Abstract

We report on a glassy carbon electrode modified with carbon-coated nickel nanoparticles (C-Ni/GCE) that can be used to study the electrochemical properties of rutin and its interaction with bovine serum albumin (BSA) via cyclic voltammetry and differential pulse voltammetry. The effects of pH value, accumulation potential, accumulation time and reaction time were optimized. A pair of reversible peaks is found in the potential range of 0 to around 0.6 V at pH 5.0. Two linear response ranges (with different slopes) are found, one in the 2 to 210 nM concentration range, the other between 0.21 and 1.72 μM. The detection limit is as low as 0.6 nM. On addition of BSA to the rutin solution, a decrease of the current is observed that is proportional to the concentration of BSA. The binding constant and stoichiometric ratio were calculated.

1. Preparation of carbon-coated nickel nanoparticles modified glassy carbon electrode (C-Ni/GCE). 2. C-Ni/GCE improves the electrochemical redox of rutin. 3. The prepared electrode determines rutin with high sensitivity and selectivity. 4. The developed method can determine rutin and its interaction with bovine serum albumin.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rutin, 3′,4′,5,7-tetrahydroxyflavone-3β-D-rutinoside, is one of the most abundant flavonoids, which are a group of antioxidant activities polyphenolic compounds [1, 2]. Rutin has been shown to act as a scavenger of various oxidizing species, i.e. superoxide anion, hydroxyl radical and peroxyl radicals [3], and has been widely used clinically as the therapeutically medicine [4]. So far, various analytical methods have been reported for the separation and determination of rutin, including high performance liquid chromatography [5], resonance light scattering [6] and capillary electrophoresis [7]. However, most of these methods have their disadvantage, such as low sensitivity, time consuming and relatively complicated sample pretreatment. The electrochemical analysis has many advantages over conventional methods. Wu et al. successfully prepared single-sided heated graphite cylindrical electrodes to detect rutin [4]. Lin and co-workers determined rutin at multi-wall carbon-nanotube paste electrodes [8]. Oliveira et al. developed a biosensor based on gilo peroxidase immobilized on chitosan chemically crosslinked with epichlorohydrin for determination of rutin [9]. Rutin have also been determined by acetylene black nanoparticle-modified glassy carbon electrode (GCE) [10], Nafion-graphene oxide-ionic liquid modified electrode [11], graphene nanosheets- chitosan-a poly (amidoamine) dendrimer modified GCE [12]. Recently, our group [13] had developed a DNA-modified ionic liquid-carbon paste electrode for the detection of rutin. However, the preparations of those electrodes were comparably complicated.

As one of the most abundant carrier proteins, serum albumin plays an important role in the transport and disposition of endogenous and exogenous ligands present in blood [14], binding covalently or reversibly to these ligands and increasing the passive tumor selectivity of the drug by enhanced permeation and retention effect [15]. The binding properties of chemicals with serum albumin are clearly important for providing a pathway to the pharmacokinetic and pharmacodynamic mechanisms of these substances in various tissues [16]. In this paper, bovine serum albumin (BSA) is selected as model protein because of its long-standing interest in protein community and structural homology with human serum albumin. Up to now, many researches have focused on the interaction of BSA with small molecules [17]. The interaction of BSA with rutin has been studied by fluorescence [18], resonance light scattering technique [19] and capillary electrophoresis [20]. To the best of our knowledge, there was no report about the interaction of BSA with rutin using electrochemical methods.

Recently, some new materials, due to unique electrical and chemical properties, have drawn much attention in various fields. In 1993, a new class of nano-materials, which is carbon-coated metal crystals, was first synthesized [21]. The application of the magnetic nanocapsules ranges from magnetic inks, magnetic recording media, toner for xerography, ferrofluids to biomedical applications such as contrast agents in magnetic resonance imaging, because of their magnetic properties and protective coatings against environmental degradation [22]. Carbon-coated nickel nanoparticles (C-Ni) are one kind of the carbon-coated metal crystals. It has some special features due to the effect of Ni when compared with carbon onions consisting only of carbon layers [23]. It could potentially absorb a micromolecular pharmaceutical and be used as a magnetism-targeted drug carrier in cancer treatments [24]. However, the reports about applications of C-Ni in electrochemistry are quite seldom.

In the present work, a fast and sensitive C-Ni modified electrode was fabricated to detect rutin, which presented obvious electrocatalytic activities toward the redox of rutin. The interactions of rutin with BSA have been explored by electrochemical method and fluorescence spectra in details.

Experimental

Chemicals and reagents

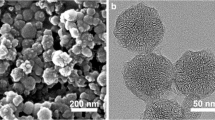

Rutin was purchased from Shanghai Boyun Biotech Co., Ltd. (Shanghai, China, www. xiepingtn.bioon.com.cn) and its stock solution was prepared with ethanol absolute. BSA came from Sigma (St. Louis, MO, USA, www.sigmaaldrich.com/china-mainland.html). C-Ni (the average diameter 10–50 nm and nickel metal content 64.5 %) was obtained from Professor Xungao Zhang (the Center for Analysis and Measurement, Wuhan University, Wuhan, China). It was synthesized by an alternative current (AC) arc discharge method and the morphologies of C-Ni nanoparticles had been reported [25]. Phosphate buffer comprised Na2HPO4 and NaH2PO4; pH value was adjusted with NaOH and H3PO4. All solutions were with double-distilled water. All other reagents were of analytical grade.

Apparatus

Cyclic voltammetry (CV) and differential pulse voltammetry (DPV) measurements were performed by a model CHI 660A electrochemical workstation (CH Instrument, Chenhua Co., Shanghai, China, www.chinstruments.com), which was controlled by a personal computer. A three-electrode system was used in the measurements, with a bare GCE (3 mm diameter) or a C-Ni/GCE as the working electrode, a saturated calomel electrode (SCE) as the reference electrode and a platinum wire as the auxiliary electrode. Transmission electron microscopy (TEM) was performed with a TEM-100CX11 (JEOL, Tokyo, Japan, www.jeol.cn) operating at 200 kV. Shimadzu RF-540 spectrofluorometer (Tokyo, Japan, www.shimadzu.com.cn) was equipped with a 1.0 cm quartz cell. The excitation and emission wavelengths for BSA were 290 and 350 nm, respectively, with the excitation and emission slit widths set at 10 nm. Ultrasonic cleaner (Branson2000, USA, www.branson.com.cn) and 320-S acidometer (Mettler-Toledo, Switzerland, www.mt.com) were used in this experiment. All the data were obtained at room temperature.

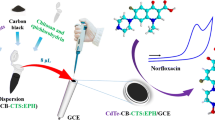

Preparation of the C-Ni modified electrode

C-Ni (1.0 mg) was dispersed in 1.0 mL of double-distilled water and the mixture was agitated in an ultrasonic bath for an hour to achieve a well-dispersed suspension. A total of 10 μL of the resulting dispersion was coated onto the bare GCE and then allowed to dry at room temperature. Then C-Ni/GCE was fabricated. The effective working area of electrode was calculated by CV with 1 mM K3Fe(CN)6 as a probe at different scan rates. For a reversible process, the following equation applies:

where ip refers to the peak current (A) and A is the electrode area (cm2). For 1 mM K3Fe(CN)6, n = 1, DR = 7.6 × 10−6 cm2 s−1 (0.1 M KCl) [26], co is the concentration of K3Fe(CN)6 (M), ν is the scan rate (V s−1) and the unit of constant is C mol−1 V−1/2. Then the surface area of the bare GCE and C-Ni/GCE can be calculated to be 0.0333 cm2 and 0.0611 cm2, respectively. The effective working area of modified electrode is almost 2 times larger than that of the bare GCE, which proved that the bare electrode was modified efficiently by C-Ni nanoparticles.

Results and discussion

Electrochemical behaviors of rutin at C-Ni/GCE

The electrochemical responses of rutin were characterized by CV. As shown in Fig. 1, there was no redox peaks on C-Ni/GCE (Fig. 1b) in the absence of rutin, indicating that C-Ni was nonelectroactive in the potential range of 0 ~ 0.6 V in phosphate buffer. While in the presence of rutin, the bare electrode showed a couple of peaks (Fig. 1a), with a ΔE p (the difference between the anodic and cathodic peak potentials) value of 42 mV. A pair of much more reversible redox peaks generated at C-Ni/GCE (Fig. 2c). The cathodic and anodic peaks were 0.328 V and 0.348 V, respectively, with ΔE p = 20 mV. The reversibility of rutin was significantly improved at C-Ni/GCE, which was the result of the acceleration of electron-transfer reactions of nanoparticles. The redox peak current was 10 times higher than that on the bare GCE, which indicated that the bare electrode was modified efficiently by C-Ni nanoparticles. Considering the working area of the C-Ni/GCE was only 2 times larger than that of the bare GCE, such current enhancement may be due to not only the big working area of the C-Ni/GCE, but also electrocatalysis of C-Ni nanoparticles for rutin. The C-Ni nanoparticles made more rutin take part in the electrochemical reaction. While on the grounds of |E p − E p/2| = 56.5/n, the electron transfer number (n) was 2.

The effect of the medium’s pH on the electrochemical signal was analyzed. It was found that the peak currents of rutin increased gradually with increasing pH and reached its maximum at pH 5.0, then decreased. Thus, pH 5.0 was chosen as the best pH in the following experiments. In addition, the peaks shifted negatively with increasing of pH, indicating that protons participated in the reaction. The equations between peak potential and pH values were as follows: E pc (V) = 0.62–0.059pH (a), R 2 = 0.994; E pa (V) = 0.68–0.064pH (b), R 2 = 0.998. As the slope was approximately close to the theoretical value of −57.6 mV pH−1 [27], it suggested that the total number of electrons and protons taking part in the reaction was the same, namely two electrons and two protons were involved in the reaction. The details of redox mechanism of rutin at C-Ni/GCE can be described as Fig. 2.

CV was employed to study the influence of scan rate on the responses of rutin. It was found that the both the cathodic and anodic peak currents were proportional to the scan rates in the range from 0.01 to 0.20 V s−1, the linear relationship of i p and υ can be expressed in the following equations: i pc (A) = −2.3 × 10−7 − 5.2 × 10−5 υ (V s−1), R 2 = 0.998; i pa (A) = 6.1 × 10−7 + 6.0 × 10−5 υ (V s−1), R 2 = 0.996. It suggested that the electrode reaction of rutin on C-Ni/GCE was controlled by adsorption.

The effect of accumulation potential on the responses of 5 μM rutin was investigated between −0.2 and 0.3 V (Fig. 3a). Varying the accumulation potential with a 210 s accumulation time, the peak current increased with the increase of the potential starting from −0.2 V, and reached a plateau at 0.1 V. Therefore, 0.1 V was chosen as the optimum accumulation potential. Accumulation time also has a great influence on the peak current. The accumulation time was varied between 0 and 350 s with an accumulation potential of 0.1 V. Figure 3b shows that the peak current increases, and then reaches a plateau around 210 s. The results suggested that the amount of rutin adsorbed at the surface of C-Ni/GCE tended to reach saturation when accumulation time exceeded 210 s. Considering both sensitivity and work efficiency, 210 s was employed for the determination of rutin.

Electrochemical determination of rutin at C-Ni/GCE

DPV was used in quantitative measurements because of its higher sensitivity. Figure 4 shows DPVs obtained for different concentrations of rutin. The results show two linear segments with different slopes for rutin concentrations, for 2 to 210 nM, the regression equation: i pa(A) = 7.27 × 10−5 + 8.30 × 10−6 lg c (M) (Fig. 4 Inset: curve a), R 2 = 0.996 (n = 10), while for 0.21 and 1.72 μM, the regression equation: i pa(A) = 1.23 × 10−4 + 1.59 × 10−5 lg c (M) (Fig. 4 Inset: curve b), R 2 = 0.996 (n = 8). The detection limit was 0.6 nM (S/N = 3), which was much lower then that reported using β-Cyclodextrin incorporated carbon nanotubes-modified electrode (0.2 μM) [28], Nafion-graphene oxide-ionic liquid modified electrode (16 nM) [11]. The low detection limit may be due to the strong adsorption of rutin on the C-Ni nanoparticles. As shown in Table 1, the specific features of the proposed method were compared with other typical methods, and the results showed that the proposed method in this work was preferable in the determination of rutin.

The reproducibility of C-Ni/GCE was examined by the detection of 5 μM rutin. A relation standard deviation (RSD) value of 2.59 % was obtained for five successive determinations, which showed that the C-Ni/GCE had good reproducibility. The stability of C-Ni/GCE was also investigated. The anodic peak current of rutin on the modified electrode decreased only 2.5 % of its original response after 50 days, which demonstrated that the C-Ni/GCE had excellent stability.

In order to evaluate the validity of this method, the recovery test was carried out by adding different known amounts of rutin into the pure rutin solution. As shown in Table 2, the recoveries were from 92.2 % to 103.4 %, indicating that the method was reliable for the quantitative determination of rutin.

The effects of some potentially interfering ions on the detection of 5 μM rutin were evaluated. It was concluded that 500 folds higher levels of glucose, ascorbic acid, Gly, Zn2+, SO4 2−, Ba2+, Cl−, Na+, NO3 −, Cu2+, K+ didn’t interfere with the determination of rutin. But 100 folds higher levels of citric acid make the current higher up to 121.2 % of the original response. After putting a Nafion coating on the modified electrode surface (result not shown), citric acid acted as an anion at pH 5.0 and its amperometric response could be efficiently eliminated [29]. Morin and 10 folds higher levels of quercetin interfered with the determination of rutin.

Studies of the interaction between rutin and BSA

Figure 5 shows the CVs of rutin in the absence and presence of BSA. After the addition of BSA, the currents of rutin decreased and without the shift of peak potential. There was no new peak found in the range of 0 ~ 0.6 V (curves b and c). The decrease of current may be caused by two reasons. One was that the adsorption of BSA to C-Ni/GCE was stronger than rutin. The other was that the electro-inactive complex of BSA and rutin was produced. But in these experimental conditions, such a short accumulation time and lower concentration of protein, the competitive adsorption between small molecule and protein hardly existed [30]. Hence, these changes of currents indicated that there were interactions between BSA and rutin, and the complex was electro-inactive.

According to the method of Li and Min [31], the binding constant (β s ) and the binding ratio (m) can be calculated based upon the current changes of rutin on C-Ni/GCE in the presence of BSA.

Where ΔI corresponds to the peak current change of the absence and presence of BSA; ΔI max was the maximum of the peak current change. In this study, the concentrations of the added rutin was in the range of 0.01 to 1.96 μM, while the concentration of BSA was kept constant (0.2 μM).

The log [ΔI/(ΔI max − ΔI)] was linear with the log [rutin], and the regression equation was log [ΔI/(ΔI max − ΔI)] = 5.5913 + 0.9901 log [rutin], R 2 = 0.986 (Inset of Fig. 5). From the intercept and the slope, the m = 1 and log β s = 5.59 were obtained, which indicated that rutin binding to BSA formed the complex of BSA-rutin and the binding constant was 3.89 × 105.

Fluorescence quenching measurement is a simple and important method to explore the interaction between a small molecule and biomolecules [17]. Thus, it is used to confirm the binding constant and the binding ratio of BSA with rutin in this study. Since the fluorescence quenching behavior of BSA with rutin was a static quenching mechanism [18], it was supposed that the binding sites in the bimolecular were similar and independent. The relationship between fluorescence quenching intensity and the concentration of quenchers can be obtained by the formula [32]:

where K was the binding constant and n was the number of binding site per albumin molecule. The regression equation was log [(F0 − F)/F] = 5.2560 + 1.1337 log [rutin]. From the intercept and the slope in Fig. 6, log K and n can be obtained and were 5.26 and 1, respectively. The results were almost the same to the ones obtained using electrochemical method.

Conclusions

C-Ni/GCE was prepared and had been used to investigate the electrochemical behaviors of rutin and BSA. In pH 5.0 phosphate buffer, rutin exhibited a couple of well-defined peaks at the electrode. The electrochemical behavior of rutin at the modified electrode was a surface-controlled electrochemical process. The reaction of rutin involved two electrons and two protons transfer. Moreover, with addition of BSA into the rutin solution, the currents of redox peaks decreased and an electrochemically non-active complex was formed. It was the first time to determining BSA with rutin as an electrochemical probe. The excellent results obtained for C-Ni/GCE indicated that the modified electrode might be suitable for the determination of other electro-active flavonoids.

References

Dias K, Nikolaou S, Giovani WFD (2008) Synthesis and spectral investigation of Al(III) catechin/β-cyclodextrin and Al(III) quercetin/β-cyclodextrin inclusion compounds. Spectrochim Acta A 70:154–161

He JB, Wang Y, Deng N, Lin XQ (2007) Study of the adsorption and oxidation of antioxidant rutin by cyclic voltammetry-voltabsorptometry. Bioelectrochemistry 71:157–163

Zhang Y, Zheng JB (2008) Sensitive voltammetric determination of rutin at an ionic liquid modified carbon paste electrode. Talanta 77:325–330

Wu SH, Sun JJ, Zhang DF, Lin ZB, Nie FH, Qiu HY, Chen GN (2008) Nanomolar detection of rutin based on adsorptive stripping analysis at single-sided heated graphite cylindrical electrodes with direct current heating. Electrochim Acta 53:6596–6601

Liu Q, Cai W, Shao X (2008) Determination of seven polyphenols in water by high performance liquid chromatography combined with preconcentration. Talanta 77:679–683

Chen Z, Zhu L, Chen J, Liu J, Han Y (2008) A sensitive rutin assay using a simple probe manganese sulfate based on its novel resonance light scattering decrease phenomenon. Spectrochim Acta A 71:344–349

Chen Z, Zhang L, Chen G (2008) Microwave-assisted extraction followed by capillary electrophoresis-amperometric detection for the determination of antioxidant constituents in Folium Eriobotryae. J Chromatogr A 1193:178–181

Lin XQ, He JB, Zha ZG (2006) Simultaneous determination of quercetin and rutin at a multi-wall carbon-nanotube paste electrodes by reversing differential pulse voltammetry. Sens Actuators B 119:608–614

Oliveira IRWZ, Fernandes SC, Vieira IC (2006) Development of a biosensor based on gilo peroxidase immobilized on chitosan chemically crosslinked with epichlorohydrin for determination of rutin. J Pharm Biomed Anal 41:366–372

Song J, Yang J, Zeng J, Tan J, Zhang L (2010) Acetylene black nanoparticle-modified electrode as an electrochemical sensor for rapid determination of rutin. Microchim Acta 171:283–287

Hu S, Zhu H, Liu S, Xiang J, Sun W, Zhang L (2012) Electrochemical detection of rutin with a carbon ionic liquid electrode modified by Nafion, graphene oxide and ionic liquid composite. Microchim Acta 178:211–219

Yin H, Zhou Y, Cui L, Liu T, Ju P, Zhu L, Ai S (2011) Sensitive voltammetric determination of rutin in pharmaceuticals, human serum, and traditional Chinese medicines using a glassy carbon electrode coated with graphene nanosheets, chitosan, and a poly(amido amine) dendrimer. Microchim Acta 173:337–345

Wang Y, Xiong H, Zhang X, Wang S (2010) Detection of rutin at DNA modified carbon paste electrode based on a mixture of ionic liquid and paraffin oil as a binder. Microchim Acta 170:27–32

Wang J, Zhang YY, Guo Y, Zhang L, Xu R, Xing ZQ, Wang SX, Zhang XD (2009) Interaction of bovine serum albumin with Acridine Orange (C.I. Basic Orange 14) and its sonodynamic damage under ultrasonic irradiation. Dyes Pigments 80:271–278

Idowu M, Nyokong T (2008) Photosensitizing properties of octacarboxy metallophthalocyanines in aqueous medium, their interaction with bovine serum albumin. J Photochem Photobiol A 200:396–401

Zhou Q, Xiang J, Tang Y, Liao J, Yu C, Du H, Yang Q, Xu G (2008) Interaction of spiro-[(2R,3R,4S)-4-benzyloxy-2,3–iso-propylidenedioxy-1-oxacyclopentane-5,5′-(2-nitromethylene-1,3-diazacyclohexane)] with bovine serum albumin. Pestic Biochem Physiol 92:43–47

Xu H, Liu Q, Wen Y (2008) Spectroscopic studies on the interaction between nicotinamide and bovine serum albumin. Spectrochim Acta A 71:984–988

Yu TZ, Yang RD (2003) Study on the interaction of rutin and serum albumin. Spectrosc Spectr Anal 23:763–765

Liu Y, Yang JH, Liu SF, Wu X, Su BY, Wu T (2005) Resonance light scattering technique for the determination of protein with rutin and cetylpyridine bromide system. Spectrochim Acta Part A 61:641–646

Lu Q, Ba C, Chen D (2008) Investigating noncovalent interactions of rutin-serum albumin by capillary electrophoresis-frontal analysis. J Pharm Biomed Anal 47:888–891

Ruoff RS, Lorents DC, Chan B, Ripudaman M, Shekhar S (1993) Single Crysanotal metals encapsulated in carbon nanoparticles. Science 259:346–348

Si PZ, Zhang ZD, Geng DY, You CY, Zhao XG, Zhang WS (2003) Synthesis and characteristics of carbon-coated iron and nickel nanocapsules produced by arc discharge in ethanol vapor. Carbon 41:247–251

He CN, Zhao NQ, Shi CS, Du XW, Li JJ (2009) Effect of annealing on the structure of carbon onions and the annealed carbon coated Ni nanoparticles fabricated by chemical vapor deposition. J Alloys Compd 472:230–233

Wang SF, Xie F, Hu RF (2007) Electrochemical study of brucine on an electrode modified with magnetic carbon-coated nickel nanoparticles. Anal Bioanal Chem 387:933–939

Ling J, Liu Y, Hao G, Zhang X (2003) Preparation of carbon-coated Co and Ni nanocrystallites by a modified AC arc discharge method. Mater Sci Eng B Solid 100:186–190

Bard AJ, Fanlkner LR (1980) Electrochemical methods fundamentals and applications. Wiley, New York

Bond AM (1980) Modern polarographic methods in analytical chemistry. Marcel Dekker, New York

He JL, Yang Y, Yang X, Liu YL, Liu ZH, Shen GL, Yu RQ (2006) β-Cyclodextrin incorporated carbon nanotube-modified electrode as an electrochemical sensor for rutin. Sens Actuators B 114:94–100

Bindra DS, Wilson GS (1989) Pulsed amperometric detection of glucose in biological fluids at a surface-modified gold electrode. Anal Chem 61:2566–2570

Zhang HM, Zhu Z, Li NQ (1999) Electrochemical studies of the interaction of tetraphenylporphyrin tetrasulfonate (TPPS) with albumin. Fresenius J Anal Chem 363:408–412

Li NQ, Min J (1989) Polarographic study on the non-electroactive complex of scandium–carminic acid. Chin J Anal Chem 17:346–348

Cheng Z, Zhang Y (2008) Spectroscopic investigation on the interaction of salidroside with bovine serum albumin. J Mol Struct 889:20–27

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 20575017), the Natural Science Fund for Creative Research Groups of Hubei Province of China (No. 2011CDA111), and the Educational Commission of Hubei Province of China (No. D20113004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Duan, L., Yang, L., Xiong, H. et al. Studies on the electrochemistry of rutin and its interaction with bovine serum albumin using a glassy carbon electrode modified with carbon-coated nickel nanoparticles. Microchim Acta 180, 355–361 (2013). https://doi.org/10.1007/s00604-012-0931-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-012-0931-1