Abstract

The effect of thermal treatment on several physical properties and the tensile strength of Laurentian granite (LG) are measured in this study. Brazilian disc LG specimens are treated at temperatures of up to 850 °C. The physical properties such as grain density, relative volume change per degree, and P-wave velocity are investigated under the effect of heat treatment. The results indicate that both the density and the P-wave velocity decrease with the increase in heating temperature. However, the relative volume change per degree is not sensitive below 450 °C, while a remarkable increase appears from 450 to 850 °C. All cases are explained by the increase in both number and width of the thermally induced microcracks with the heating temperature. Brazilian tests are carried out statically with an MTS hydraulic servo-control testing system and dynamically with a modified split Hopkinson pressure bar (SHPB) system to measure both static and dynamic tensile strength of LG. The relationship between the tensile strength and treatment temperatures shows that static tensile strength decreases with temperature while the dynamic tensile strength first increases and then decreases with a linear increase in the loading rate. However, the increase in dynamic tensile strength with treatment temperatures from 25 to 100 °C is due to slight dilation of the grain boundaries as the initial thermal action, which leads to compaction of rock. When the treatment temperature rises above 450 °C, the quartz phase transition results in increased size of microcracks due to the differential expansion between the quartz grains and other minerals, which is the main cause of the sharp reduction in tensile strength.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Thermal effect is one of the most important environmental conditions to which rocks may be subjected. Rocks are heated or thermally cooled in many engineering applications, such as rock drilling, ore crushing, deep petroleum boring, geothermal energy extraction, and deep burial of nuclear wastes (Heuze 1983; Homandetienne and Houpert 1989). Therefore, the mechanical behaviour of rocks under thermal treatment is an important aspect for engineering excavation. The basic physical and mechanical properties of thermally treated rocks under static loading have been studied, such as compressive strength (Homandetienne and Houpert 1989; Dwivedi et al. 2008; Masri et al. 2014), fracture toughness (Nasseri et al. 2009), and tensile strength (Rao et al. 2007).

Rocks are much weaker in tension than in compression. Therefore, it is important to investigate the tensile strength of thermally treated rocks and to understand the relationship between strength and increased temperatures. Homandetienne and Houpert (1989) obtained the tensile strength of two kinds of rocks before and after thermal treatment. They found an important decrease in the tensile strength with the increase in thermal treatment temperature. Furthermore, the reduction was found to be greater when the tests were conducted at high temperatures using thermally treated specimens (Lee et al. 1996). In contrast, Rao et al. (2007) thought that the tensile strength of rocks increased below 250 °C and decreased above 250 °C with the temperature increase. Many research studies on tensile strength of thermally treated rocks are carried out under quasi-static loading conditions. However, in many engineering practices as mentioned above, rocks are stressed dynamically. Only a few researches have been conducted on the dynamic mechanical properties of temperature or thermally treated rocks; for instance, Nojima et al. (1989) characterized the impact properties of three types of engineering ceramics up to 1,200 °C. Dutta et al. (1993) investigated the stress–strain behaviour, fracture strength and energy absorption in the dynamic fracturing of sedimentary and igneous rocks at −40 and 24 °C. Zhang et al. (2001) measured the dynamic fracture toughness of Fangshan gabbro and Fangshan marble subjected to high temperature, and Li et al. (2010) and Yin et al. (2012) investigated the dynamic mechanical properties of sandstone under high temperatures. The role of temperature and strain rate on the characteristics of brittle rock materials has been reviewed by Paterson et al. (2005) in detail. In general, increase in temperature or decrease in strain rate will lead to decrease in fracture strength. Brittle–ductile transition, i.e. a transition from partly cataclastic to fully crystal-plastic deformation, occurs with high temperature and confining pressure. The change of deformation mechanism was also supported by Lindholm et al. (1974), who stated that a transition from cataclasis/cleavage (a more brittle variant of cataclasis) to apparent cataclasis can be achieved with the increase of temperature. Zhang and Zhao (2013b) has also critically reviewed the dynamic testing at high temperatures by different methods such as uniaxial compression, triaxial compression, Brazilian disc test, short rod, and notched semi-circular bending, etc. Experimental observations show a strong dependence of the fracture strength on both temperature and strain rate.

In order to determine the tensile strength of rocks, a number of methods have been suggested. Due to the complicated experimental setup and high testing cost, direct tension method is rarely employed to determine the dynamic tensile strength of rock materials. As summarized by Zhang and Zhao (2013b), several indirect testing methods have been proposed and are widely used, such as the Brazilian disc (BD) test (Bieniawski and Hawkes 1978; Mellor and Hawkes 1971; Hudson et al. 1972; Coviello et al. 2005), the ring test (Hudson 1969; Mellor and Hawkes 1971; Coviello et al. 2005), and the bending test (Coviello et al. 2005) and spalling methods, etc. All of these are indirect tensile methods, which are much easier and cheaper in terms of both sample preparation and experimental apparatus than the direct pull test (Dai and Xia 2010). Therefore, a considerable number of researches have been done by means of indirect tensile methods, particularly the BD test, which was supported by the International Society for Rock Mechanics (Zhou et al. 2012). Many authors have also applied the Brazilian test to measure dynamic properties of rocks, for example, Zhao and Li (2000) and Dai and Xia (2010) measured the dynamic tensile characteristics of granite with the BD test. Wang et al. (2009) compared dynamic tensile strengths at different strain rates using flattened Brazilian disc specimens of marble. Huang et al. (2010) investigated the tensile strength of soft Longyou sandstone from China and found the relationship between tensile strength and loading rates. However, the determination of dynamic tensile strength of rock materials by BD test has not been systematically introduced, and there are several drawbacks to previous works: (1) the influence of temperature on different physical properties of rock materials is not exactly the same, sometimes even show opposite trends. The evolution with temperature of different properties should be discussed and compared with each other, and the mechanism underlying the phenomenon should be uncovered. (2) Different ranges of temperature have different influences on the properties, and further discussions and explanations are needed to explain the overall evolution process. (3) It is necessary for direct observation of the tensile failure process with high-speed photography to verify that the crack initiates after the stress equilibrium is achieved in the whole specimen. The employment of a high-speed camera can also contribute to the contrast between the failure modes of rock materials with and without thermal treatment.

This study focuses on the measurement of dynamic tensile strength in thermally treated Laurentian granite using the Brazilian test. In rock drilling and blasting, two types of engineering applications subjected to dynamic loading and thermal effect due to blasting produce transient mechanical and thermal loading onto rock. To evaluate these engineering applications, dynamic laboratory tests were carried out for measurement of the dynamic properties of thermally treated Laurentian granite (LG) using the split Hopkinson pressure bar (SHPB). By means of the dynamic Brazilian test, the relationship between dynamic tensile strength and thermal treatment temperature is established. The static Brazilian tests are investigated to measure the tensile strength of thermally treated LG.

2 Experimental Setup

The static Brazilian tensile tests were carried out with an MTS hydraulic servo-control testing system. A constant loading rate of 200 N/s was selected for all the tests following the method suggested by ISRM (Bieniawski and Hawkes 1978).

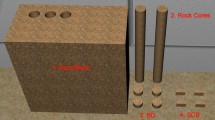

The dynamic Brazilian tensile tests were conducted with an SHPB system, which is shown schematically in Fig. 1. The SHPB system consists of a striker bar, an incident bar, and a transmitted bar, all made of high-strength maraging steel with high yield strength of 2.5 GPa. For our SHPB system, the lengths of the striker bar, incident bar, and transmitted bar are 200, 1,500, and 1,200 mm, respectively. Strain gauges were pasted 733 and 655 mm away from the bar–sample interfaces on the incident bar and transmitted bar, respectively. A sample was sandwiched between the incident bar and the transmitted bar, and after the test setup with the sample was ready, the striker bar was launched by a high-speed gas gun. A longitudinal compressive pulse was induced when the striker bar impacted on the free end of the incident bar. In the sample the incident pulse (\(\varepsilon_{i}\)) was partly reflected (\(\varepsilon_{r}\)) and partly transmitted (\(\varepsilon_{t}\)). The loading forces P 1 and P 2 on the two ends of the sample can be determined by the following formula:

Here, \(\varepsilon\) is the strain and, \(E\) and \(A\) are the Young’s modulus and the cross-sectional area of the bar, respectively.

3 Sample Preparation and Physical Properties

3.1 Sample Preparation

LG is taken from the Laurentian region of Grenville province of the Precambrian Canadian Shield, north of St. Lawrence and north-west of Quebec City, Canada. The mineralogical composition determined using the X-ray diffraction technique is feldspar 60 %, quartz 33 %, and biotite 3–5 %. The physical and strength properties of LG are given in Table 1.

The BD samples from the same block of LG were made into discs with nominal diameter of 40 mm and thickness of 18 mm. In this study, six sets of samples were provided including one obtained at room temperature and five treated at 100, 250, 450, 600, and 850 °C, respectively. The thermal treatment was conducted in a servo-controlled electrical furnace at a rate of 2 °C/min. As soon as the temperature reached a specified value in the furnace, the temperature was maintained for 2 h so that the whole sample from the outside to the inside would be heated to the specified temperature. Then the furnace was cooled down to room temperature at a lower rate in order to avoid thermal shock during cooling.

3.2 Grain Density

Density is one of the basic physical properties of rocks. The density (\(\rho\)) of LG is 2.64 × 103 kg/m3 at room temperature; however, it shows variation after thermal treatment at different temperatures. The relationship between temperature and density was obtained as shown in Fig. 2. It can be seen that the density shows a small decrease with increases in temperature up to 450 °C; after that, a significant decrease occurred from 450 to 850 °C. This is close to the results of Yavuz on carbonate rocks (Yavuz et al. 2007).

3.3 Thermal Expansion

The relative volume change per degree (\(\beta\)) can be defined as the volumetric variation of the rock material per degree of change in temperature, which is expressed as:

where \(\Delta T\) is the temperature variation, \(\Delta V\) is the variation in sample volume under \(\Delta T\), and \(V\) is the initial volume of the sample.

Thermal expansion evolution with temperature reflects the microstructural characteristics. However, high temperature has complex influence on the internal microstructure of the granite. The relative volume measurement was carried out at room temperature after thermal treatment from 25 to 100 °C, 250, 450, 600, and 850 °C, respectively, at a heating rate of 2 °C per min. The results are presented in Fig. 3, which shows that there is no significant change in the relative volume change per degree when the temperature is below 450 °C; however, a remarkable increase appears at 600 and 850 °C. This can be supported by the increase in both number and width of the thermally induced microcracks with the heating temperature.

In fact, when the temperature is below 450 °C, the internal moisture in the granite sample evaporates firstly and the dilation induced by the initial thermal action leads to the compaction of rock. However, the granite specimen remains in the elastic stage at this temperature range and the relative volume change per degree can roughly maintain constant below 400 °C. But when the temperature ranges from 450 to 850 °C, some complex changes occur such as mineral component decomposition, constitution water evaporation and phase transition due to the combined action of melting and structural thermal stress. Therefore, as for the granite, the dynamic mechanical properties degrade seriously and the relative volume change per degree increases dramatically with temperature when the temperature exceeds 450 °C.

3.4 P-Wave Velocity

The ultrasonic P-wave velocity is another important physical property of rocks. It was measured by ultrasonic pulse transmission technique. The variation in the P-wave velocity with the heating temperature is shown in Fig. 4. It can be seen that when the treatment temperature is 100 °C, the P-wave velocity is not sensitive to heating. Beyond 100 °C, there is a sharp decrease in the P-wave velocity, which can be explained by the increase in both number and width of the thermally induced microcracks with the heating temperature (Nasseri et al. 2007). These observations are very similar to those of a few other rock types (Chen et al. 2003; Chaki et al. 2008).

4 Tensile Strength Determination

4.1 Determination of Tensile Strength in BD

As the tensile strength of rock material is typically an order of magnitude smaller than the compressive strength, tensile failure often occurs in rock masses (Wang et al. 2009). In the Brazilian tensile test, both the static test in the MTS machine and the dynamic Brazilian test in the SHPB system, illustrated schematically in Fig. 5a, b, respectively, are used to determine the tensile strength using the following equation (Zhao and Li 2000):

where \(\sigma_{t}\) is the Brazilian tensile strength, \(P_{\hbox{max} }\) is the load when the failure occurs, and D and B are the diameter and thickness of the disc specimen, respectively.

The static stress analysis applied to dynamic experiment was reported by Dai and Xia (2010). The essential requirement is that the dynamic force balance must be achieved by the BD specimen during the dynamic tests.

4.2 Determination of Loading Rate

In the Brazilian test, we obtain the history of the tensile stress by substituting the loading history as shown in Fig. 6 into Eq. (3). There exists a roughly linear range before the peak-load between 60 and 80 μs as shown in Fig. 6. We determined this slope as the loading rate for the test and denote it as \(\sigma_{t}\) following the previous study (Dai et al. 2009). For the typical tensile stress–time cure shown in Fig. 6, the loading rate is determined as 96 GPa s−1.

5 Results and Discussion

5.1 Dynamic Equilibrium

We utilize a pulse shaping technique in order to ensure a quasi-static situation in all our dynamic Brazilian tests. In this technique, a C1100 copper slice is stuck on the free end of the incident bar to shape the loading pulse, in the same way as was done in some other researches (Chen et al. 2003). Figure 7 shows the dynamic forces on both ends of the specimen in a typical test, which are calculated using Eq. (1). From Fig. 7, it can be seen that the dynamic force on one side of the sample, which is the sum of the incident (In) and reflected (Re) stress waves, is absolutely equal to the dynamic force transmitted on the other side (Mahabadi et al. 2010). The balance of dynamic forces on both ends of the specimen has been reached. The dynamic force balance of all tests in this study has been proved.

5.2 Static Tensile Strength with Temperature

The static tensile strength was measured by MTS hydraulic servo-control testing system. Figure 8 shows the typical static tensile strength histories at different thermal treatment temperatures. Figure 9 presents the relationship of static tensile strength and treated temperatures, indicating that the static tensile strength decreases with the increase in thermal treatment temperature. At treatment temperatures below 100 °C, there was a sharp 30.4 % decrease in the static tensile strength. This can be due to the fact that water in the rock evaporates and a large amount of pores come into being, which reduces the cohesion between rock granules. However, a slight decrease is observed from 100 to 450 °C, which is due to the microcracks induced and propagated by thermal stress. A significant decrease in tensile strength occurs in the range of 450–600 °C (65.9 % reduction) due to the \(\alpha - \beta\) quartz phase transition that occurs at roughly 573 °C, leading to increased microcracks in the specimen (Nasseri et al. 2009). However, a slight decrease in tensile strength is presented from 600 to 850 °C. All the results are summarized in Table 2.

5.3 Dynamic Tensile Strength

The dynamic tensile strength values corresponding to the loading rates obtained at different temperatures in this study are tabulated in Table 3. It can be seen from Fig. 10 that the tensile strength obtained tends to increase linearly with the loading rate for each temperature group. The dynamic tensile strength is sensitive to the loading rate, according to previous research (Cai et al. 2007; Dai and Xia 2010). But the specimens would be degraded so seriously after thermal treatment at temperatures above 600 °C that no correct data could be obtained at strain rates higher than 1,500 GPa/s.

From Fig. 11, which shows the average values of tensile strength with treatment temperatures in the loading rate range of 800–1,100 GPa/s, we can see that temperature affects the dynamic tensile strength of granite in three phases (I is the increase phase, II is the slow decrease phase, and III is the fast decrease phase). In the first phase (I) from 25 to 100 °C, contrary to the trend for static tensile strength with treatment temperature, the dynamic tensile strength values at the same loading rate for specimens increase slightly from 33.3 to 34.8 MPa because of the dilation of grain boundaries as the initial thermal action, which leads to the compaction of rock. This phenomenon is consistent with the results obtained by Vishal et al. (2011), who pointed out that in the initial stage, the tensile strength increases up to 100 °C, after which it begins to decrease with further rises in temperature. The second phase (II) shows the slow decrease of tensile strength from 100 to 450 °C, which was calculated as 10.1 %. It may be due to the variation in the internal structure and chemical composition of the sample and the microcracks induced by thermal stress. Very similar results were reported by Dwivedi et al. (2008), who measured the tensile strength of some Indian granite and obtained a decrease in tensile strength with increasing temperature. However, Rao et al. (2007) reported that the static tensile strength of sandstone increases linearly with temperature below 250 °C, and decreases above this temperature. They believe that evaporation of the free moisture and different expansion coefficients of minerals in rock result in the development of microcracks and the degradation of mechanical properties.

The dynamic tensile strength of rocks in the third phase (III) presents a significant decrease in the temperature range from 450 to 850 °C; for example, within the loading rate range of 800–1,100 GPa/s, the average value of tensile strength of 19.35 MPa at 850 °C is reduced by 41 % compared to the values at room temperature. The reason for this phenomenon is the \(\alpha - \beta\) quartz phase transition, which is known to occur at approximately 573 °C under atmospheric conditions (Nasseri et al. 2009). This phase transition leads to increased and enlarged microcracks in the sample due to increased differential expansion between the quartz grains and other minerals. This is the main cause of the sharp reduction in tensile strength from 450 to 850 °C.

In general, it can be concluded that the temperature have different influence on the mechanical properties of granite in three different temperature ranges. (I) 25–100 °C: on the one hand, the internal moisture in the granite sample evaporates firstly and the porosity increases, which explains the increase of the peak strain and the decrease of elastic modulus in the static Brazilian tests. On the other hand, the sample is compacted and the existing fracture is squeezed to close due to the dilation of rock granules, which reduces the porosity and densifies the sample. Therefore, the dynamic tensile strength rises a little at this stage. (II) 100–450 °C: the melting of some mineral composition due to the thermal treatment plays a primary role at this stage. The deformation induced by high temperature changes the contact and bond status between rock granules and the friction is reinforced to some extent. Therefore, the bearing capacity, deformation resistance and toughness go down slowly, which explains the relative stable peak strain and dynamic tensile strength. (III) 450–850 °C: structural thermal stress can be caused due to the inharmonious thermal expansion of the mineral composition at this stage. So the dynamic mechanical properties are influenced by the combined action of melting and structural thermal stress, during which process some complex changes occur such as mineral component decomposition, constitution water evaporation and phase transition, etc. The internal microcracks extend and connect under high temperature, which reduces the bearing capacity and deformation resistance of the sample. Therefore, the peak stress and toughness of granite decrease significantly and the mechanical properties degraded seriously compared with that at room temperature.

5.4 Use of a High-Speed Camera to Record the Tensile Failure

A high-speed video with 1,25,000 frames per second (fps) was used to capture the fracture processes of the dynamic Brazilian test. Two representative examples both at room temperature and after thermal treatment at 600 °C are presented in Fig. 12 illustrating the initiation and propagation of the cracks (the incident bar is shown on the left and the transmitted bar on the right).

It can be observed from Fig. 12a that the tensile failure occurs along the line of loading direction, which is consistent with previous studies at room temperature (Bohloli 1997; Wong et al. 2013; Zhang and Zhao 2013a). The cracks initiate from the centre and the specimen was separated into two pieces along the impact direction. This is because crack initiation is more likely to be induced at tips of internal defect such as rock granule boundary, soft medium, microvoids and cracks, etc. The initial cracks extend along the loading direction to both sides in a short time, far before other microcracks initiate. During the process, the cracks along radial direction connect, merge and finally form a macrocrack, which causes the specimen to split into two roughly identical halves. Both the tensile and shear failure modes can be observed in rock specimens and high-speed photography captured the transition between shear and tensile failure modes. After the coalescence of the splitting crack, the zone around the loading points is crushed into small fragments, which form an apparent shear-zone.

The first picture of Fig. 12b shows the disc specimen before failure. A primary crack occurs near the centre of the sample along the loading direction within the range of 0–80 μs. Afterward, both ends of the sample produce “X”-shaped cracks along the primary loading orientation when the primary crack continues to penetrate, as schematically illustrated in Fig. 13. The last two pictures present the sample failure, where the specimen is split into several fragments along the central line of the specimen. This is because when the temperature is up to 600 °C, the rock experiences a series of complex changes including the decomposition of mineral constituents, the evaporation of constitution water and the quartz phase transition. Compared with that at room temperature, the deformation resistance and toughness of the granite both decrease to some extent, which leads to serious degradation of the mechanical property. Before the loading stress by the bar ends reaches the peak value, it exceeds the granite strength and the specimen begins to yield before the primary crack is connected. It explains the fast expansion of cracks in the vicinity of the two interfaces and the generation of new cracks in the process. Therefore, a crushed zone is formed enclosing a quasi-triangle area near the bar ends, which develops into “X”-shaped cracks in a macroscopic scale. Comparison between failure modes with and without thermal treatment indicates that the area of the crushed wedges increases under high temperature, and the damaged edge wedges are crushed to larger fragments.

It is notable that the BD method has several limitations: (1) the validity under biaxial stress state, (2) the peak stress recorded by the strain gauge is debatable to represent the tensile strength without correction and (3) stress concentration leads to failure near the loading points (Zhang and Zhao 2013b). Notwithstanding its limitation, this study does reveal the influence of high temperature on the dynamic tensile strength of brittle rock with the aid of high-speed camera observation and comparison with previous studies.

6 Conclusions

In this paper, we utilized the BD test method to measure the static and dynamic tensile strength of thermally treated Laurentian granite up to 850 °C using an MTS hydraulic servo-control testing machine and a split Hopkinson pressure bar system. The samples were separated into six groups obtained at 25, 100, 250, 450, 600, or 850 °C. The static tensile strength exhibited a reduction with increasing temperature, the dynamic tests also showed that dynamic tensile strength increased at a certain temperature and then decreased, and a rate dependence was detected.

The basic physical properties of thermally treated Laurentian granite were measured, such as the density, relative volume change per degree, and P-wave velocity. In dynamic tests, the dynamic force balance is achieved with a pulse shaping. Several samples of each group were monitored using high-speed photography to observe the initiation and propagation process of sample failure. The test results in this work will be a useful tool to understand the thermo-mechanical characteristics of rock.

References

Bieniawski ZT, Hawkes I (1978) International-Society-for-Rock-Mechanics-Commission-on-Standardization-of-Laboratory-and-Field-tests-suggested methods for determining tensile-strength of rock materials. Int J Rock Mech Min 15(3):99–103

Bohloli B (1997) Effects of the geological parameters on rock blasting using the Hopkinson split bar. Int J Rock Mech Min 34(3):32.e1–32.e9

Cai M, Kaiser PK, Suorineni F, Su K (2007) A study on the dynamic behavior of the Meuse/Haute-Marne argillite. Phys Chem Earth 32(8–14):907–916

Chaki S, Takarli M, Agbodjan WP (2008) Influence of thermal damage on physical properties of a granite rock: porosity, permeability and ultrasonic wave evolutions. Constr Build Mater 22(7):1456–1461

Chen W, Song B, Frew DJ, Forrestal MJ (2003) Dynamic small strain measurements of a metal specimen with a split Hopkinson pressure bar. Exp Mech 43(1):20–23

Coviello A, Lagioia R, Nova R (2005) On the measurement of the tensile strength of soft rocks. Rock Mech Rock Eng 38(4):251–273

Dai F, Xia K (2010) Loading rate dependence of tensile strength anisotropy of barre granite. Pure appl Geophys 167(11):1419–1432

Dai F, Chen R, Xia K (2009) A semi-circular bend technique for determining dynamic fracture toughness. Exp Mech 50(6):783–791

Dai F, Xia K, Tang L (2010) Rate dependence of the flexural tensile strength of Laurentian granite. Int J Rock Mech Min 47(3):469–475

Dutta PK, Kim K (1993) High-strain-rate tensile behavior of sedimentary and igneous rocks at low temperatures. No. CRREL-93-16. Cold regions research and engineering lab Hanover NH

Dwivedi RD, Goel RK, Prasad VVR, Sinha A (2008) Thermo-mechanical properties of Indian and other granites. Int J Rock Mech Min 45(3):303–315

Heuze FE (1983) High-temperature mechanical, physical and thermal-properties of granitic-rocks—a review. Int J Rock Mech Min 20(1):3–10

Homandetienne F, Houpert R (1989) Thermally induced microcracking in granites—characterization and analysis. Int J Rock Mech Min Sci Geomech Abstr 26(2):125–134

Huang S, Xia K, Yan F, Feng X (2010) An Experimental Study of the Rate Dependence of Tensile Strength Softening of Longyou Sandstone. Rock Mech Rock Eng 43(6):677–683

Hudson JA (1969) Tensile strength and ring test. Int J Rock Mech Min 6(1):91–97

Hudson JA, Rummel F, Brown ET (1972) Controlled failure of rock disks and rings loaded in diametral compression. Int J Rock Mech Min 9(2):241–248

Lee DH, Juang CH, Lei IM (1996) High-temperature Brazilian test for tensile strength of metamorphic limestone. Geotech Test J 19(2):223–226

Li X, Yin T, Zhou Z, Hong L (2010) Study on mechanical properties of sandstone under coupling effects of temperature and pressure. Chin J Rock Mech Eng 29(12):2377–2384

Lindholm U, Yeakley L, Nagy A (1974) The dynamic strength and fracture properties of dresser basalt. Int J Rock Mech Min Geomech Abstr 11(5):181–191

Mahabadi OK, Cottrell BE, Grasselli G (2010) An example of realistic modelling of rock dynamics problems: FEM/DEM simulation of dynamic brazilian test on barre granite. Rock Mech Rock Eng 43(6):707–716

Masri M, Sibai M, Shao JF, Mainguy M (2014) Experimental investigation of the effect of temperature on the mechanical behavior of Tournemire shale. Int J Rock Mech Min 70:185–191

Mellor M, Hawkes I (1971) Measurement of tensile strength by diametral compression of discs and annuli. Eng Geol 5(3):173–225

Nasseri MHB, Schubnel A, Young RP (2007) Coupled evolutions of fracture toughness and elastic wave velocities at high crack density in thermally treated Westerly granite. Int J Rock Mech Min Sci 44(4):601–616

Nasseri MHB, Tatone BSA, Grasselli G, Young RP (2009) Fracture toughness and fracture roughness interrelationship in thermally treated westerly granite. Pure appl Geophys 166(5–7):801–822

Nojima T, Ogawa K (1989) Impact strength of ceramics at high temperatures. In: Harding J (ed) The 4th International Conference on the Mechanical Properties of Materials at High Rates of Strain, Oxford: 371–378

Paterson MS, T-f Wong, Géologue A (2005) Experimental rock deformation: the brittle field. Springer, New York

Rao Q, Wang Z, Xie H, Xie Q (2007) Experimental study of mechanical properties of sandstone at high temperature. J Cent South Univ Technol 14:478–483

Vishal V, Pradhan SP, Singh TN (2011) Tensile strength of rock under elevated temperatures. Geotech Geol Eng 29:1127–1133

Wang QZ, Li W, Xie HP (2009) Dynamic split tensile test of Flattened Brazilian Disc of rock with SHPB setup. Mech Mater 41(3):252–260

Wong LNY, Zou C, Cheng Y (2013) Fracturing and failure behavior of carrara marble in quasistatic and dynamic brazilian disc tests. Rock Mech Rock Eng 47(4):1117–1133

Yavuz AB, Topalb T (2007) Thermal and salt crystallization effects on marble deterioration: examples from Western Anatolia, Turkey. Eng Geol 90(1–2):30–40

Yin T, Li X, Xia K, Huang S (2012) Effect of thermal treatment on the dynamic fracture toughness of laurentian granite. Rock Mech Rock Eng 45(6):1087–1094

Zhang Q, Zhao J (2013a) Determination of mechanical properties and full-field strain measurements of rock material under dynamic loads. Int J Rock Mech Min 60:423–439

Zhang Q, Zhao J (2013b) A review of dynamic experimental techniques and mechanical behaviour of rock materials. Rock Mech Rock Eng 47(4):1411–1478

Zhang ZX, Yu J, Kou SQ, Lindqvist PA (2001) Effects of high temperatures on dynamic rock fracture. Int J Rock Mech Min 38(2):211–225

Zhao J, Li HB (2000) Experimental determination of dynamic tensile properties of a granite. Int J Rock Mech Min 37(5):861–866

Zhou YX, Xia K, Li XB, Li HB, Ma GW, Zhao J, Zhou ZL, Dai F (2012) Suggested methods for determining the dynamic strength parameters and mode-I fracture toughness of rock materials. Int J Rock Mech Min 49:105–112

Acknowledgments

The authors acknowledge financial support by the National Natural Science Foundation of China (Grant No. 51304241) and the China Scholarship Council (CSC). The thermal treatment was conducted at Prof. Young’s Laboratory at the University of Toronto.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yin, T., Li, X., Cao, W. et al. Effects of Thermal Treatment on Tensile Strength of Laurentian Granite Using Brazilian Test. Rock Mech Rock Eng 48, 2213–2223 (2015). https://doi.org/10.1007/s00603-015-0712-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-015-0712-3