Abstract

We report on a glassy carbon electrode modified with bismuth nanoparticles (NanoBiE) for the simultaneous determination Pb2+ and Cd2+ by anodic stripping voltammetry. Operational parameters such as bismuth nanoparticles labelling amount, deposition potential, deposition time and stripping parameters were optimized with respect to the determination of Pb2+ and Cd2+ in 0.1 M acetate buffer solution (pH 4.5). The NanoBiE gives well-defined, reproducible and sharp stripping peaks. The peak current response increases linearly with the metal concentration in a range of 5.0–60.0 μg L−1, with a detection limit of 0.8 and 0.4 μg L−1 for Pb2+ and Cd2+, respectively. The morphology and composition of the modified electrode before and after voltammetric measurements were analysed by scanning electron microscopy and energy dispersive X-ray analysis. The NanoBiE was successfully applied to analysis of Pb2+ and Cd2+ in real water samples and the method was validated by ICP-MS technique, suggesting that the electrode can be considered as an interesting alternative to the bismuth film electrode for possible use in electrochemical studies and electroanalysis.

A bismuth nanoparticles modified glassy carbon electrode (NanoBiE) was developed for the simultaneous determination of Pb2+ and Cd2+. The NanoBiE exhibited very high sensitivity and selectivity over trace heavy metal ions in the solution.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, bismuth-based electrodes have been considered as a favourable replacement for toxic mercury electrodes in voltammetric analysis of trace heavy metals, owning to their simple preparation, high sensitivity, well-defined and separated stripping signals, insensitivity to dissolved oxygen and the very low toxicity [1–4]. Extensive studies have been carried out on developing high sensitive bismuth-based electrodes [3, 5–10] and exploring the application of the bismuth electrodes in different areas [11–13]. A recent review [4] has summarized the major achievements on bismuth-based electrodes in the last decades since the first publication of the pioneering report in 2000 [1]. It indicates that the main advantage of this class of material is its ability to form “fused” alloy with other metals, in a way comparable to the ability of mercury to form amalgams. The formation of the alloys between bismuth and metals is responsible for the superior voltammetric performance of bismuth-based electrodes, as the metals are concentrated onto the surface during the reductive preconcentration step [14]. To date, the research on bismuth-based electrodes is mainly focused on the bismuth film coated electrodes (BiFEs) [5–8, 11–13, 15–17], which have exhibited high selectivity, sensitivity and reproducibility in the electrochemical analysis of heavy metals. However, for a wider application of the bismuth-based electrode, there are some instances where the preparation of the pre-plated bismuth film is impossible or the introducing of bismuth ions into the solution is undesirable.

To overcome the above weakness of the bismuth film coated electrodes, it is necessary to develop electrodes with other bismuth forms. Besides a solid or bulk bismuth electrode, the incorporation of a bismuth precursor or particles into the bulk of the electrode can be applied. The introduction of nanoparticles onto electrode surface has been known to enhance electroanalytical properties of the electrode in some areas, primarily due to their increased surface area coupled with the enhanced mass transfer effect [14, 18–22]. On the other hand, it avoids the time-consuming procedures consisting of pre-plating and polishing steps. Therefore, a bismuth nanoparticles modified electrode should be ideal for effectively improving the electrochemical properties and application of bismuth-based electrodes. Initial attempts showed that bismuth nanoparticles have been successfully employed to modify carbon paste electrodes (CPEs) and screen-printed carbon electrodes (SPCEs) for stripping analysis [14, 18–21]. The modified electrodes exhibited high sensitivity and selectivity over trace heavy metal ions in the solution, which is comparable or even superior to that of bismuth film coated electrodes [23]. However, the inherent disadvantages of CPEs and SPCEs such as low mechanical stability and reproducibility limit their practical application. Moreover, for CPEs the use of nonconductive binders such as paraffin oil may weaken the electrochemical performance of the electrode. The advantageous analytical properties of glassy carbon electrode, together with the simplicity of its surface renewal and its wide availability, make it suitable to develop the voltammetric studies of the modified electrodes [24].

In the present work, we describe the fabrication and the analytical performance of a bismuth nanoparticles modified glassy carbon electrode (NanoBiE) for the anodic stripping voltammetry (ASV) of Pb2+ and Cd2+. To maximize the electrochemical performance of the modified electrode, the optimum conditions of ASV and the bismuth labelling amount on the electrode were investigated. Scanning electron microscopy (SEM) and energy dispersive X-ray analysis (EDX) analyses were employed to characterise the bismuth nanoparticles modified electrodes and probe the long-time stability of the modified electrode after voltammetric measurements. Finally, the modified electrode was used for the stripping voltammetric quantification of Pb2+ and Cd2+ and to the analysis of the natural water samples.

Experimental

Reagents

All chemicals were of analytical grade, obtained from Sigma-Aldrich (http://www.sigmaaldrich.com/sigma-aldrich/home.html) and used without further purification unless stated otherwise. Bismuth nanoparticles, 99.9 %, average particle size 80 nm, were purchased from US Research Nanomaterials, Inc. (http://www.us-nano.com/). The morphology and composition of as-received nanoparticles was investigated by SEM and EDX (shown in Fig. S1 in Electronic supplementary Materials (ESM)). Nafion was of 5 wt% solution in a mixture of water and lower aliphatic alcohols. Coating solutions were prepared by mixing proper amount of bismuth nanoparticles and Nafion with absolute ethanol. Standard solutions of Cd2+ and Pb2+ (1,000 mg L−1) were prepared after appropriate dilution with 1 % nitric acid (w/v). An acetate buffer solution (0.1 mol L−1, pH 4.5) was used as supporting electrolyte. Millipore-Q (18.2 MΩ•cm) water was used for all experiments. All glassware was soaked in 2 % nitric acid for at least 24 h, rinsed with copious of deionized water and then rinse twice with Milli-Q water before use.

Apparatus

All voltammetric measurements were performed with an electrochemical analyzer (Model BAS-100B), in connection with a personal computer. The electrochemical cell was assembled with a conventional three-electrode system: a modified glassy carbon electrode (GCE) (dis diameter of 3 mm, BAS) was used as the working electrode, with the Ag/AgCl (3 M NaCl) and Pt wire as the reference electrode and counter electrode, respectively. Stirring was carried out using a magnetic stirrer. No deaeration of the solutions was applied at any stage of this study. Scanning electron micrographs were obtained with a FEI Quanta 450 FEG ESEM with an EDAX Apollo X SDD EDX detector, using an accelerating voltage of 30 kV. For the validation of the stripping voltammetric method, ICP-MS technique was employed using Bruker 820-MS instrument.

Electrode preparation

The GCEs were polished with water slurry of 0.3 μm Al2O3 powder on a polishing kit to a visually shiny surface. The electrodes were rinsed with copious of Milli-Q water and placed in an ultrasonic bath to remove any residual polishing material. Bismuth nanoparticles of 0.025 g were dispersed well into 5 mL ethanol using an ultrasonic vibrator. To gain information about the effect of the amount of labeled bismuth nanoparticles on the stripping performance, modifying solutions of different concentration of bismuth nanoparticles were prepared by mixing 1 % Nafion and proper amount of the dispersed nano-bismuth solution, and diluted to 1,000 mm3 with ethanol (Nafion was used as a strong adhesion reagent for bismuth nanoparticle coating). Then a 2.0 μL drop of the freshly prepared solution containing proper amount of Nafion and nano-bismuth was placed onto the clean GCE surface with a microsyringe (Agilent Technologies, Inc.), and solvents were left to dry in the air. The freshly prepared modified electrode was tested by performing at least three, 120 s accumulation/stripping voltammetric measurements in a solution containing 20 μg L−1 Pb2+ and Cd2+ to ensure a repeatable response. The electrode was then suitable for use in various experiments undertaken. In-situ BiFEs were prepared by spiking the sample with 500 μg L−1 Bi3+ and simultaneously depositing Bi and the metals on the surface of the electrode according to a procedure described elsewhere [1].

Sample preparation

Natural water samples were collected from lakes in Mawson Lakes (Adelaide, South Australia). These samples were filtered through a 0.45 μm filter and stored after acidification to pH 4–5 with conc. nitric acid. Generally, 10 cm3 of water sample was mixed with equal volume of 0.2 M acetate buffer (pH 4.5) and then analysed by the optimized square wave anodic stripping voltammetry (SWASV) method.

Procedures

The three electrodes were immersed into an electrochemical cell, containing 0.1 M acetate buffer (pH 4.5). Standard solution of Pb2+ and Cd2+ was added into the cell and the mixed solution was stirred at the potential of −1,200 mV for 2 min. Following the preconcentration step, the stirring was stopped. After 10 s of quiet time, square wave stripping voltammetric measurement was performed by potential scan from −1,200 to −400 mV with frequency 20 Hz, pulse amplitude 25 mV and potential step of 5 mV. The modified electrode was regenerated by holding the electrode at −400 mV for 40 s to remove the residual target metals.

Results and discussion

Voltammetric performance of the bismuth nanoparticles modified glassy carbon electrode

Figure 1 shows the square wave anodic stripping voltammograms of 20 μg L−1 Pb2+ and Cd2+ at the bare GCE, Nafion-coated GCE, BiFE and NanoBiE. As can be seen from the figure, the stripping responses of the metals at the bare GCE and Nafion-coated GCE were very poor, especially for the peak of lead (see Fig. 1, curve a and b). However, after the introducing of bismuth into the electrode, it exhibited high sensitivity toward Pb2+ and Cd2+ detection with well-defined, sharp and separate stripping peaks (Fig. 1, curve c–d). This phenomenon can be attributed to the fact that bismuth can form “fused” alloys with Pb2+ and Cd2+ which makes them more readily to be reduced [1, 2]. The peak currents of Pb2+ and Cd2+ measured at NanoBiE were even better than that of BiFE (with the peaks registered from a NanoBiE were more than 1.5 times higher than the peaks registered from the BiFE). At NanoBiE, the bismuth nanoparticles should contain a great number of active sites due to the increased surface area of the nanoparticles. Consequently, the increased number of the active surface sites at the electrode surface results in an improved signal-to-noise ratio at NanoBiE compared with conventional BiFE, as observed in Fig. 1.

SWASVs of 20 μg L−1 Pb2+ and Cd2+ by different working electrodes: (a) Bare GCE; (b) Nafion coated GCE; (c) BiFE; and (d) NanoBiE. Supporting electrolyte: 0.1 M acetate buffer (pH 4.5); deposition potential: −1.2 V; deposition time: 120 s; quiet time; 10 s; Frequency: 20 Hz; pulse amplitude: 25 mV; potential step: 5 mV

In addition, the peak potential values of the two metals at NanoBiE were also shifted to the negative direction compared with the BiFE. These shifts indicated a different coulombic interaction between bismuth and the accumulated metals (most probably due to the incorporation of Nafion at the electrode surface) and thus affected the redox potential of the latter [6].

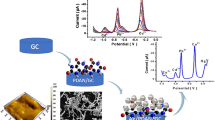

Surface morphologies

SEM can take useful insight into the microstructure and distribution of the bismuth nanoparticles on the electrode surface. Figure 2a (left) illustrates the SEM image of the as-prepared NanoBiE surface. It can be seen that the spherical bismuth nanoparticles are condensed in small portions and scattered randomly on the electrode surface. A closer look (Fig. 2a, right) shows that the bead-shaped bismuth nanoparticle domains were surrounded by a non-homogeneous cloudy surface of Nafion polymer. The great surface area provided by the particles promotes more interaction between bismuth and the target metal; this can thus promote greater signal-to-noise ratio, as observed in Fig. 1.

Figure 2b (left) exhibits the SEM image of the NanoBiE after 25 measurements of SWASV. The image shows that the agglomerates of bismuth nanoparticles were still randomly scattered on the electrode surface but at a higher magnification (Fig. 2b, right), the sphere shapes of the bismuth nanoparticles were broken after the measurements. The shape change of the bismuth nanoparticles may result from the electrochemical reaction of bismuth from the solution or at the electrode surface during the potential scan and this may potentially affect the voltammetric performance of the electrode. From the EDX analysis of the SEM images, the relative amounts of Bi significantly decreased after 25 voltammetric measurements (see Table 1), suggesting the possible decomposition and/or dissolution of Bi at the electrode after long time use. The long-term stability of the electrode will be discussed later in this study.

Experimental conditions optimization

To optimize the bismuth nanoparticles amount applied on the electrode surface, electrodes with different bismuth nanoparticles applied ranging from 25 to 200 μg were prepared. Figure 3 shows the effect of the applied amount of bismuth nanoparticles on the stripping responses of the 20 μg L−1 Pb2+ and Cd2+. As shown in the figure, the peak currents increased quickly with the increase of bismuth nanoparticles applied on the electrode surface but decreased rapidly over the highest point. The decrease of the peak currents at higher amount of bismuth nanoparticles may be due to the severe agglomeration of the nanoparticles occurring with increasing bismuth nanoparticles in the modification solution [19]. The other reason can be attributed to the lower adhesion between the polymer film and the electrode surface as a consequence of the increased bismuth nanoparticles at the electrode surface. The optimum amount of bismuth labeled at the electrode surface was chosen to be 50 μg for the maximized electrochemical performance of the sensor electrode.

Effects of the amount of bismuth nanoparticles labeled on the electrode surface on the stripping responses of 20 μg L−1 Pb2+ and Cd2+. Other conditions are the same as in Fig. 1

To further optimize the performance of the NanoBiE for the determination of Pb2+ and Cd2+, the deposition conditions including deposition potential and deposition time effects were investigated. Figure 4a shows the effect of deposition potential on the stripping currents of 20 μg L−1 Pb2+ and Cd2+. As the deposition potential decreased from −1.0 to −1.2 V, the peak currents of lead and cadmium increased. However, as the deposition potential further negatively shifted, both the peak currents decreased. This is most probably due to the reduction of certain other chemicals (e.g. hydrogen evolution) interfering with the determination [19, 21]. Therefore, a deposition potential of −1.2 V was chosen for further experiments. Figure 4b illustrates the influence of the deposition time (from 30 to 400 s) on the stripping currents of Pb2+ and Cd2+. The peak currents increased linearly with the deposition time and started to level off after 300 s, which is due to the saturation of heavy metals on the modified electrode surface. A deposition time of 120 s is adequate for the analysis of the metal ions with the standard solutions in this work and was then selected for all subsequent work. However, for the determination of low concentration of heavy metals, a longer deposition time is recommended as the stripping peak currents are also dependent on ion concentrations; a lower concentration gradient slows the diffusion of the ion toward the electrode surface during the deposition step and thus, takes longer time to reach the equilibrium state.

Effects of deposition potential (a) and deposition time (b) on the stripping response of 20 μg L−1 Pb2+ and Cd2+ obtained at NanoBiE. Other conditions are the same as in Fig. 1

To further optimize the voltammetric performance of the electrode, the ASV parameters (step potential, pulse amplitude and frequency) were optimized on the basis of the stripping response of 20 μg L−1 Pb2+ and Cd2+. The optimized conditions selected for quantitative measurements of low concentration of heavy metal ions (Pb2+ and Cd2+) were: SW frequency: 20 Hz; step height: 5 mV; and pulse amplitude: 25 mV.

Long-term stability

Figure 5 shows the peak currents of Pb2+ and Cd2+ which were obtained from the repetitive measurement by SWASV at NanoBiE from a solution containing 20 μg L−1 Pb2+ and Cd2+. It can be seen that the peak currents for both metal ions fluctuated at the first three measurements and then stabilized. After certain runs (25 and 17 runs for lead and cadmium, respectively), the peak currents gradually decreased. The decrease of the peak current was faster for cadmium than lead. Previous XRD studies [25] have showed that the decrease of the stability at bismuth nanoparticles modified electrodes were associated with the phase change of the bismuth nanoparticles caused by the oxidation of Bi into BiOCl/Bi2O2CO3 after long time soaking of the electrode in the electrolyte solution. A similar reaction might have occurred at NanoBiE that caused the change of the structure and composition of the bismuth nanoparticle as observed SEM and EDX.

The peak currents of 20 μg L−1 Pb2+ and Cd2+ obtained from repetitive measurements at NanoBiE by SWASV. Other conditions are the same as in Fig. 1

Analytical features

Calibration for the simultaneous determination of Pb2+ and Cd2+ using the modified electrode by SWASV was illustrated in Fig. 6. The stripping responses of the modified electrode for lead and cadmium were linear over the range from 5.0 to 60.0 μg L−1 with the correlation coefficients of 0.994 and 0.996 for Pb2+ and Cd2+, respectively. The estimated detection limits of the modified electrode were determined to be 0.8 and 0.4 μg L−1 for lead and cadmium respectively, on the basis of the signal-to-noise characteristics (S/N = 3) under a 10 min accumulation (the experimental data were present in Fig. S2 in ESM). Lower detection limit can be expected by prolonging the deposition time. Repetitively measurement (15 times) of 20 μg L−1 Pb2+ and Cd2+ yields a stable response with a relative standard deviation smaller than 5 % for both Pb2+ and Cd2+. The measurement reproducibility at different electrodes was also studied. Six electrodes were prepared from the same batch and they were evaluated by performing the determination of 20 μg L−1 Pb2+ and Cd2+. The RSD for the responses among electrodes was 4.2 and 3.4 % for Pb2+ and Cd2+, respectively. The analytical performance of the NanoBiE for Pb2+ and Cd2+ detection is comparable or even superior to other reported bismuth nanomaterial-based electrodes, as summarized in Table 2.

a A series of voltammograms for simultaneous determination of Pb2+ and Cd2+ obtained at NanoBiE (bottom to top: 5, 10, 20, 30, 40, 60 μg L−1 Pb2+ and Cd2+, respectively). b The calibration curves for the determination of Pb2+ and Cd2+. Other conditions are the same as in Fig. 1

Interference study

The interference study was performed by adding various potentially interfering ions in 100-fold excess into a standard solution containing 20 μg L−1 Pb2+ and Cd2+. No significant alteration of the voltammetric responses of the heavy metal ions was experienced in excess of the following ions: Na+, K+, Mg2+, Ca2+, Al3+, Mn2+, NH4+, Cl−, and SO4 2−. However, in presence of Cu2+, the stripping response has altered significantly. The interfering effect from Cu2+ appears even at low concentrations ratio (1:1) at the NanoBiE. This is probably due to the competition between copper and heavy metal ions for active surface sites on the electrode as well as the formation of an intermetallic compound between copper and lead as discussed in the previous studies [13, 26]. The interfering effect from copper can be alleviated by masking the copper in the solution via selective complexation with ferrocyanide [26].

Application

The modified electrode was applied to the analysis of Pb2+ and Cd2+ in real water samples under the optimum experimental conditions. As shown in Table 3, the results obtained for the water samples are comparable to the reference values obtained with ICP-MS methods, indicating the good accuracy and the reliability of the proposed method. Therefore, the modified NanoBiE can provide an effective method for the simultaneously determination of Pb2+ and Cd2+ at low concentration level in real water samples.

Conclusion

In this work, a high sensitive bismuth nanoparticles modified glassy carbon electrode has been developed for Pb2+ and Cd2+ detection. The relevant calibration curves for Pb2+ and Cd2+ were linear in the range of 5–60 μg L−1, with a detection limit of 0.8 and 0.4 μg L−1 for Pb2+ and Cd2+ under 600 s deposition time, respectively. The modified electrode was successfully applied to the determination of Pb2+ and Cd2+ from water samples and the results were in satisfactory agreement with ICP-MS determination. Compared with conventional BiFE, the modified electrodes exhibited superior sensitivity, due to the increase of the surface area at bismuth nanoparticles which makes them more electrochemically sensitive than BiFEs. However, the stability of the electrode decreased after successive SWASV measurements caused by the phase change of the nanoparticles. Therefore further investigations are desired to improve the phase stability of this new electrode. In spite of the long-term instability, bismuth nanoparticles modified electrodes possess many attractive properties and holds great promise for wide application of bismuth in electrochemical analysis.

References

Wang J, Lu J, Hocevar SB, Farias PAM, Ogorevc B (2000) Bismuth-coated carbon electrodes for anodic stripping voltammetry. Anal Chem 72(14):3218–3222

Wang J (2005) Stripping analysis at bismuth electrodes: a review. Electroanalysis 17(15–16):1341–1346

Legeai S, Vittori O (2006) A Cu/Nafion/Bi electrode for on-site monitoring of trace heavy metals in natural waters using anodic stripping voltammetry: an alternative to mercury-based electrodes. Anal Chim Acta 560(1–2):184–190

Švancara I, Prior C, Hočevar SB, Wang J (2010) A decade with bismuth-based electrodes in electroanalysis. Electroanalysis 22(13):1405–1420

Hočevar SB, Ogorevc B, Wang J, Pihlar B (2002) A study on operational parameters for advanced use of bismuth film electrode in anodic stripping voltammetry. Electroanalysis 14(24):1707–1712

Kefala G, Economou A, Voulgaropoulos A (2004) A study of Nafion-coated bismuth-film electrodes for the determination of trace metals by anodic stripping voltammetry. Analyst 129(11):1082–1090

Jia J, Cao L, Wang Z (2007) Nafion/Poly(sodium 4-styrenesulfonate) mixed coating modified bismuth film electrode for the determination of trace metals by anodic stripping voltammetry. Electroanalysis 19(17):1845–1849

Torma F, Kádár M, Tóth K, Tatár E (2008) Nafion®/2,2′-bipyridyl-modified bismuth film electrode for anodic stripping voltammetry. Anal Chim Acta 619(2):173–182

Pan D, Zhang L, Zhuang J, Yin T, Qin W (2012) A novel tin-bismuth alloy electrode for anodic stripping voltammetric determination of zinc. Microchim Acta 177(1–2):59–66

Yang G, Wang Y, Qi F (2012) Differential pulse anodic stripping voltammetric determination of traces of tin using a glassy carbon electrode modified with bismuth and a film of poly(bromophenol blue). Microchim Acta 177(3–4):365–372

Kefala G, Economou A, Voulgaropoulos A, Sofoniou M (2003) A study of bismuth-film electrodes for the detection of trace metals by anodic stripping voltammetry and their application to the determination of Pb and Zn in tapwater and human hair. Talanta 61(5):603–610

Xu H, Zeng L, Huang D, Xian Y, Jin L (2008) A Nafion-coated bismuth film electrode for the determination of heavy metals in vegetable using differential pulse anodic stripping voltammetry: An alternative to mercury-based electrodes. Food Chem 109(4):834–839

Liu B, Lu L, Wang M, Zi Y (2008) A study of nafion-coated bismuth-film electrode for the determination of zinc, lead, and cadmium in blood samples. Electroanalysis 20(21):2363–2369

Toghill KE, Wildgoose GG, Moshar A, Mulcahy C, Compton RG (2008) The fabrication and characterization of a bismuth nanoparticle modified boron doped diamond electrode and its application to the simultaneous determination of cadmium(II) and lead(II). Electroanalysis 20(16):1731–1737

Wang J, Lu J, Kirgöz ÜA, Hocevar SB, Ogorevc B (2001) Insights into the anodic stripping voltammetric behavior of bismuth film electrodes. Anal Chim Acta 434(1):29–34

Kefala G, Economou A (2006) Polymer-coated bismuth film electrodes for the determination of trace metals by sequential-injection analysis/anodic stripping voltammetry. Anal Chim Acta 576(2):283–289

Jia J, Cao L, Wang Z, Wang T (2008) Properties of Poly(sodium 4-styrenesulfonate)-ionic liquid composite film and its application in the determination of trace metals combined with bismuth film electrode. Electroanalysis 20(5):542–549

Lee G-J, Lee H-M, Rhee C-K (2007) Bismuth nano-powder electrode for trace analysis of heavy metals using anodic stripping voltammetry. Electrochem Comm 9(10):2514–2518

Lee G-J, Kim CK, Lee MK, Rhee CK (2010) Advanced use of nanobismuth/nafion electrode for trace analyses of zinc, cadmium, and lead. J Electrochem Soc 157(7):J241–J244

Lee G-J, Kim CK, Lee MK, Rhee CK (2010) Simultaneous voltammetric determination of Zn, Cd and Pb at bismuth nanopowder electrodes with various particle size distributions. Electroanalysis 22(5):530–535

Ping JF, Wu J, Ying YB (2012) Determination of trace heavy metals in milk using an ionic liquid and bismuth oxide nanoparticles modified carbon paste electrode. Chin Sci Bull 57(15):1781–1787

Li Y, Sun G, Zhang Y, Ge C, Bao N, Wang Y (2013) A glassy carbon electrode modified with bismuth nanotubes in a silsesquioxane framework for sensing of trace lead and cadmium by stripping voltammetry. Microchim Acta 180:1–7

Saturno J, Valera D, Carrero H, Fernández L (2011) Electroanalytical detection of Pb, Cd and traces of Cr at micro/nano-structured bismuth film electrodes. Sensor Actuat B Chem 159(1):92–96

Królicka A, Bobrowski A (2004) Bismuth film electrode for adsorptive stripping voltammetry – electrochemical and microscopic study. Electrochem Comm 6(2):99–104

Lee GJ, Kim CK, Lee MK, Rhee CK (2010) Effect of phase stability degradation of bismuth on sensor characteristics of nano-bismuth fixed electrode. Talanta 83(2):682–685

Yang D, Wang L, Chen Z, Megharaj M, Naidu R (2013) Investigation of copper(II) interference on the anodic stripping voltammetry of lead(II) and cadmium(II) at bismuth film electrode. Electroanalysis 25(12):2637–2644

Sosa V, Serrano N, Ariño C, Díaz-Cruz JM, Esteban M (2014) Sputtered bismuth screen-printed electrode: a promising alternative to other bismuth modifications in the voltammetric determination of Cd(II) and Pb(II) ions in groundwater. Talanta 119:348–352

Hwang G-H, Han W-K, Park J-S, Kang S-G (2008) An electrochemical sensor based on the reduction of screen-printed bismuth oxide for the determination of trace lead and cadmium. Sensor Actuat B Chem 135(1):309–316

Acknowledgments

The authors gratefully acknowledge the CRC CARE (Australia) in funding this research.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 253 kb)

Rights and permissions

About this article

Cite this article

Yang, D., Wang, L., Chen, Z. et al. Anodic stripping voltammetric determination of traces of Pb(II) and Cd(II) using a glassy carbon electrode modified with bismuth nanoparticles. Microchim Acta 181, 1199–1206 (2014). https://doi.org/10.1007/s00604-014-1235-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-014-1235-4