Mater 190:451–459

Alizadeh T, Ganjali MR, Nourozi P, Zare M, Hoseini M (2011) A carbon paste electrode impregnated with Cd 2+ imprinted polymer as a new and high selective electrochemical sensor for determination of ultra-trace Cd2+ in water samples. J Electroanal Chem 657:98–106

Alizadeh T, Ganjali MR, Zare M (2011) Application of an Hg 2+ selective imprinted polymer as a new modifying agent for the preparation of a novel highly selective and sensitive electrochemical sensor for the determination of ultratrace mercury ions. Anal Chim Acta 689:52–59

Garcia R, Pinel C, Madic C, Lemaire M (1998) Ionic imprinting effect in gadolinium/lanthanum separation. Tetrahedron Lett 39:8651–8654

Alizadeh T, Ganjali MR (2015) Alizadeh T (2015) competitive extraction of Gd(III) into a carbon paste electrode impregnated with a nano-sized Gd(III)-imprinted polymer as a new method for its indirect voltammetric determination. Microchim Acta 182:1205–1212

Jiajia GUO, Jibao CAI, Qingde SU (2009) Ion imprinted polymer particles of neodymium: synthesis, characterization and selective recognition. J Rare Earths 27:22–27

Shirvani-Arani S, Ahmadi SJ, Bahrami-Samani A, Ghannadi-Maragheh M (2008) Synthesis of nano-pore samarium (III)-imprinted polymer for preconcentrative separation of samarium ions from other lanthanide ions via solid phase extraction. Anal Chim Acta 623:82–88

Prasad K, Kala R, Rao TP, Naidu GRK (2006) Ion imprinted polymer based ion-selective electrode for the trace determination of dysprosium (III) ions. Anal Chim Acta 566:69–74

Kala R, Biju VM, Rao TP (2005) Synthesis, characterization, and analytical applications of erbium (III) ion imprinted polymer particles prepared via gamma-irradiation with different functional and crosslinking monomers. Anal Chim Acta 549:51–58

Alizadeh T, Amjadi S (2013) Synthesis of nano-sized Eu3+−imprintedpolymeranditsapplication for indirectvoltammetricdeterminationofeuropium. Talanta 106:431–439

Pan J, Zou X, Li C, Liu Y, Yan Y, Han J (2010) Synthesis and applications of Ce (III)-imprinted polymer based on attapulgite as the sacrificial support material for selective separation of cerium (III) ions. Microchim Acta 171:151–160

Sinha N, Ma J, Yeow JT (2006) Carbon nanotube-based sensors. J Nanosci Nanotechnol 6:573–590

Dam HA, Kim D (2009) Selective copper (II) sorption behavior of surface-imprinted core-shell-type polymethacrylate microspheres. Ind Eng Chem Res 48:5679–5685

Javanbakht M, Khoshsafar H, Ganjali MR, Norouzi P, Badei A, Hasheminasab A (2008) Stripping voltammetry of cerium (IIl) with a chemically modified carbon paste electrode containing functionalized nanoporous silica gel. Electroanalysis 20:203–206

Javanbakht M, Khoshsafar H, Reza Ganjali M, Norouzi P, Adib M (2009) Adsorptive stripping voltammetric determination of nanomolar concentration of cerium (III) at a carbon paste electrode modified by N′-[(2-hydroxyphenyl)methylidene]-2-furohydrazide. Electroanalysis 21:1605–1610

Li J, Liu S, Yan Z, Mao X, Gao P (2006) Adsorptive voltammetric studies on the cerium (III)-alizarin complexon complex at a carbon paste electrode. Microchim Acta 154:241–246

Prasad BB, Jauhari D (2015) Double-ion imprinted polymer@ magnetic nanoparticles modified screen printed carbon electrode for simultaneous analysis of cerium and gadolinium ions. Anal Chim Acta 875:83–91

Liu S, Li J, Zhang S, Zhao J (2005) Study on the adsorptive stripping voltammetric determination of trace cerium at a carbon paste electrode modified in situ with cetyltrimethylammonium bromide. Appl Surf Sci 252:2078–2084

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

ESM 1

(DOC 57 kb)

Rights and permissions

About this article

Cite this article

Alizadeh, T., Ganjali, M.R., Akhoundian, M. et al. Voltammetric determination of ultratrace levels of cerium(III) using a carbon paste electrode modified with nano-sized cerium-imprinted polymer and multiwalled carbon nanotubes. Microchim Acta 183, 1123–1130 (2016). https://doi.org/10.1007/s00604-015-1702-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-015-1702-6