Abstract

Considering the influence of carbon emissions trading, the fuzzy stochastic programming model was established to cut back the total cost of carbon trading balance. Modeling this chain is carried out by accounting for carbon cap-and-trade considerations and total cost optimization. In this paper, we analyze the low-carbon integrated forward/reverse logistics network and made relevant simulation tests. The results show that the changes of the confidence level and carbon emission limits have obvious influences on logistics costs. If the emission limit is large, carbon trading mechanism has little effect on the total logistics cost in the same scenario. Therefore, the government needs to use the appropriate emission limits to guide enterprises to reduce carbon emissions, and enterprises can make coping strategies according to the different limit at the same time. Therefore, the fuzzy random programming model proposed in this paper is practical. Its decision making applying the proposed algorithm is reasonable and applicable and could provide decision basis for enterprise managers.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In recent years, due to governmental legislation and protecting natural resources as well as the growing concern of carbon emission, integrated forward/reverse logistics network has come to the forefront of agendas by researchers and business managers [1, 2]. Logistics industry is an important bridge and link between production and consumption. It integrates complex services into various industries, such as transportation, packaging, handling and handling, and forms an important support for other industries. Nowadays, the consumption of fossil energy such as fuel oil and coal is more and more in all operation links of logistics industry in our country, especially in transportation and distribution tools and logistics facilities. As a result, more and more carbon dioxide is generated in all links of logistics, and the carbon emissions of logistics industry remain high. Its research mainly focuses on the theoretical concept, implementation path, qualitative and quantitative theoretical model calculation, application and feedback effect of low-carbon logistics [3]. As far as the low-carbon logistics transportation network is concerned, the current academic research mainly focuses on the optimization of logistics network, and there are few studies on the combination of low-carbon and logistics transportation network. Only a few studies are limited to the study of low-carbon city logistics transport network planning through the government and other macro-level, and do not pay attention to the selection of transport routes by cargo owners.

The essence of low-carbon logistics is to use a small amount of greenhouse gas emissions as far as possible to achieve efficient logistics services. To truly achieve low-carbon logistics, we must solve three aspects: technology, planning and policy. The logistics transportation network under the low-carbon environment discussed here belongs to the second macro-planning level, focusing on the improvement and upgrading of logistics transportation network. Constructing low-carbon logistics transportation network optimization is a necessary process for low-carbon logistics industry to carry out scientific planning and effective allocation of resources [4,5,6]. The first mechanism is reducing carbon emissions by economic incentives for companies. The government can set specific limits on carbon emissions for a company that is known as a carbon cap and form a market of carbon trading. If a company wants to exceed the prescribed limit, it must be able to buy from the company that produces less greenhouse gas or less than the market value.

For the optimization of low-carbon logistics network, it is caused by a series of complex behaviors of coordination and game between different city governments and many logistics companies. In order to get the lowest carbon emission of local logistics distribution, local governments need to plan and set up logistics transportation network from the level of low-carbon development of the whole region, and logistics companies will determine the relevant logistics routes and distribution channels according to the specific situation of the logistics network system and the benefit and efficiency objectives set by enterprises, and at the same time, the allocation of logistics volume in the routes will be carried out at any time [7,8,9]. For management units, in the process of optimizing the route structure of regional low-carbon logistics transportation network, more factors must be considered, including carbon emissions, time and cost and so on. Therefore, in the process of logistics transportation network optimization and planning, it is necessary to create a top-level planning model aiming at the lowest cost mentioned above. For logistics companies, they must make the best choice and determination of their logistics routes at the micro-level and establish the path selection mode with the lowest cost as the bottom planning [10,11,12].

Since low-carbon logistics has just been proposed in recent years, the research of ant colony algorithm for low-carbon logistics optimization is mostly focused on fuel consumption minimization. Most studies use pheromone updating method of parallel ant colony algorithm to improve ant colony algorithm, effectively simulate the parallel strategy of ants in natural environment, and study the parameter settings that affect the performance of basic ant colony algorithm. Empirical results show that the improved scheme achieves more effective results. Low-carbon logistics should consider not only the objective of optimizing logistics distribution system, reducing logistics transportation cost, improving distribution efficiency and improving cargo turnover, but also how to make rational and effective use of resources and reduce carbon emissions in logistics operations. Low-carbon logistics is realized through advanced application technologies such as energy renewable technology, energy efficiency technology, low-carbon technology and green house gas emission reduction. Low-carbon logistics needs not only liquid forklift truck, green transport vehicle and other logistics equipment, but also advanced and applicable software, operation process, operation standards and operation methods. All of these require continuous innovation, otherwise low-carbon logistics will be difficult to achieve. This paper presents a fuzzy stochastic design of low-carbon forward and backward integrated logistics network (IFRLN). In the last part of paper, numerical tests show the accuracy and efficiency of the proposed algorithm and using a test to study the model under the change of carbon emission limit and confidence level.

The rest of this article is as follows. In Sect. 2, we made the literature review of relative research and the problem description for the IFRLN is given in Sect. 3. Then, Sect. 4 gives the mathematical description for an integrated forward/reverse logistics network model. In Sect. 5, a GA-pw with frs is designed to solve the model. In Sect. 6, the results show the local search proposed in this paper is useful for improving the accuracy of the objective value. From the above analyses, the GA-pw with frs proposed in this paper has certain accuracy. In Sect. 7, we made the conclusion.

2 Literature review

2.1 Logistics network and carbon cap-and-trade

Logistics industry is an important link between production and consumption. However, logistics development mode is relatively extensive. Economic growth and expansion of logistics scale are always accompanied by serious energy consumption and environmental pollution. In order to realize emission reduction, the logistics industry must change its development mode and implement low-carbon transportation. Penkuhn et al. [13] argued that low-carbon logistics reduces CO2 emissions in logistics industry through various modern new low-carbon technologies or business management modes. With the goal of lower energy consumption, lower environmental pollution and lower carbon dioxide emissions, various renewable emission reduction technologies are used to reduce carbon dioxide emissions in logistics operations, thereby reducing the impact of logistics on the ecological environment [14]. According to the characteristics of low-carbon logistics, some scholars analyzed the influencing factors and put forward corresponding countermeasures and suggestions [15]. Wong et al. [16] expounded the main driving factors of carbon footprint management in logistics industry from three aspects: CO2 emission control, carbon dioxide emission reduction requirements of logistics industry and supply chain services.

Chen [17] explored the relationship between transport cost and carbon dioxide in the multimodal transport portfolio. The mode and route choice of intermodal transport of goods changed with the change of trading conditions. It was clear that the main factors affecting carbon dioxide emissions were the demand and capacity of the transport system. Zhang et al. [18] used the network equilibrium theory, a three-tier logistics network including producers, distributors and retailers is constructed, and a simulation carbon emission network with the intensity of CO2 emission as the network flow was constructed for the non-tiered decision makers. Low-carbon logistics is different from general logistics, which only aims at pursuing its own economic interests. Low-carbon logistics also takes into account the interests of consumers, society and the ecological environment. These four objectives are mutually conflicting and restrictive in the implementation process. To reduce the carbon emissions of logistics activities, some logistics costs will be brought in the initial stage. Low-carbon logistics should achieve a certain balance among these objectives, take into account the coordinated development of economy and ecology, and organically integrate economy, consumers, society and ecological environment [19,20,21]. The bi-directionality of low-carbon logistics refers to the realization of both low-carbon forward logistics and low-carbon reverse logistics in logistics activities [22, 23]. The low carbonization of forward logistics refers to the low carbonization of all activities in the process of realizing ‘production–circulation–consumption’ of commodities. Reverse logistics is a variety of derivatives generated in the process of forward logistics. Reasonable treatment of these derivatives can achieve low carbonization, such as recovery, sorting, purification, packaging and reprocessing.

There are many methods to calculate carbon emissions, among which measurement, material measurement, model analysis and carbon emission coefficient method are the main methods. Among the existing methods used to study carbon emission measurement in logistics industry, carbon emission coefficient method is the most common one. Based on the carbon emission calculation method provided by IPCC in the ‘2006 Carbon Emission Computing Guidelines,’ the carbon emission coefficients of various energy sources are calculated, and the carbon content and carbon emission coefficients of various fuels are listed. The carbon emission coefficients of various energies can be found directly in the IPCC work report, so the carbon emission coefficient method is widely used [24].

Under the trend of low-carbon logistics development, there are inevitable and various problems in low-carbon transformation of logistics enterprises. By reviewing the literature, we can see that the research direction can be divided into external and internal problems of logistics enterprises, such as imperfect low-carbon policies and regulations, immature public awareness, low-carbon awareness of business managers and advanced low-carbon management methods. [25]. Logistics enterprises can only integrate internal and external resources for low-carbon development capacity, turn the problems encountered into power, and comprehensively promote the low-carbon transformation of enterprises. Low-carbon logistics requires ‘low-carbon’ operation in the whole logistics system [26].

Only by paying attention to the interconnection, interconnection, interdependence and mutual restriction of all links within the logistics system and implementing global coordination planning, can the effect of low-carbon logistics be really brought into play. Low-carbon logistics is different from general logistics, which only aims at pursuing its own economic interests. Low-carbon logistics also takes into account the interests of consumers, society and the ecological environment. The four objectives are mutually conflicting and restrictive in the implementation process. To reduce the carbon emissions of logistics activities, some logistics costs will be brought in the initial stage. Low-carbon logistics should achieve a certain balance among these objectives, take into account the coordinated development of economy and ecology, and organically integrate economy, consumers, society and ecological environment [27,28,29]. Chang et al. [28] measured the total factor energy efficiency of China’s logistics industry using DEA model and examined the impact of four factors, namely institutional factors, human capital factors, infrastructure level and regional economic development level, on the total factor energy efficiency of logistics industry.

Benjaafar et al. [30] analyzed structural factor decomposition method based on input–output model is used to analyze the intensity of carbon emissions, and the efficiency indicators for minimizing carbon emissions pollution under given input factors and output levels in the production process are solved. When evaluating the development level of low-carbon logistics in the existing literature, the starting point of selecting the influencing factors is often different. The selection of indicators lacks sufficient theoretical support and does not form a complete and comprehensive influencing factor system. The construction of the index system is often lack of systematicness and depth. The research object of carbon emissions in China’s logistics industry will be more transferred to micro-subjects, the data of logistics industry will be more accurate, the research methods need using quantitative analysis of modeling, and the low-carbon practice of China’s logistics industry will also be greatly improved.

2.2 Uncertainty in logistics network

The uncertainties of logistics network mostly arise in the process of collecting goods, transporting between nodes and remanufacturing. Logistics process includes storage, transportation, remanufacturing and other activities, which are generally not completed by a single enterprise, and need the cooperation of enterprises and third-party enterprises to complete [31]. But because different companies have great differences in management level, informatization level and employee quality, many problems often arise, such as deterioration of product storage, accidental damage in transportation process, change of transportation time, inconsistency of circulation process and adjustment of production plan, which will seriously damage the accuracy of time and quantity of product operation process [32,33,34].

Random phenomena, fuzzy phenomena and rough phenomena are the three most basic uncertain phenomena in the study of uncertainty theory. Stochastic phenomenon is also called contingency, which means although there are many uncertain variables in the optimization problem, its probability distribution can be obtained from a large number of historical data. Fuzzy phenomenon, also known as non-clarity, is aimed at those who cannot obtain detailed historical data, and can only be analyzed by giving the fuzzy membership function of uncertain factors based on some available data or expert opinions. Rough phenomenon, also known as indiscernibility, can neither get its probability distribution through a large number of historical data, nor give the fuzzy membership function [35,36,37].

Aiming at these uncertain phenomena, we often need the assistance of relevant mathematical theories. Random phenomena can be described by probability distribution function of value in [0,1] interval using probability and statistics theory as an auxiliary tool. However, the application of probability theory needs a lot of historical data. Rough phenomena can be analyzed by rough set theory as an assistant tool [38]. Because there are many optimization problems to be solved in many research fields such as decision science, system science, computer science and industrial engineering, it is unrealistic to use deterministic models to describe uncertain optimization problems, or there will be large errors. Uncertain programming method can deal with the optimization of reverse logistics in uncertain environment. The model can transform uncertain optimization problems into deterministic optimization problems by using the transformation method of expected values instead of directly using uncertain parameters. Chance-constrained programming is mainly a method to obtain optimal values under certain probabilistic conditions. The main object of this theory is to solve the uncertain parameters in the constraints. At the same time, it may not fully satisfy the constraints, but it should be established at a certain level of confidence. For practical application scenarios, the theory can transform some uncertainties into equivalent deterministic mathematical programming problems, but if the problems are more complex, the simulation-based genetic algorithm is used to calculate them.

2.3 Solving the problem of the logistics network

Genetic algorithm is an intelligent algorithm, which is generally used to solve the main method of VRP [39]. Genetic algorithm simulates Darwin’s theory of natural evolution and genetic variation. It has wide application value [40]. The scientific layout of logistics nodes is an important prerequisite for the operation of reverse logistics network. The number and location of nodes to be selected will affect the operation efficiency of the whole logistics network. The company cannot increase the node density indefinitely, which will inevitably increase the operation cost, and cannot excessively reduce the number of nodes, which will easily lead to the operation efficiency of reverse logistics network: slow down, slow response and even information distortion [41,42,43].

At the same time, the regional location of nodes can not only consider the distribution of consumer markets and recycling areas, but also the degree of transportation convenience and land availability in the region. Logistics path planning in network is closely related to the scientific layout of nodes and the rational allocation of node size. Node layout and size allocation have a very important impact on the volume, type and distance of transportation between network nodes, thus causing changes in product transportation routes [44]. Because the transportation cost of logistics network can be greatly reduced by planning transportation routes scientifically, and the transportation cost between nodes occupies a high proportion in the total logistics cost, and thus, the total cost can be optimized [45, 46]. Similarly considering fuzzy random variables, Chakraborty et al. [47] transformed models into deterministic nonlinear programming models using chance constraint operator in supply chain design problem. But the method of dealing with fuzzy random variables in [46, 47] is not completely appropriate to show the essence of fuzzy random theory, the fuzzy random simulation [48] method is more consistent with fuzzy random theory.

This paper introduces carbon emissions into the design and planning stage of reverse supply chain network, and changes the environmental benefits of supply chain network from traditional qualitative evaluation to quantitative measurement. Aiming at uncertain environment, the mixed integer programming with minimization of cost as objective function is established. Meanwhile, the chance-constrained method is used to deform the model. Secondly, the hybrid genetic algorithm is mainly used to solve the model. As shown in Tables 1 and 2, total carbon emissions and stochastic fuzzy stochastic are the focus of current research. Some scholars focus on the optimization of reverse logistics network design by combining some waste products and specific environment. The main modeling method is mixed integer linear programming, and the hybrid intelligent algorithm is chosen in the solution stage. However, most scholars do not take into account the uncertainty factors of reverse logistics network when they build the model, which may lead to discrepancies between the model and the actual situation, and it is difficult to ensure the robustness of the network.

3 Proposed method for improved model

3.1 Fuzzy random variables

In reality, it is impossible for every goal to reach the expectation level of the decision maker. The decision closest to the expectation level is often regarded as the best decision making. The uncertainty of market demand for product J increases the difficulty of decision making. The emergence of fuzzy theory can solve this kind of problem. The model shows that under the condition of fuzzy and stochastic demand, the fuzzy profit of all parties in the supply chain can be maximized to the maximum extent possible.

At the optimal level of expectations of all decision makers, the total profit in the supply chain can be maximized. In practical decision making, the satisfaction of each objective function depends on the satisfaction of the decision maker. For simplicity, the minimum expected profit deviation for each product is 0, and the probability space is \(\left\{ {\varOmega ,A,\Pr } \right\}\) where

\(\tilde{\bar{d}}(\omega )\) is clearly a fuzzy random variable. Random phenomena, fuzzy phenomena and rough phenomena are the three most basic uncertain phenomena in the study of uncertainty theory. Stochastic phenomenon is also called contingency, which means that although there are many uncertain variables in the optimization problem, its probability distribution can be obtained from a large number of historical data.

3.2 Carbon cap-and-trade

Low-carbon policies aimed at reducing carbon emissions can not only solve the problems of market failure existing in pure market mechanism to a certain extent, but also further promote the development and structural optimization of logistics industry to get win–win economic and environmental benefits. Countries and regions aim to adapt to the trend of low-carbon economy, improve the ecological environment, formulate a series of national macro-control low-carbon policies, and create a low-carbon development environment for the whole society. Most developing countries are in the mid-stage of industrialization. Many negative environmental impacts brought about by social development have destroyed the ecological environment. The logistics industry, one of the pillar industries in the national economy, has formed an inverted mechanism. Facing the environment of low-carbon development, logistics industry inevitably faces challenges brought by new requirements, but new requirements also bring new opportunities.

In order to simplify the mathematical model, the amount of CO2 is regarded as index for amount of greenhouse gas. Major sources of CO2 emissions from the network are as follows: (1) the discharge of the energy consumed during the operation of each center, namely the carbon emission from the operation process of the facility. These carbon emissions are mainly generated by electricity consumption, fuel consumption and heat consumption. This paper only considers the carbon emissions generated by electricity consumption. (2) The amount of energy consumed by each center during the transportation process, namely the carbon emission of the transport process. Because of the difference of weight [18], transport distance [24], road slope and road congestion and other factors, the carbon emissions produced from consumption of fuel are different, and this paper only considers the weight of cargo load and the distance of transportation.

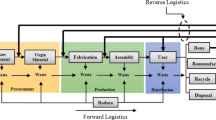

3.3 Forward/reverse logistics network

The network is connected by points and lines. Points represent all kinds of operation functions. Lines connect the supply and demand sides of each other. The number of network links, the number of node enterprises and the material flow among various nodes not only affect the operation cost of the network, but also produce different carbon emissions. The significance or value of network optimization design lies in optimizing all kinds of alternative points and job flows according to the constraints of construction. Different network concentration and hierarchy will result in different input of fixed facilities, various derivative consumption, and the number and types of operations, which will eventually lead to complex and diverse network layout. The carbon emission of reverse logistics network is mainly generated in the process of transportation and node treatment. Reasonable network layout structure can ensure the optimal path planning, which can reduce the waste of transportation resources, maximize the allocation of resources, and ensure that the carbon emissions in the transportation process can be reduced as much as possible to achieve the purpose of environmental protection.

Recycling is not only the beginning of reverse network, but also the link most affected by uncertainties in reverse operation. Compared with other operation links, the technical difficulty and operation type of recycling are relatively simple. Its main cost and carbon emissions are generated in the recycling and transportation of waste products. Frequency, efficiency, distance, speed and fuel consumption of transportation operations will affect carbon emissions and operating costs in the process of collecting goods. It is necessary to scientifically predict the quantity of waste products in order to rationalize the allocation of resources. The logistics network presented in this paper is shown in Fig. 1.

Within a single economy, there is a significant inverse relationship between economic benefits and environmental benefits: The acquisition of environmental benefits will reduce the economic benefits of enterprises and increase additional costs. In order to reduce costs, enterprises will invest expenditures for environmental benefits into the production of products or services to increase production, thereby improving their own benefits. In the absence of carbon constraints, economies form network alliances with the goal of maximizing returns. Benefits or costs are the only indicators of partnership selection. Cost–benefit is no longer the only planning index in planning and constructing reverse logistics network with carbon emission constraints. Environmental performance of network operation and emission reduction capability of enterprises will be considered as new standards. The network will achieve a win–win result between economy and environment. The factors affecting carbon emissions in the treatment process mainly include the reusability of incoming materials and the differences in the ways of reprocessing. According to the research of remanufacturing practice, the economic and environmental performance of recycling operation is significantly higher than that of recycling operation. Therefore, under the premise of cost-paying economy, the proportion of recycling should be increased as far as possible according to the current technology level.

4 Modeling

4.1 Symbol descriptions

Logistics network optimization is to realize the needs of enterprise logistics development and reduce the logistics cost of the system as the primary objective, to ensure the scientific layout of logistics network nodes and the rational planning of transportation routes. The scientific layout of logistics nodes is an important prerequisite for the operation of reverse logistics network. The number and location of nodes to be selected will affect the operation efficiency of the whole logistics network. The company cannot increase the node density indefinitely, which will inevitably increase the operation cost, and cannot excessively reduce the number of nodes, which will easily lead to the operation efficiency of reverse logistics network: slow down, slow response and even information distortion. At the same time, the regional location of nodes can not only consider the distribution of consumer markets and recycling areas, but also the degree of transportation convenience and land availability in the region.

4.2 Objective functions

Global warming is a serious environmental problem facing the international community today, and greenhouse gas emissions is mainly caused by human activities. Logistics industry is one of the main sources of carbon emissions in China. Developing low-carbon logistics not only helps to improve the efficiency of carbon emission reduction in China as a whole, but also has important significance for achieving the goal of sustainable development. Logistics industry is an important link between production and consumption. Economic growth and expansion of logistics scale are always accompanied by serious energy consumption and environmental pollution. The logistics industry must change its development mode and implement low carbon to realize emission reduction. We mainly consider the two factors, which are the actual loading capacity [18] and the transportation distance [24], and think that the carbon emission is proportional to the distance of transportation. If the vehicle needs to start, it will generate fixed energy consumption. Therefore, it is assumed that the carbon emission is proportional to the number of vehicles. In general, when the amount of transportation is less or equal to the vehicle capacity (\(vc\)), a vehicle can complete the transportation. When the transport is larger than a vehicle capacity (\(vc\)), it will need more car. Former \(r - 1\) car is loaded, the \(r{\text{th}}\) loading car for transportation and loading capacity of the remainder of the total. The carbon emissions from facility include the facility’s fixed carbon emission and the emission for treatment of products. Thus, the total carbon dioxide emission is as follows:

Logistics path planning in network is closely related to the scientific layout of nodes and the rational allocation of node size. Node layout and size allocation have a very important impact on the transport volume, type and distance between network nodes, thus causing changes in product transport routes, because the transportation cost of logistics network can be greatly reduced by planning transportation routes scientifically, and the transportation cost between nodes occupies a high proportion in the total logistics cost, and thus, the total cost can be optimized. The objective function is as follows:

4.3 Constraint

Carbon emission cost of logistics network is the minimum goal. Carbon emission in logistics network is mainly composed of carbon emissions generated during transportation and operation. According to the different carbon emission, cost, time and other factors of logistics distribution channels, a scientific and effective regional low-carbon logistics transportation network system with different modes and coordinated cooperation is established, which focuses on the competition coordination and burden of commodities in the turnover of relevant logistics transportation channels in the region. The goal of creating the top layer is to minimize carbon emissions, time and cost. Because of the complexity of the solution, genetic algorithm is mainly used to solve the problem. The advantage of this method is that the best solution can be obtained more quickly, so that the direction for the establishment of low-carbon logistics transportation network and scientific planning is clear.

5 GA based on priority and weight with frs

In this section, a genetic algorithm based on priority and weight with a fuzzy random simulation (GA-pw with frs), for the optimization of low-carbon logistics network, is caused by a series of complex behaviors of coordination and game between different city governments and many logistics companies. For achieving the lowest carbon emission of local logistics distribution, local governments need to plan and set up logistics transportation network from the level of low-carbon development of the whole region, and logistics companies will determine the relevant logistics routes and distribution channels according to the specific situation of the logistics network system and the benefit and efficiency objectives set by enterprises, and at the same time, the allocation of logistics volume in the routes will be carried out at any time. For management units, in the process of optimizing the route structure of regional low-carbon logistics transportation network, more factors must be considered, including carbon emissions, time, cost and so on. Therefore, in the process of logistics transportation network optimization and planning, it is necessary to create a top-level planning model aiming at the lowest cost mentioned above. For logistics companies, they must make the best choice and determination of their logistics routes at the micro-level and establish the path selection mode with the lowest cost as the bottom planning.

5.1 GA-based fuzzy random simulation

Genetic algorithm is essentially a direct search method independent of specific problems. At present, the existing research schemes for optimal control rules are basically divided into two categories Within the scope of a certain number of fuzzy rules, the more rules, the better the performance, but if the number of rules is too large, the longer the running time of the experiment, the more resources will be spent. In this paper, we refer to the processing method of Ref. [48] and construct a fuzzy stochastic constraint model. The objective function with fuzzy variables can be used in the logistics network model under uncertain environment. By defuzzification, the uncertain fuzzy programming model can be transformed into a definite fuzzy model, and then, the model can be solved.

The proposed pessimistic method is shown as below.

For the update of the shipping cost, this paper set up a method, which is shown in Algorithm 2.

Reverse logistics network model under fuzzy environment is a typical NP problem, which cannot be solved directly. Aiming at this kind of NP-hard problem, intelligent methods are generally adopted. Because genetic algorithm has the advantages of stable performance, high computational efficiency and strong search ability, this paper uses genetic algorithm as a model solving tool. The genetic algorithm can infer the set of advantages that the expected performance of the next generation will improve according to historical information. Generations of genetic evolution will eventually converge to an individual that is best suited to the environment, and then, the optimal solution can be obtained. [48].

Logistics path planning in network is closely related to the scientific layout of nodes and the rational allocation of node size. Node layout and size allocation have a very important impact on the transport volume, type and distance between network nodes, thus causing changes in product transport routes, because the transportation cost of logistics network can be greatly reduced by planning transportation routes scientifically, and the transportation cost between nodes occupies a high proportion in the total logistics cost, and thus, the total cost can be optimized. The objective function with fuzzy variables can be used in the logistics network model under uncertain environment. By defuzzification, the uncertain fuzzy programming model can be transformed into a definite fuzzy programming model, and then, the model can be solved.

For the update of the demand, this paper set up a method, which is shown in Algorithm 4.

5.2 GA-based initializing method

The decoding algorithm of the decoding based on priority and weight is presented below.

- (1)

Algorithm 5: decoding based on priority and weight

Table 3 represents a priority and weight of transportation tree with 3 sources and 4 depots (weight are inside of the parentheses, whose initial value and range of values are 1 and [0,1], respectively). Low-carbon policies aimed at reducing carbon emissions can not only solve the problems of market failure existing in pure market mechanism to a certain extent, but also further promote the development and structural optimization of logistics industry. Table 4 shows the logistics network model chromosome (Table 5).

(2) Algorithm 6: IFRLN decoding algorithm

Input:\(\tilde{\bar{d}}_{k}\),\(r_{k}\),\(s\),\(caw_{i}\),\(cay_{j}\),\(caz_{l}\),\(cav_{m}\),\(car_{i}\) |

|---|

Output: \(X_{ij}\),\(U_{jk}\),\(Q_{kl}\),\(T_{lm}\),\(P_{li}\) |

Step 1: calculate \(U_{jk}\) using Algorithm 5 |

Step 2: calculate \(X_{ij}\) using Algorithm 5 |

Step 3: calculate \(Q_{kl}\) using Algorithm 5 |

Step 4: calculate \(T_{lm}\) using Algorithm 5 |

Step 5: calculate \(P_{li}\) using Algorithm 5 |

5.3 GA-based operators

Fitness: The fitness is the reciprocal of the objective function value, that is, fitness = 1/individual objective function value. The optimal operation strategy and roulette selection method are adopted in the selection operation.

Genetic algorithm is a computational method to simulate the evolutionary process of organisms. It is a new computational method formed by the combination and infiltration of natural genetics and computer science. Heredity is a phenomenon in which organisms inherit characteristics and shapes from their parents. Inheritance information is carried by genes, and multiple genomes form chromosomes. Locations of genes in chromosomes are loci. All genes in the same locus are alleles. Alleles and loci determine the characteristics of chromosomes and individuals. In terms of chromosome expression, there are two corresponding expression modes, genotype and phenotype. Phenotype refers to the shape of an individual, while genotype refers to the composition of genes closely related to expression. Individuals of the same genotype have different phenotypes under different environmental conditions.

The characteristic of genetic algorithm is that it can search from the number set of problems, not just from a single solution. These genetic algorithms are quite different from the traditional ones. The traditional optimization algorithm solves the optimal solution from the initial value of a single solution, but it is easy to get into the local misunderstanding. Starting from the number set, genetic algorithm can ensure a wide range of searches and is conducive to global optimization. Table 6 represents insert mutation.

Genetic operation is a very important part of genetic algorithm. It transfers genetic material to the next generation through selection, crossover and mutation operators and generates new genes through mutation, so that the population gradually approaches the optimal solution. Selection operators usually use roulette to select chromosomes from new populations. The probability that each chromosome can be selected and inherited to the next generation is positively correlated with the fitness of the chromosome. The mutation operation is to randomly change one or more chromosome genes in a population.

5.4 Dynamic local search

The scientific layout of logistics nodes is an important prerequisite for the operation of reverse logistics network. The number and location of nodes to be selected will affect the operation efficiency of the whole logistics network. The company cannot increase the node density indefinitely, which will inevitably increase the operation cost, and cannot excessively reduce the number of nodes, which will easily lead to the operation efficiency of reverse logistics network. The performance of search algorithm depends largely on the quality of initial solution. A good initial solution can speed up the calculation and improve the quality of the solution. In this paper, we choose 2 method as 3-opt (Table 7) and RPA (random probability assignment method as Table 8). The detailed dynamic local search program is shown in Algorithm 7 (Table 9).

6 Computational experiments

6.1 Algorithm evaluation

In logistics distribution, once there are many alternative paths, the conflict between the attributes will lead to the instability of the optimal path solution calculated according to the attributes. For testing the performance of the proposed algorithm, a test example is designed at first, and then, for different experimental purposes, the solution is tested separately. Starting from the number set, genetic algorithm can ensure a wide range of searches and is conducive to global optimization. In genetic algorithm, chromosomes correspond to a series of symbolic sequences. In standard genetic algorithm (i.e., basic genetic algorithm), the number of 0,1 is usually used to represent the number of loci corresponding to each location, and the value of each location corresponds to alleles. Genetic algorithms deal with chromosomes, which are called gene individuals. A certain number of gene individuals constitute a gene population. The number of individuals in a population is the size of the population, and the degree of adaptation of individuals to the environment is called fitness.

The size of test problems is shown in Table 10 and parameter range of test problems is shown in Table 11, running 30 times for each problem. The results were compared with CMGA proposed by Chakraborty et al. [47] and a simple GA without a local search (SGA). In these experiments, there is no local search in the SGA and Pc = 0.7, Pm = 0.15, and Capco is 50,000,000. These experiments using MATLAB 7.0 were all done by a laptop with Intel (R) Core (TM) i5 processor 2.53 GHz, 4.0G RAM.

In Table 11, we can see that although the running time of GA-pw with frs is longer than the time of CMGA and the time of SGA for the 4 test problem, the objective function value of GA-pw with frs to obtain is smaller than the other two algorithms. In contrast to SGA and GA-pw with frs, the running time of simple without a local search is less than that of GA-pw with frs, indicating that local search takes a lot of time to search for. But for the 4 test problem, the objective function value of SGA is bigger than that of CMGA and GA-pw with frs, which shows that in the absence of local search, CMGA is more effective than GA-pw with frs. In other words, it can be seen from the side that the local search proposed in this paper contribute greatly to helping the algorithm to search the optimization value. In summary, although the running time of GA-pw with frs is long, the result is good, so the GA-pw with frs proposed in this paper is effective.

Compared to GA-pw with frs with CMGA and SGA in Table 11, the error rate of CMGA and SGA with the size of the test problem is larger and larger, indicating that the GA-pw with frs is more accurate and more suitable for solving large-scale problems. Compared CMGA with SGA, the error rate of CMGA is smaller than that of SGA. It indicates that CMGA is more accurate than GA-pw with frs in the absence of local search. It also can be seen from the side that the local search proposed in this paper is useful for improving the accuracy of the objective value. From the above analyses, the GA-pw with frs proposed in this paper has certain accuracy.

Figure 2 represents the iterative process of GA-pw with frs, and Fig. 3 represents the iterative process of GA-pw with frs, CMGA and SGA. Starting from the number set, genetic algorithm can ensure a wide range of searches and is conducive to global optimization. In the real word, the logistics enterprises often need to solve the problem of large-scale transportation route arrangement, and hope to get a better transportation plan as far as possible in order to decreasing the logistics cost. In this paper, the GA-pw with frs can get a better solution in a reasonable time, which means that the algorithm has some practical significance. Therefore, from this analysis and comparison, it can be seen that the performance of GA-pw with frs is better than both CMGA and the SGA.

By using the simulation test, it is proved that the performance of the GA-pw with frs is better than CMGA and SGA, and the algorithm is effective. It shows that the level of confidence will affect the trend and magnitude of logistics cost’s change. From the above analysis, it can be seen that the change of the external uncertainty has an impact on the logistics cost. Therefore, the enterprise decision makers should grasp the confidence level, i.e., to grasp the reality of the environment and changes in the market, to reduce logistics costs.

6.2 Result analysis

We use the test 1 to study the model under the change of confidence level and carbon emission quota. Specific data are as follows:

- (1)

Consumer areas: The coordinates are K2(34, 93), K4(98, 159), K6(125, 224), K8(109, 62), K10(203, 179), K11(289, 156), K13(335, 122), K15(393, 214), K17(450, 106), K19(499, 113). Recovery rates were 0.75, 0.86, 0.83, 0.76, 0.79, 0.87, 0.75, 0.8, 0.75, 0.83.

- (2)

Distribution centers: The coordinates are J2(55, 168), J5(190, 132), J6(301, 76), J9(428, 194), J10(497, 83). The fixed costs are 200000, 250,000, 300,000, 200000, 250000. Unit product processing cost is 30. The capacities are 900, 1000, 1100, 900, 1000. The fixed carbon emissions are 82000, 85000, 88000, 82000, 85000.

- (3)

Recycling/inspection centers: The coordinates are L1(54, 128), L8(443, 183), L9(146, 151), L10(375, 125). The fixed costs are 250,000, 300,000, 350,000, 400,000. Unit product processing cost is 100. The capacities are 800, 900, 1000, 1100. The fixed carbon emissions are 820,000, 830,000, 840,000, 850,000.

- (4)

Production/recovery centers: The coordinates are I1(73, 151), I3(420, 138), I5(259, 157). The fixed costs are 450,000, 550,000, 650,000. Unit product processing cost is 250. For forward logistics, the capacities are 1000, 1300, 1600. For reverse logistics, the capacities are 300, 600, 900. The fixed carbon emissions are 2,300,000, 2,500,000, 2,700,000.

- (5)

Disposal centers: The coordinates are M1(102, 190), M3(283, 135), M4(486, 137). Average processing rate is 0.2. The fixed costs are 250,000, 350,000, 400,000. Unit product processing cost is 20, and the capacities are 500, 600, 700. The amount of fixed carbon emission is 820,000, 850,000, 880,000.

Vehicle capacity is 5, CO2 emission coefficient for processing unit product in production/recovery center and distribution center, collection/inspection center and disposal center is, respectively, 975, 350, 760 and 530 g/unit product, and some data are shown in Tables 12, 13, 14, 15, 16, 17.

There are four scenes, namely scene 1 (\(\alpha_{1} = \alpha_{2} = 0.98\), \(\beta_{1} = \beta_{2} = 0.8\)), scene 2 (\(\alpha_{1} = \alpha_{2} = 0.78\),\(\beta_{1} = \beta_{2} = 0.6\)), scene 3 (\(\alpha_{1} = \alpha_{2} = 0.68\),\(\beta_{1} = \beta_{2} = 0.5\)) and scene 4 (\(\alpha_{1} = \alpha_{2} = 0.48\),\(\beta_{1} = \beta_{2} = 0.3\)), respectively. The value of Capco is 45,000,000, 46,000,000, 47,000,000, 48,000,000, 49,000,000, 50,000,000, 51,000,000, 52,000,000, 53,000,000, 54,000,000 and 55,000,000. Table 18 is obtained by using GA-pw with frs, and according to Table 18, Fig. 4 is drawn.

As is shown in Fig. 4, logistics costs of the scene 1–4 decrease gradually in the same amount of carbon emissions; this is because the decline with the confidence level \(\alpha_{1}\), \(\alpha_{2}\), \(\beta_{1}\) and \(\beta_{2}\), the demand and unit transportation cost is reduced, thereby reducing logistics costs, indicating that the level of confidence affects the change of logistics cost. For each carbon emissions quota, logistics costs change trend of scene 1 and scene 2 is not significant, similarly, logistics costs change trend of scene3 and scene 4 is not significant, but after the amount of carbon emission exceed 49,000,000, logistics costs change trend of scene 1 and scene 2 is quite different, and the magnitude of the difference in logistics cost’s change becomes larger. It shows that the level of confidence will affect the trend and magnitude of logistics cost’s change. From the above analysis, it can be seen that the change of the external uncertainty has an impact on the logistics cost. Therefore, the enterprise decision makers should grasp the confidence level, i.e., to grasp the reality of the environment and changes in the market, to reduce logistics costs.

By looking at Fig. 4, in scene 1 and 2, the logistics costs decease with the increase in the carbon emission amount gradually when the amount of carbon emission is from 44,000,000 to 48,000,000. However, there is a turning point when the amount of carbon emission is between 48,000,000 and 50,000,000. After that point, the costs stay stable. Similarly, in scene 3 and 4, the logistics costs decease with the increase in the carbon emission amount gradually when the amount of carbon emission is from 44,000,000 to 49,000,000. However, there is a turning point when the amount of carbon emission is between 49,000,000 and 51,000,000. After that point, the costs stay stable. These show that in the same scenario, if emission limit is large enough, carbon trading mechanism has a little effect on the total logistics cost, so the appropriate emission limits are used to guide enterprises to reduce carbon emissions, and enterprises can make coping strategies according to the different limit at the same time.

In conclusion, the changes of the confidence level and carbon emission limits have obvious influences on logistics costs. Managers need to consider the future development of the enterprise, to analyze correctly changes of the environment and market as well as carbon emission limits, in order to get a reasonable and practical strategy. Therefore, the fuzzy random programming model proposed in this paper is practical. Its decision making applying the proposed algorithm is reasonable and applicable and provides decision basis for enterprise managers.

7 Conclusions

In this article, IFRLN was studied as an ever important problem in the contemporary world. Considering the influence of carbon emissions trading, the fuzzy stochastic programming model was established for some parameters which are fuzzy random variables. Most developing countries are in the mid-stage of industrialization. Many negative environmental impacts brought about by social development have destroyed the ecological environment. Countries and regions aim to adapt to the trend of low-carbon economy, improve the ecological environment, formulate a series of national macro-control low-carbon policies. We first proposed GA structure to solve the NP-hard problem. Then, an initialization method (a decoding based on priority and weight) and two fuzzy random simulation was employed. Finally, in order to improve the effectiveness of GA, the dynamic local search mechanism is used to help to search for the objective value.

By using the simulation test, it is proved that the performance of the GA-pw with frs is better than CMGA and SGA, and the algorithm is effective. It shows that the level of confidence will affect the trend and magnitude of logistics cost’s change. From the above analysis, it can be seen that the change of the external uncertainty has an impact on the logistics cost. Therefore, the enterprise decision makers should grasp the confidence level, i.e., to grasp the reality of the environment and changes in the market, to reduce logistics costs. The model is studied by test problems under the change of the confidence levels and carbon emissions limits, which has proved the rationality and applicability of the network. Model’s decision making applying the proposed algorithm provides a reference for enterprise decision makers and it is of great significance. These properties and characteristics of genetic algorithm have been analyzed and discussed by relevant researchers in various countries and have been widely used. Great achievements have been made in combinatorial optimization, learning, signal reception and processing, artificial intelligence, artificial life and adaptive control.

References

IPCC (2007) The physical science basis. Contribution of working group I to the fourth assessment report of the Intergovernmental Panel on Climate Change. Cambridge University Press, Cambridge

Carbon, Trust (2006) Carbon Footprint in the supply chain: the next step for business. Report No. CTC616, Carbon Trust London

Daskin MS, Benjaafar S (2010) National science foundation symposium on low carbon supply chain final. NSF Symposium report, USA

Guo J, Wang X, Fan S et al (2017) Forward and reverse logistics network and route planning under the environment of low-carbon emissions: a case study of shanghai fresh food E-commerce enterprises. Comput Ind Eng 106(C):351–360

Daryanto Y, Wee HM, Astanti RD (2019) Three-echelon supply chain model considering carbon emission and item deterioration. Transp Res Part E Logist Transp Rev 122:368–383

Wang J, Lim MK, Tseng M, Yang Y (2019) Promoting low carbon agenda in the urban logistics network distribution system. J Clean Prod 211:146–160

Jabbarzadeh A, Haughton M, Khosrojerdi A (2018) Closed-loop supply chain network design under disruption risks: a robust approach with real world application. Comput Ind Eng 116:178–191

Liao TY (2018) Reverse logistics network design for product recovery and remanufacturing. Appl Math Model 60:145–163

Schiffer M, Walther G (2018) Strategic planning of electric logistics fleet networks: a robust location-routing approach. Omega 80:31–42

Amin S, Ramezanian R (2018) An efficient hybrid genetic algorithm for multi-product competitive supply chain network design with price-dependent demand. Appl Soft Comput 71:872–893

Mahdi PM, Marjan O (2018) Designing and solving a reverse logistics network for polyethylene terephthalate bottles. J Clean Prod 195:605–617

Jing L, Zhong Y, Futao Z et al (2018) A novel method to solve supplier selection problem: hybrid algorithm of genetic algorithm and ant colony optimization. Math Comput Simul 156:294–309

Penkuhn T, Spengler T, Puchert H, Rentz O (1997) Environmental integrated production planning for ammonia synthesis. Eur J Oper Res 97(2):327–336

Cherrafi A, Garza-Reyes JA, Kumar V et al (2018) Lean, green practices and process innovation: a model for green supply chain performance. Int J Prod Econ 206:79–92

Mtalaa W, Aggoune R, Schaefers J (2009) CO2 emission calculation models for green supply chain management . http://coba.georgiasouthern.edu/hanna/FullPapers/Fullpaper.htm. Accessed 05 April 2010

Wong EYC, Tai AH, Emma Z (2018) Optimizing truckload operations in third-party logistics: a carbon footprint perspective in volatile supply chain. Transp Res Part D Transp Environ 63:649–661

Chen JX, Chen J (2017) Supply chain carbon foot printing and responsibility allocation under emission regulations. J Environ Manag 188:255–267

Zhang D, Zhan Q, Chen Y et al (2018) Joint optimization of logistics infrastructure investments and subsidies in a regional logistics network with CO2 emission reduction targets. Transp Res Part D Transp Environ 60:174–190

Ding H, Liu Q, Zheng L (2016) Assessing the economic performance of an environmental sustainable supply chain in reducing environmental externalities. Eur J Oper Res 255(2):463–480

Ding H, Zhao Q, An Z et al (2016) Collaborative mechanism of a sustainable supply chain with environmental constraints and carbon caps. Int J Prod Econ 181:191–207

Li F, Haasis HD (2017) Imposing emission trading scheme on supply chain: separate- and joint implementation. J Clean Prod 142:2288–2295

Bai Q, Gong Y, Jin M, Xu X (2019) Effects of carbon emission reduction on supply chain coordination with vendor-managed deteriorating product inventory. Int J Prod Econ 208:83–99

Mohan MN, Peter K (2019) Managing a dual-channel supply chain under price and delivery-time dependent stochastic demand. Eur J Oper Res 272(1):147–161

Xiao Z, Sun J, Shu W, Wang T (2019) Location-allocation problem of reverse logistics for end-of-life vehicles based on the measurement of carbon emissions. Comput Ind Eng 127:169–181

Zaid AA, Jaaron AAM, Abdul TB (2018) The impact of green human resource management and green supply chain management practices on sustainable performance: an empirical study. J Clean Prod 204:965–979

Ruiz-Benitez R, López C, Juan C, Real JC (2017) Environmental benefits of lean, green and resilient supply chain management: the case of the aerospace sector. J Clean Prod 167:850–862

Fahimnia B, Jabbarzadeh A, Sarkis J (2018) Greening versus resilience: a supply chain design perspective. Transp Res Part E Logist Transp Rev 119:129–148

Chang X, Xia H, Zhu H et al (2015) Production decisions in a hybrid manufacturing–remanufacturing system with carbon cap and trade mechanism. Int J Prod Econ 162:160–173

Lang X, Chuanxu W, Junjie Z (2018) Decision and coordination in the dual-channel supply chain considering cap-and-trade regulation. J Clean Prod 197:551–561

Comasmarti J, Tancrez JS, Seifert RW (2015) Carbon footprint and responsiveness trade-offs in supply chain network design. Int J Prod Econ 166:129–142

Abbassi A, Elhilali Alaoui A, Boukachour J (2019) Robust optimization of the intermodal freight transport problem: modeling and solving with an efficient hybrid approach. J Comput Sci 30:127–142

Asim Z, Jalil SA, Javaid S (2019) An uncertain model for integrated production-transportation closed-loop supply chain network with cost reliability. Sustain Prod Consum 17:298–310

Andres G, Laurence D, Nacima L et al (2018) A multi-population algorithm to solve the VRP with stochastic service and travel times. Comput Ind Eng 125:144–156

Langroodi RRP, Amiri M (2016) A system dynamics modeling approach for a multi-level, multi-product, multi-region supply chain under demand uncertainty. Expert Syst Appl 51:231–244

Noh J, Kim JS (2016) Cooperative green supply chain management with greenhouse gas emissions and fuzzy demand. J Clean Prod 208:1421–1435

He F, Yang J, Li M (2018) Vehicle scheduling under stochastic trip times: an approximate dynamic programming approach. Transp Res Part C Emerg Technol 96:144–159

Wei M, Chen X, Sun B, Zhu YY (2015) Model and algorithm for resolving regional bus scheduling problems with fuzzy travel times. J Intell Fuzzy Syst 29(6):2689–2696

Wang C, Matthies HG, Xu M et al (2018) Hybrid reliability analysis and optimization for spacecraft structural system with random and fuzzy parameters. Aerosp Sci Technol 77:353–361

John H (1992) Adaptation in natural and artificial systems. MIT Press, Cambridge

Khanduzi R, Sangaiah AK (2019) A fast genetic algorithm for a critical protection problem in biomedical supply chain networks. Appl Soft Comput 75:162–179

Senoussi A, Dauzère-Pérès S, Brahimi N et al (2018) Heuristics based on genetic algorithms for the capacitated multi vehicle production distribution problem. Comput Op Res 96:108–199

Cui YY, Guan Z, Saif U et al (2017) Close loop supply chain network problem with uncertainty in demand and returned products: genetic artificial bee colony algorithm approach. J Clean Prod 162:717–742

Woo YB, Kim BS (2018) A genetic algorithm-based metaheuristic for hydrogen supply chain network problem with two transportation modes and replenishment cycles. Comput Ind Eng (In press)

Mitsuo G, Lin L, Youngsu Y et al (2018) Recent advances in hybrid priority-based genetic algorithms for logistics and SCM network design. Comput Ind Eng 125:394–412

Dai Z, Aqlan F, Zheng X et al (2018) A location-inventory supply chain network model using two heuristic algorithms for perishable products with fuzzy constraints. Comput Ind Eng 119:338–352

Afrouzy ZA, Nasseri SH, Mahdavi I (2016) A genetic algorithm for supply chain configuration with new product development. Comput Ind Eng 101:440–454

Chakraborty D, Jana DK, Roy TK (2015) Multi-item integrated supply chain model for deteriorating items with stock dependent demand under fuzzy random and bifuzzy environments. Comput Ind Eng 88:166–180

Liu B (2001) Fuzzy random chance-constrained programming. IEEE Trans Fuzzy Syst 9(5):713–720

Ma Y, Yan F, Kang K et al (2016) A novel integrated production-distribution planning model with conflict and coordination in a supply chain network. Knowl-Based Syst 105:119–133

Acknowledgements

This research is supported by the National Nature Science Foundation of China (Project No: 71373157).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ren, Y., Wang, C., Li, B. et al. A genetic algorithm for fuzzy random and low-carbon integrated forward/reverse logistics network design. Neural Comput & Applic 32, 2005–2025 (2020). https://doi.org/10.1007/s00521-019-04340-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-019-04340-4