Abstract

A novel, single-step route has been developed for the synthesis of solid phase adsorbent silica modified with xylenol orange. The addition of cationic surfactant cetyl tri-methylammonium bromide during the synthesis of the adsorbent supports the formation of a stable coating of xylenol orange on silica. The adsorbent showed no signs of degradation in contact with organic solvents and with solutions of varying pH between 1 and 9. This adsorbent has been used for separation and pre-concentration of uranium from hydro-geochemical samples with high calcium content and from sea water. Quantitative sorption of uranium was observed above pH 3 and complete desorption can be achieved using 0.2 M sodium pyrophosphate solution. The uranium content in the extract was determined by laser fluorimetric technique. The equilibration time is 30 min. The sorption capacity of the adsorbent for uranium is 10 mg g−1. An enrichment factor of 50 was obtained by this procedure taking 500 mL of sample solution. Uranium concentrations down to 0.05 ng mL−1 can be determined after pre-concentration using this method. The relative standard deviation at an 0.1 ng mL−1 level is ±15%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

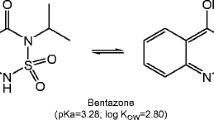

Pre-concentration is an essential step for the analysis of various trace elements especially when they are present at nanogram and picogram levels. The pre-concentration techniques include liquid-liquid extraction, ion-exchange separation, co-precipitation, extraction chromatography, electro-deposition and solid phase extraction [1, 2]. Owing to the advantages possessed by the solid phase extraction system (SPE), such as, wide choice for modification, higher enrichment factor, safety with respect to hazardous samples, absence of emulsion formation, cost effectiveness due to low consumption of reagents and most importantly its environment friendly nature [3, 4], it has found wide applications for the isolation and concentration of target analytes and clean up of samples. Amongst the solid state support, silica based SPE possesses many advantages as it does not swell or strain, has good mechanical, chemical and thermal stability [5]. Plenty of references are available on the use of SPE systems containing chelating groups for the pre-concentration of trace elements [6–15]. Though xylenol orange is a well known complexing agent which form complexes with different metal ions like Bi3+, Th4+, Zr4+, Hg2+, Cd2+, Fe2+, REE3+, Pb2+, Zn2+, Al3+, Fe3+, U6+, Ga3+,In3+ etc [16], there are very few reported work on the use of adsorbent silica modified with xylenol orange [17, 18]. Probably the reason can be due to the difficulty involved in the synthesis or in the stability of the adsorbent.

Uranium is usually present in natural waters at nanogram to picogram per milliliter levels. Laser induced fluorimetry which is a sensitive and selective technique is commonly used for the determination of uranium at ng mL−1 levels in hydro-geochemical samples [19–23]. Sodium pyrophosphate solution is used as the fluorescence enhancing reagent during the determination of uranium [24] in view of its good buffering and fluorescence enhancing capabilities. Quantification limit, for uranium by this method is 1 ng mL−1. During the hydro-geochemical survey for locating the concealed uranium mineralization, samples containing high calcium were encountered. Difficulties were encountered during the estimation of these samples for uranium. It was noticed that the addition of fluorescence enhancing reagent, resulted in the formation of a precipitate. This precipitate renders the solution inhomogeneous and makes the solution unsuitable for the determination of uranium by laser induced fluorimeter. The possible solution to overcome the problem is taking a lesser quantity of the sample or by separating the uranium from the matrix constituents. This no doubt brings down the level of calcium, it also brings down the uranium concentration to such levels which will be below the determination limit of the laser induced fluorimetry. Hence the second option of separation of uranium from the matrix will be the preferred route for the estimation. Some of the methods reported for the pre-concentration and separation of uranium in such hydro-geochemical samples include co-precipitation with ferric hydroxide [25, 26] and aluminium phosphate [27], adsorption on salicylaldehyde modified meso-porous silica [28] and bio-sorption of uranium on baker’s yeast [29]. However, the co-precipitation method, is time consuming and many a times require further separation of analyte from the precipitate. Other adsorption methods including bio-sorption methods are time consuming, and sometimes adsorptions are irreversible. Similarly, difficulties are met during the direct determination of uranium in sea water using laser fluorimetric technique due the presence of high salt content as well as due to the presence of the strong fluorescence quenching chloride ions. Some of the techniques that have been reported for the determination of uranium in sea water include (a) aluminium phosphate co-precipitation [27], (b) use of Amberlite-XAD resin modified with 8-hydroxy quinoline [30], (c) Malonamide grafted polystyrene divinyl benzene resin [31] and (d) activated alumina [32]. The present work describes a simple method of synthesizing a stable form of the adsorbent silica modified with xylenol orange (SXO) and its application for pre-concentration and separation of uranium from calcium rich hydro-geochemical samples and sea water. The uranium content is subsequently estimated by laser fluorimetric technique. Conditions for extraction of uranium using SXO, like pH, quantity of adsorbent, contact time, and conditions for desorption Etc., have been standardized. Results obtained have been compared with the results obtained using standard ferric hydroxide co-precipitation method and through recovery studies by the standard addition technique.

Experimental

Instrumentation

Laser induced fluorimeter (LIF)

Nitrogen laser based Scintrex UA-3 uranium analyser (Scintrex Ltd, Canada) is used for the fluorescence measurement in aqueous medium. The nitrogen laser pulse rate is 16 times per second and pulse duration is 3–4 nano-seconds. Excitation wavelength is 337.1 nm and wavelength of measurement is 495 nm. Integration time is 4 sec. The instrument also incorporates an electronic gating mechanism (time discrimination) which registers the long lived uranyl fluorescence while it cuts off the short lived organic fluorescence.

Procedure for determination of uranium using LIF

1 to 5 mL of the sample is mixed with 1 mL of 0.2 M sodium pyrophosphate solution and made up to 10 mL. The fluorescence intensity is measured and the concentration of uranium is calculated from a calibration plot obtained using solutions of known uranium content.

Reagents

Preparation of uranium standard

1 mg mL−1 solution of hexavalent uranium solution was prepared by dissolving 0.2226 g of uranyl nitrate UO2(NO3) 6H2O (Johnson and matthey, www.matthey.com) in 100 mL de-ionised water. 5 mL con HNO3 was added to the solution to suppress hydrolysis.

Sodium meta silicate Na2SiO3 5 H2O (Merck GR, www.merck-chemicals.in)—0.3 M solution of sodium meta silicate was prepared by dissolving 30 g of sodium meta silicate in 500 mL water.

Cetyl tri-methyl ammonium bromide (CTAB) (Rolex, India, www.rolex.com): 0.1% (w/v) solution in water.

Xylenol Orange: (XO) (Merck GR)—0.1% (w/v) solution in water.

Sodium pyrophosphate: Na4P2O7.10H2O (Merck GR)—0.2 M solution was prepared by dissolving 8.92 g sodium pyrophosphate in 100 mL de-ionised water and pH is adjusted to 7 using H3PO4(Merck GR).

All the other reagents including electrolytes and other metal ions are of analytical reagent grade.

Synthesis of silica modified with xylenol orange (SXO)

500 mL 0.3 M sodium meta-silicate solution was taken in a 1 L beaker. 50 mL ethyl alcohol was added to it. This solution was mixed with 25 mL 0.1% (w/v) CTAB, and 25 mL of 0.1% (w/v) xylenol orange. The solution was acidified using 50% (v/v) HCl with constant stirring and kept overnight. The gel formed was filtered and washed thoroughly till free from chloride ions. The gel was dehydrated by drying in an air oven at 110° C. It was Ground in an agate mortar and stored in a desiccator.

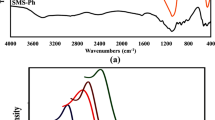

Stability of the adsorbent

In separate 50 mL beakers, 100 mg of the adsorbent was kept in contact for 2 h with water, solutions of pH 1 to 9 and organic solvents alcohol, and acetone. After filtration, the visible spectra of the filtrate was scanned on a spectrophotometer from 300 to 600nms.

Optimisation of parameters for pre-concentration uranium using SXO sorbent

Experiments were carried out to optimise pH, equilibration time and amount of adsorbent required for adsorption of uranium onto SXO. Desorption studies were also carried out using different complexing agents.

Optimisation of pH

50 ng uranium was taken in different beakers, and pH of the solutions were adjusted from 1 to 10 using 10% (v/v) ammonia solution and 10% (v/v) nitric acid. The solution after dilution is kept in contact with 0.5 g of SXO for 2 h. The solutions were filtered and the un-adsorbed uranium in the filtrate was determined by laser induced fluorimeter. The results are shown graphically in Fig. 1.

Optimisation of quantity of adsorbent

50 ng uranium was taken in different beakers and pH of the solutions were adjusted to 3 and kept in contact with 0.02–0.5 g of SXO for 2 h. The solutions were filtered and the un-adsorbed uranium in the filtrate was determined by laser induced fluorimeter. The results are shown graphically in Fig. 2.

Optimisation of contact time

50 ng uranium was taken in different beakers and pH of the solutions were adjusted to 3 and kept in contact with 0.05 g of SXO from time intervals of 15 min to 6 h. The solutions were filtered and the un-adsorbed uranium in the filtrate was determined by laser induce fluorimeter. The results are shown graphically in Fig. 3.

Desorption of uranium

De-sorption of uranium from the adsorbent was carried out using different concentrations of various reagents which form stable complexes with uranium like, hydrogen peroxide, sodium carbonate, ammonium carbonate, and sodium pyrophosphate. The concentrations of the reagents used were up to a maximum of 0.5 M, keeping in view to keep low salt content in final solution. Recovered uranium in the leach solutions was estimated by laser induced fluorimeter. The results are given in Table 1.

Sorption capacity of SXO for uranium

Experiments were performed to calculate the sorption capacity of the adsorbent for uranium using 5 mL of 1 mg mL−1 uranium. pH of the solution was adjusted to 3 and kept in contact with 0.1 g of the adsorbent for 30 min and filtered. The filtrate was analysed for uranium content using laser fluorimetry. The sorption capacity (qe) was calculated using the formula

where X is the amount of uranium added, Y the amount remaining in the solution after adsorption and Z the weight of the adsorbent.

Effect of calcium on the extraction of uranium

Experiments were carried out to find the effect of calcium on the extraction of uranium using SXO. 100 mL water in different beakers was doped with 50 ng uranium and with 0.5 mg, 1.0 mg, 1.5 mg, 2.0 mg and 2.5 mg of Calcium. Effect of concentrations of calcium beyond this, was not studied. pH of the solutions were adjusted to 3 and kept in contact with 50 mg of the adsorbent for 30 min. The adsorbent was filtered and washed with water thoroughly to remove excess calcium. The uranium adsorbed on SXO was recovered by leaching with 6 mL of 0.2 M Na4P2O7 of pH-7. Recovered uranium was estimated using laser induced fluorimeter. The results obtained are given in Table 2.

Effect of presence of other cations and anions on the adsorption of uranium

Interference effect of the normally occurring cations and anions in hydro-geochemical samples, on the adsorption of uranium to SXO was studied individually up to the levels of 1 mg mL−1 for the ions sodium, potassium, magnesium, chloride and sulphate and up to levels of 50 µg mL−1 for phosphate and 20 µg mL−1 for fluoride. 100 mL water containing 50 ng standard uranium in different beakers was doped separately with different concentrations of individual ions. pH of the solutions were adjusted to 3 and kept in contact with 50 mg of the adsorbent for 30 min. The adsorbent was filtered and washed thoroughly with water to remove salts. The adsorbed uranium from SXO was leached out using 6 mL of 0.2 M Na4P2O7 of pH-7. Recovered uranium was estimated using laser induced fluorimeter. In the case of sea water, a synthetic sea water sample containing 10 mg mL−1 Na, 0.4 mg mL−1 K, 0.4 mg mL−1 Ca, 1.3 mg mL−1 Mg, 19 mg mL−1 Chloride, 2.5 mg mL−1 sulphate and 2 mg L−1 Fe was prepared. A 50 mL quantity of the synthetic sample was doped with 50 ng of uranium. pH of the solution was adjusted to 3 and kept in contact with 50 mg of the adsorbent for 30 min. The adsorbent was separated by filtration and washed thoroughly with water to remove the un-adsorbed cations and anions. The adsorbed uranium from the SXO was leached out using 6 mL of 0.2 M Sodium pyrophosphate solution of pH 7. The uranium content was estimated by laser fluorimeter. The extent of recovery was calculated.

Recommended procedure for the determination of uranium in hydro-geochemical samples with high calcium content

100 mL of water sample was filtered and then treated with 5 mL con. nitric acid and boiled for 15 min in order to oxidize any trace organic matter and to expel dissolved carbon dioxide. pH of the solution was adjusted to 3 and the solution was kept in contact with 50 mg of SXO for 30 min. The Solution was filtered and the adsorbent was washed thoroughly with water. The adsorbed uranium was leached from SXO with 6 mL of 0.2 M sodium pyrophosphate solution of pH-7. The recovered uranium was estimated by laser induced fluorimeter. The results obtained were compared with the values obtained by standard ferric hydroxide co-precipitation method. The results are given in Table 3.

Recommended procedure for the determination of uranium in sea water samples

50 mL sea water sample was filtered and then treated with 5 mL con. nitric acid and boiled for 15 min in order to oxidize any trace organic matter and to expel dissolved carbon dioxide and diluted to 100 mL. This solution was kept in contact with 100 mg of SXO for 30 min. Solution was filtered and the adsorbent was washed thoroughly to remove the salts completely. Adsorbed uranium was extracted from SXO with 6 mL of 0.2 M sodium pyrophosphate solution at pH-7. The recovered uranium was estimated using Laser induced fluorimeter. The results obtained were compared with the results of the standard addition technique and results obtained from ferric hydroxide co-precipitation. The results are given in Table 4.

Procedure for pre-concentration of uranium by ferric hydroxide co-precipitation

100 mL of water sample/sea water was filtered and then treated with 5 mL con. nitric acid and boiled for 15 min in order to oxidize any trace organic matter and to expel dissolved carbon dioxide. To this solution 6.5 mg mL−1 Fe3+ solution is added along with few drops of BCG indicator and 3 g of ammonium nitrate. Then 25% (v/v) ammonia solution is added while stirring till the indicator colour changed to blue along with the formation of precipitate. The solution is filtered through Whatman 540 ash less filter paper and precipitate is washed with a wash solution containing ammonium nitrate whose pH is adjusted to neutral colour of the BCG indicator. The precipitate taken back in the same beaker and dissolved in 1.5 mL of nitric acid and made up to 50 mL. 2 mL of the aliquot is pipetted into a 25 mL flask and 10 mL of sodium pyrophosphate buffer solution of pH 7 is added. The fluorescence intensity of the solution is compared with that of standards containing same quantity of iron and acid.

Procedure for the recovery studies by standard addition

Two 50 mL portions of sea water sample were filtered and then treated with 5 mL con. nitric acid and boiled for 15 min in order to oxidize any trace organic matter and to expel dissolved carbon dioxide and diluted to 100 mL. One of the solutions was doped with 50 ng of the standard uranium solution. The pH of the solutions were adjusted to 3. Both the solutions were kept in contact with 100 mg of SXO each for 30 min. Solutions were filtered and the adsorbent was washed thoroughly. Adsorbed uranium was extracted from SXO with 6 mL of 0.2 M sodium pyrophosphate solution of pH-7. The uranium content in both the solutions were estimated laser fluorimetrically and the recoveries were calculated.

Results and discussion

The reagent xylenol orange was chosen for immobilisation on silica due to its high chelating tendency for several metal ions via -N, -S and -O donors. Silica modified with xylenol orange has been synthesized using a novel procedure involving only one step. The procedure followed involves the neutralization of the sodium meta silicate solution containing CTAB. In-situ modification of the gel with xylenol orange takes place in presence of the added surfactant CTAB. The gel is filtered, washed and dehydrated to obtain SXO adsorbent. The role of CTAB during the synthesis can be that the cationic surfactant CTAB gets adsorbed onto the silica surface due to the electrostatic attraction between positively charged head group of surfactant [(CH3)3 N+(CH2)15(CH3)] and negatively charged silanol (SiO−) group on the silica [33]. Non polar chain of the surfactant projects out of the silica surface giving it a hydrophobic character. Xylenol orange molecule is adsorbed onto this layer due to the hydrophobic interaction. Thus xylenol orange is attached to silica surface due to the chemical interaction between CTAB and XO. This results in obtaining a chemically modified adsorbent, exhibiting resistance for easy removal of XO. The stability studies carried out indicated that there is no dissolution or leaching out of the XO from the adsorbent as indicated by the absence of peak at 434 nm or at 580 nm. They are the characteristic peaks for XO below pH 5 and pH above 6.5 respectively. Therefore it can be concluded that a stable form, possibly formed through chemical modification, is obtained by the above scheme of synthesis of the adsorbent.

Studies were performed to optimize the parameters such as pH of the solution, contact time, amount of the adsorbent, eluents and effects of normally associated ions, with a view to obtain maximum adsorption of uranium on the adsorbent. Figure 1 shows the results of the studies carried out on adsorption of uranium with varying pH from 1 to 9. I t can be seen that quantitative adsorption of uranium takes place above pH 2.5 through complex formation. The nitrogen atom and the adjacent phenolic -OH groups of XO facilitates the easy ring formation. The nitrogen atom undergoes protonation at lower pHs. Due to the non-availability of nitrogen atoms at lower pH, uranium adsorption is not quantitative below pH 2.5.

Figure 2 shows the minimum optimum quantity of adsorbent required to bring about maximum adsorption of 50 ng of uranium from solution. After a contact period of 2 h, it is seen from the figure that there is gradual increase in adsorption at quantities below 50 mg and then a steady state is achieved above 50 mg. A quantity of 50 mg is ideal. Figure 3 shows that a contact time of 30 min is sufficient to bring about maximum adsorption.

The time in which SXO attains 50% saturation with uranium is called loading half time (t1/2). From Fig. 3 it is clear that loading half time was less than 15 min. Extraction rate of uranium is very high for this adsorbent. Like in all solid phase extraction studies amount of adsorbent required for adsorption is very less in this method also. This is due to the high sorption /retention capacity of SXO. The sorption capacity (qe) is the amount of uranium ion required for the saturation of 1 g of the synthetic sorbent in (mg/g). From the experiment carried out, the sorption capacity of the SXO for uranium was found to be 10 mg g−1.

The efficiency of an adsorbent is not solely determined by the sorption characteristics but also by the desorption behavior. Desorption step allows the metal ion to be removed and recovered from the adsorbent. Recovery of uranium from SXO was carried out using different leaching agents which complex uranium. Recovery results obtained are given in Table 1. I t is evident from Table 1 that the quantitative recovery of uranium from SXO was obtained both by 10 mL of 0.5 M sodium carbonate solution and 6 mL 0.2 M sodium pyrophosphate solution. In general it was noticed that the strength of the eluting reagent was not that critical and almost the entire uranium was getting leached out. It was noticed that leaching observed with Na2CO3 was well above 95% and is due to the formation of strong carbonate complex with uranyl ions. Pyrophosphate also forms another highly stable complex of uranium, uranyl pyrophosphate, which brings about uranium leaching of 95%. Sodium pyrophosphate solution of pH 7 is selected as the desorbing solution, instead of sodium carbonate solution, as it accomplishes the purposes of de-sorption, fluorescence enhancing and buffering action, enabling no further treatment of sample prior to uranium determination by laser fluorimeter. Experiments carried out to find out the interference of the commonly associated cations and anions with uranium in hydro-geochemical samples has shown that there was no interference on the adsorption of uranium to SXO. Since it was evident from the above study that majority of the anions, alkali and alkaline earth cations do not interfere on the extraction of uranium by the adsorbent, the study was extended to synthetic sea water sample doped with uranium. Quantitative recoveries were obtained. Table 2 shows the study of the presence of varying quantities of calcium on the extraction of uranium by the adsorbent. It is seen that quantitative adsorption of uranium takes place, even in presence of high calcium content of 2.5 mg. Therefore it can be concluded that separation of uranium from calcium can be easily effected by simple contact of the solution with SXO for 30 min. Subsequently the uranium can be leached out using pyrophosphate solution and estimated laser fluorimetrically.

This method was applied for the estimation uranium in hydro-geo-chemical samples with high calcium content. Uranium content obtained by this method has been compared with that obtained by Ferric hydroxide precipitation method. Table 3 gives the composition of the hydro-geochemical samples along with the results of uranium content obtained by the suggested method using SXO extraction and by ferric hydroxide precipitation method. It can be seen that the results are comparable.

The recommended method was applied for the determination of uranium in sea water. The results obtained have been compared with the results obtained from ferric hydroxide co-precipitation and standard addition methods. The results are given in Table 4. The results are comparable and recoveries are quantitative.

Conclusions

A novel single-step synthesis procedure for silica modified with xylenol orange has been developed. The synthesized adsorbent has been used for pre-concentration and determination of ultra trace levels of uranium in calcium rich hydro-geo-chemical samples and sea water. This procedure facilitates a fifty fold enrichment of uranium from hydro-geochemical samples. The adsorbent has a very high extraction rate for uranium with its loading half time was less than 15 min. This adsorbent has a good potential to separate uranium from high concentration of calcium and host of co-existing alkali, alkaline earth and other anions present in hydro-geochemical and sea water samples. Direct laser fluorimetric determination of uranium in the eluent solution can be carried out by this procedure, since the same reagent is used as an eluting agent and fluorescence enhancing reagent (sodium pyrophosphate). This method is very simple and the sorption capacity of the adsorbent 10 mg g−1 is much higher than other common adsorbents. Uranium concentrations up to 0.1 ng mL−1 can be determined easily after pre-concentration using this method. R.S.D of this method is ±15% at 1 ng mL−1 level.

References

Puri BK, Salake M, Usami S (1987) Selective Pre-concentration of iron in beverages and water samples using 2, 4, 6, tri- pyridinyl 1, 3, 5 triazine tetra phenyl borate naphthalene. Anal Chem 59:1850

Obala H, Keratini H, Nakayama C (1993) Automated determination of iron in sea water by chelating resin concentration and chemiluminescence detection. Anal Chem 65:1570

Thuman EM, Mills MS (1998) Solid phase extraction, principles and practices. Wiley, New York

Sturgeon RE, Berman SS, Desaulniers A, Russel DS (1980) Pre-concentration of trace metals from sea water for determination by graphite furnace atomic absorption spectrometry. Talanta 27:85

Sarkar AR, Dutta PK, Sarkar M (1996) Sorption recovery of metal ions using silica gel modified with salisilaldoxime. Talanta 43:857

Blain S, Appriov P, Handel H (1991) Column pre-concentration of trace metals from sea water with mesoporous resins impregnated with lipiphilic tetraaza macrocycles. Analyst 116:815

Kumar M, Rathore DPS, Singh AK (2001) Quinalizarin anchored on Amberlite XAD-2, A new matrix for solid phase extraction of metal ions for flame atomic absorption spectrometric determination. Fresenious J Anal Chem 370:377

Mahmoud ME, Soliman EM (1997) Silica immobilised formylsalicylic acid as a selective base for extraction of iron (III). Talanta 4:15

Ramesh A, Rama MK, Seshaiah K (2002) Pre-concentration of trace elements on Amberlite XAD-4 resin coated with dithiocarbamate and determination by inductively coupled plasma—Atomic emission spectrometry in saline water. Talanta 57:243

Zaporozhets O, Gawer O, Sukhan V (1998) Determination of Fe(II), Cu(II), and Ag(I) by using silica gel loaded with 1, 10-phenanthroline. Talanta 46:1387

Isabel DH, Mariano F, Isabel S (2009) Solid phase extraction of Pb(II) in water samples using a new hybrid inorganic-organic meso-porous silica prior to its determination by FAAS. Microchim Acta 166:391

Lijun Z, Qun H, Xinping H, Zheng H (2009) Determination of trace metals in natural samples by ICP-OES after pre-concentration on modified silica gel and on modified silica nano particles. Microchim Acta 169:347

Sereje T, Vedat Y, Senol K, Ali D, Cengiz S (2009) Solid phase extraction of Pd (II) on a newly synthesized chelating resin prior to determination by FAAS. Microchim Acta 165:347

Limin W, Meihua Z, Zhijuan J, Aifu Z (2009) Selective separation of lead from aqueous solution with a novel Pb (II) surface ion-impregnated sol gel sorbent. Microchim Acta 65:367

Lian Z, Xijun C, Zheng H, Lijun Z, Jianping S, Ru G (2010) Selective solid phase extraction and separation of mercury environmental and biological samples by nanometer silica functionalized with 2, 6, pyridine di-carboxylic acid. Microchim Acta 168:79

Curie J (1978) Hand book of anal chemistry. MIR, Moscow

Zaporozhets OA, Tsyukalo LY (2002) Xylenol orange adsorbed on silica surface as a solid phase reagent for lead determination using diffuse reflectance spectroscopy. Talanta 58:861

Jing F, Chunlai W, Yafang W, Chuanyun P, Pingan P (2007) Preparation of xylenol orange functionalized silica gel as a selective solid phase extractor and its application for pre-concentration. J Hazard Mater 145:323

Robbins JC (1978) Field technique for measurement of uranium in natural water. GIM Bulletin 793:61

Whitkop PG (1982) Determination of uranium in aqueous samples by laser induced fluorescence spectrometry. Anal Chem 54:2475

Hong KB, Jung KW, Jung KH (1989) Application of laser induced fluorescence for the determination of trace uranium, europium and samarium. Talanta 36:1095

Eral M, Kinaci SR (1989) Determination of uranium in natural waters by laser exited fluorescence for uranium exploration. Spectrosc Lett 22:855

Campen W, Bachmann K (1979) Laser induced fluorescence for direct determination of small concentration of uranium in water. Mikro Chim Acta 11:159

Creig ZA, Linde CH, Charles PE (1981) Determination of nano gram quantities of uranium by pulsed laser fluorimetry. Mikro Chim Acta 11:457

Nakanishi M (1950) Fluorimetric micro determination of uranium. Bull Chem Soc Jpn 23:198

Balaji BK, Bincy C, Mishra G (1996) A rapid method for the determination of uranium in brines by laser fluorimetric technique. EARFAM 9:99

Smith AP, Grimaldi FS (1954) The fluorimetric determination of uranium in non saline and saline waters Part-17, Collected papers on analysis for uranium and thorium. U.S.Geological survey Bulletin 125–131

Kochan IG, Shuktomova II (1994) Separation of uranium from soil for its determination. J Radioanal Nucl Chem 188:27

Leela G, Nayeem MA, Murty DSR (2007) Biosorption of uranium for separation / pre-concentration prior to its estimation by fluorimetry. EARFAM 17:31

Singh BN, Maiti B (2006) Separation and pre-concentration of U (VI) on XAD-4 modified with 8-hydroxy quinoline. Talanta 69:393

Ansari SA, Mohapatra PK, Manchanda VK (2008) A novel malonamide grafted polystyrene-divinyl benzene resin for extraction, pre-concentration and separation of actinides. J Hazard Mater 04:93

Dojozan D, Pourna Ghiazar MH, Toutounchiasr J (1998) Pre-concentration of trace uranium from sea water with solid phase extraction followed by differential pulse polorographic determination in chloroform eluate. Talanata 46:123

Israclachvilli JN, Pashely RM (1984) Measurement of hydrophobic interaction between two hydrophobic surfaces in aqueous electrolyte solution. J Colloid Interface Sci 98:500

Acknowledgements

The authors are thankful to the Shri.A.K.Rai, Regional Director, Southern Region, AMD, Bangalore; Additional Director (OP-I) and Additional Director (R&D), AMD, Hyderabad, for their encouragement and providing facilities to carry out this work. The authors are thankful to Dr. K.Satyanarayana, SO/G, Head, Chemistry Group, AMD, Hyderabad and Dr.A. Premadas SO/G, Chemistry Laboratory, Bangalore for their constant encouragement and technical advice. Authors are also grateful to the Director, AMD for presentation/publication of the investigation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cyriac, B., Balaji, B.K. A novel method of synthesizing solid phase adsorbent silica modified with xylenol orange: application for separation, pre-concentration and determination of uranium in calcium rich hydro-geochemical samples and sea water—Part 1. Microchim Acta 171, 33–40 (2010). https://doi.org/10.1007/s00604-010-0369-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-010-0369-2