Abstract

The uniaxial compressive strength (UCS) of intact rock, which can be estimated using relatively straightforward and cost-effective techniques, is one of the most practical rock properties used in rock engineering. Thus, constitutive laws to represent the strength and behavior of (intact) rock frequently use it, along with additional intrinsic rock properties. Although triaxial tests can be employed to obtain best-fit failure criterion parameters that provide best strength predictions, they are more expensive and require time-consuming procedures; as a consequence, they are often not readily available at early stages of a project. Based on the analysis of an extensive triaxial test database for intact rocks, we propose a simplified empirical failure criterion in which rock strength at failure is expressed in terms of confining stress and UCS, with a new parameter which can be directly estimated from the UCS for a specified rock type in the absence of triaxial test data. Performance of the proposed failure criterion is then tested for validation against experimental data for eight rock types. The results show that strengths of intact rock estimated by the proposed failure criterion are in good agreement with experimental test data, with small discrepancies between estimated and measurements strengths. Therefore, the proposed criterion can be useful for preliminary (triaxial) strength estimation of intact rocks when triaxial tests data are not available.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

A rock failure criterion represents the strength of rock under different loading conditions. Several failure criteria have been proposed during the past decades by many researchers (see Hoek and Brown 1997, 1980; Sheorey 1997; Singh and Singh 2005; Singh et al. 2011), and a new working group of the International Society of Rock Mechanics (ISRM) on “Suggested Methods for Failure Criteria” was established to “to standardize the different failure criteria used in practice and make the ISRM members aware of new developments” (Haimson and Bobet 2012). Table 1 lists the failure criteria covered by the working group and the associated references.

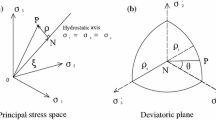

Some of these failure criteria utilize the principal stresses (i.e., the intermediate principal stress, σ 2, and the minor principal stress, σ 3) to find the major principle stress, σ 1 at failure. Several failure criteria neglect the influence of σ 2 and they are referred to as “two-dimensional” (2D) criteria; however, in many cases, “three-dimensional” (3D) criteria that incorporate the influence of σ 2 could better represent the behaviour of rock in the field. However, 3D failure criteria are not yet so commonly employed in practice; a practical limitation is that “the use of a true triaxial testing apparatus” is required, even though “at this time only a few such devices are available” (Chang and Haimson 2012).

Triaxial tests can be employed to estimate the criterion parameters that optimize strength predictions over a wide range of stress values. However, in addition to specific equipment requirements, they require time-consuming setup and testing procedures. The uniaxial compressive strength of intact rocks (UCS or σ ci)—which is the most common parameter for rock failure criteria, as well as a useful parameter for rock mass behavior and rock mass classifications (Zare-Naghadehi et al. 2011; Bieniawski 1989; Mark and Molinda 2005)—can be more easily measured in the laboratory using simpler equipment (Ulusay and Hudson 2007); it can also be estimated using the point load test with unprepared rock cores (ISRM 1985) or other non-destructive methods such as the sound velocity test (Karakus et al. 2005).

In many practical rock engineering applications—specially at early stages of a project or in projects with time and/or budget constraints—we need to estimate (intact) rock strength without using advanced tests. Therefore, a failure criterion that provides good strength predictions with basic information, such as UCS and rock type, is useful. We propose one such criterion, and we compare it with the predictive capabilities of other common rock failure criteria.

2 A New Criterion for Intact Rock Strength

After the analysis of an extensive database of triaxial test data for intact rock and by a trial and error process that explores analogies with the non-linear criterion proposed by (Bieniawski 1974), we propose a new failure criterion for intact rock. With our new criterion, the maximum (effective) principal stress at failure, σ 1, can be computed as a function of the confining (effective) stress, σ 3, as:

where σ ci is the uniaxial compressive strength of intact rock and B is a dimensionless parameter. If N triaxial tests are available, the best-fitting estimate of B can be computed as:

3 Database and Background for Comparison of Results

3.1 Database of Triaxial Testing Results

To check the validity of the new criterion and to estimate B when triaxial data is not available, we collected an extensive database of intact rock strengths, which includes 1579 triaxial tests corresponding to 28 rock formations from projects worldwide. Our database extends the one originally compiled by Singh et al. (2011) (available as supplementary material with their publication); including 389 additional sets of triaxial data from RocData 4.0 (RocData 2012).

3.2 Other Failure Criteria Used for Comparison

Sheorey (1997) reviewed failure criteria for intact rock available in the literature up to 1997. Here, we briefly present some of the criteria that have gained a wide acceptance in rock engineering; further below, we will compare them with our proposed criterion.

3.2.1 The Hoek–Brown Criterion for Intact Rock

The Hoek–Brown (HB) failure criterion for intact rock (see e.g., Hoek and Brown 1980) is a non-linear criterion developed by empirical curve-fitting to a large database of triaxial tests on different rocks. The fit is conducted in terms of σ 1/σ ci and σ 3/σ ci, for which a parabolic function fits naturally as:

where m i is the criterion parameter.

Hoek and Brown (1997) provided regression solutions to estimate m i and σ ci when triaxial data is available, and they recommended that only data within a 0 ≤ σ 3 ≤ 0.5 σ ci range should be used for such task. When triaxial data is not available, Hoek and Brown (1997) also recommended a table of m i values to produce “estimates can be used for preliminary design purposes” and Hoek (2007) later updated such recommendations.

3.2.2 The Parabolic MC Criterion

Another common failure criterion for intact rock is the Mohr–Coulomb (MC) criterion. The original form of the MC criterion is linear—therefore, neglecting the rock strength is a non-linear function of confining stress. Using the critical state concept of Barton (1976), Singh and Singh (2005) extended the original MC criterion to the following non-linear parabolic criterion:

where A is the criterion parameter.

Singh and Singh (2005) provided expressions to compute A for a given set of triaxial data, and suggested that “If sufficient number of triaxial test data are available, the fitting of the experimental data into the strength criterion may be improved further by treating both A and σ ci as unknowns, and determining them through the least square method.” They also indicated that, when no triaxial data is available, A can be estimated from σ ci using the following expression:

where σ ci is expressed in MPa and falls within a (7–500) MPa interval.

3.2.3 The Modified Mohr–Coulomb Criterion

Singh et al. (2011) built on the parabolic MC criterion of Singh and Singh (2005) to propose a “Modified Mohr–Coulomb” (MMC) criterion. Their MMC criterion can be expressed as:

where the internal friction angle for low confinement pressures, ϕ 0, is the criterion parameter for intact rocks.

When N triaxial tests conducted at 0 ≤ σ 3 ≤ σ ci are available, ϕ 0 can be computed as (Singh et al. 2011):

3.3 Criteria for Comparison of Performance

We use three different error measurements to assess the validity of predictions computed with different criteria: the regression R-square value (R 2); the discrepancy percentage or relative difference (D p); and the average absolute relative error percentage (AAREP) (AAREP is preferably used below because it is a simple estimator that provides a direct indication of the absolute size of the error in the prediction). Their definitions are:

where N is the number of available observations, σ obs1 indicates observed test results, σ pred1 indicates values predicted by the criteria, and \(E[\cdot]\) denotes the expectation (or statistical mean) operator.

Based on the definitions above, it is clear that, the smaller the AAREP, the more reliable the model. On the other hand, R 2 increases with the quality of the predictions, so that higher R 2 values correspond to models with lower AAREP values. D p,i, that is needed to compute AAREP, is the relative difference between predicted and observed values for the i-th test.

4 Results and Discussion

4.1 Sensitivity of Parameters to Stress Range of Fitting Dataset

A robust estimation of criterion parameters [i.e., B in Eq. (1); m i in Eq. (3); A in Eq. (4); and ϕ 0 in Eq. (7)] is critical for users employing a failure criterion in practice. Rock engineers commonly use regression methods to derive criterion parameters, so that their estimated values—and their associated uncertainties—will depend on the number and quality of available data. Similarly, when available data correspond to low-stress regimes only, the reliability of the predictions may be reduced if the “shape” of the criterion mathematical expression does not “capture” the real curvature of the failure criterion for that specific rock. In that sense, Singh et al. (2011) emphasized the importance of having criteria which are insensitive to the range of confining stress used for fitting; otherwise, they state that “to get true behaviour of rock at high confining pressure, it will be necessary to conduct triaxial tests at higher confining pressure”—and these tests are more difficult and expensive.

As an example, Table 2 compares the criterion parameters fitted, for increasing confining stresses, with a well-known dataset of triaxial tests conducted on marble (Schwartz 1964). To illustrate the variability of estimated parameters with confining stress, we employ T = p max/p min that represents the ratio between the maximum and the minimum (in absolute value) of the estimated parameters, p max and p min. Of course, T values close to one indicate that the estimation of criterion parameters is ‘robust’ (i.e., it is insensitive to the range of stresses employed for fitting); whereas higher T values indicate that criteria are more sensitive to the range of confining stresses employed for fitting.

The illustrative example of Table 2, of course, needs to be extended to other rock types and other sets of testing results. Figures 1 and 2 show histograms of T values for a complete analysis of the database. Since some authors recommend fitting the criteria for low-stress regimes (with σ 3 values lower than 0.5σ ci or σ ci), we conduct two comparisons: first, considering only data points with σ 3 ≤ σ ci (Fig. 1); and second, considering all data points in the database (i.e., also including those for σ 3 > σ ci; Fig. 2).

Results suggest that the HB criterion parameter, m i, is the most sensitive to the range of stresses employed for fitting; whereas the ϕ 0 parameter of the MMC criterion is the least sensitive to such stress range. The B parameter of our proposed criterion, as well as the A parameter of the SS criterion, have an intermediate (and very similar) variability as a function of the fitting stress range.

4.2 Predictive Capabilities with Triaxial Data Available

Next, we compare the predictive capabilities of the different strength criteria when triaxial data, from which their parameters can be fitted, are available. To identify the stress conditions of different tests, we use ‘open’ plotting symbols for tests in the ‘low’ stress range (i.e., with σ 3 ≤ σ ci), and ‘filled’ symbols for tests in the ‘high’ stress range (i.e., with σ 3 > σ ci). The stress ranges employed for fitting in each case, as well as the associated prediction errors (as expressed by their AAREPs), are discussed below.

Using Eq. (2) to compute the B parameter for each set of triaxial tests, we can compare the predictions of our criterion [σ 1,proposed, computed with Eq. (1)] with the testing results (σ 1,obs, see Fig. 3). The best results, with AAREP values of 5.49 % for ‘low’ stresses and 4.49 % for ‘high’ stresses, are obtained when the B parameter is fitted considering the full range of σ 3 values (i.e., 0 ≤ σ 3; see Fig. 3), although very good results are also obtained when more limited stress ranges are employed for fitting. In particular, AAREP values become 5.28 and 8.79 %, respectively, for data in ‘low’ and ‘high’ stress regimes when B is fitted using 0 ≤ σ 3 ≤ σ ci data only; and 5.53 and 10.74 % when B is fitted using σ 3 ≤ 0.5 σ ci.

Similarly, we compare observed and predicted strengths for the other criteria considered. Figure 4 presents the results for the HB criterion when m i is fitted using Hoek and Brown’s recommended expressions and stress ranges (i.e., for 0 ≤ σ 3 ≤ 0.5 σ ci), providing AAREP values of 7.91 and 9.58 %, respectively, for ‘low’ and ‘high’ stress values (when the stress range is extended to 0 ≤ σ 3 ≤ σ ci, the AAREP becomes 9.60 % for ‘low’ stress data and 9.44 % for ‘high’ stress data; for 0 ≤ σ 3, the AAREP becomes 11.36 % for ‘low’ stress data and 27.31 % for ‘high’ stress data).

Finally, Fig. 5 compares observed strengths and those predicted with the SS/MMC criteria (they are presented together because they provide very similar results). Following the authors’ original recommendations, the criteria were fitted using Eq. (10) with data for ‘low’ stress regimes (i.e., 0 ≤ σ 3 ≤ σ ci), providing AAREP values of 5.08 % for ‘low’ stresses and 20.23 % for ‘high’ stresses (fitting for 0 ≤ σ 3 ≤ 0.5σ ci, AAREP values become 5.57 % for ‘low’ stress data and 20.40 % for ‘high’ stress data; fitting for σ 3 ≥ 0, they become, respectively, 12.49 and 98.95 %.)

It can be observed that our proposed criterion has very good predictive capabilities and, in particular, that it provides adequate predictions of rock strength even in the ‘high’ stress range of σ 3 ≥ σ ci. Those predictive capabilities are particularly good when B is fitted using data for all stress ranges, and they also outperform other methods when B is fitted using data for ‘low’ stress regimes only.

4.3 Predictive Capabilities Without Available Triaxial Data

To estimate rock strength with the proposed criterion when triaxial data is not available, we need to be able to infer the B parameter from other available information. To that end, we will assume that the uniaxial compressive strength of the intact rock is known, since σ ci can be easily measured in the laboratory or estimated in the field—using, for instance, correlations with point load test results. We first consider predictions based on σ ci only (for a ‘general’ rock type), and then, we showed that they improve significantly using rock type specific predictions.

4.3.1 Predictions Using σ ci Only

First and despite the conceptual drawbacks discussed below, we proceed without incorporating ‘rock type’ into the analysis. The reason is that this allows us to compare our results with predictions obtained with the criterion by Singh and Singh (2005) and their proposed general expression to estimate A (Eq. 6).

Our analyses of the database suggest that B can be estimated, with a relatively small error, when σ ci of the intact rock is known (B values are computed using Eq. (2) and the existing triaxial tests from the database). Figure 6 shows that there is a clear relationship between B/σ ci and σ ci; fitting a regression curve, we obtain that, given σ ci (MPa) and for a ‘general rock’, we can estimate B as:

where the best-fit for a ‘general’—or unspecified—rock type is obtained for a = 2.0 and b = −0.97.

B values estimated from σ ci using Eq. (14) can be employed, using the criterion proposed in Eq. (1), to estimate the strength of a ‘general’ intact rock at different confining stresses. Figure 7 compares strength values estimated using such procedure with experimental results, and we can compare our results with results provided by the SS criterion with their general predictive relationship given by Eq. (6) (see Fig. 8).

Comparison of measured and predicted strength values [proposed criterion; B estimated from σ ci using Eq. (14) for a ‘general’ rock]

Comparison of measured and predicted strength values [SS criterion; A estimated from σ ci using Eq. (6) for a ‘general’ rock]

As expected, the predictive capabilities of both criteria decrease when triaxial data is not available, with AAREP values that are significantly greater than those presented in Sect. 4.2. The predictive capabilities of both methods are similar: although the SS criterion provides slightly better estimates for ‘low’ stresses (AAREPs of 13.40 % for SS vs. 14.04 % for the proposed method), our method performs slightly better than SS for ‘high’ stresses (AAREPs of 31.12 vs. 27.16 %) (we do not compare with the HB criterion because recommended m i values are only available for specific rock types; see below for additional discussion).

The conceptual drawback with this ‘general’ relationship between UCS and B is that although supported by statistics, it is not strictly correct. The reason is that, based on Coulomb’s failure theory, 2D rock strength criteria should define two independent parameters: (1) a reference point (e.g., UCS) and (2) a dependency on confining pressure, which is expressed by internal friction (B in our criterion, as well as m i, A, and ϕ 0 in the other criteria considered herein, are related to internal friction). The two parameters (e.g., UCS and internal friction) are independent and that is why most criteria require at least two material constants. With Eq. (14), we correlate these two parameters, which is a much more reasonable assumption for a specific rock type than for a ‘general’ rock. That explains why ‘rock specific’ relationships, that incorporate information about σ ci and rock type, perform better and why, if possible, they should be preferred in practice.

4.3.2 Predictions Using σ ci and Rock Type

Next, we try to improve the predictions of the proposed criterion, when triaxial data is not available, using information of the rock type for which σ ci is known. To that end, we consider eight rock types from the database for which there are, at least, four groups of data and 27 tests available—i.e., at least four projects with a total of 27 tests. Then, for each rock type and following the same procedure discussed above, we develop specific B − σ ci correlations, obtaining the a and b parameters that provide best-fit regression results using Eq. (14).

Figure 9 shows the best-fit regression curve [based on Eq. (14)] for each specific rock type and compares experimental values with those predicted using σ ci and the computed best-fit a and b parameters for each rock type. Table 3 lists the best-fit estimates of a and b that can be employed [together with Eq. (14)] to estimate B using σ ci for a given rock type. It also includes information, for each rock type, about (1) their performance, as indicated by the R 2 coefficient and by AAREP [%]; (2) the number of groups and of triaxial tests available; and (3) ranges of σ ci, σ 3, and σ 1 of tests (note that relationships with reduced number of data should be employed with care).

4.4 Discussion of Results

First, we should mention that comparisons between predicted and measured strengths presented above (see Figs. 3, 4, 5, 7, 8) are presented in a log–log scale. Although this allows us to present data covering several orders of magnitude, readers should be aware that these plots may give an impression of a better fit than it is. This can be observed when two plots with the same level of AAREP—such as Fig. 4 (in log–log scale) and Fig. 9c (in standard scale)—are compared.

In addition, although our criterion provides good agreement with triaxial data conducted at high confinement stresses, it should be emphasized that σ 2 plays a relevant role on rock failure, so that a 3D failure criterion could preferred in such cases. However, given that true-triaxial testing devices are not easily available (Chang and Haimson 2012), the use of true-triaxial tests to fit such criteria at early stages of a project is even more unusual than with conventional triaxial tests. Similarly, currently available true triaxial data are limited, so that it would be unfeasible to derive reliable predictive equations. For those reasons and since neglecting σ 2 simplifies the criterion and is usually conservative, we decided to focus our efforts on developing predictive relationships for a conventional (triaxial) failure criterion.

The results presented above are fitted using mathematical formulas proposed by the original authors of each criterion. Those formulas, however, are not guaranteed to provide minimum AAREP values. Therefore, we may use optimization procedures readily available in common spreadsheet or mathematical software to analyze the ‘best’ predictive capabilities that each criterion can achieve. In other words, we find the criterion parameter that minimizes AAREP for a specific triaxial dataset.

Table 4 presents an example of such an analysis. In particular, it compares the quality of the fit—or, in other words, the predictive capabilities of each criterion—for the marble test results employed above. To compare results, we select the parameters that minimize the AAREP of the N = 5 tests for which σ 3 < σ ci, although we also provide the AAREP for the total number of tests (N = 11).

Figure 10a compares the original test results with the estimations provided by all failure criteria using their optimally fitted parameters that minimize AAREP.

Comparison of testing data and values estimated with different failure criteria for the marble dataset (Schwartz 1964)

Figure 10b shows the predictions that different criteria would provide had only σ ci and rock type been known at the time of prediction. For our criterion, we use two B values computed for σ ci = 28.9 MPa: B = 2.21, corresponding to ‘general rock’ a and b parameters (see Table 3) in Eq. (14) and B = 2.92, obtained using specific a and b parameters for marble (Table 3). Respectively, this gives values of AAREP (N = 11) at 14.03 and 1.73 %. Similarly, we use the SS criterion with A = −0.098, as obtained by introducing σ ci into Eq. (6); as well as the HB criterion with the recommended value for marble of m i = 9 (Hoek and Brown 1997). This gives values of AAREP (N = 11) at 10.05 % (for SS) and 14.75 % (for HB). These results illustrate that our proposed criterion can provide good estimates of (intact) rock strength, for a wide range of confining stresses, using only its uniaxial compressive strength. It also emphasizes that such estimates can improve with type-specific relationships.

Results presented in Fig. 10 and Table 4, however, provide only one example for a specific type of rock (marble). To compare the predictive capabilities of the different criteria, we need to go beyond and compare the criteria with additional datasets and additional types of rocks. Figure 11 presents the results of such an analysis, in which we use the (empirical) cumulative distribution functions (CDF’s) of AAREP values to assess the quality of the fits provided by different criteria; i.e., for each criterion and each AAREP value, the CDF indicates the ‘probability’ that the prediction error is less than such threshold (probabilities are obtained by dividing the number of cases where the AAREP is smaller than the threshold by the total number of cases considered). With this definition, curves with a ‘higher’ position in the plot indicate criteria that provide a better fit to the available data.

Figure 11a shows the results obtained using all available data (i.e., for the full range of σ 3 values), where criteria are ‘optimally’ fitted for their parameters to minimize AAREP (note that an optimization problem is solved to minimize AAREP in each case). Results indicate that, on average, the HB criterion has the greatest flexibility, as it can be fitted to provide the minimum AAREP, hence providing a CDF line that is above the others. Our criterion and critical-state based criteria (SS and MMC) provide similar flexibility in their estimations, although their CDF values are slightly smaller than for the HB criterion (the maximum difference with our criterion is approximately 10 %).

Finally, Fig. 11b shows strength predictions based on σ ci and rock type only (for the HB criterion, we use m i values recommended in Table 3 of Hoek (2007), and we use an intermediate m i value for coal as suggested in Table 2 of Hoek and Brown (1997). In this case, we include two CDF lines representative of our method: one for ‘general’ a and b parameters and one for ‘specific’ parameters for each rock type. Results indicate that, when no rock type specific information is included, our criterion provides very similar predictions to those of the SS/MMC criteria (note that, although predictions with the HB criterion are better, it uses information about rock types to select m i values for the prediction). However, when rock specific information is included, our criterion provides the best predictive capabilities with an AAREP CDF curve clearly above the others.

Therefore, the newly proposed criterion can be employed, together with the proposed rock type specific relationships, to develop good estimates of intact rock strength when only σ ci and rock type are known.

5 Conclusions

Rock failure criteria express the strength of (intact) rock as a function of confining stress and of additional parameters. Although conventional triaxial or true triaxial tests can be employed to obtain best-fit failure criterion parameters—a set of conventional triaxial tests should indeed be considered as a minimum requirement to define a rock strength criterion for relevant rock engineering projects—they are more time-consuming and expensive, and therefore not always readily available at early stages of a project. For that reason, there is an interest to develop failure criteria that provide good (intact, triaxial) rock strength estimates, even in the absence of triaxial data, based on information about the UCS of intact rock and of rock type.

We propose one such criterion and compare its predictive capabilities—as measured by the AAREP, of predictions conducted with an extensive database of triaxial tests compiled from the literature—with those of other failure criteria commonly employed in rock engineering: the Hoek–Brown (HB), the Singh–Singh (SS) and Modified Mohr–Coulomb (MMC) criteria.

When triaxial data over a wide stress range are available, results show that our proposed criterion has good predictive capabilities, providing adequate predictions of rock strength even in the ‘high’ stress range of σ 3 ≥ σ ci. Those predictive capabilities are particularly good when the criterion is fitted using data for all stress ranges, and they continue to outperform the predictions of other methods (fitted using their traditional formulas) when B is fitted using data for ‘low’ stress regimes only. If parameters are fitted to minimize AAREP values over a wide stress range, the HB is the most flexible criterion, although it is more heavily influenced by the fitting stress range than our criterion and, with a greater difference, than the MMC criterion, hence suggesting that the availability of high-stress data is more important for the HB criterion than for the proposed criterion and the SS/MMC criteria.

In many practical applications, we need to estimate rock strength without available triaxial data. Then, at the expense of a reduced accuracy, we can estimate rock strength with simpler methods (e.g., based on rock type and UCS): Hoek and Brown (1997) recommend m i values for different rock types, whereas Singh and Singh (2005) recommend a formula to estimate their A parameter (Eq. 6) for a ‘general’ rock; similarly, we present a ‘general’ relationship between B and σ ci as well as ‘rock specific’ relationships (see Table 3).

When triaxial data are not considered and UCS is the only information available, of course, the predictive capabilities of all methods decrease. Our method provides very similar results to the SS criterion when information about rock type is not included and a ‘general’ rock type is considered; however, when rock type is considered in addition to UCS, strength predictions with our method outperform predictions of the other criteria (SS criterion, or the HB criterion with m i values estimated using rock-type information). Since rock type is usually known in practice and measuring—or estimating—σ ci is fast and inexpensive, this leads to an improved method for estimating intact rock strength, at early stages of a project, and with tools that are readily available in rock engineering applications.

Finally, it should be noted that the proposed B vs. σ ci relationships for different rock types are based on the analysis of existing triaxial test data, so that their reliability, and the corresponding level of accuracy of the approach, depends on the quality and quantity of triaxial test data. Therefore, the proposed relations are open for further improvements as more triaxial test data become available.

References

Alejano LR, Bobet A (2012) Drucker–Prager criterion. Rock Mech Rock Eng 45(6):995–999

Barton N (1976) The shear strength of rock and rock joints. Int J Rock Mech Mining Sci Geomech Abstr 13(9):255–279

Bieniawski ZT (1974) Estimating the strength of rock materials. J South Afr Inst Min Metall, pp 312–320

Bieniawski ZT (1989) Engineering rock mass classifications. Wiley, New York

Chang C, Haimson B (2012) A failure criterion for rocks based on true triaxial testing. Rock Mech Rock Eng 45(6):1007–1010

da Fontoura SAB (2012) Lade and modified Lade 3D rock strength criteria. Rock Mech Rock Eng 45(6):1001–1006

Eberhardt E (2012) The Hoek–Brown failure criterion. Rock Mech Rock Eng 45(6):981–988

Haimson B, Bobet A (2012) Introduction to suggested methods for failure criteria. Rock Mech Rock Eng 45(6):973–974

Hoek E (2007) Practical rock engineering. In: Rock mass properties. http://www.rocscience.com/education/hoeks_corner/ (last accessed 31/12/2012)

Hoek E, Brown E (1997) Practical estimates of rock mass strength. Int J Rock Mech Min Sci 34(8):1165–1186

Hoek E, Brown ET (1980) Underground excavations in rock. Institution of Mining and Metallurgy, London

ISRM (1985) Suggested methods for determining point load strength. Int J Rock Mech Min Sci Geomech Abstr 22(2):51–60

Karakus M, Kumral M, Kilic O (2005) Predicting elastic properties of intact rocks from index tests using multiple regression modelling. IntJ Rock Mech Min Sci 42(2):323–330

Labuz JF, Zang A (2012) Mohr–Coulomb failure criterion. Rock MechRock Eng 45(6):975–979

Mark C, Molinda GM (2005) The coal mine roof rating (CMRR)—a decade of experience. Int J Coal Geol 64(1–2):85–103

Priest S (2012) Three-dimensional failure criteria based on the Hoek–Brown criterion. Rock Mech Rock Eng 45(6):989–993

RocData (2012) Rocdata 4.0. http://www.rocscience.com/products/4/RocData

Schwartz AE (1964) Failure of rock in the triaxial shear test. In: Proceedings of the 6th US rock mechanics symposium. pp 109–135

Sheorey PR (1997) Empirical rock failure criteria. Balkema, Rotterdam

Singh M, Raj A, Singh B (2011) Modified Mohr–Coulomb criterion for non-linear triaxial and polyaxial strength of intact rocks. Int J Rock Mech Min Sci 48:546–555

Singh M, Singh B (2005) A strength criterion based on critical state mechanics for intact rocks. Rock Mech Rock Eng 38:243–248

Ulusay R, Hudson JA, ISRM (2007) The complete ISRM suggested methods for rock characterization, testing and monitoring: 1974–2006. In: Ulusay R, Hudson JA (eds) Commission on testing methods. International Society of Rock Mechanics. Compilation arranged by the ISRM Turkish National Group, Ankara, Turkey, p 628

Zare-Naghadehi M, Jimenez R, KhaloKakaie R, Jalali S-ME (2011) A probabilistic systems methodology to analyze the importance of factors affecting the stability of rock slopes. Eng Geol 118(3–4):82–92

Acknowledgments

The PhD scholarship provided by China Scholarship Council (CSC) to the first author is gratefully acknowledged. We are also indebted to two anonymous reviewers for their comments, which greatly helped us to improve the manuscript. In particular, much of the discussions about the reliability of the model, as well as on Coulomb’s failure theory, are based on their feedback.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shen, J., Jimenez, R., Karakus, M. et al. A Simplified Failure Criterion for Intact Rocks Based on Rock Type and Uniaxial Compressive Strength. Rock Mech Rock Eng 47, 357–369 (2014). https://doi.org/10.1007/s00603-013-0408-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-013-0408-5