Abstract

Reliability and longevity comprise two of the most important concerns when designing micro-electro-mechanical-systems (MEMS) switches. Forcing the switch to perform close to its operating limits underlies a trade-off between response bandwidth and fatigue life due to the impact force of the cantilever touching its corresponding contact point. This paper presents for first time an actuation pulse optimization technique based on Taguchi’s optimization method to optimize the shape of the actuation pulse of an ohmic RF-MEMS switch in order to achieve better control and switching conditions. Simulation results show significant reduction in impact velocity (which results in less than 5 times impact force than nominal step pulse conditions) and settling time maintaining good switching speed for the pull down phase and almost elimination of the high bouncing phenomena during the release phase of the switch.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

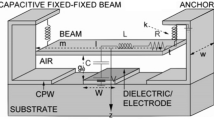

Radio frequency applications require state of the art circuitry to achieve performance and reliability. Irrespective of their use for signal transmission in personal, RADAR or satellite communication systems or power delivery applications, switches essentially comprise of design part of microwave circuits designs and significant efforts have been invested to develop configurations that perform their best under any operating conditions. Ohmic RF MEMS switches are gradually substituting the traditional solid state switches offering higher isolation and lower insertion loss, lower power dissipation and higher linearity. However, due to the nature of their structure they are usually prone to failure (Rebeiz 2003; McKillop 2007).

In general, a RF-MEMS switch should be able to switch very fast without settling periods due to the bouncing phenomena. Additionally, the contact force should be sufficient and constant as soon as the switch closes. During the release phase, the switch should return to its null position as fast as possible in order to be ready for the next actuation pulse. In reality, there is always a trade-off between the switching speed, settling time and contact force. Fast switching can be achieved by increasing the amplitude of the actuation pulse. Nevertheless, increased cantilever pull down velocity implies bouncing and hence settling time is necessary for the switch to perform well. Moreover, the contact force during the settling period is not constant, reaching undesirable peak values when cantilever touches its corresponding contact area for the first time. This, results in unstable contact resistance, power loss and arching as far as the signal is concerned and induces local hardening, pitting or dislocations in the metal crystal structures of the materials used, reducing the reliability and the longevity of the switch (Newman et al. 2008).

Although a lot of effort has been invested in developing materials capable of maintaining high electrical contact conductance while keeping structural failures low, it still remains one of the major reasons for device failure. Thus, a different design approach is necessary to be followed acknowledging material properties and limitations and also controlling the switch via an optimized actuation pulse.

In the past few years several efforts have been made to tailor the shape of the actuation pulse using either analytical equations on a simplified single-degree-of-freedom (SDOF) models (parallel plate capacitor) on their own (Czaplewski et al. 2006; Massad et al. 2005), or in combination with Simplex optimization algorithms (Sumali et al. 2006; Allen et al. 2008). All these efforts focused on the minimization of the impact force and bouncing during the pull-down phase of the switch but without taking into account the damping or adhesion forces. Recently, two new publications presented a more accurate solution that includes all the involved parameters (Guo et al. 2007; Ou et al. 2008). Nevertheless, the SDOF model is not considered as an accurate method to describe efficiently a non-linear system like an RF-MEMS switch during its ON–OFF operation. Besides concerning damping, note that except for a linear system with viscous damping, it is not possible to obtain an analytical expression. This implies that in all cases which are mentioned above, the tailored pulse which has been created under analytical means needs manual fine tuning in order to fulfill the requirements of soft landing and bouncing elimination.

This paper presents for the first time the optimization of the switch’s actuation pulse with a simple and efficient way, using Taguchi’s technique (Taguchi and Yokoyama 1993), in collaboration with the Coventorware software package, comprising a complete solution concerning switch behavior. As a result high switching speed simultaneously with low bouncing phenomena and low impact force, the moment the cantilever reaches its corresponding contact area, achieved.

2 Controlling the switch

Under step pulse implementation, the contact force at the moment the contact is made is very high due to the high impact velocity of the cantilever which collapses. The conductance becomes very high but unstable due to the bouncing of the cantilever which follows the first contact, (due to the elastic energy stored in the deformed contact materials and in the cantilever) and it needs time to develop a stable contact force and thereof a stable conductance. This bouncing behavior also increases the effective closing time of the switch. Additionally, bouncing affects the opening time (ON to OFF transition) since the cantilever needs time to settle to its null position. That behavior introduces system noise as the distance between cantilever and its corresponding contact point is not constant affecting the isolation.

Meanwhile, the contact may get damaged by the large impact force which can be much greater than the high static contact force necessary for low contact resistance. This instantaneous high impact force may induce local hardening or pitting of materials at the contact. Besides, it may facilitate material transfer or contact welding, which is not desirable for a high-reliability switch. All the above increase the adhesive force, which is a function of the maximum contact force and they result in contact stiction. Thus, the impact force increases the force required to separate the contact by a large factor. This is observed readily in gold-contact switches that stick immediately or right after a few cycles with square wave actuation pulse, but operate for extended periods when actuated by slower waveforms (Hyman and Mehregany 1999).

Instead of using a continuous step command to control the electrode, a tailored pulse as presented by Ou et al. 2008, with different levels of applied voltages and time intervals can be applied, as shown in Fig. 1. The entire operation can be classified in two phases, the “pull down” phase and the “release phase”. The pull down phase mainly refers to the actuation of a contact switch from its original null position to the final contact position. A well designed switch should achieve a rapid and low impact response (ideally zero velocity) at the time of contact and a fast settling, once the switch is released from its contact position back to the null position. Special effort must be paid in the release phase due to the fact that considerable residual vibration at the null position could be generated before settling. Consequently, the switching rate will get reduced during repeat operations and produces undesirable noise, as the isolation of the switch become unstable.

The main drawback of the above procedure is that there are many parameters that have to be modified in order to reach a good convergence to the targets. Due to the large number of parameters and the nonlinear structure of the problem it is very difficult to work through equations. Thus, the only solution is the implementation of an optimization method.

Recently, thanks to the rapid development of computing, several stochastic optimization techniques that incorporate random variation and selection such as genetic algorithms (GA) (Donelli et al. 2004), particle swarm optimization (PSO) (Deligkaris et al. 2009) and gradient-based algorithms (Karatzidis et al. 2008) have been implemented via computer codes to solve various problems. These optimization methods can be divided into two categories: global and local techniques. Global techniques such as GA, PSO are capable of handling multidimensional, discontinuous and nondifferentiable objective functions with many potential local maxima and are largely independent of initial conditions. However, a main drawback is their slow convergence rate (Haupt 1995).

In contrast, for the local techniques such as gradient-based algorithms, the main advantage is that the solution converges rapidly. However, local techniques work well only for a small number of continuous parameters and depend highly on the starting point or initial guess while react poorly to the presence of discontinuities in solution spaces.

In order to bridge the weak points of these two techniques is to apply the design of experiments (DOE) technique, another way for achieving optimization on the target and reduction in variation around the target. DOE is a powerful statistical technique for improving product or process design and solving production problems. A standardized version of the DOE has been introduced by Dr. Genichi Taguchi, an easy to learn and apply technique for design optimization and production problem investigation. Taguchi’s optimization technique can handle multidimensional, discontinuous and nondifferentiable objective functions with many potential local maxima while converges rapidly to the optimum result but within a well defined area.

Applying Taguchi’s approach to optimize the actuation pulse of an ohmic RF MEMS switch allows soft landing (low impact force), without the expense of more switching speed as well as eliminates the bouncing phenomena. The appropriate magnitude of voltages and time intervals of the actuation pulse train are calculated combining a Taguchi’s Optimization algorithm and the module Architect of Coventorware®).

3 Taguchi optimization method

Dr. Genichi Taguchi has developed a method based on orthogonal array (OA) experiments which offers significantly reduced variance for the experiment by setting optimum values to the control parameters. Thus, the combination of DOE with optimization of control parameters is achieved in the Taguchi’s method. Orthogonal arrays are highly fractional orthogonal designs, which provide a set of well balanced (minimum) experiments.

The optimization procedure begins with the problem consideration, which includes the initial conditions, the selection of a proper OA and an appropriate expression of the fitness function (ff). The selection of an OA depends on the number of input parameters and the number of levels for each parameter. The ff is a particular mathematical function and is developed according to the nature of the problem and the optimization goals.

After a simple analysis, the simulation results serve as objective functions for optimization and data analysis and an optimum combination of the parameter values can be obtained. The log functions of the outputs, named by Taguchi as signal-to-noise ratios (S/N), are used for prediction of the optimum result. It can be demonstrated via statistics that although the number of experiments are dramatically reduced, the optimum result obtained through the orthogonal array usage is very close to that obtained from the full factorial approach.

When the Taguchi method is implemented at the design level and the efforts are focused on the optimization of the control values, the experiments can be replaced by simulations.

In order to achieve as high convergence with the goal as possible, successive implementations of the method have to be applied. Under this procedure the optimum results of the last iteration serve as central values for the next, reducing each time with a predefined factor the level-difference of each parameter. The procedure terminates when the level-difference becomes negligible and maximum available accuracy has been reached.

The procedural steps in detail are shown below.

-

1.

Consideration of the problem that must be solved.

-

2.

Extraction of the ff and definition of the optimum goal (minimum, nominal or maximum).

-

3.

Definition of the main parameters and their estimated (center) values

-

4.

Definition of the levels L init for each parameter within ±10% of the center values. In order to describe the non-linear effect so as to gradually minimize each iteration-level’s difference, an odd number of levels must be used for each input parameter.

-

5.

Definition of the maximum resolution of the parameters.

-

6.

DOE using Taguchi’s suggested Orthogonal arrays OAn(mk) in order to minimize the effect of any erroneous assumptions that have been made due to effects considered negligible, which consist of:

-

n rows (number of experiments),

-

k columns (number of parameters) and

-

m levels (on which each parameter will vary).

-

-

7.

Simulation using the module Architect of Coventorware® according to the selected OA.

-

8.

Evaluation of the compliance of the ff for each combination of the levels of parameters based on the simulation results.

-

9.

Computation of the mean value of the fitness functions of the experiment

$$ \overline{Y} = \frac{1}{n}\sum\limits_{i = 1}^{i = n} {Y_{i} } $$ -

10.

Computation of the mean value for each level of each parameter

$$ \overline{Y}_{{m_{i} }} = \frac{m}{n}\sum\limits_{i = 1}^{{i = \frac{n}{m}}} {Y_{{m_{i} }} } $$(Example: For the parameter A when level is 1, add the values of all corresponding ff and compute their mean value)

-

11.

Consideration of the optimum level for each parameter depending on the \( \overline{Y}_{{m_{i} }} \) and the nature of the goal (minimum, nominal or maximum).

-

12.

Prediction of the optimum value of the experiment’s ff, based on the 20·Log10 values of \( \overline{Y} \) and the \( \overline{Y}_{{m_{i} }} \). (The conversion is essential in order to avoid negative values especially at the beginning, when the differences between of \( \overline{Y} \) and \( \overline{Y}_{{m_{i} }} \) are high).

$$ Y_{0(Log)} = \overline{Y}_{(Log)} - (\overline{Y}_{(Log)} - \overline{Y}_{1m(opt(Log))} ) - \cdots (\overline{Y}_{(Log)} - \overline{Y}_{km(opt(Log))} ) $$The predicted value might not be the optimum because the OA is a fractional factorial design, but never the less it shows the direction of the optimization. During the next iterations, as the gap between the mean and optimum predicted value becomes smaller, the possibility that the optimum predicted value to be the real optimum value rises significantly.

-

13.

Definition of the reducing percentage (RP) of the initial deference between the levels of the parameters. The RP depends on the nature of the problem and can be high for simple cases with only one optimum condition or low for more complex situations.

-

14.

Creation of new level differences by multiplying the RP with the initial level of the parameters.

$$ LD_{i} = L_{init} \cdot \left( {1 - RP} \right) $$ -

15.

Creation of new levels for the next iteration by adding the estimated optimum levels of the parameters of the 1th iteration with the LD i .

-

16.

The procedure stops when the LD i . reaches the limits of the allowed resolution of the parameters.

4 Optimizing the actuation pulse

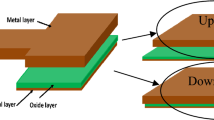

An ohmic all-metal in-line-series RF-MEMS switch is considered for the case study (Spasos et al. 2010). The proposed switch has been designed and evaluated using the software package of Coventorware®. Initially the proposed switch has been designed in 2D using the module Designer under the predefined fabrication process. For dynamic simulations of a multi degree of freedom (MDOF) system like a cantilever, which takes into account various damping effects, a FEM analysis using Rayleigh expressions is necessary to be used. Thus, the model is transferred to module Analyzer where a 3D FEM model is developed to enable accurate prediction of the switch damping coefficients, under specific environmental conditions (temperature, pressure, and gas type). Following that, the switch is designed under the reduced module Architect3D using the same fabrication process. The Rayleigh damping parameters which have been calculated in Analyzer module are transferred on this model and a contact model is established to investigate the adhesion, too. The Architect3D module collaborates with Saber simulator of Synopsis in order to analyze and verify the functionality of the switch in the time and frequency domain.

The procedure followed towards the design of the switch and the optimization of the tailored pulse used for its actuation is described in a few steps, bellow.

-

Initially, a step actuation pulse has been applied to the switch to observe its switching characteristics and verify that there are considerable weaknesses as far as the impact force and the bouncing phenomena are concerned.

-

A tailored pulse has been applied next, instead of the single step pulse, following references from previously published work (Guo et al. 2007; Ou et al. 2008). The performance of the switch got better but there was still plenty of room for further improvement.

-

Finally, Taguchi’s optimization technique has been applied to modify the actuation pulse in order to further improve the behavior of the switch.

During the design and simulation process Coventorware® produces an output file which includes data regarding simulation conditions, design components and power sources. Importing this file to a specially customized algorithm written in C++, the simulation conditions as well as the characteristics of the switch’s actuation pulse can be optimized to achieve performance. This is done because Coventorware® supports the AIMFootnote 1 scripting language, which allows simulation control from external sources. Once the simulation is over, the custom made algorithm evaluates and processes the results written in the output file, running the optimization algorithm based on Taguchi’s method. The optimized actuation pulse parameters are then imported back to the Coventorware® file and the simulation is run again, repeating the same process up to the point the simulation results meet the goals, which have been set at the beginning of the process.

The objective of Taguchi’s algorithm in this case study is the minimization of the ff. According to the nature of the problem two separate optimization procedures have to be realized within two different switching operation phases. The pull down phase (ff p-d ) and the release phase (ff r .)

4.1 Pull down phase

The ff p-d is suitably determined according to the next three conditions.

-

Lowest contact time (highest switching speed)

-

Lowest contact force (lower impact velocity)

-

Existence or non existence of a gap (bouncing) after the first contact up to the end of the time interval.

Thus a weighted ff p-d has been chosen with the form:

Search for time gap between the contact force measurements.

Where t (impact) is the time needed for the first contact to occur and F (max) is the maximum impact force measured during the pull-down phase.

4.2 Release phase

The ff r is suitably determined according to the difference between maximum and minimum cantilever’s displacement, after a predefined time, which includes the pull down time, the switch-on time and the time that the cantilever needs to reach its zero position after the switch-off. Thus, a weighted ff r has been chosen with the form:

where the \( t_{(initial)} > 164\;\mu \text{s} \) includes the pull-down phase time, the hold-down time (ON) and the time that the switch needs to reach its null position (OFF) (These time intervals have been investigated during the step pulse implementation). The weight-factors (105, 106, 107) are used according to the magnitude (in micron) of the factors and factor 10 indicates the penalty that has to be paid in the case of bouncing during the pull down phase, otherwise the ff could be driven to false results.

For practical implementations, the most suitable way for measuring velocity and impact force as well as for revealing discontinuities (bouncing) during the pull-in phase is by measuring the conductance variations. On the other hand the only available way to measure the displacement of the cantilever during the release phase is by measuring the capacitance variations, created in between the contacts and the cantilever.

Taguchi’s method is accurate within a well defined initial area. Thus, taking into account the magnitudes of the tailored actuation pulse of the previous step and considering a ±20% deviation from these predefined values, the initial levels of the parameters for Taguchi optimization can be created, as shown in Tables 1 and 2.

The parameters of the actuation pulse which will be calculated through the optimization process are 5 with 3 initial levels each and are considered for the two actuation phases as following:

Pull down phase (tP).

-

A.

The magnitude of the pull down pulse Vp-d (volts)

-

B.

The ON-state of the pulse tp-on (μs)

-

C.

The fall-time of the pulse tp-f (μs)

-

D.

The OFF-state of the pulse tp-off (μs)

-

E.

The rise-time of the pulse tp-r (μs)

Release phase (tr).

-

A.

The magnitude of the release pulse Vr (volts)

-

B.

The OFF-state of the pulse tr-off (μs)

-

C.

The rise-time of the pulse tr-r (μs)

-

D.

The ON-state of the pulse tr-on (μs)

-

E.

The fall-time of the pulse tr-f (μs)

For an OA with 5 parameters and 3 levels for each parameter a configuration with at least \( n_{rows} = 1 + (k \cdot DOF_{m} ) = 1 + (5 \cdot 2) = 11\;rows \) is needed.

Where DOF m = m − 1 means degrees of freedom and in a statistical analysis is equal with the number of the levels of a parameter minus 1.

Taguchi suggests the solution of the OA18(37, 2) that can handle up to 7 parameters with 3 levels each and one with 2 levels in an array of 18 rows.

For this case 5 columns of the OA18(37,2) have been chosen to assign the five parameters in their 3 levels, thus an OA18(35) has been created, as shown in Table 3.

Taking into account the above considerations the algorithm of Taguchi’s optimization method for the actuation pulse implemented in C++.

5 Results

The optimization procedure graphs shown in Figs. 3 and 4 present the curves of mean and optimum values for the pull down and release phase, as they converged through Taguchi process, respectively. The results for optimum dimensions which extracted through Taguchi Optimization method after 20 iterations (less than 1 h of processing time), for the pull down and release switching phases of the ohmic RF-MEMS switch are illustrated in Table 4.

Continuing with the analysis, the switch is examined under transient conditions in Coventorware Architect environment. Simulations have been carried out using, initially, a step pulse as an actuation pulse, a tailored pulse and finally the optimized pulse, as described in Time-Tables 5, 6 and 7, respectively, and shown in Fig. 5.

The results show great improvement for impact velocity (4.5 cm/s instead of 38 cm/s of the step pulse and 8.5 cm/s of the tailored pulse), which implies true ‘soft landing’ of the cantilever, reducing dramatically the impact force (215 μN instead of 968 μΝ of the step pulse and 303 μΝ of the tailored pulse) as shown in Fig. 6. Meanwhile, the switching speed is kept high (15 μs, same switch-ON time as for the step pulse and faster than the tailored pulse, 16.2 μs) in the pull down phase. Additionally, the bouncing phenomena are practically eliminated (instead of deviation of ±2 μm for the step pulse and ±0.6 μm for the tailored pulse) during the release phase, as presented in Fig. 7. A comparison between the results implementing different actuation pulses are shown in Table 8.

6 Conclusion

A novel open-loop control procedure based on Taguchi’s optimization technique has been presented and implemented to improve the operation, therefore the reliability and longevity of an ohmic RF-MEMS switch. The new technique allows calculation of the time intervals and voltage magnitudes of the actuation pulse train achieving superior switching characteristics. The simulation process, carried out in the module Architect of Coventorware®, presented very low impact force during the pull down phase, elimination of any bouncing phenomena during the pull down and release phases, keeping the on–off switching times the same as for a step actuation pulse.

Notes

AIM is a superset of the Tcl/Tk scripting language developed by John K. Ousterhout at UC Berkeley. AIM is the high-level, embedded scripting language that was developed to control and manage user input, graphing, measurement, symbol creation and other kinds of analyses and processes in Saber applications.

References

Allen M, Field R, Massad J (2008) Input and design optimization under uncertainty to minimize the impact velocity of an electrostatically actuated MEMS switch. J Vib Acoust 130(2):021001–021009. doi:10.1115/1.2827981

Czaplewski D, Dyck C, Sumali H, Massad J, Kuppers J, Reines I, Cowan W, Tigges C (2006) A soft-landing waveform for actuation of a single-pole single-throw ohmic RF-MEMS switch. J Microelectromech Syst 15(6):1586–1594. doi:10.1109/JMEMS.2006.883576

Deligkaris K, Zaharis Z, Kampitaki D, Goudos S, Rekanos I, Spasos M (2009) Thinned planar array design using Boolean PSO with velocity mutation. IEEE Trans Magnetics 45(3):1490–1493. doi:10.1109/TMAG.2009.2012687

Donelli M, Caorsi S, De Natale F, Pastorino M, Massa A (2004) Linear antenna synthesis with a hybrid genetic algorithm. PIER 49:1–22. doi:10.2528/PIER03121301

Guo Z, McGruer N, Adams G (2007) Modeling, simulation and measurement of the dynamic performance of an ohmic contact, electrostatically actuated RF-MEMS switch. J Micromech Microeng 17(9):1899–1909. doi:10.1088/0960-1317/17/9/019

Haupt R (1995) Comparison between genetic and gradient-based optimization algorithms for solving electromagnetic problems. IEEE Trans Magnetics 31(3):1932–1935. doi:10.1109/20.376418

Hyman D, Mehregany M (1999) Contact physics of gold microcontacts for MEMS switches. IEEE Trans Compon Packag Technol 22(3):357–364. doi:10.1109/6144.796533

Karatzidis D, Yioultsis T, Tsiboukis T (2008) Gradient-based adjoint-variable optimization of broadband microstrip antennas with mixed-order prism macroelements. Int J Electron Commun 62(6):401–412. doi:10.1016/j.aeue.2007.05.011

Massad J, Sumali H, Epp D, Dyck C (2005) Modeling, simulation, and testing of the mechanical dynamics of an RF-MEMS switch. In: Proceedings of international conference on MEMS, NANO and smart systems (ICMENS’05) 337–240. doi:ieeecomputersociety.org/10.1109/ICMENS.2005.77

McKillop J (2007) RF-MEMS: ready for prime time. Microwave J 50(2):1–24

Newman H, Ebel J, Judy D, Maciel J (2008) Lifetime measurements on a high-reliability RF-MEMS contact switch. IEEE Microwave Wirel Compon Lett 18(2):100–102. doi:10.1109/LMWC.2007.915037

Ou K-S, Chen K-S, Yang T-S, Lee S-Y (2008) A command shaping approach to enhance the dynamic performance and longevity of contact switches. Elsevier J Mechatronics 19(3):375–389. doi:10.1016/j.mechatronics.2008.09.009

Rebeiz G (2003) RF MEMS: theory, design and technology. Wiley, Hoboken

Spasos M, Charalampidis N, Tsiakmakis K, Nilavalan R (2010) An easy to control all-metal in-ine-series ohmic RF-MEMS switch. Springer Jof Analog integrated circuits and signal processing. doi:10.1007/s10470-010-9573-6

Sumali H, Massad J, Czaplewski D, Dyck C (2006) Waveform design for pulse-and-hold electrostatic actuation in MEMS. Elsevier J Sens Actuat 134(1):213–220. doi:10.1016/j.sna.2006.04.041

Taguchi G, Yokoyama Y (1993) Taguchi methods: design of experiments, quality engineering, vol 4. Amer Supplier Institute, Nasr

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Spasos, M., Tsiakmakis, K., Charalampidis, N. et al. RF-MEMS switch actuation pulse optimization using Taguchi’s method. Microsyst Technol 17, 1351–1359 (2011). https://doi.org/10.1007/s00542-011-1312-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-011-1312-0