Abstract

Cadmium telluride quantum dots (QDs) were prepared and coated with cysteamine using ultrasonic irradiation. The QDs were characterized by fluorescence spectroscopy, UV-vis absorption spectra, X-ray diffraction and infrared spectroscopy. The QDs possess a quantum yield as high as 46% and a quite narrow emission band (full width at half maximum of 38 nm). The fluorescence of these QDs is quenched by bisphenol A (BPA), and quenching can be described by a Stern-Volmer equation with correlation coefficient of 0.998. These findings resulted in a simple and rapid technique for determination of BPA that was applied to its determination in feeding bottles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Bisphenol A (BPA), also known as 2,2- (4,4-dihydroxydiphenyl) propane is a monomer used in the synthesis of epoxy resins, polycarbonate plastics and corrosion-resistant unsaturated polyester-styrene resins [1], and also is a stabilizing material or antioxidant for numerous types of plastics [2]. Low levels of BPA had already been detected in a diverse range of products such as canned vegetables, desserts, seafood, meat products, environmental water, articial teeth, nail polish, food pack-aging materials etc. [1, 3]. However, BPA had been proved to be an endocrine disrupter [2, 4], which caused an increase in testicular and breast cancer rates [5]. There were a number of methods being previously developed to identify trace BPA based primarily on chromatographic technology, including gas chromatography (GC) and liquid chromatography (LC) [3, 4]. Gas chromatography-mass spectrometry (GC-MS) was also applied. However, these analysis need preconcentration for trace BPA from samples such as liquid-liquid extraction, solid-phase extraction and solid-phase microextraction [6–8], which involve reversed-phase materials and complicated procedures. GC and GC-MS require the derivatization of BPA before analysis, which are time-consuming and expensive. Therefore, in order to detect and quantify low concentration of BPA, the development of a sensitive analytical method with the process of a relatively simple, rapid, organic solvent-free pretreatment is necessary.

In the past two decades, photoluminescence (PL) semiconductor nanocrystals or quantum dots (QDs) have been widely applied as fluorescence probes in biology and medicine, more recently in analytical chemistry due to their strong size-dependence, superior optical and electronic properties [9–13], which had been well documented in some reviews [3, 14]. In comparison with conventional probes of organic dye and protein, QDs often exhibit a broad excitation spectrum, a narrow, tunable and symmetric emission spectrum as well as highly stable against photobleaching [15, 16]. It is well known that fluorescence detection has been used extensively as analytical technique with high levels of sensitivity and selectivity. For QDs, a surface-coating agent, namely an organic ligand introduced onto their surface could afford their stability and desired surface functionality. Therefore, a chemical sensing system could be developed based on the variation of the PL intensity of the QDs induced by changed surface [17]. In the light of the principle, a few papers have reported that some inorganic ions and small organic molecules could be detected by the fluorescence quenching of surface-coated QDs, such as Pb2+ [18], Cu2+ [19], VB1[20], glucose [20], spironolactone [21] and methimazole [22].

To our knowledge, the use of QDs as selective probes for fluorescence determination of BPA had not developed. In addition, as an alternative to thermally driven syntheses, sonochemistry had been successfully applied to a variety of chemical reactions and had prepared a wide range of products [4, 23]. The remarkable advantages of the approach include a rapid reaction, a narrow size distribution for prepared products [24]. In the present work, we directly synthesized CdTe QDs in aqueous medium by a simple, rapid ultrasonic irradiation, cysteamine was used as the surface-coating agent. The cysteamine-coated QDs possess a quantum yield as high as 46% and a quite narrow emission band, full width at half maximum ( FWHM) of 38 nm. The determination method of trace BPA in a simple and rapid technique based on fluorescence quenching of the QDs was established and was successfully applied to BPA analysis in feeding-bottles.

Experimental

Materials and instruments

All chemicals were of analytical grade or of the highest purity and used as received without further purification. Double deionized water was used throughout the experiment. Tellurium powder (100 mesh, 99.9%) were purchased from Sinopharm Chemical Reagent Beijing Co. Ltd. (Beijing, China, http://reagent.instrument.com.cn). Cadmium chloride (CdCl2·2H2O, 99.99%), cysteamine (99.99%), sodium borohydride (NaBH4, 96.0%) and some routine chemicals were from Shanghai Reagent Co. Ltd. (Shanghai, China, www.china-reagent.com). Rhodamine 6G with a PL quantum yield of 95% in ethanol was also obtained from Sinopharm Chemical Reagent Beijing Co. Ltd. to determine quantum yields of QDs.

Feeding-bottle samples of three brands with different prices were obtained from local supermarket. These are made of polycarbonate.

UV–vis absorption spectra were obtained using a UV-4802 spectrophotometer (UNIC, Shanghai, China, www.unico1.com.cn). The PL emission spectra were performed using a RF-5301 luminescence spectrometer (Shimadzu, Japan, www.shimadzu.com.cn). The crystal structure of QDs were taken on a D/MAX-RB X-ray diffractometer (Rigaku, Japan, www.rigaku.com.cn). The analysis of surface binding structure of QDs were carried out on a Magna 750 Fourier Transform-Infrared (FT-IR) Spectrometer (Nicolet, America, www.thermonicolet.com). pH values were measured with a MODEL 818 pH meter (Jinpeng Analytical Instruments Co. Ltd, Shanghai, China, www.17bio.com). Ultrasonic irradiation was carried out using a ultrasonic cleaning instrument (Jiangsu Zhangjiagang Aohua Appliance Manufacturing Co. Ltd., China, www.ahcsb.com).

Synthesis of cysteamine-coated CdTe QDs

Cysteamine-coated CdTe QDs were synthesized in aqueous medium by ultrasonic irradiation. NaBH4 and Te powder were added to a small one-necked flask, double deionized water and anhydrous ethanol were also added at a volumer ratio of 3:1, respectively. A small outlet was connected to the flask to release resulting hydrogen. The solution was then heated at 50 °C until Te powder was dissolved, thus NaHTe solution was obtained. CdCl2 and cysteamine were dissolved to 300 mL water in a three-necked flask. The pH of the solution was adjusted by stepwise addition of 0.5 mol·L−1 NaOH, and the solution was N2-saturated for 20 min. Subsequently, the prepared fresh NaHTe solution was injected into the solution under vigorous stir. The CdTe precursors were formed at this stage, accompanied by a faint color. Afterward, the solution was immersed into the water bath with a ultrasonic radiation, and was kept at 100 °C refluxing temperature for a specified period. To monitor the growth of the QDs, aliquots of reaction solution were taken at various time for optical measurement.

To obtain cysteamine-coated CdTe QDs precipitate, the QDs solution was added in acetone, then precipitated QDs were separated by centrifugation at 15,000 rpm for 10 min and were repeated several times to remove unreacted cysteamine. The sedimentation was dried in a vacuum drying chamber for XRD and IR spectroscopy analysis.

Determination of BPA in samples

Each feeding-bottle with different brands was cut up into small fragments about 0.5 mm × 0.5 mm size. The sample of 100 g was transferred in a round-bottomed flask, and 1,000 mL double deionized water was added in it. And then, the mixture was heated in a constant temperature at 90 °C for 2 h under continuing stir, and then cooled to room temperature and leached. The leachate was concentrated to 50 mL.

One mL QDs solution, 1 mL phosphate buffer and 20 uL BPA standard solution or a sample solution were added to the calibrated test tube of 10 mL, respectively. Subsequently, the mixture was diluted with double deionized water to mark and incubated for an optimized time to equilibrate the system. The solution was transferred into a quartz cell for sense. The PL intensity of the solution was measured under the excitation wavelength of 347 nm, and emissions was monitored between 350 nm and 800 nm. Both slit widths of excitation and emission were 5 nm and 10 nm, respectively. All optical measurements were equipped at room temperature.

Results and discussion

Response of optical properties of cysteamine-coated CdTe QDs on time

Coated agents of QDs have important role in recognition of detected substances. To determine cytochrome c, Cao et al. synthesized CdTe QDs capped by glutathione and obtained satisfactory results [25]. Lai et al. prepared high quality CdS QDs fluorescence sensor coated with chitosan for Cu2+ detection due to good chelating ability of chitosan with transition metal ions [26]. A number of researches focused on the synthesis of CdTe QDs using thioglycolic acid or mercaptopropionic acid as coated agents [8, 18]. In current work, we chosen cysteamine to synthesize cysteamine-coated CdTe QDs for determination BPA. Cysteamine, a bifunctional ligand, can afford thiol groups to strongly bond Cd2+ on the QDs surface by chemical bond, besides, hydrophilic amine groups to achieve water-compatibility of the QDs. Especially, the amine groups could serve as the points of hydrogen bond attachment to BPA molecules for modifying the surface structure and optical properties of QDs.

Figure 1 showed dependent of PL emission and UV–vis spectra of cysteamine-coated CdTe QDs on time. The QDs were synthesized by ultrasonic irradiation at refluxing temperature. Figure 2 summarized PL emission peak positions, FWHM of emission spectra and quantum yields of the QDs during reacting process. The emission and absorption peaks of the QDs were noticeable red-shifted with increased refluxing time, and all emission spectra were good symmetrical. The PL intensity showed a rising tendency with refluxing time from 10 min to 60 min, followed by a great drop as further increase to 120 min. The maximum PL intensity was observed for refluxing 60 min. These indicated that the QDs grew gradually at controlled speed. The results were attributed to the changes of size and constituent of the QDs during growth.

Effects of reaction time on optical properties of cysteamine-coated CdTe QDs. PL emission spectra (a); UV–vis absorption (b); From (a) to (f), corresponding to 5 min after form CdTe precursor, and 10 min, 20 min, 40 min, 60 min, 120 min after ultrasonic irradiation; Ultrasonic irradiation power 120 W, refluxing temperature 100 °C, Te: NaBH4: CdCl2: cysteamine = 1: 3: 2: 5 (molar ratio)

A narrow FWHM of QDs is an important requirement for synthesizing high quality QDs. Figure 2b showed that cysteamine-coated CdTe QDs possessed a narrow FWHM platform of 38 nm with refluxing from 20 min to 60 min, which was narrower than the value of CdTe QDs described previously using thioglycolic acid as coated-agent following conventional method [27]. After 60 min, the FWHM gradually turned up from 50 nm to 81 nm corresponding to refluxing 120 min and 240 min. This suggested that the high quality cysteamine-coated CdTe QDs could be synthesized within refluxing 60 min in a so simple and rapid technique. With increased refluxing time from 10 min to 60 min, the quantum yields of the QDs rised up from 1.6% to 46.5% (Fig. 2c). After 60 min, it gradually shifted down. The quantum yield as high as 46.5% was harvested when refluxing 60 min. This reflected the quantum size function of QDs, and also demonstrated that QD sizes could be tuned by simply controlling reaction time. The synthetic method of the QDs is much simpler than those reported in organic solvents that took several hours with complicated process. Besides, the QDs with refluxing 60 min were optical stable for 90 days when reserved in the dark at 20–25 °C. Therefore, the QDs with refluxing 60 min was used in below detecting experiments.

XRD and IR characterization

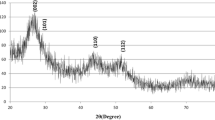

Figure 3 revealed powder XRD patterns for the cysteamine-coated CdTe QDs corresponding to reaction 60 min and 240 min. As shown in Fig. 3, the spectra were scaned over the 2 theta (θ) range of 10–70°, well-crystallized QDs were obtained. The XRD pattern of the QDs at reaction 60 min in Fig. 3a belonged to a cubic zinc blende structure, which was represented by the diffractive peaks at 24.5, 40.1 and 47.5°. The XRD pattern corresponding to reaction 240 min in Fig. 3b exhibited a obvious shift from CdTe to CdS structure, and three distinct diffractive peaks at 25.1, 42.7, and 48.1° were observed between CdTe and cubic CdS phase. This may be due to released sulfur from decomposed cysteamine entering the CdTe crystal lattice. The average crystal sizes of the QDs is determined by Debye-Scherrer’s formula [11]:

Where D is the nanocrystal diameter, λ is the wavelength of the incident XRD, β is the FWHM, θ is the diffraction angle. Based on the XRD spectra, the reflection angle at 2θ = 24.2° is used, the estimated average crystallite diameter of the CdTe QDs nanocrystal is 3.5 nm.

To identify the conjugation mode between cysteamine and CdTe QDs coated by cysteamine, the IR spectra of pure cysteamine and the QDs were measured and were shown in Fig. 4. The resemblance in both spectral features and several peak positions proves a successful chemical attachment of cysteamine onto the QDs surface. However, the IR spectra of the QDs is distinctively different from that of pure cysteamine. For cysteamine, the absorption at 2,600–2,500 cm−1 are assigned to S-H stretching vibration. The absorption occurred at 3,500–3,000 cm−1 are produced by stretching vibration of O-H (H2O) and N-H (-NH2). The absorption at 1,583.2 cm−1 is attributed to N-H deformation vibration. Especially, the absorption of S-H stretching vibration at 2,600–2,500 cm−1 for the QDs has not been found. This reflects that –SH in cysteamine of the QDs is covalently bound on the QDs surface. Additionally, the broad absorption region at 3,300–3,000 cm−1 in the QDs almost disappears. More—NH2 exposured onto the QDs surface could be illuminated by much narrower absorption band around 3,400 cm−1, a decreased absorption at 1,675 cm−1, a blue-shifted from 1,609 cm−1 to 1,673 cm−1.

Detection of BPA

Exploring experiments showed that the PL emission intensity of BPA in aqueous medium was too low to be directly detected, while it exhibited a sensitive fluorescence quenching to cysteamine-coated CdTe QDs. Thus, the influence of incubating time of the QDs with BPA on the PL emission properties of the QDs was firstly examined. The concentrations of QDs and BPA were 5 × 10−9 mol·L−1 and 2 × 10−7 mol·L−1, respectively. As shown in Fig. 5, the PL emission quenching gradually enhanced with incubated time, and reached a almost constant maximum value during following 5–15 min. And then, it changed a little with increasing time. Hence, PL emission measurement in below experiments was made at incubated 8 min.

Figure 6 showed the quenching effects of BPA concentrations on the PL emission of the cysteamine-coated CdTe QDs. The results indicated that the PL intensity of the QDs decreased obviously with the increase of BPA concentration, the sensitive quenching could be observed. A linear relationship of Io/I and BPA concentration ranging from 4 × 10−9 mol·L−1 to 4.5 × 10−7 mol·L−1 can be described by a Stern-Volmer equation with the correlation coefficient of 0.998 as follows:

where Io and I are the PL emission intensity of the QDs in the absence and presence of quencher BPA, respectively, CBPA is the concentration of BPA. The detection limit is 1 × 10−9 mol·L−1 with the ratio of signal to noise of 3 (S/N = 3). The standard deviation for six replicate measurements of a solution containing 1.0 × 10−8 mol·L−1 BPA is 2.1%. This reveals that the method offers a good accuracy and precision for the detection of BPA.

a Response of BPA quenching PL emission intensity of cysteamine-coated CdTe QDs on BPA concentration; b The linear regression curves of detection BPA using the QDs; BPA concentration from (a) to (h): 0, 4 × 10−9 mol·L−1, 1.1 × 10−8 mol·L−1, 2.2 × 10−8 mol·L−1, 4.4 × 10−8 mol·L−1, 8.8 × 10−8 mol·L−1, 1.3 × 10−7 mol·L−1 and 4.5 × 10−7 mol·L−1; The QDs concentration 2 × 10−7 mol·L−1, incubated time of the QDs and BPA 8 min, PH 4–5

Interference analysis

Table 1 described the influence of coexistence ions on the PL intensity of the cysteamine-coated CdTe QDs added BPA. For coexistence ions, Al3+, Zn2+, Mg2+ ,Ca2+ ,K+, Na+, CO 2−3 and SO 2−4 did not produce noticeable effects on the PL intensity of the QDs, the tolerance limits of these ions were more than 10−5 mol· L−1, 1,000 times than the concentration of coexisted BPA, therefore, the ions did not interfered the determination of BPA at the concentration of 1 × 10−8 mol· L−1. Fe3+, Cu2+, Hg2+ and Ag+ exhibited effective quenching effects on the QDs. This is contributed to their strong chemical adsorption onto the QDs surface. But the tolerance limits of these ions at least were 50 times than the BPA amount, these are much higher than the concentration present in samples. These experimental results showed that these ions at a concentration of 5.0 × 10−7 mol· L−1 had no measurable effect on 1.0 × 10−8 mol· L−1 BPA using cysteamine-coated CdTe QDs.

Application

The proposed method was applied for the determination of BPA in feeding-bottle samples with different brands. To calculate the recovery efficiency of this method, BPA at 5 μg·L−1 spiking level was added to a sample solution. The recoveries of this method were tested by three spiked samples and the result were listed in Table 2. High recoveries from 95.2% to 103.7% were obtained for all analytes with RSD values between 1.76% and 2.03%. These results demonstrate that the analysis method is suitable for trace level BPA. As shown in Table 2, BPA from two samples was detected at amounts of 21.42 μg·kg−1 and 1.32 μg·kg−1, it was not detected in another sample.

Quenching mechanism

In a relatively alkaline environment, the progress of complexation reaction between BPA and Cd2+ on CdTe QDs surface may occur. While the current CdTe QDs-BPA system is weak acidic, there is little probability of the complexation reaction. The quenching may be due to the hydrogen bond function of molecules between BPA and cysteamine on the surface of the QDs. The hydrogen bond leads cysteamine molecules to be partly peeled off the surface of the QDs, the surface changes of CdTe QDs induce the fluorescence quenching of the QDs. This result is in according with the previous supposing that the amine groups serve as the points of hydrogen bond attachment to BPA molecules for the quenching fluorescence of the QDs to sence BPA.

Conclusion

In this paper, cysteamine-coated CdTe QDs were synthesized in aqueous solution by convenient ultrasonic irradiation. These QDs possess the highest PL quantum yield of 46.5% and the most narrow FWHM of 38 nm at 100 °C refluxing temperature and about 60 min reaction time. The response of PL emission of the QDs is highly sensitive to trace BPA. Thus, a novel, simple technique of determinating BPA was established. Quantitative detection of BPA ranging from 4 × 10−9 to 4.5 × 10−7 mol·L−1 with a low detection limit of 1 × 10−9 mol·L−1 was achieved. The present method was applied to analyze BPA in feeding-bottle samples, high recovery from 95.2% to 103.7% were obtained with RSD values between 1.76% and 2.03%. The quenching mechanism may be due to the surface changes of the QDs from the hydrogen bond between molecules of BPA and cysteamine on the surface of the QDs.

References

Olmo M, Zafra A, Jurado AB, Vilchez JL (2000) Determination of bisphenol A (BPA) in the presence of phenol by first-derivative fluorescence following micro liquid extraction (MLLE). Talanta 50:1141

Chang CM, Chou CC, Lee MR (2005) Determining leaching of bisphenol A from plastic containers by solid-phase microextraction and gas chromatography-mass spectrometry. Anal Chim Acta 539:41

Yoshida H, Harada H, Nohta H, Yamaguchi M (2003) Liquid chromatographic determination of bisphenols based on intramolecular excimer-forming fluorescence derivatization. Anal Chim Acta 488:211

Braunrath R, Cichna M (2005) Sample preparation including sol-gel immunoaffinity chromatography for determination of bisphenol A in canned beverages, fruits and vegetables. J Chromatogr A 1062:189

Li XL, Lin L, Zou SC, Lan CY, Luan TG (2006) Determination of bisphenol A in landfill leachate by solid phase microextraction with headspace derivatization and gas chromatography-nass spectrophotometry. Chin J Anal Chem 34:325

Olmo M, González-Casado A, Navas NA, Vilchez JL (1997) Determination of bisphenol A (BPA) in water by gas chromatography-mass spectrometry. Anal Chim Acta 346:87

Kuo HW, Ding WH (2004) Trace determination of bisphenol A and phytoestrogens in infant formula powders by gas chromatography−mass spectrometry. J Chromatogr A 1027:67

Gaponik N, Talapin DV, Rogach AL, Hoppe K, Shevchenko EV, Kornowski A, Eychmüller A, Weller H (2002) Thiol-capping of CdTe nanocrystals: an alternative to organometallic synthetic routes. J Phys Chem B 106:7177

Qu FG, Li HB (2009) Selective molecular recognition of polycyclic aromatic hydrocarbons using CdTe quantum dots with cyclodextrin as supramolecular nano-sensitizers in water. Sens Actuators B 135:499

Michalet X, Pinaud FF, Bentolila LA, Tsay JM, Doose S, Li JJ, Sundaresan G, Wu AM, Gambhir SS, Weiss S (2005) Quantum dots for live cells, in vivo imaging and diagnostics. Science 307:538

Chen JL, Zheng F, Gao YC, He CY, Wu GH, Chen YC, Kai XM, Zhu CQ (2008) Functionalized CdS quantumdots-based luminescence probe for detection of heavy and transition metal ions inaqueous solutiona. Spectrochim Acta Part A 69:1044

Zhang MQ, Zheng G, Fang JB, Xia XB, Cao J, Li JH, Li F (2009) Microwave-mediated nonaqueous synthesis of quantum dots at moderate temperature. Langmuir 15:13370

Chen YF, Ji TH, Rosenzweig Z (2002) Luminescent CdS quantum dots as selective ion probes. Anal Chem 74:5132

Bailey RE, Smith AM, Nie SM (2004) Quantum dots in biology and medicine. Physica E 25:1

Zhang L, Xu C, Li B (2009) Simple and sensitive detection method for chromium (VI) in water using glutathione capped CdTe quantum dots as fluorescent probes. Microchim Acta 166:61

Gao XH, Yang LL, Petros JA, Marshal FF, Simons JW, Nie SM (2005) In vivo molecular and cellular imaging with quantum dots. Curr Opin Biotechnol 16:63

Wu HM, Liang JG, Han HY (2008) A novel method for the determination Pb2+ based on the quenching of the fluorescence of CdTe quantum dots. Microchim Acta 161:81

Wang J, Liang JG, Sheng ZH, Han HY (2009) A novel strategy for selective detection of Ag+ based on the red-shift of emission wavelength of quantum dots. Microchim Acta 167:281

Zhang LH, Shang L, Dong SJ (2008) Sensitive and selective determination of Cu2+ by electrochemiluminescence of CdTe quantum dots. Electrochem Commun 10:1452

Sun JF, Liu LH, Ren CL, Chen XG, Hu ZD (2008) A feasible method for the sensitive and selective determination of vitamin B1 with CdSe quantum dots. Microchim Acta 163:271

Liang JG, Huang S, Zeng DY, He ZK, Ji XH, Ai XP, Yang HX (2006) CdSe quantum dots as luminescent probes for spironolactone determination. Talanta 69:126

Dong F, Hu KW, Han HY, Liang JG (2009) A novel method for methimazole determination using CdSe quantum dots as fluorescence probes. Microchim Acta 165:195

Murcia MJ, Shaw DL, Woodruff H, Naumann CA, Young BA, Long EC (2006) Facile sonochemical synthesis of highly luminescent ZnS-shelled CdSe quantum dots. Chem Mater 18:2219

Cao M, Cao C, Liu M, Wang P, Zhu C (2009) Selective fluorometry of cytochromec using glutathione-capped CdTe quantum dots in weakly basic medium. Microchim Acta 165:341

Lai S, Chang X, Fu C (2009) Cadmium sulfide quantum dots modified by chitosan as fluorescence probe for copper (II) ion determination. Microchim Acta 165:39

Sánchez-Acevedo ZC, Riu J, Rius FX (2009) Fast picomolar selective detection of bisphenol A in water using a carbon nanotube field effect transistor functionalized with estrogen receptor-α. Biosens Bioelectron 24:2842

Feng XJ, Shang QK, Liu HJ, Wang HD, Wang WL, Wang ZD (2009) Effect of adenine on the photoluminescence properties and stability of water-soluble CdTe quantum dots. J Phys Chem C 113:6929

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 30972044).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kuang, R., Kuang, X., Pan, S. et al. Synthesis of cysteamine-coated CdTe quantum dots for the detection of bisphenol A. Microchim Acta 169, 109–115 (2010). https://doi.org/10.1007/s00604-010-0323-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-010-0323-3