Abstract

A hydrothermal technique was used to synthesize nickel ferrite nanoparticles (NF-NPs) deposited on multi-walled carbon nanotubes (MWCNTs). The material was characterized by scanning electron microscopy, energy dispersive spectrometry, and X-ray powder diffraction which showed that the NF-NPs are located on the surface of the carboxylated MWCNTs. The material was used to modify a glassy carbon electrode which then was characterized via cyclic voltammetry, electrochemical impedance spectroscopy, and amperometry. The electrode displays strong electrochemical response to hydrazine. A potential hydrazine sensing scheme is suggested.

A fast and sensitive hydrazine electrochemical sensor has been fabricated by dipping nickel ferrite/multi-walled carbon nanotubes onto the pretreated glassy carbon electrode. The sensor had excellent stability, rapid response, ease of construction and utilization for hydrazine determination.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Since the first synthesis of hydrazine from diazoacetic ester [1], it has been greatly interested in both chemical and pharmaceutical industry. Also, it has been widely used as rocket fuel, emulsifiers, catalysts, weapons for mass destruction, corrosion inhibitors, insecticides and plant-growth regulators, etc. In the meanwhile, it can threaten people’s health from injection, inhalation of vapors, or skin contact. The threshold value range from 1 μg ml−1 to 10 μg ml−1 according to the regulation of the American Conference of Governmental Industrial Hygienists (1963). Thus, sensitive and fast detection and determination of hydrazine is becoming more and more important. Numerous methods have been developed to determine hydrazine, such as chromatography [2], spectrometry [3, 4], chemiluminescence [5], flow injection analysis [5–7] and electrochemical technique [8–12]. Among them, electrochemical technique is the most development potential method because of its fast response, high sensitivity, low cost, etc.

Unfortunately, hydrazine exhibited irreversible oxidation required large overpotential at bare carbon electrode. As a result from this, most of the modified electrodes have been fabricated and applied in the detection and determination of hydrazine, which can dramatically lower the overpotential and increase the oxidation current response to hydrazine. Such as reduced graphene sheets modified glassy carbon electrode (GCE) [13], polypyrrole/GCE [14], palladium-modified microdisk array electrode [15], Ag/MWCNTs/GCE [16], ZnO/GCE [17], Ni(II)-baicalein complex modified MWCNTs paste electrode [18], etc.

Nickel ferrite, with the formula of NiFe2O4, has a face-centered cubic structure with a large unit cell containing eight formula units [19]. And it is not only quite commonly used as a kind of magnetic material [20], but also used as the catalyst in the decomposition of carbon dioxide. What’s more, because of the properties of nano nickel ferrite, such as its large specific surface area, various redox states, electrochemical stability, pseudocapacitive behavior [21] and so on, it has been used in the preparation of semiconducting gas sensors [22, 23], glucose biosensor [24], etc. Besides, the search for techniques for the immobilization of redox mediators, which would provide a stable catalytic response for the analyte at the electrode surface is quite reasonable [25]. To enhance the attachment of nano-nickel ferrite onto the glassy carbon electrode, MWCNTs have been used, which are suitable materials for electrode modification and support in biosensor applications because of the high accessible surface area, low electrical resistance, extremely high mechanical strength and stiffness, outstanding charge-transport characteristics and high chemical stability [26–29].

Herein, we, for the first time, have successfully synthesized NiFe2O4/MWCNTs via one-step process using hydrothermal technique, as confirmed directed by scanning electron microscopy (SEM), energy dispersive spectrometry (EDS), X-ray powder diffraction (XRD). Glassy carbon electrode was modified using NiFe2O4/MWCNTs to form NiFe2O4/MWCNTs/GCE as an amperometric sensor for the electrocatalytic oxidation of hydrazine. The electrochemical sensor exhibited wide linear range and low detection limit, excellent stability and reproducibility.

Experimental

Reagents and apparatus

Carboxylated multi-walled carbon nanotubes (MWCNTs) (diameter 30–50 nm) were purchased from Chengdu Institute of Organic Chemistry of Academy of Sciences (http://www.timesnano.com) and synthesized by chemical vapor deposition. Ni(NO3)2·6H2O was obtained from Shanghai Hengxin Chemical Reagent Co., Ltd. (China). Other chemicals were obtained from Shanghai Chemical Reagent Co. Ltd. (Shanghai, China, http://www.china-reagent.com), such as hydrazine, Fe(NO3)3·9H2O, NaH2PO4 and Na2HPO4, etc. All of them were of analytical grade and used as received without further purification. Doubly distilled water was used throughout this research. Phosphate buffer saline (PBS, 0.1 M) were prepared by varying the ratio of NaH2PO4 to Na2HPO4. And all experiments were conducted at 20 °C

SEM and EDS were performed with a Hitachi S-4300 (Japan); XRD study was carried out on an X-ray diffractometer (Shimadzu, Japan) using Cu Kα source (λ = 1.5406 Angstroms) at 40 kV, 30 mA in the range of 10° < 2θ < 70° at the scan rate of 6.0°/min. The electrochemical experiments were performed on CHI660B electrochemical workingstation (CH Instruments, Chenhua Corp. Shanghai, China, http://chi.instrument.com.cn). All electrochemical experiments were carried out by three-electrode system with bare glassy carbon electrode or the modified electrode as the working electrode, a platinum wire as the auxiliary electrode, and a saturated calomel electrode (SCE) as the reference electrode.

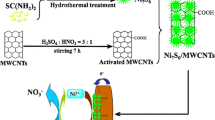

Synthesis of NiFe2O4/MWCNTs nanocomposites

NiFe2O4/MWCNTs nanocomposites were synthesized via a facile hydrothermal method refered from [30]. The procedure of the synthesis was performed as follows: 0.04 g MWCNTs were dispersed into 2 mL ethylene glycol to form a turbid liquid. And then 10 mL solution, containing 0.15 g nickel nitrate, 0.40 g ferric nitrate, 3.60 g sodium acetate and 0.20 g polyethylene glycol, was rapidly poured into the turbid liquid and vigorously stirred for 30 min at room temperature. After that, the mixture was transferred into a Teflon-lined stainless steel autoclave. The clave was maintained at 200 °C for 12 h, and finally cooled to room temperature naturally. The product was collected by a magnet and washed with distilled water and absolute alcohol alternately for several times and dried at 70 °C.

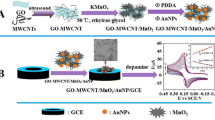

Fabrication of NiFe2O4/MWCNTs/GCE

Prior to modification, the bare glassy carbon electrode was polished to a mirror-like surface with alumina slurry followed by rinsing thoroughly with doubly distilled water. After that, the electrode was sonicated in nitric acid (1:1), absolute alcohol and doubly distilled water for 5 min, successively, in order to remove any adsorbed substances on the surface of the electrode. Finally, it was dried under nitrogen atmosphere ready for use.

5 mg the synthesized NiFe2O4/MWCNTs nanoparticles were suspended in 0.5 mL doubly distilled water under ultrasonic to form a suspension. 6 μL above suspension were dipped onto the pretreated glassy carbon electrode and the electrode was dried in air to obtain the NiFe2O4/MWCNTs modified GCE (NiFe2O4/MWCNTs/GCE).

Results and discussion

Characterization of NiFe2O4/MWCNTs nanocomposites

Figure 1 shows the SEM images of the MWCNTs before and after NiFe2O4 deposition. The pristine MWCNTs are curved and twisted with each other with very smooth surfaces (Fig. 1a). After the deposition of NiFe2O4, the MWCNTs became visibly hackly (Fig. 1b), which indicating that nanoparticles adsorbed onto the surface of MWCNTs.

To make sure the nanoparticles were nickel ferrite, EDS and XRD were investigated. The EDS result (Fig. 2a) shows that the weight content of C, O, Fe, Ni is 36.14%, 25.19%, 25.30%, 13.37% and the atom content of C, O, Fe, Ni is 57.16%, 29.91%, 8.61%, 4.32%. From the data given above, it can be easily calculated that the nickel-to-iron atomic ratio is 1:2, which goes well with the nickel-to-iron ratio in NiFe2O4. However, iron-to-oxygen atomic ratio is smaller than 2:4, which was ascribed to carboxylated MWCNTs. Figure 2b shows the XRD pattern of the NiFe2O4/MWCNTs powders. (111), (220), (311), (222), (400), (422), (511), (440) belong to NiFe2O4 according to the standard JCPDS (Card No. 10–0325). The diffraction angle at 2θ = 26.24° corresponds to the characteristic peak of MWCNTs. The results indicate that NiFe2O4/MWCNTs composites are successfully synthesized.

Electrochemical behavior of the NiFe2O4/MWCNTs/GCE

To study the electrochemical properties of NiFe2O4/MWCNTs/GCE, the cyclic voltammetries (CVs) and Nyquist plots of impedance measurements for 5 mM [Fe(CN)6]3-/4- solution containing 0.1 M KCl were investigated, as shown in Fig. 3. The NiFe2O4/GCE (curve b) showed a sluggish voltammetric response, with a ΔEp value of 160 mV, indicating that the NiFe2O4 on the electrode surface hinders the electron transfer kinetics. However, a significant increase in the peak current associated with a decrease in the ΔEp value was noticed at NiFe2O4/MWCNTs/GCE (curve c). The ΔEp value observed at the NiFe2O4/MWCNTs/GCE are very close to that of the bare GCE (curve a), suggesting nearly reversible or quasireversible electron transfer kinetics for these electrode interfaces. In the case of the NiFe2O4/MWCNTs/GCE, a significant increase in the peak currents were observed (curve c) because of the increase of the surface area. In Fig. 3b, the semicircular portion at higher frequencies represents the electron transfer-limited process The NiFe2O4/MWCNTs/GCE (curve c) shows lower interfacial electron transfer resistance than that of the NiFe2O4/GCE (curve b) and of bare GCE (curve a). These facts suggest that the electron transfer is faster at the NiFe2O4/MWCNTs/GCE in comparison with that of the NiFe2O4/GCE and the bare GCE, which facilitates the arrival of the electrochemical probe on the surface of the electrode. This illustrates that MWCNTs not only help to moor the NiFe2O4 nanoparticles onto the surface of the glassy carbon electrode, but also to increase the electron transferrate.

a Cyclic voltammograms of different electrodes in 5 mM [Fe(CN)6]3-/4- solution containing 0.1 M KCl at a scan rate of 50 mVs−1 and b Nyquist plots of 5 mM [Fe(CN)6]3-/4- in 0.1 M KCl from 10 kHz to 0.1 Hz at an ac amplitude of 10 mV under open-circuit potential conditions, obtained for (a) bare GCE, (b) NiFe2O4/GCE and (c) NiFe2O4/MWCNTs/GCE

Electrocatalytic activity of hydrazine at NiFe2O4/MWCNTs/GCE

In order to investigate the electrocatalytic activity of hydrazine on the NiFe2O4/MWCNTs/GCE, the responses of bare GCE (curve a), MWCNTs/GCE (curve b), NiFe2O4/MWCNTs/GCE (curve c) were explored with 0.5 mM hydrazine in N2-saturated 0.1 M PBS (pH = 7.4) at 50 mVs−1, shown in Figure 4. It is obvious that hydrazine couldn’t be oxidized on the bare GCE (curve a). Under the same experimental conditions, the oxidation of hydarzine on MWCNTs/GCE demostrated increase background current, but no defined anodic peaks were observed (current b) [31–33]. Nevertheless, with the addition of NiFe2O4, NiFe2O4/MWCNTs/GCE (curve c) demostrated an anodic peak at around 0.38 V. The electrochemical response of hydrazine on NiFe2O4/MWCNTs/GCE is irreversible, as no cathodic current is observed during the reverse sweep. According to previous reports [34], a possible electrochemical reaction for hydrazine is suggested to be N2H4+4OH-→N2+4H2O+4e-. As faster electron transfer leads to a well-defined peak, the substantial increasement in the peak current reflects a faster electron transfer process. Therefore, hydrazine is effectively detected by oxidation on the suggested electrode.

Amperometric response for the determination of hydrazine

Figure 5 shows a typical amperometric response of the NiFe2O4/MWCNTs/GCE upon the successive addition of hydrazine into continously stirred 0.1 M PBS (pH = 7.4) at an applied potential of 0.40 V. The amperometric sensor exhibited a linear response in the concentration range from 5.0 μM to 2.5 mM, with r 2 = 0.9982. Based on the signal-to-noise ratio (S/N) of 3, it has a very low detection limit, which was estimated to be 1.5 μM. Besides, the detection limit was lower than BiHCF-modified CCEs [34], Ru-complex films [35], etc. (shown in Table 1). Our hydrazine electrochemical sensor exhibited a rapid response (within 3 s) and sensitive response (0.1 μA μM−1) to the change of hydrazine concentration, and an obvious increasement in the oxidation current upon successive addition of hydrazine was obtained. The modified electrode achieved 96% of the steady-state current within 3 s.

Stability, reproducibility and interference

To investigate the reproducibility of the NiFe2O4/MWCNTs/GCE, ten modified electrodes made independently, showed an acceptable reproducibility with a relative standard deviation of 4.2% for the current determined at the hydrazine concentration of 250 μM. With one sensor, the mean steady-state current was −25.0 μA with a relative standard deviation of 4.1% for six determinations at a hydrazine concentration of 250 μM. When the modified electrode was not in use, it was stored in air at room temperature. The peak currents almost unchange with cyclic voltammetry at the optimum conditions for 100 cycles. Also, the peak currents of the modified electrode could remain 95% after 30 days in air at room temperature. The results demonstrated that the mentioned sensor has outstanding stability.

The effect of various substances, as the potential interference compounds, was studied on the determination of 250 μM hydrazine under the optimum conditions. Test results showed that 100-fold quantities of common cations and anions (Na+, Ca2+, Fe3+, K+, Mg2+, Cl-, NO -2 ) did not obviously interfere with the determination of hydrazine. There was no or little interference of 40-fold quantities of ascorbic acid, dopamine, L-tryptophan, glucose, guanine, adenine.

Application to real sample analysis

The validity of the mentioned method for the determination of hydrazine was evaluated. Five tap water samples were spiked with different concentrations of hydrazine and were analyzed under optimized conditions using the above technique. The results were shown in Table 2. The results were satisfactory, exhibiting that the mentioned methods could be efficiently used for the determination of hydrazine in sample analysis.

Conclusions

A sensitive hydrazine sensor has been fabricated by dipping NiFe2O4/MWCNTs nanoparticles synthesized by a facile hydrothermal method. The NiFe2O4/MWCNTs/GCE possesses better response to the electrocatalytic oxidation of hyrazine than any other electrode mentioned in the manuscript. A low detection limit, wide linear range, excellent selectivity, good stability and repeatablility make it potential candidate for the design and invention of hydrazine sensors.

References

De Witt BJ, Patent US, Patent No. 2,787,525, Patented Apr. 2, 1957, 1

Gilbert R, Rioux R (1984) Ion chromatographic determination of morpholine and cyclohexylamine in aqueous solutions containing ammonia and hydrazine. Anal Chem 56:106

Safavi A, Ensafi AA (1995) Kinetic spectrophotometric determination of hydrazine. Anal Chim Acta 300:307

Brown AB, Gibson TL, Baum JC, Ren T, Smith TM (2005) Fluorescence-enhancement sensing of ammonia and hydrazines via disruption of the internal hydrogen bond in a carbazolopyrinophane. Sens Actuators B 110:8

Safavi A, Karimi MA (2002) Flow injection chemiluminescence determination of hydrazine by oxidation with chlorinated isocyanurates. Talanta 58:785

Ebadi M (2003) Electrocatalytic oxidation and flow amperometric detection of hydrazine on dinuclear ruthenium phthalocyanine modified elctrode. Can J Chem 81:161

Ensafi AA, Rezaei B (1998) Flow injection determination of hydrazine with fluorimetric detection. Talanta 47:645

Nassef HM, Radi AE, O’Sullivan CK (2006) Electrocatalytic oxidation of hydrazine at o-aminophenol grafted modified glassy carbon electrode: Reusable hydrazine amperometric sensor. J Electroanal Chem 592:139

Bo XJ, Bai J, Ju J, Guo LP (2010) A sensitive amperometric sensor for hydrazine and hydrogen peroxide based on palladium nanoparticles/onion-like mesoporous carbon vesicle. Anal Chim Acta 675:29

Hu GZ, Zhou ZP, Guo Y, Hou HQ, Shao SJ (2010) Electrospun rhodium nanoparticle-loaded carbon nanofibers for highly selective amperometric sensing of hydrazine. Electrochem Comm 12:422

Zare HR, Shishehbore MR, Nematollahi D, Tehrani MS (2010) Electrochemical behavior of nano-composite containing 4-hydroxy-2-(triphenylphosphonio)phenolate and multi-wall carbon nanotubes spiked in carbon paste and its application for electrocatalytic oxidation of hydrazine. Sens Actuators B 151:153

Morais A, Pissetti FL, Lucho AMS, Gushikem Y (2010) Influence of copper hexacyanoferrate film thickness on the elctrochemical properites of self-assembled 3-mercaptopropyl gold electrode and application as a hydrazine sensor. J Solid State Electrochem 14:1383

Wang Y, Wan Y, Zhang D (2010) Reduced graphene sheets modified glassy carbon electrode for electrocatalytic oxidation of hydrazine in alkaline media. Electrochim Commun 12:187

Majidi MR, Jouyban A, Zeynali KA (2007) Electrocatalytic oxidation of hydrazine at overoxidized polypyrrole film modified glassy carbon electrode. Electrochim Acta 52:6248

Liu J, Zhou WH, You TY, Li FL, Wang EK, Dong SJ (1996) Detection of hydrazine, methylhydrazine, and isoniazid by capillary electrophoresis with a Palladium-modified microdisk array electrode. Anal Chem 68:3350

Wang GW, Gao GY, Wang C, Xu CL, Li HL (2008) Controllable deposition of Ag nanoparticles on carbon nanotubes as a catalyst for hydrazine oxidation. Carbon 46:747

Fang B, Zhang CH, Zhang W, Wang GF (2009) A novel hydrazine electrochemical sensor based on a carbon nanotube-wired ZnO nanoflower-modified electrode. Electrochim Acta 55:178

Zheng L, Song JF (2009) Ni(II) baicalein complex modified multi-wall carbon nanotube paste electrode toward electrocatalytic oxidation of hydrazine. Talanta 79:319

Li F, Liu JJ, Evans DG, Duan X (2004) Stoichiometric synthesis of pure MFe2O4 (M=Mg, Co, and Ni) spinel ferrites from tailored layered double hydroxide (hydrotalcite-like) precursors. Chem Mater 16:1597

Bao NZ, Shen LM, Wang Y, Padhan P, Gupta A (2007) A facile theromolysis route to monodisperse ferrite nanocrystals. J Am Chem Soc 129:12374

Gunjakar JL, More AM, Shinde VR, Lokhande CD (2008) Synthesis of nanocrystalline nickel ferrite (NiFe2O4) thin films using low temperature modified chemical method. J Alloy Compd 465:468

Reddy CVG, Manorama SV, Rao VJ (1999) Semiconducting gas sensor for chlorine based on inverse spinel nickel ferrite. Sens Actuators B 55:90

Rezlescu N, Iftimie N, Rezlescu E, Doroftei C, Popa PD (2006) Semiconducting gas sensor for acetone based on the fine grained nickel ferrite. Sens Actuators B 114:427

Luo LQ, Li QX, Xu YH, Ding YP, Wang X, Deng DM, Xu YJ (2010) Amperometric glucose biosensor based on NiFe2O4 nanoparticles and chitosan. Sens Actuators B 145:293

Shaidarova LG, Budnikov GK (2008) Chemically modification electrodes based on noble metals, polymer films, or their composites in organic voltammetry. J Anal Chem 63:922

Guldi DM, Rahman GMA, Zerbetto F, Prato M (2005) Carbon nanotubes in electron donor-acceptor nanocomposites. Acc Chem Res 38:871

Zhang XJ, Wang GF, Zhang W, Wei Y, Fang B (2009) Fixture-reduce method for the synthesis of Cu2O/MWCNTs nanocomposites and its application as enzyme-free glucose sensor. Biosens Bioelectron 24:3395

Liu B, Lee JY (2005) Ordered alignment of CdS nanocrystals on MWCNTs without surface modification. J Phys Chem B 109:23783

Gundiah G, Govindaraj A, Rajalakshmi N, Dhathathreyan KS, Rao CNR (2003) Hydrogen storage in carbon nanotubes and related materials. J Mater Chem 13:209

Zhang YL, Zhu MF, Zhang QH, Yu H, Li YG, Wang HZ (2010) Solvothermal one-step synthesis of MWCNTs/Ni0.5Zn0.5Fe2O4 magnetic composites. J Magn Magn Mater 322:2006

Salimi A, Abdi K (2004) Enhancement of the analytical properties and catalytic activity of a nickel hexacyanoferrate modified carbon ceramic electrode amine. Talanta 63:475

Shen Y, Xu Q, Gao H, Zhu NN (2009) Dendrimer-encapsulated Pd nanoparticles anchored on carbon nanotubes for electro-catalytic hydrazine oxidation. Electrochem Commun 11:1329

Chen L, Hu GZ, Zou GJ, Shao SJ, Wang XL (2009) Efficient anchorage of Pd nanoparticles on carbon nanotubes as a catalyst for hydrazine oxidation. Electrochem Commun 11:504

Zheng JB, Sheng QL, Li L, Shen Y (2007) Bismuth hexacyanoferrate-modified carbon ceramic electrodes prepared by electrochemical deposition and its electrocatalytic activity towards oxidation of hydrazine. J Electroanal Chem 611:155

Pinter JS, Brown KL, DeYoung PA, Peaslee GF (2007) Amperometric detection of hydrazine by cyclic voltammetry and flow injection analysis using ruthenium modified glassy carbon electrodes. Talanta 71:1219

Abbaspour A, Khajehzadeh A, Ghaffarinejad A (2009) Electrocatalytic oxidation and determination of hydrazine on nickel hexacyanoferrate nanoparticles-modified carbon ceramic electrode. J Electroanal Chem 631:52

Auley CB, Banks CE, Simm AO, Jones TGJ, Compton RG (2006) The electroanalytical detection of hydrazine: a comparison of the use of palladium nanoparticles supported on boron-doped diamond and palladium palted BDD microdisc array. Analyst 131:106

Ozoemena KI, Nyokong T (2005) Electrocatalytic oxidation and detection of hydrazine at gold electrode modified with iron phthalocyanine complex linked to mercaptopyridine self-assembled monolayer. Talanta 67:162

Acknowledgements

This work was financially supported by the projects (20675001, 20901003, 21073001 and 21005001) from National Natural Science Foundation of China, Natural Science Foundation of Anhui (KJ2009B013Z), the project of Anhui Key Laboratory of Controllable Chemistry Reaction & Material Chemical Engineering (OFCC0905), the Young Teacher Program of Anhui Normal University (2009xqnzc19), the Higher Education Excellent Youth Talents Foundation of Anhui Province (2011SQRL103), and the Higher Education Natural Science Foundation of Anhui Province (KJ2011Z389).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 314 kb)

Rights and permissions

About this article

Cite this article

Fang, B., Feng, Y., Liu, M. et al. Electrocatalytic oxidation of hydrazine at a glassy carbon electrode modified with nickel ferrite and multi-walled carbon nanotubes. Microchim Acta 175, 145–150 (2011). https://doi.org/10.1007/s00604-011-0662-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-011-0662-8