Abstract

The presented work focuses on the investigations of a metallo-porphyrin and its gasochromic behavior to different gases. Gasochromic materials change their color while they are exposed to a certain gas. So they offer the possibility to develop highly selective chemical gas sensors and gas sensing systems. The focus of this work is the characterization of the metallo-porphyrin 5, 10, 15, 20-tetraphenylporphyrin-zinc (ZnTPP). Nonetheless, there is a wide range of other possible metallo-porphyrins. When embedded into a polymeric matrix (PVC) a color change to the toxic gas NO2 can be detected. To develop a stand-alone gas sensor, the porphyrin/PVC matrix is deposited onto a planar optical waveguide. The color change of the porphyrin dye can be detected in the evanescent field of the optical waveguide. Therefore, the light of a high power LED is coupled into the waveguide. The color change of the porphyrin is detectable with photodiodes as a variation of the out-coupled light intensity. The sensor shows no unwished sensitivities to CO2 and CO and only low to NH3. NO2 is detectable with a resolution of 1 ppm.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

A continuous control of gases in ambient atmosphere is required in many industrial branches, such as the chemical industry, automotive, food chain management or fire detection. In most applications there is no room for high end sensor systems, which are often big and expensive in acquisition and maintenance. Many applications require small and low-cost gas sensing systems. Often semiconducting metal oxide gas sensors are used. In spite of some disadvantages such as low selectivity, high power consumption and strong drifting behavior (Wang et al. 2010; Yamazoe and Shimanoe 2009), these sensors are widely spread in all industrial fields. The need goes to small, affordable and selective gas sensor as an alternative to metal oxide sensors.

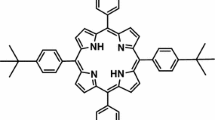

This work focuses on an alternative principle for low-cost gas sensors with lower power consumption. The approach is the detection of gases with gasochromic materials. Gases reacting with these materials induce a color change. Well established sensors, which are based on a color change, are Dräger gas tubes™ (Dräger 2011). These tubes, used by fire departments, determine the composition of a fire. The endings of these glass tubes are broken and the gas is pumped through the tube. In case of a matching between gas and gasochromic material changes its color. The gas concentration can be directly read on the imprinted scale. The main advantage of such sensors is the selective behavior of the gasochromic material which ideally reacts to only one gas. The main disadvantage is the need of manual handling and readout. The approach presented here goes a step further and offers the possibility of a standalone sensor system without the need for an operator. The focus lies on the gasochromic detection of nitrogen dioxide (NO2): a highly toxic gas occurring during many fires. The investigated gasochromic materials are metallo-porphyrins. Porphyrins are natural pigments and already widely used in industry and research. They consist of four pyrrole rings connected by four methins. Metallo-porphyrins additionally have a metallic ion in the center of the structure. Typical metals are zinc, iron or cobalt. These metallo-porphyrins are, as prosthetic groups, part of many proteins with varying functions. Hemoglobin and myoglobin manage the oxygen transport and storage; cytochromes and chlorophyll are responsible for electron- and energy transfer; vitamin B12 catalyses biochemical reactions (Matsui et al. 2010; Mansuy 2007). We focused on 5, 10, 15, 20-tetraphenylporphyrin-zinc (ZnTPP) and its gasochromic behavior to low concentrations of NO2 (Kurtikyan et al. 1998; Kurtikyan and Ford 2008).

Many different gasochromic reactions to NO2 have already been described in literature. One of the oldest and manifold cited method is the Saltzmann-method (Saltzman 1954). He used a mixture of sulfanilic acid, N-(1-naphthyl)ethylenediamine and acetic acid. The mixture shows a stable color change in contact with NO2. In 1972 Smith patented a variation of the Saltzman-method. He extended the mixture to form pellets to realize the first sensor system (Smith 1972). Another modification was published in 1996 by Nakano (Nakano 1996). He embedded a mixture of p-toluenesulfonic acid, sulfanic acid, N-(1-naphtyl)ethylenediamine dihydrochloride (NED), glycerin and methanol into a cellulose tape. During NO2 exposure, the tape changed its color to red. Another approach of developing a sensor using the Saltzman-method was by Tanaka (Tanaka et al. 1998). He replaced NED by Dimethylnaphthalamine and implemented the indicator into a highly porous glass. Different publications reported on the colorimetric behavior of metal complexes to NO2. Wayland presented studies on the gasochromic performance of an iron porphyrin to NOx (Wayland and Olson 1974). Filippini published a principle to detect NO2 by using dots of porphyrin which form a matrix to monitor absorption and emission changes optically (Filippini 2006). Another approach of gasochromic sensors was published by Nezel. He used aquacyanocobalt(III)-cobyrinat as indicator. The investigations targeted on the application of this principal as fire detectors (Nezel et al. 2001). Yet most of them have the disadvantage that they require laboratory equipment such as UV/VIS-spectroscopy for monitoring the color change.

2 Sensor principle

It was our aim to develop a simple sensing principle using gasochromic effects. The sensor set-up, presented here, is based on a planar optical waveguide. In the easiest case, this can be a glass slide onto which the dye is deposited. To obtain a planar and stable sensing film, the gasochromic material is embedded into a polymer matrix and deposited on the waveguide. The light of an LED, depending on the wavelength of the color change, is coupled into one end of the waveguide and passes through it under the conditions of total internal reflection (TIR). Above the surface exists the exponentially decaying evanescent field, in which color changes of the dye are detectable. After coupling out at the opposite side, the light is focused on a photo detector. Changes in the dye induce direct changes in the light intensity. Compared to measurements in transmission, the waveguide principle has much lower detection limits, caused by the longer optical path due to TIR. A scheme of the sensor set-up is shown in Fig. 1. This sensor principle is described in detail in Courbat et al. (2009).

Cross-sectional view of the waveguide. The light of an LED is coupled into one end of the waveguide and travels through the waveguide under conditions of total internal reflection before it is focused onto a photo detector. Top the waveguide is covered with the gasochromic film. Bottom schematic view after gas exposure and induced color change

In the system, two independent photo diodes are used as detectors, so that half of the waveguide surface serves as measurement channel onto which the polymer including the gasochromic reagent is deposited, while the other half is only coated with the polymer and used as reference channel. In this way, drifts in the light intensity of the LED, leading to erroneous signal changes, are minimized.

The measurement principle requires a special measurement chamber, shown in Fig. 2. The waveguide is positioned in a metallic carrier. From the left, the light of a blue LED operating at 460 nm, is coupled into the waveguide. On the right side the light is focused on two photo detectors, one for the measurement and one for the reference channel. Next to the photo detectors, the implemented electronics amplify the resulting output voltage. The gas is directly led through a 0.08 cm3 gas cell via gas-tight connectors.

Photograph of the measurement chamber for colorimetric gas measurements. From the left, the light of a blue LED is coupled into the waveguide and, after being coupled out on the other side, focused on two photo detectors. During gas exposure, the gasochromic film changes its color which leads to changes in the decoupled light of the LED due to different absorption

3 Experimental

The ZnTPP dyes are prepared from different components, consisting of the basic color dye, a polymer carrier matrix, solvents and plasticizers to obtain homogeneous and stable films. As polymer matrix, polyvinyl chloride (PVC) was used. PVC has the advantage of being chemically inert to a large extent and not showing hygroscopic behavior. PVC powder is soluble in tetrahydrofuran (THF). The ZnTPP was directly added to the polymer mixture. Stirring at room temperature for 2 h leads to a homogeneous fluid with a characteristic purple color. The exact composition is given in Table 1. All chemicals, except the plasticizer, were obtained from Sigma Aldrich; the plasticizer Hexamoll™ DINCH is available at BASF. This dye was used for all experiments.

As reference, UV/VIS-measurements were carried out. The use of an adapted UV/VIS-measurement chamber, with an integrated gas in- and outlet, allows the detection of changes in the transmission spectra during gas exposure. For UV/VIS sample preparation, 100 μl of the dye were spin coated onto a glass window and dried for 3 h.

For waveguide based measurements, 40 μl of the dye was used to coat one half of a glass slide and dried for 3 h. The resulting layer had a thickness of about 1.5 μm.

4 Results and discussion

The synthesized ZnTPP/PVC dye was characterized in terms of reaction and sensitivity to NO2 and other gases, the influence of humidity and its long-term stability.

The color changing reaction of ZnTPP to NO2 is shown in Fig. 3. The dye was exposed to 5 ppm NO2 in dry synthetic air. The gas exposure leads to a color change of the dye in the blue wavelength range. ZnTPP in atmospheric ambience has characteristic transmission spectra with minima at 594 nm, 555 nm, 516 nm and complete absorption between 419 nm and 428 nm. When exposed to NO2, the dye appears yellow.

On the basis of Beer-Lambert’s law, it is possible to calculate a factor of the material specific absorption coefficient α multiplied by the gas concentration. This factor is an indicator of the processed gas at a certain wavelength. It is calculated from the signal ratio of incoupled and transmitted light, the wavelength and the layer thickness and is a direct indicator for the color change. Changes in transmission at 460 nm during the gas exposure are shown Fig. 4.

The chemical reaction principle of ZnTPP with NO2 was already described in Shine et al. (1979) and is shown in Fig. 5. The chemical reaction is a two-step mechanism. In the first step, NO2 oxidizes the porphyrin complex. This leads to changes in the infrared, but not in the visible range. In a second reaction step, a second NO2 molecule reacts covalently with the oxidized complex. This second reaction induces the color change from purple to yellow. Since the color change requires two NO2 molecules, the ZnTPP is less fast than other gasochromic materials.

Two-step reaction mechanism of ZnTPP to NO2. In the first step NO2 oxidizes the complex. This oxidized complex can react with another NO2 molecule, which is covalently bound to one phenyl ring. This second reaction step leads to the visible color change. The first reaction step is only detectable in the infrared

The waveguide-based measurements were carried out with the measurement chamber described in Sect. 2. The dye was exposed to 5 ppm NO2 in dry synthetic air for 60 min. An increase in the output signal is a direct measure for a color change of the dye. Figure 6 shows the sensor response to NO2. At the beginning of the measurement, the sensor was exposed to dry air for 30 min. Afterwards the chamber was filled with a flow of 200 ml/min. This slow flow rate in combination with the two-step reaction process leads to a delay in the output signal.

Key factors in the development of gas sensors are their sensitivities to different gases and to humidity. To investigate the selective behavior of ZnTPP to NO2, the dye was exposed to high concentrations of test gases: 100 ppm ammonia, 100 ppm carbon monoxide and 1,500 ppm carbon dioxide in synthetic air at 40% relative humidity. Transmission spectra were recorded before and after 110 min of gas exposure. Figure 7 shows the transmission spectra of the single measurements. The dye shows low sensitivity to high concentrations of NH3. The reaction leads to a maximum change of 1% the transmission at 460 nm, which is uncritical compared to the change induces by NO2 at this wave length.

Left transmission spectra of ZnTPP after exposure to different test gases to investigate cross sensitivities. Measurements were taken after 110 min exposure to 1,500 ppm CO2, 100 ppm NH3 and 100 ppm CO. The dye shows low cross sensitivities to NH3. Right zoom into the transmission spectra between 440 and 520 nm to show the low sensitivity to NH3

The influence of the ambient humidity to the gas reaction was measured for 70% r.H., 40% r.H. and dry air. Therefore, the transmission of the dye was measured before and after 2 h exposure to 5 ppm NO2. The analysis is shown in Fig. 8. Shown is the mean value of the difference of the transmission at 460 nm before and after gas exposure. Each measurement was repeated five times to calculate the mean value and the according standard deviation. These are for 0% r.H. 3.14/0.31%; for 40% r.H. 2.54/0.41%; and for 70% r.H. 3.37/0.27%. The error bars show that there is only a small influence of the humidity to the sensor response.

Another critical factor of chemical gas sensors is the long-term stability of the chemical matrix. Very often chemical matrices are affected by UV-radiation, heat and/or ambient atmosphere. We used a complex which is embedded into the commonly stable polymer PVC. To investigate aging effects, the transmission of the dye as well as of the pure polymer were measured over a time of 90 days. The dyes were stored in a translucent box at room temperature. Figure 9 shows the reduction in the transmission at 460 nm over 90 days.

The main disadvantage of implementing ZnTPP into gasochromic sensors is its reversibility. Our observations have shown that the back reaction of ZnTPP is so slow, that it’s not reversible in terms of a gas sensors performance, due to a relaxing time of several days.

5 Conclusion and outlook

We presented the development of a novel optical gas sensor based on 5, 10, 15, 20-tetraphenylporphyrin-zinc as gas-reactive dye. The working principle of the sensor is based on the gasochromic behavior of the dye. The ZnTPP is embedded into a PVC matrix. A characteristic color change, due to exposure to NO2, from purple to yellow was shown in transmission spectra. In addition to UV/VIS-measurements and measurements with a waveguide based set-up showed the capability of this working principle. NO2 in the range of one ppm could be detected. This sensing principle offers high potential for small scale selective gas sensors and the development of a low-power NO2 gas sensor. The small sensor set-up and the simple periphery allow the implementation into a small micro system. Investigations on reactions to other gases demonstrated the excellent selective behavior of ZnTPP. The low sensitivity to NH3 can be easily eliminated in a later measurement system by regarding the differentiated sensor signal.

Other porphyrins such as e.g. FeTPPCl are also possible gasochromic materials (Lim et al. 2005) that should be investigated in terms of their sensing behavior to NO2. Next steps will be the implementation of metallo-porphyrins in measurement systems using RFID-technology and fire detectors to measure under real life conditions.

References

Courbat J, Briand D, Damon-Lacoste J, Wöllenstein J, de Rooij NF (2009) Evaluation of pH indicator-based colorimetric films for ammonia detection using optical waveguides. Sens Actuators B 143:62–70

Dräger (2011) http://www.draeger.de/media/10/00/92/10009262/labor_hinter_glas_br_9046078_de.pdf, available at 15.03.2011

Filippini D (2006) Chemical sensing with familiar devices. Angew Chem Int Ed 45:3800–3803

Kurtikyan TS, Ford PC (2008) FTIR and optical spectroscopic studies of the reaction of heme models with nitric oxide and other NOx in porous layered solids. Coord Chem Rev 252:1486–1496

Kurtikyan TS, Stephanyan TG, Gasparayan AV, Zhamkochyan GA (1998) Interaction of nitrogen dioxide with sublimed films of meso-tetraphenylporphyrinatozinc. Russian Chem Bull 47:644–647

Lim MD, Lorkovic IM, Ford PC (2005) NO and NOx interactions with group 8 metalloporphyrins. J Inorg Biochem 99:151–165

Mansuy D (2007) A brief history of the contribution of metalloporphyrin models to cytochrome P450 chemistry and oxidation catalysis. Compt Rend Chim 10(4–5):392–413

Matsui T, Unno M, Ikeda-Saito M (2010) Heme oxygenase reveals its strategy for catalyzing three successive oxygenation reactions. Acc Chem Res 43(2):240–247

Nakano N (1996) Development of a monitoring tape for nitrogen dioxide in air. Anal Chim Acta 321:41–45

Nezel T, Spichiger-Keller UE, Ludin C, Hensel A (2001) Gas-selective optical sensors for fire detectors. CHIMIA Int J Chem 55:725–731

Saltzman BE (1954) Colorimetric microdetermination of nitrogen dioxide in the atmosphere. Anal Chem 26:1949–1955

Shine HJ, Padilla AG, Wu SM (1979) Reactions of zinc tetraphenyporphyrin cation radical perchlorate with nucleophiles. J Org Chem 44:4069–4075

Smith AB (1972) Colorimetric indicator for the detection of nitrogen dioxide. US 3,681,027

Tanaka T, Ohyama T, Maruo YY, Hayashi T (1998) Coloration reactions between NO2 and organic compounds in porous glass for cumulative gas sensor. Sens Actuators B 47:65–69

Wang C, Yin L, Zhang L, Xiang D, Gao R (2010) Metal oxide gas sensors: sensitivity and influence factors. Sensors 10:2088–2106

Wayland BB, Olson LW (1974) Spectroscopic studies and bonding model for nitric oxide complexes of iron porphyrins. J Am Chem Soc 96(19):6037–6041

Yamazoe N, Shimanoe K (2009) New perspectives of gas sensor technology. Sens Actuators B 138:100–107

Acknowledgments

This research has been supported by the internal programs of the Fraunhofer Gesellschaft (WISA Food Chain Management) and the Spitzencluster Microtec Südwest in cooperation with the Federal Ministry of Education and Research (BMBF) (project SensRFID).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Peter, C., Schmitt, K., Apitz, M. et al. Metallo-porphyrin zinc as gas sensitive material for colorimetric gas sensors on planar optical waveguides. Microsyst Technol 18, 925–930 (2012). https://doi.org/10.1007/s00542-011-1412-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-011-1412-x