Abstract

The modeling and performance of mechanical resonators used for mass detection of bio-cells, nanocrystalline materials characterization, and disease diagnosis of human immune-viruses (HIVs) are investigated. To simulate the real behavior of these mechanical resonators, a novel distributed-parameter model based on Euler–Bernoulli beam theory is developed. This model is equipped with a micromechanical model and an atomic lattice model to capture the inhomogeneity nature of the material microstructure. Compared with lumped-parameter model predictions, the results show that this developed model best fits with the real behavior of the mechanical resonators when detecting the mass of vaccinia virus. In terms of material characterization, the developed model gives very good estimations for the densities and Young’s moduli of the grain boundary of both the nanocrystalline silicon and nanocrystalline diamond. For disease diagnosis, it is shown that the number of human immune-deficiency virus particles in a liquid sample can be easily detected when using the proposed model. The results also show that the developed model is beneficial and can be used to design mechanical resonators made of nanocrystalline materials with the ability to control the resonators’ sizes and the material structure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nowadays micro/nanomechanical resonators are widely used for biological, chemical, and physical applications (Binnig et al. 1986; Fritz et al. 2000; Johnson et al. 2006; Tao et al. 2014). Due to their high sensitivity, these systems are widely recognized by their range of applications which vary from nanoscale detection of forces (Binnig et al. 1986) to mass detection of biological cells or molecules (Fritz et al. 2000; Tao et al. 2014). It had been demonstrated that using very thin resonators enhances their sensitivities (Tao et al. 2014). However, these resonators have small stiffnesses \(\left( {\mu {\text{N/m}-\text{mN/m}}} \right)\) (Tao et al. 2014) which give small quality factors and hence affect their measuring accuracy and sensitivity. Therefore, some attempts had been made to propose resonators with high sensitivity and high quality factors. One attempt is to use actuated resonators to increase the quality factor (Johnson et al. 2006), but usually these resonators give sensitivity in the femto- or atto-ranges. Another attempt is to control the dimensions of the resonator along with the material type and their microstructure contents. Thus, a quality factor up to 10,000 is obtained by fabricating 40 nm thick resonators with grain sizes within the range 10–100 nm (Sekaric et al. 2002; Hutchinson et al. 2004). In a recent research study, quality factors exceeding one million are achieved using a single-crystal diamond nanoresonator (Tao et al. 2014). Therefore, for design purposes of resonators, many trials are needed to catch a desired quality factor or sensitivity including the size of the structure, its material type, and the nature of the material microstructure. This motivated us to propose a novel beam model equipped with a micromechanical model and an atomic lattice model in order to design mechanical resonators made of nanocrystalline materials (NcMs) with the ability to control the resonators’ sizes and the material structure.

One of the applications in which mechanical resonators have shown a great impact is detecting the mass of tiny low mass particles or molecules, such as a single bacteria cell (Gupta et al. 2004a), a single virus particle (Gupta et al. 2004b; Johnson et al. 2006), and a single bio-cell (Aboelkassem et al. 2010). The operating principle of mechanical resonators used for mass detections is based upon mathematically estimating the mass value that is proportional to the induced shift in the beam frequency due to the added mass. The accuracy of the measurement is highly affected by how much the used mathematical model fits with the real behavior of the resonator. Lumped-parameter models have been used for mass estimations by some investigators (Gupta et al. 2004a, b; Ghatkesar et al. 2004; Ilic et al. 2004; Johnson et al. 2006). However, when compared with the distributed-parameter models, the lumped-parameter models misfit with the real behavior of mechanical resonators which strongly affects the accuracy of the estimated added mass. To this end, we propose a distributed-parameter model to provide more accurate estimations for mass detections applications.

Mechanical resonators were also used as biosensors for disease diagnosis (Su et al. 2003; Hewa et al. 2009; Lu et al. 2012). By measuring the shift in the resonant frequency of the antibody-coated resonator, a quantitative and a qualitative detection of the virus or bacteria particles in blood or urine samples could be achieved with the aid of the proposed beam model. A microcantilever-based DNA biosensor is developed by Su et al. (2003) to detect DNA at very low concentrations through a hybridization reaction. This reaction leads to the attachment of gold nanoparticles to the microcantilever and helps for the growth of silver particles when exposed to a photographic developing solution. The growth of silver particles increased the effective mass of the microcantilever and led to an enhanced frequency shift. This method could detect the target DNA at a concentration of nanomolar scale. Hewa et al. (2009) developed an immune-sensor for detection of influenza A and B viruses while Lu et al. (2012) proposed a biomimetic sensor to detect HIV-1 in a blood sample.

A reduction in the effective Young’s modulus of NcMs is observed when the grain size is decreased (Mohr et al. 2014). It had been attributed to the increase in the volume fraction of the grain boundary which has a lower Young’s modulus due to the increase in the interatomic spacing and the increase in the amount of impurities residing in the grain boundary (Mohr et al. 2014; Gleiter et al. 2000; Wang et al. 2003; Kim and Bush 1999; Zhou et al. 2007; Duan et al. 2005; Fitzsimmons et al. 1995; Swygenhoven et al. 1999; Sanders et al. 1997). Thus, the atomic structure as well as the Young’s modulus of the grain boundary significantly affects the behavior of NcMs in different applications. In this research study, we propose a strategy which is based on a distributed-parameter model for the beam’s structure and a micromechanical model for the beam’s material, to estimate the Young’s modulus of NcMs and Young’s modulus of their grain boundaries. The density of the grain boundary of NcMs is also investigated with the aid of the density results for nickel reported by (Fitzsimmons et al. 1995). Then, an atomic lattice model is proposed in order to mathematically estimate the effective Young’s modulus of the material.

The rest of this paper is organized as follows: in Sect. 2, an adequate Euler–Bernoulli beam model equipped with a micromechanical model and an atomic lattice model is derived in order to simulate the real behavior of micro/nanomechanical resonators used for mass detection, material characterization, and disease diagnosis. Then, the equation of motion and the natural frequencies of the mechanical resonators for mass detection and disease diagnosis are presented. Using the developed distributed-parameter model, a mass detection analysis for the vaccinia virus is accurately estimated in Sect. 3.1. The effective Young’s moduli of nanocrystalline silicon and nanocrystalline diamond are determined along with densities and Young’s moduli of their grain boundaries using the proposed model in Sect. 3.2. For disease diagnosis purposes, a mechanical resonator is proposed in Sect. 3.3 and used for detecting the presence of the human immune-deficiency virus (HIV) in a liquid sample. Finally, summary and conclusions are presented in Sect. 4.

2 Representation of micro/nano mechanical resonators

An adequate distributed-parameter model is derived which best simulates the real behavior of micro/nanomechanical resonators. Due to their intensive decrease in size, micro/nanomechanical resonators are usually made of NcMs with nano grains and nano grain boundaries. Thus, the effects of the grain size and the material inhomogeneities have to be considered in the developed model. To this end, a distributed-parameter model based on Euler–Bernoulli beam theory which is equipped with a micromechanical model is proposed to investigate the effects of the grain size and the material inhomogeneities on the resonant behaviors of micro/nanomechanical resonators. The material structure of the resonator made of a NcM is presented as a two-phase composite with the grain is the inclusion and the gain boundary is the matrix, as shown in Fig. 1. The grain’s Young’s modulus is assumed to be the same as the single-crystal while the Young’s modulus of the grain boundary could be estimated using the proposed atomic lattice model.

2.1 Effective Young’s modulus of mechanical resonators made of NcMs

The effective Young’s modulus of micro/nano mechanical resonator, \(E\), depends on many factors, such as the inhomogeneity nature of the material structure. Due to the ease of fabrication, most of micro/nano mechanical resonators are made of nanocrystalline silicon or nanocrystalline diamond (Tao et al. 2014). Due to their distinct atomic structure (Gleiter et al. 2000; Wang et al. 2003; Kim and Bush 1999; Zhou et al. 2007; Duan et al. 2005; Fitzsimmons et al. 1995; Swygenhoven et al. 1999; Sanders et al. 1997), grain boundaries have lower Young’s moduli than the interior of the grains in polycrystalline materials (Sanders et al. 1997; Fougere et al. 1995; Xing et al. 1998; Shen et al. 1995; Wang et al. 1995; Spriggs 1961; Boccaccini et al. 1993). The grain boundary volume fraction could be as high as 50 % for a NcM whose grain average size is 5 nm (Sharma and Ganti 2003). Thus, for micro/nanomechanical resonators made of NcMs, the significant decrease in their effective Young’s modulus is attributed to the increase in the grain boundary volume fraction as the grain size is decreased. To determine the effective Young’s modulus of mechanical resonators made of NcMs with considering the grain size effects, a micromechanical model is developed for a two-phase material such that the matrix is the grain boundary with Young’s modulus \(E_{gb}\) and the grains are the inclusion phase with Young’s modulus \(E_{g}\).

Usually, the grain’s Young’s modulus, \(E_{g}\), is the same as the Young’s modulus of the single-crystal of the material. However, the Young’s modulus of the grain boundary, \(E_{gb}\), could be estimated using an atomic lattice model for the grain boundary atomic structure. Starting from Fürth’s (MGF) model (Furth 1944), an interatomic potential model is introduced for two atoms separated by a distance \(r\) which has the following form:

where \(\phi \left( r \right)\) is the potential energy, \(d_{0}\) is the dissociation energy, \(r_{0}\) is the equilibrium interatomic separation at which the potential is a minimum (\(\phi \left( {r_{0} } \right) = - d_{0}\)). The interatomic force which is required to hold two atoms at a distance \(r\) from each other is \(F\left( r \right) = d\phi \left( r \right)/dr\) and the interatomic force required to change the distance between the two atoms from \(r\) to \(r + \delta r\) is defined by \(\delta F\left( r \right) = \left( {d\phi \left( r \right)/dr} \right)\delta r\). Since the density of the atomic bonds per unit area is approximately equals \(1/r^{2}\) (Wang et al. 2003) and the induced average strain is \(\varepsilon = \delta r/r\), hence the induced stress can be expressed as:

Consequently, the Young’s modulus of the solid is given by:

For a NcM, the atomic spacing inside the grain is approximately \(r_{0}\), and the corresponding elastic modulus, \(E_{g} = E\left( {r_{0} } \right)\), is identical to that of the perfect crystal of material. However, in the grain boundary, the average atomic spacing is \(r_{gb}\) which is larger than \(r_{0}\), and the corresponding elastic modulus \(E_{gb} = E(r_{gb} )\). Usually, the interatomic spacing \(r\) is related to the mass density \(\rho \left( r \right)\) of the material by (Wang et al. 2003):

where \(\rho_{0} = \rho \left( {r_{0} } \right)\) is the mass density of the perfect crystal. Hence, if the mass density of the grain boundary, \(\rho_{gb}\), is obtained, its elastic modulus can be estimated as follows:

where the atomic spacing is related to the densities of the grain boundary \(\rho_{gb}\) and the grain \(\rho_{g}\). \(m\) and \(n\) are two material constants defined by Furth (1944) which are dependent on the material’s type.

To investigate the atomic density of the grain boundary, the plotted curves in Fig. 2 show the distribution of the atomic density of the grain boundary, \(\rho_{gb}\), along its thickness for nickel (Fitzsimmons et al. 1995). An 8th-order polynomial function fits the atomic density distribution of the nickel, such that the minimum atomic density value is approximately \(\rho_{gb}^{min} = 0.6133\rho_{g}\) and the distributed density through the incoherent grain boundary thickness is likely to be within the following range, as presented in Fig. 2:

According to the proposed atomic lattice model presented in Eq. (5), the minimum possible value for the grain boundary density is:

It should be mentioned that, the minimum grain boundary density, \(\rho_{gb}^{min}\), could be a little bit shifted upward or downward from the value estimated according to Eq. (7) due to the impurities in the grain boundary. Therefore, neglecting the effects of the impurities on the grain boundary density is acceptable for most of materials. For example, based on the results of Furth (1944), n and m are, respectively, equal to 7 and 4 for nickel. Thus, according to Eq. (7), the minimum atomic density of the nickel is \(\rho_{gb}^{min} = 0.625\rho_{g}\) which is in good agreement with its minimum detected counterpart by Fitzsimmons et al. (1995), as shown in Fig. 2. Therefore, using Eqs. (6) and (7), the atomic density of the grain boundary of NcMs is distributed according to a polynomial function through the incoherent grain boundary thickness within the following range:

where \(\varPsi\) represents the fraction of the density added to the lower density value of the grain boundary to get the upper limit of the density. Based on the results presented in Fig. 2, for nickel \(\varPsi = 0.2 \to 0.25\). The most interesting is that, for the different types of nanocrystalline materials, Eq. (8) could be effectively used to define the upper and the lower limits of the grain boundary density where it is distributed between these two limits through the thickness according to a polynomial function. Thus, once the density of the grain boundary is obtained, with the aid of Eq. (8), the grain boundary Young’s modulus could be obtained using Eq. (5).

By defining \(\eta = E_{gb} /E_{g}\) and assuming that the grain boundary and the grain interior having the same Poisson’s ratio, \(\nu\), the effective Young’s modulus of the NcM, \(E\), could be estimated using Mori–Tanaka model as follows:

where

The grain volume fraction depends mainly on the grain average size, \(2R\), and it could be estimated as follows:

where \(R\) is the average radius of the grain and \(t\) is the grain boundary thickness. For most of the materials, the grain boundary thickness is approximately \(0.5 nm\) (Kim and Bush 1999).

Equations (5) (8) and (9) form an adequate micromechanical model equipped with an atomic lattice model used for estimating the Young’s modulus of NcMs.

2.2 Equation of motion and natural frequencies

The mechanical resonators under investigation are mainly used for mass detection, disease diagnosis, and material characterization. To do so, we first derive the equation of motion of these resonators. Then, an eigenvalue problem analysis is performed to determine their natural frequencies. The mechanical resonator is composed of a cantilever beam, as shown in Fig. 3, with length \(L\), width \(b\), and thickness \(h\). A tip mass, \(M_{t}\), is attached at the beam free-end to serve as an attractor on which the mass or virus particles are deposited. The classical Euler–Bernoulli beam is adopted for the grain size and the grain boundary effects. Thus, according to the usual treatment of the Euler–Bernoulli beam model, the equation of motion of mechanical beam resonators has the following form:

It should be mentioned that the beam under consideration is made of a NcM with an effective Young’s modulus \(E\) and a mass density \(\rho\). The effective Young’s modulus of the resonator is determined using the proposed micromechanical and atomic lattice models [Eqs. (5), (9), respectively]. The effective density of the beam could be estimated using the simple rule of mixture as follows:

The beam deflection \(w\) can be obtained by solving the equation of motion (18) and applying the following boundary conditions:

where \(M_{c}\) is the mass of the particles deposited over the tip mass at the beam free-end.

By neglecting the static deflection that could be induced in the beam due to the mass of the deposited particles, the mode shapes associated to Eq. (18) have the form:

where \(\beta = \left( {\frac{12\rho }{{Eh^{2} }}} \right)^{\frac{1}{4}} \sqrt \omega\) and \(C_{i}\) are constants to be determined by applying the boundary conditions (20). The natural frequencies of the resonator, \(\omega\), could be obtained by solving the following characteristics equation:

Equations (18) and (20) form the equation of motion and the corresponding boundary conditions for a cantilever beam whose resonant frequency is affected by its mass inertia and the mass inertia of the deposited particles and the tip mass. The operating principle of micro/nanomechanical resonators is based on the frequency shift that is induced in the beam’s resonant frequency due to the deposited particles. This gives the resonator the ability to measure effectively the mass of the deposited particles or to qualitatively and quantitatively confirm the presence or absence of a certain virus in blood or urine samples for disease diagnosis purposes.

3 Results and discussions

3.1 Mechanical resonators used for mass detection of bio-cell particles

The applicability of micro/nano mechanical resonators to detect the mass of tiny low mass particles, such as a single gas bubble, a single bio-cell, a single virus particle, and a single bacteria cell is investigated. The general fabrication sequence of mechanical resonators using chemical etching process (Gupta et al. 2004b; Ilic et al. 2004) is shown in Fig. 4. The process begins by preparing a three layered wafers, as shown in Fig. 4a. Then, photolithography followed by reactive ion etching is performed to etch the NcM layer in order to pattern the cantilevers, as presented in Fig. 4b. A vapor phase etching process is used to etch the underlying oxide layer, as shown in Fig. 4c.

After fabrication, the mechanical resonator is initially excited and its frequency spectrum is obtained by using an optical detection system (Ghatkesar et al. 2004) or a laser Doppler vibrometer (Johnson et al. 2006), as shown in Fig. 5a, in order to determine the unloaded resonant frequency \(F_{0}\). This unloaded frequency is measured for the case of zero added mass particles where the beam is only loaded with its mass inertia. Then, a loaded resonant frequency, \(F_{1}\), is measured for the deposited mass particles, as shown in Fig. 5b, c.

To determine the added mass of the deposited particle, lumped-parameter or distributed-parameter models can be used which depend on the considered assumptions. The accuracy of the measurements of the deposited mass is highly affected by how much the used model fits with the real behavior of the resonator. A lumped-parameter model has been used in several investigations (Gupta et al. 2004a, b; Ghatkesar et al. 2004; Ilic et al. 2004; Johnson et al. 2006) in order to determine the deposited mass of a bio-cell particle. In this method, the cantilever beam stiffness \(k\) was calculated using the unloaded frequency as follows:

where \(m_{eq} = 0.24\rho bhL\) is the equivalent mass of the mechanical resonator. Then, the mass of the deposited particles on the beam surface is estimated as follows (Gupta et al. 2004a):

Using the lumped-parameter model, Gupta et al. (2004a) used a surface micro-machined silicon cantilever resonator to detect the mass of Listeria innocua bacteria and the mass of proteins, such as Bovine Serum Albumin and antibodies for Listeria. Moreover, the mass of vaccinia virus was detected using microcantilever silicon resonators by Gupta et al. (2004b) and Johnson et al. (2006). By using antibody-coated nanocrystalline silicon nanoresonators, Ilic et al. (2004) were able to detect concentrations of baculo viruses in a liquid. Usually, lumped-parameter models were used to describe the behavior of spatially distributed physical systems by simplifying the distributed systems into a set of discrete entities that approximate the behavior of the system. However, for physical systems in micro/nano scales, these approximations might be inconvenient and hence distributed-parameter models are preferred to be used. Therefore, using the lumped-parameter model [Eqs. (23), (24)] can result in erroneous predictions and then can affect the accuracy of the resonator to detect the mass of the deposited particles. Consequently, a distributed-parameter model, as the one proposed in this study, is needed to provide more accurate estimations for the mass of tiny particles for chemical, physical, and medical applications.

When the bio-cell particle is deposited on the tip of the beam, the natural frequency of the mechanical resonator is changed from F 0 to F 1 . Substituting the modified natural frequency F 1 in the characteristic equation of the natural frequency which is given in Eq. (22), it is easy to numerically solve for the deposited mass M c . Table 1 presents a comparison between the proposed distributed-parameter model and the lumped-parameter model in calculating the bio-cell mass, \(M_{c}\), values for vaccinia virus based on the experimental parameters of Gupta et al. (2004b) and Johnson et al. (2006). The proposed strategy based on the distributed-parameter model reflects a high accuracy in detecting the virus mass when compared to its counterpart when using the lumped-parameter model. In fact, the measured unmodified natural frequency of the mechanical resonator F 0 when using the distributed-parameter model is in very good agreement with its experimental counterpart. Therefore, detecting the beam stiffness, \(k\), using the distributed-parameter model is more accurate than using the simple lumped-parameter model. Furthermore, the proposed strategy to determine the deposited bio-cell mass is based on the physical values of the system, such as the nature of the material microstructure. However, when using the lumped-parameter model, the deposited mass, \(M_{c}\), is determined based on the mechanical stiffness of the system and the natural frequencies \(F_{0}\) and \(F_{1}\), as given in Eq. (24). Inspecting Table 1, it is noted that there is discrepancy between the obtained values of the deposited mass when considering the two different methods. This discrepancy can attain 12 % difference between the predicted deposited bio-cell particles. This percentage difference is very significant which can lead to an underestimation or overestimation of the physical properties of single cells. For example in biomedical applications and disease diagnosis, accurate and early detection of a certain virus or a certain disease will reduce the probability of sudden death in some vital cases. It is concluded that the proposed strategy based on the developed distributed-parameter model is a very sensitive and accurate tool to predict the deposited bio-cell particles which can be used in many applications and in different places.

3.2 Mechanical resonators used for nanocrystalline materials characterization

A reduction in the effective Young’s modulus of the NcM is observed when decreasing the resonator size and hence the grain average size (Mohr et al. 2014). It had been attributed to the increase in the volume fraction of the grain boundary which has a lower Young’s modulus due to the increase in the interatomic spacing and the increase in the amount of impurities residing in the grain boundary. Thus, the atomic structure and the Young’s modulus of the grain boundary play an essential role in controlling the sensitivity of the mechanical resonator. To this aim, we present a strategy, using the proposed distributed-parameter model and micromechanical model, to estimate the Young’s modulus of the grain boundary. At first, the material under consideration is shaped into a number of microcantilever specimens with different sizes and different grain sizes, as shown in Fig. 6a. Then, as presented in Fig. 6c, the frequency spectrum is recorded for each specimen to detect their resonant frequencies. The effective Young’s modulus, \(E\), of each specimen is mathematically estimated using the characteristic equation of the natural frequency which is given in Eq. (23) of the distributed-parameter model. The material microstructure morphology could be obtained (using SEM, as shown in Fig. 6b) to estimate the average grain size and hence the grain volume fraction, \(f\). The proposed micromechanical model for NcMs [Eq. (9)] is then used to estimate the Young’s modulus of the grain boundary. By defining the grain Young’s modulus, \(E_{g}\), which is the same as the single crystal of the material and by using the estimated Young’s modulus of the NcM, \(E\), the grain boundary Young’s modulus to the grain Young’s modulus ratio, \(\eta\), is obtained from Eq. (9) and hence the grain boundary Young’s modulus could be obtained.

The Young’s modulus of the grain boundary of nanocrystalline diamond has been investigated in a recent work using microresonators (Mohr et al. 2014). Two cantilever specimens (L = 1,500 μm, b = 200 μm, and h = 17 μm) are fabricated and their resonant frequencies are measured to be used for the Young’s modulus estimations. Two effective Young’s moduli are recorded \(752 \pm 22\;\) and \(463 \pm 11\;{\text{GPa}}\) for two distinct average grain sizes \(2R = 20 \;{\text{nm}}\) and \(2R = 6 \;{\text{nm}}\), respectively. Table 2 shows the Young’s modulus values of the grain boundary of the nanocrystalline diamond for both considered configurations when using the proposed micromechanical model in Eq. (9). It should be mentioned that the grain volume fraction, \(f\), is calculated using Eq. (17) for a grain boundary thickness \(t = 0.5 \;{\text{nm}}\).

To investigate the ability of the proposed atomic lattice model [Eqs. (8) and (5)] in estimating the grain boundary Young’s modulus of nanocrystalline diamond, we compare in this section the obtained values of the grain boundary Young’s modulus of nanocrystalline diamond when using the atomic lattice model with its counterpart given in Table 2 which is based on the micromechanical model. According to Furth (1944), the parameters m and n for diamond are, respectively, equal to 4 and 6. In addition, the density of diamond grain, \(\rho_{gb}\), is equal to 3,400 kg/m3. Therefore, according to Eq. (8), the lower and upper limits of the grain boundary density are \(\hbox{2,052.5} \to \hbox{2,817.5}\) kg/m3. For the sake of simplicity, the density of the grain boundary for nanocrystalline diamond could be approximated as the average value between these two limits, such that \(\rho_{gb} = 2,435\) kg/m3. Using the atomic lattice Eq. (5), the grain boundary Young’s modulus can be determined as \(E_{gb} = 159.24 {\text{GPa}}\), which is in a good agreement with the ranges given in Table 2. This result approves the effectiveness of the proposed atomic lattice model [Eqs. (8) and (5)] in estimating the Young’s modulus of the grain boundary of NcMs.

Nanocrystalline silicon is also widely used as mechanical resonators for many applications. The proposed micromechanical model along with the atomic lattice model are used to estimate the grain boundary Young’s modulus and the effective Young’s modulus of nanocrystalline silicon with different grain sizes. For nanocrystalline silicon, \(n = 12\) and \(m = 8\) (Furth 1944). Hence, the density of the grain boundary is within the range \(\rho_{gb} = \hbox{1,745.6} \to \hbox{2,263}\) kg/m3 according to Eq. (8), where \(\rho_{g} = \hbox{2,300}\) kg/m3. Thus, by approximating the density as the average of the two limits, \(\rho_{gb} = \hbox{2,004.3}\) kg/m3, the grain boundary Young’s modulus for nanocrystalline silicon is then \(E_{gb} = 45.56\; {\text{GPa}}\), where \(E_{g} = 169 \; {\text{GPa}}\) and \(\nu = 0.064\).

To show the effects of the grain average radius on the effective Young’s modulus of silicon and diamond, we plot in Fig. 7 the variations of the effective Young’s modulus as a function of the grain average size for nanocrystalline silicon and nanocrystalline diamond with grain boundary thickness, \(t = 0.5 \;{\text{nm}}\). Clearly, a decrease in the grain average radius is accompanied by a significant decrease in the effective Young’s modulus of the NcM. This is particularly true when the grain average radius, is lower than \(20 \;{\text{nm}}\). When the grain average radius is varied from 40 to 20 nm, there is a decrease in the effective Young’s modulus with a smaller slope. For high values of the grain average radius (>40 nm), there is a negligible change in the effective Young’s modulus which is due to the decrease in the grain boundary.

Due to impurities and/or defects of the crystal structure of silicon or diamond, the variation of the Young’s modulus of the grain boundary as a function of the grain radius of the real structure of material could deviate from the curves shown in Fig. 7. For example, natural diamond crystals contain varying amounts of impurities like atomic nitrogen. In addition, other local or extended crystal structural defects could be present (Hess 2012). Therefore, for the same grain size different values of the Young’s modulus could be obtained according to the real feature of the material structure. Hess (2012) had experimentally reported the variation of the Young’s modulus of nanocrystalline diamond as a function of the grain average size for different samples of nanocrystalline diamond with different material structure defects and impurities. By taking the average values of the obtained results by Hess (2012), Fig. 7 shows a high agreement with these average values for nanocrystalline diamond. Therefore, the proposed micromechanical model along with the atomic lattice model form a reliable method which can be used to estimate the effective Young’s modulus of NcMs with reasonable accuracy.

3.3 Mechanical resonators used for disease diagnosis of HIVs

A biosensor is a device which converts biochemical interaction into a quantifiable signal. It is a device that is made up of a biological material, such as micro-organisms, tissue, enzymes, antibodies or biologically derived material that acts as the recognition molecules (Tothill 2009; Darsanaki et al. 2013). These biosensors have to be utilized in conjunction with or attached to a resonator that can give an electronic signal proportional to the concentration of a specific analyte or group of analytes. Biosensors are classified according to the type of transducer employed; hence they are categorized into electric, radiant, optical, thermal, magnetic, and mechanical frequency transducers.

In this section, the ability of mechanical resonators as biosensors used for disease diagnosis is investigated. The operating principle of these biosensors is presented in Fig. 8. The process starts by fabricating an antibody-coated resonator such that biological molecules, that indicate the presence of a particular disease, attach to the matching antibodies. For more details about the process of antibody coating of cantilever beams, the reader is referred to the research study of Gupta et al. (2004a). Then, the induced shift due to the added mass of the attracted molecules in the resonant frequency of the cantilever beam could be measured and used to estimate the number of virus or bacteria particles attached to the cantilever tip mass. Increasing the number of antibodies increases the sensitivity of the mechanical resonator to quantitatively and qualitatively diagnose the presence of a particular disease. Moreover, using several cantilevers in an array with each cantilever coated with a different antibody allows for several types of disease to be diagnosed faster and more efficient.

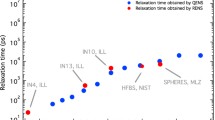

To determine the number of HIV virus particles that exist in a blood sample as an example, the frequency shift induced in a mechanical resonator is investigated. The human immune-deficiency virus (HIV) is a lentivirus (a subgroup of retrovirus) that causes the acquired immunodeficiency syndrome (AIDS) (Weiss 1993; Douek et al. 2009), a condition in humans in which progressive failure of the immune system allows life-threatening opportunistic infections and cancers to thrive. Infection with HIV occurs by the transfer of blood, semen, vaginal fluid, pre-ejaculate, or breast milk. Within these bodily fluids, HIV is present as both free virus particles and virus within infected immune cells. A mechanical resonator coated by HIV antigens is used to detect the presence and the number of HIV virus particles in a blood sample. Two mechanical resonators are considered with the following dimensions: length L = 25 μm, width b = 5 μm, and h = 200 nm. One is made of nanocrystalline silicon and the other is made of nanocrystalline diamond. The tip mass at the free-end is coated by HIV antigens, as shown in Fig. 8a, to serve as an attractor for the HIV virus. The average mass of the HIV virus single particle is detected by \(1 \;{\text{fg}}\) and the average diameter is approximately detected by \(126 \;{\text{nm}}\) (Zhu et al. 2003). The attracted area coated by antigens is 64 μm2 which can attract approximately 3,900 virus particles. The plots in Fig. 9 show the frequency shift induced in the mechanical resonator as a function of the number of virus particles in the blood sample for different tip-mass values and different grain average radius. It follows from these plotted curves that an increase in the frequency shift is observed by increasing the number of virus particles. For example, if a shift of frequency 10 kHz is recorded for a resonator made of diamond with grain average radius 50 nm, 1,140 and 1,980 HIV virus particles are reported to be exist in the blood sample for a tip-mass \(0.2\rho bhL\) and \(0.4\rho bhL\), respectively. However, for a resonator made of silicon with grain average radius 10 nm, 1,780 and 3,120 HIV virus particles are reported for a frequency shift 10 kHz. Hence, the material type and the material microstructure of the resonator along with the mass of the attractor are highly affecting the accuracy and the sensitivity of the mechanical resonator in order to detect the number of virus particles in the blood sample.

3.4 Design of sensitive resonators

In this section, the design of sensitive micro/nanomechanical resonators is investigated. For optimum design, many trials are needed to manipulate between many factors to enhance the sensitivity. The dimensions and the material type are the most important factors influencing the sensitivity of mechanical resonators. The proposed distributed-parameter model along with the micromechanical model and the atomic lattice model provide an effective, cheap, and time saving method to design micro/nano mechanical resonators with high sensitivities. Table 3 and Fig. 10 show the effects of the grain boundary, the dimensions, and the material type on the sensitivity of microresonators with nano thicknesses made of nanocrystalline diamond and nanocrystalline silicon for mass sensing. Two resonators are considered for this study with different lengths L = 25 and 100 μm. The results show that resonators with lower dimensions give enhanced sensitivity. For example, the resonator made of nanocrystalline diamond with a grain volume fraction \(f = 0.5\) and with length L = 25 μm requires \(0.06333 \;{\text{fg}}\) of mass to achieve a frequency shift of \(1 \;{\text{Hz}}\); while the resonator with length L = 100 μm requires \(4.05515 \,{\text{fg}}\) to achieve a frequency shift of \(1\; {\text{Hz}}\).Therefore, resonators with lower dimensions have better sensitivity than resonators with large sizes. This result can be explained due to the fact that the natural frequency is higher when the beam’s dimensions are decreased and hence the frequency shift can be easily detected, as shown in Fig. 10. Moreover, the grain volume fraction significantly affects the sensitivity of the resonator. In fact, an increase in the grain volume fraction is accompanied by an increase in the sensitivity of the resonator. For resonators with nano thicknesses, their sensitivities are more affected by the nature of the grain boundary while the beam thickness, almost, has no effect. Inspecting Table 3, it is clear that resonators made of nanocrystalline diamond are more sensitive than those made of nanocrystalline silicon. The performed analysis gives a useful guideline in order to design efficient mechanical resonators with high sensitivities.

4 Conclusions

The ability of mechanical resonators for mass detection of bio-cells, nanocrystalline materials characterization, and disease diagnosis of human immune-viruses (HIVs) has been investigated. A novel distributed-parameter model based on Euler–Bernoulli beam theory was developed to simulate the real behavior of these mechanical resonators. This model is equipped with a micromechanical model and an atomic lattice model to capture the inhomogeneity nature of the material microstructure. The micromechanical model was used for estimating the effective Young’s modulus of the NcM-based resonators by representing the material morphology as a two-phase composite with the grains as the inclusions and the grain boundary as the matrix phase. The proposed atomic lattice model was used to effectively estimate the Young’s modulus of the grain boundary of NcMs. With the aid of the proposed atomic lattice model, two limits are defined for the density of the grain boundary of NcMs such that the density is distributed between these two limits according to a certain polynomial function. Using the developed distributed-parameter model, a mass detection analysis for the vaccinia virus was accurately estimated. Based on the performed comparison between results based on the proposed distributed-parameter model and results of the simple lumped-parameter model, it was demonstrated that the proposed strategy is very sensitive and accurate tool to predict the deposited bio-cell particles which can be used in many applications and in different places. Another investigated application for mechanical resonators is detecting the effective Young’s modulus of NcMs. The effective Young’s moduli of nanocrystalline silicon and nanocrystalline diamond were accurately determined along with densities and Young’s moduli of their grain boundaries using the proposed model. For disease diagnosis purposes, a mechanical resonator was also proposed and used for detecting the presence of the human immune-deficiency virus (HIV) in a liquid sample. It was shown that the material morphology size highly affects the accuracy of the resonator in qualitatively and quantitatively detecting the presence of a certain virus particle in a blood sample.

The proposed distributed-parameter model along with the micromechanical model and the atomic lattice model provide an effective, cheap, and time saving method to design micro/nano mechanical resonators with high sensitivities. For optimum design, many trials are needed to manipulate between many factors to enhance the sensitivity. The dimensions and the material type are the most important factors influencing the sensitivity of mechanical resonators. Based on the performed analysis, it could be concluded that designing resonators with smaller sizes and made of a high stiff nanocrystalline material can significantly enhance their sensitivities.

References

Aboelkassem Y, Nayfeh AH, Ghommem M (2010) Bio-mass sensor using an electrostatically actuated microcantilever in a vacuum microchannel. Microsyst Technol 16:1749–1755

Binnig G, Quate CF, Gerber C (1986) Atomic force microscope. Rev Lett 56:930

Boccaccini AR, Ondracek G, Mazilu P, Windelberg D (1993) On the effective Young’s modulus of elasticity for porous materials: microstructure modelling and comparison between calculated and experimental values. J Mech Behav Mater 4:119–132

Darsanaki PK, Azizzadeh A, Nourbakhsh M, Raeisi G, Aliabadi MA (2013) Biosensors: functions and applications. J Biol 2:53–61

Douek DC, Roederer M, Koup RA (2009) Emerging concepts in the immunopathogenesis of AIDS. Annu Rev Med 60:471–484

Duan HL, Wang J, Huang ZP, Karihaloo BL (2005) Size-dependent effective elastic constants of solids containing nano-inhomogeneities with interface stress. J Mech Phys Solids 53:1574–1596

Fitzsimmons MR, Roll A, Burkel E, Sichafus KE, Nastasi MA, Smith GS, Rynn R (1995) The magnetization of a grain boundary in nickel. Nanostruct Mater 6:539–542

Fougere GE, Riester L, Ferber M, Weertman JR, Siegel RW (1995) Young’s modulus of nanocrystalline Fe measured by nanoindentation. Mater Sci Eng, A 204:1–6

Fritz J et al (2000) Translating biomolecular recognition into nanomechanics. Science 288:316–318

Furth R (1944) On the equation of state for solids. Proc R Soc A 183:57

Ghatkesar MK, Barwich V, Braun T, Bredekamp AH, Drechsler U, Despont M, Lang HP, Hegner M, Gerber C (2004) Real-Time Mass Sensing by Nanomechanical Resonators in Fluid. Sens, Proc IEEE IEEE 2:1060–1063

Gleiter H (2000) Nanostructured materials: basic concepts and microstructure. Acta Mater 48:1–29

Gupta A, Akin D, Bashir R (2004a) Detection of bacterial cells and antibodies using surface micromachined thin silicon cantilever resonators. J Vac Sci Technol, B 22(6):2785–2791

Gupta A, Akin D, Bashir R (2004b) Single virus particle mass detection using microresonators with nanoscale thickness. Appl Phys Lett 84(11):1976–1978

Hess P (2012) The mechanical properties of various chemical vapor deposition diamond structures compared to the ideal single crystal. J Appl Phys 111:051101

Hewa TMP et al (2009) The detection of influenza A and B viruses in clinical specimens using a quartz crystal microbalance. J Virol Methods 162(1–2):14–21

Hutchinson AU et al (2004) Dissipation in nanocrystalline-diamond nanomechanical resonators. Appl Phys Lett 84:972–974

Ilic B, Yang Y, Craighead HG (2004) Virus detection using nanoelectromechanical devices. Appl Phys Lett 85(13):2604–2606

Johnson L, Gupta AK, Ghafoor A, Akin D, Bashir R (2006) Characterization of vaccinia virus particles using microscale silicon cantilever resonators and atomic force microscopy. Sens Actuators B 115:189–197

Kim HS, Bush MB (1999) The effects of grain size and porosity on the Elastic modulus of nanocrystalline materials. Nanostruct Mater 11:361–367

Lu CH et al (2012) Sensing HIV related protein using epitope imprinted hydrophilic polymer coated quartz crystal microbalance. Biosens Bioelectron 31(1):439–444

Mohr M, Caron A, Engel PH, Bennewitz R, Gluche P, Brühne K, Fecht HJ (2014) Young’s modulus, fracture strength, and Poisson’s ratio of nanocrystalline diamond films. J Appl Phys 116:124308

Sanders PG, Eastman JA, Weertman JR (1997) Elastic and tensile behavior of nanocrystalline copper and palladium. Acta Mater 45:4019–4025

Sekaric L et al (2002) Nanomechanical resonant structures in nanocrystalline diamond. Appl Phys Lett 81:4455–4457

Sharma P, Ganti S (2003) On the grain-size-dependent elastic modulus of nanocrystalline materials with and without grain-boundary sliding. J Mater Res 18(8):1823–1826

Shen TD, Koch CC, Tsui TY, Pharr GM (1995) On the elastic moduli of nanocrystalline Fe, Cu, Ni, and Cu-Ni alloys prepared by mechanical milling/alloying. J Mater Res 10:2892–2896

Spriggs RM (1961) Expression for effect of porosity on elastic modulus of polycrystalline refractory materials, particularly aluminum oxide. J Am Ceramic Soc 44:628–629

Su M, Li S, Dravid VP (2003) Microcantilever resonance-based DNA detection with nanoparticle probes. Appl Phys Lett 82(20):3562–3564

Swygenhoven H, Spaczer M, Caro A (1999) Characterisation of the microstructure of nanophase Ni: a molecular dynamics simulation study. Nanostruct Mater 12:629–632

Tao Y, Boss JM, Moores BA, Degen CL (2014) Single-crystal diamond nanomechanical resonators with quality factors exceeding one million. Nat Commun. doi:10.1038/ncomms4638

Tothill IE (2009) Biosensors for cancer markers diagnosis. Semin Cell Dev Biol 20:55–62

Wang N, Wang ZR, Aust KT, Erb U (1995) Effect of grain size on mechanical properties of nanocrystalline materials. Acta Metall Mater 43:519–528

Wang GF, Feng XQ, Yu SW, Nan CW (2003) Interface effects on effective elastic moduli of nanocrystalline materials. Mater Sci Eng, A 363:1–8

Weiss RA (1993) How does HIV cause AIDS? Science 260(5112):1273–1279

Xing LQ, Bertrand C, Dallas JP, Cornet M (1998) Nanocrystal evolution in bulk amorphous Zr57Cu20Al10Ni8Ti5 alloy and its mechanical properties. Mater Sci Eng, A 241:216–225

Zhou J, Li Y, Zhu R, Zhang Z (2007) The grain size and porosity dependent elastic moduli and yield strength of nanocrystalline ceramics. Mater Sci Eng, A 445–446:717–724

Zhu P et al (2003) Electron tomography analysis of envelope glycoprotein trimers on HIV and simian immunodeficiency virus virions. PNAS 100(26):15812–15817

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shaat, M., Abdelkefi, A. Modeling of mechanical resonators used for nanocrystalline materials characterization and disease diagnosis of HIVs. Microsyst Technol 22, 305–318 (2016). https://doi.org/10.1007/s00542-015-2421-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-015-2421-y