Abstract

A survey on the technologies employed in the modern agriculture and agri-food supply chains lately appeared, but only one paper using a fuzzy-based approach was cited. The aim of the present mini-review is to complement the above-mentioned survey and to show the application of different fuzzy-based approaches for agri-food supply chains. Agri-food supply chains represent linked events in the agricultural production of food, where all the stages of production, processing, trading, distribution and consumption are involved. These supply chains are expected to provide sustainable, affordable, safe and sufficient food and other derivatives to the consumers. Hence, it is critical to ensure that they operate properly and successfully in the volatile business environment. A first concern is to assess the service ability of the whole supply chain to preserve agri-food quality, eliminate deterioration and meet the demands of customers. Due to their complex structure, agri-food supply chains are susceptible to several vulnerabilities and risks, such as breakdowns, operational difficulties, and credit loss and economic losses due to various uncertain factors. A risk analysis can help to identify and categorize the risks. In this era characterized by the rapid industrialization of the agriculture and the increased global food demand, the sustainability and transparency of supply chains have become key factors. The new focus on sustainability emphasizes the issue of striking a balance between ecological and economic aspects in the agri-food business. In this context, problems such as the green supplier selection gained special attention.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Agri-food chains are meant as the linked events in the agricultural production of food, from production to consumption (by quoting FAO “from field to fork”) (http://www.fao.org/energy/agrifood-chains/en/). Considering that the world population is expected to grow to 8.3 billion in 2030 and to 9.3 billion in 2050 (UN 2013), the food production is also expected to increase. For instance, world demand and production of cereals are projected to be 2.84 billion tonnes in 2030 (www.fao.org/3/y4252e/y4252e00.htm). In such a context, the agri-food supply chain (AFSC) plays a pivotal role. To achieve robust, resilient and sustainable agri-food supply chain is challenging because of major sources of uncertainty and risks in comparison with other supply chains. Four types of uncertainty can be identified: product (shelf-life, deterioration rate, lack of homogeneity, food quality and food safety), process (harvesting yield, supply lead time, resource needs, production), market (demand, market prices) and environment (weather, pests and diseases and regulations) (Esteso et al. 2017). The new technologies can help to reduce uncertainty since they allow obtaining precise data in real time. Real-time information, data processing tools with intelligent decision making represent useful tools for companies to react more quickly to changing conditions in the supply chain. The new technologies linked to big data, artificial intelligence (AI), Internet of Things (IoT), which have been proved to be beneficial in the context of Industry 4.0, are paving the way to the so-called Agri-Food 4.0 (Lezoche et al. 2020). Such technologies are expected to meet the urgent need of redesigning the AFSC, allowing the different actors across it to cooperate with each other through integrated approaches for a sustainable production and distribution of high-quality food. The importance of the topic is witnessed, for instance, by recent EU funding calls (https://www.efsa.europa.eu/it/funding/calls/innovative-agri-food-value-chains-boosting-sustainability-oriented). The role of the above-mentioned new technologies, their use, potential and limitation in the agri-food sector, also with regard to AFSCs, has been well illustrated in a recent survey (Lezoche et al. 2020). Anyway, such survey did not mention the important contribution of the fuzzy approaches to the field. It can be argued that this may be due to the fact that the use and investigation of fuzzy approaches is still underway. It is the case to point out that most of the AFSC-related problems lie in the decision-making area, and more precisely multi-criteria decision making, because of the presence of multiple and usually conflicting criteria. When it comes to decision making under complex and uncertain environments, such as in the agri-food context, the fuzzy set theory offers the most suitable setting, as shown by numerous papers (Kahraman et al. 2015; Blanco-Mesa et al. 2017). There are also a number of papers, in the context of AFSCs, dealing with mathematical programming (e.g., Cruz et al. 2019 and references therein), and in this regard, the use of fuzzy sets to model the uncertain environment has been well discussed (Petrovic et al. 1999).

The aim of this mini-review is to provide an overview of what has been done in the field so far, with emphasis on fuzzy-based approaches, their limits and potential, by complementing the recent survey on supply chains and technologies for future agriculture (Lezoche et al. 2020). Hence, the next section will present models and issues of AFSCs. The third section is devoted to the fuzzy-based techniques for AFSCs. The fourth section foresees a discussion on fuzzy approaches against non-fuzzy approaches. Finally, the fifth section covers the main conclusions and perspectives for this research area. A list of acronyms is provided in Table 1.

2 Agri-food supply chains: models and issues

One of the main issues in AFSC is the sustainability. Sustainability has been studied from different perspectives in the literature. A widely accepted explanation of “sustainability” is that it meets the current needs without affecting the ability to meet the needs of future generations (WCED 1987). Sustainable agri-food supply chains can be meant as networks made of cooperating enterprises to coordinate material flow aiming at avoiding any waste and focusing upon the consumption of resources in a most effective way to produce health food (Fritz and Schiefer 2008).

The use of new emerging technologies in the AFSCs is growing, and it can help to support supply chain decision making. Technologies such as the Internet of Things (IoT) support collection and sharing of information in real time. Allowing improved communication, coordination and cooperation between nodes of the supply chain, IoT has the potential to augment the sustainability of the AFSC (Kamble et al. 2020; Cavaliere et al. 2020; Chen et al. 2020). The interested reader can refer to D’Aniello et al. (2016, 2017, 2018) for all the issues related to sensors in the IoT context. The huge amount of data generated by the IoT can be analyzed by using big data analytics, contributing to the identification of the possible weaknesses of the AFSC. It has been recently discussed (Belauda et al. 2019) the use of big data to support the management of sustainability, by valorizing agricultural waste and by-products, such as lignocellulosic biomass, which is a promising method for the production of bio-energy, biomolecules and biomaterials. The by-product valorization supply chain includes several operational stages, from biomass choice to waste disposal. Each of these steps can be described with heterogeneous data and can influence the others. The authors discuss a data architecture through the five steps data extraction, storage, curation, analysis and visualization. These steps provide all the data useful to the sustainability analysis. All this is aimed at supporting a group-based decision-making process. Blockchain technology seems also to be a promising enabler of a sustainable agri-food supply chain (Feng et al. 2020). As a distributed and decentralized technology, blockchain is a set of time-stamped blocks that are linked by a cryptographic hash. It represents a solution to the underlying trust and security issues in information transparency. A more transparent traceability can address the food safety and quality concerns. Thanks to the blockchain technology, no single party in the supply chain can alter existing information. Quality monitoring and traceability of food supply chains by IoT traceability systems is also possible. Anyway, most of the IoT solutions rely on the centralized server–client paradigm, so it may be difficult for consumers to acquire all transaction information and to track the origins of products (Feng et al. 2020). The AFSC model resulting from the application of the above-mentioned technologies turns out to be data-driven (Kamble et al. 2020). Anyhow, it must be mentioned that the technological challenges in agriculture mainly includes security issues, lack of standards and interoperability, as well as hardware and software limitations. A better insight into all this is beyond the scope of this mini-review, which focuses on fuzzy-based approaches, and the interested readers can refer to Lezoche et al. (2020) for more details.

Sustainable and green often appear in the literature as interchangeable terms, because related to the environment preservation. Green supply chain management addresses environmental issues and it involves several core links, such as green supplier evaluation and selection, green product design, green production, green packaging and transportation, green marketing and resource recycling (Fahimnia et al. 2015). In particular, green supplier selection is drawing attention, due to regulatory requirements and market trends. Green supplier selection (GSS) foresees the incorporation of environmental criteria into the traditional supplier selection practices. It can be regarded as a multi-criteria decision-making (MCDM) problem to select the optimal alternative in terms of a set of economic and environmental criteria. Price, quality and service level are the most common supplier selection criteria, while carbon footprint and emissions, energy efficiency, water usage, and recycling initiatives are the usual environmental measures. This is sketched in Fig. 1, where price, quality, service level represent the traditional box, to which the green criteria box has to be added. In the latter, there are some criteria which have been separately considered, as per the current literature, that is carbon footprint and emissions, energy efficiency and water usage, recycling. All these criteria (traditional and green) concur to the MCDM formulation of the problem, no matter if in fuzzy or non-fuzzy environment. Particular attention has been paid to carbon footprint. For example, European Union’s goal is cutting down their emission levels by 40% by the year 2030 (European Council 2014). This can be achieved by reducing the emissions in all sectors including agriculture sector. MCDM methods based on analytic hierarchy process (AHP) and Technique for order preference by similarity to ideal solution (TOPSIS) are widely used in solving green supplier selection problems, and their fuzzy version is very common (e.g., Demir and Koca 2021 and references therein).

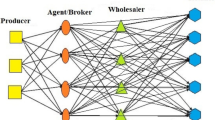

It must be mentioned that, traditionally, determining positions and number of actors, amount of product flow and best transportation costs are handled as a network design problem in supply chain management. In this sense, there are some typical models to assist the decision-making process in AFSCs, as described in Esteso et al. (2018a); they broadly lie in the area of mathematical programming, ranging from linear programming to stochastic and fuzzy programming. The role of mathematical programming is pre-eminent in the context of fresh agri-product supply chain (Fuchigami et al. 2019). The latter represents a complex large-scale system, where the decision maker needs to consider the different constraints and collisions among plantations, wholesalers and end-users, in addition to the location of facilities with different functions.

3 Agri-food supply chains and fuzzy-based techniques

In this section, we first describe the review methodology and then we discuss separately the different types of fuzzy-based approaches. All the approaches described in this section are summarized in Table 2.

3.1 Review methodology

We carried out the review process by taking into account the main steps of the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) methodology (Moher et al. 2009). The main objective of systematic reviews is to present a detailed review study for a specific research area and date interval. The methodology consists of steps such as identification, screening, eligibility. We adapted our review process to PRISMA methodology. Hence, in the first step, we considered the main academic databases, such as Scopus and WoS, to present a review of fuzzy-based methods for AFSCs. The related papers were checked one by one. The literature analysis was realized based on the following keywords, by using the Boolean operators OR, AND:

((agri*) OR (green)) AND ((chain) OR (supplier)) AND (fuzzy),

where * means any string after “agri” and the OR operators are processed before AND.

The search was performed on title, abstract and keywords. We fixed the year range [2005, 2020], but the fact that the related works are mostly from the last five years shows that the interest for this topic is lately growing (see Table 3).

The second step was about screening the papers in order to determine irrelevant or duplicated papers. Irrelevant papers were those ones where the title was misleading, presenting a content not strictly related to the topics here considered. In the third step, irrelevant or duplicated papers were removed. Initial screening was on 250 papers about, but only 40 papers were relevant. From this group, 4 ones were discarded because of unclear or incomplete presentation. The number of considered papers with the publication year is shown in Table 3.

In the last step, a meta-analysis has been realized for the included papers according to some features such as publication year and type of fuzzy-based method (MCDM or other). Regarding the type of documents, only 6 ones are conference papers, while all the others are regular articles.

3.2 Literature review with fuzzy MCDM methods

Sustainability issues in AFSCs have been addressed not only by means of classical approaches but also fuzzy-based techniques. In Mangla et al. (2018), ten key enablers for implementing sustainable initiatives in AFSCs were investigated. The identified enablers were analyzed using a hybrid approach combining interpretive structural modeling (ISM) and fuzzy decision making trial and evaluation laboratory (DEMATEL). ISM modeling was used to develop a hierarchical model of the identified enablers.

The fuzzy DEMATEL approach uncovered the interactions (causal interactions) among the identified enablers. Based on this, six enablers (pressure by various governmental, regulating agencies and non-government bodies, incentives and support of various agencies to undertake sustainable initiatives, understanding customer and other stakeholder requirements, understanding the sustainability initiative importance and benefits, management involvement, support and commitment and monitoring and auditing the ongoing supply chain activities) were categorized in the cause group and the remaining four (resources allocation and information sharing within and across the hierarchy, joint efforts, planning and capacity building for delivering sustainability focused products, competitive advantages, cost effectiveness and improvements in overall performance) in the effect group. The cause–effect diagram in Mangla et al. (2018) is useful to analyze the interactions among the sustainability enablers, even though it has the limitation of being subjective, because built on the information provided by experts from a particular industry. In general, the identification of the enablers may be challenging.

Fuzzy AHP and fuzzy TOPSIS seem to be the main decision-making techniques used to solve the green supplier selection problem, even in other sectors (Govindan et al. 2015). The pros and cons of the two techniques were illustrated in Lima Junior et al. (2014), with a case study for supplier selection from the automotive industry. With regard to the agility in the decision process, fuzzy TOPSIS seems to perform better than fuzzy AHP in most cases except when there are very few criteria and suppliers. Anyhow, fuzzy TOPSIS does not allow the deployment of the criteria into subcriteria, which is a weakness of the method when applied to supplier selection. As for the time complexity, it is in general lower for fuzzy AHP than for Fuzzy TOPSIS.

Fuzzy TOPSIS for green supplier selection was used both in Singh et al. (2018), Banaeian et al. (2018). In particular, in Singh et al. (2018), where the case study was about a low carbon footprint supplier selection in a beef abattoir and processor, once the importance of various attributes of supplier selection was obtained with the help of fuzzy AHP and fuzzy DEMATEL, the fuzzy TOPSIS method was applied to generate the ranking of the supplier. The case study in Banaeian et al. (2018) was about the supply to a company producing edible vegetable oils and detergents, with different types of oil suppliers. In Banaeian et al. (2018), a comparison of the performance of fuzzy TOPSIS against fuzzy VIseKriterijumska Optimizacija I Kompromisno Resenje (VIKOR) and fuzzy grey relational analysis (GRA) for the proposed case study was discussed. In spite of the differences among the methods, they arrive at identical outcomes. The authors also pointed out that the three techniques require the same amount of data to evaluate the alternatives and complete a supplier selection decision, with no restriction on the number of criteria and alternatives, but the run time for fuzzy GRA is lower. A similar comparison, but in the context of intuitionistic fuzzy sets, was discussed in Tian et al. (2018). In Liu et al. (2020), an integrated q-rung orthopair fuzzy (q-ROF) group best–worst method (GBWM) and Preference Ranking Organization METHod for Enrichment of Evaluations (PROMETHEE) II was introduced for green supplier selection in a grain and oil processing company. Firstly, the experts’ weight were determined under the q-ROF context. Then, the GBWM was used to derive criteria weights. Finally, based on the proposed generalized p-norm knowledge-based score function, the PROMETHEE II was improved to rank the feasible alternatives.

Sustainable supplier evaluation and selection was considered in Liu et al. (2019) by using fuzzy AHP first to derive the criteria weights and then fuzzy TOPSIS for evaluating the performance of the suppliers. The real-world case was about a value chain for sustainable pork meat in France. Supplier evaluation and selection in a rice supply chain was performed in Wang et al. (2018) by means of fuzzy analytic network process (ANP) and data envelopment analysis (DEA) models. Fuzzy ANP was used to evaluate and rank criteria, such as financial efficiency guarantee, quality of materials, ability to deliver on time, and the conditioned response to the environment; while data envelopment analysis (DEA) models were adopted to rank suppliers. Supplier evaluation in a collaborative context by means of fuzzy AHP is presented in Zhu et al. (2016).

In Dai and Bai (2020), a decision-making algorithm for agricultural product supplier selection was proposed based on the Pythagorean fuzzy power Bonferroni average (PFPBA) operator.

The distributor selection is instead considered in Haoran et al. (2014), where fuzzy TOPSIS is employed.

In Meena et al. (2019), fuzzy AHP was used for SWOT analysis. SWOT is a systematic approach for studying external and internal factors of a supply chain. In SWOT analysis, the factors are combined into four parts called SWOT groups: strengths, weaknesses, opportunities, and threats.

An analysis on drivers, enablers and resistors of agri-logistics in India was performed in Jakhar and Srivastava (2018) by means of fuzzy AHP. The authors built a hierarchy-based framework to prioritize the drivers, enablers and resistors of agri-logistics, by revealing the critical areas where decision makers should put efforts to maximize the benefits. The drivers of a sustainable supply chain for agricultural products were analyzed in Yazdani et al. (2020) by means of a new version of fuzzy DEMATEL.

Fuzzy AHP was used in Tian et al. (2015) to build the performance evaluation index system of an agri-food cold-chain logistics enterprise. Fuzzy comprehensive evaluation method is used to evaluate the performance of the target company with the performance evaluation index system. Fuzzy AHP and fuzzy comprehensive evaluation have been also used for cold chain performance evaluation in Huang et al. (2020) in the context of real-time emergency management. Fuzzy TOPSIS was used in Shi et al. (2016) for the design of fresh agricultural products supply chain.

Fuzzy cross-impact matrix multiplication applied to classification (MICMAC) was applied for risk analysis in Zhao et al. (2020) and for innovation analysis in Sharma et al. (2020b). A risk analysis of the agricultural products supply chain was also discussed in Zongxin and Dawei (2013), where AHP and fuzzy comprehensive evaluation were used by taking into account endogenous risks (agri-food quality, management, technical and logistics risks) and exogenous risks (marketing environment, natural environment and policy environment risks). Fuzzy AHP was used for risk analysis in Septifani et al. (2019), with fuzzy failure mode and effect analysis (FMEA), and in Jie (2020), the latter in particular in the context of IoT. An example of application of the sole fuzzy FMEA can be found in Mansor and Kamarulzaman (2020), where the method was used for risk identification in a seaweed supply chain.

Figure 2a shows the distribution of the different approaches for AFSCs, discarding the difference between fuzzy and intuitionistic fuzzy, and by collecting the approaches which appear just once under the noun “other.” Figure 2b is instead referred to the problem of green supplier selection and the fuzzy decision-making techniques used for it. Figure 3 shows the number of papers per country, according to the corresponding author’s country.

3.3 Literature review with fuzzy mathematical programming and other fuzzy-based methods.

There are some works related to fuzzy programming, which can assist the decision making in AFSCs (Qiang and Jiuping 2008; Yu et al. 2018; Paksoy et al. 2012; Hosseini-Motlagh 2020; Hasuike et al. 2017; Esteso et al. 2018b; Giallanza and Puma 2020; Jie 2017). In Qiang and Jiuping (2008), in order to effectively solve the vehicle routing problem to deliver fresh agricultural products (FAPs), a fuzzy multi-objective dependent-chance programming model was proposed and a genetic algorithm was used to seek the solution. The results indicated that the total delivery costs and the schedule of customers service are significantly influenced by waiting cost and penalty cost.

In Yu et al. (2018), the design of a dual-channel (traditional channel and E-commerce channel) supply chain for FAPs under information uncertainty was considered. The model aims to solve the integration network design issues about production, supply, and sales of FAP, as well as to minimize the supply chain operation cost and maximizing the satisfaction degree of the logistics demand between supply chain (SC) nodes simultaneously. The model uses triangular fuzzy numbers to represent the information uncertainty.

In Paksoy et al. (2012), a fuzzy multi-objective linear programming model to design the supply chain network of an edible vegetable oils manufacturer was proposed. The model is designed to simultaneously minimize the total transportation costs, by taking into account suppliers, silos, manufacturer and warehouses. Data were modeled by triangular fuzzy numbers to take into account incomplete or not available information. The model was conceived to facilitate the fuzzy decision-making process, enabling the decision maker to interactively modify the fuzzy/imprecise data and related parameters until a preferred satisfactory solution is obtained. In Hosseini-Motlagh (2020), a fuzzy programming approach was used to design a sustainable and resilient wheat supply chain. Multi-objective and multi-period fuzzy programming for maximizing the total profit and minimizing the environmental load with random and fuzzy parameters of an AFSC was discussed in Hasuike et al. (2017).

Fuzzy programming was also used in Esteso et al. (2018b) to maximize the profits of the supply chain in a collaboration context for small farms and modern retailers. Finally, in Giallanza and Puma (2020), a three-echelon fuzzy green vehicle routing problem was considered for designing a regional agri-food supply chain on a certain time horizon. The demands were modeled as fuzzy numbers, to account for the variability associated with the quantities requested by customers. The theory of fuzzy sets is used to implement a multi-objective fuzzy chance-constrained programming model, where the total costs and carbon emissions are minimized. The solving procedure foresees a non-dominated sorting genetic algorithm. In Jie (2017), a two-echelon model was instead considered by using fuzzy multi-objective programming. A fuzzy linear programming technique for multi-dimensional analysis of preference (LINMAP) was used in Dai and Liu (2020) for the risk assessment of agricultural supermarket supply chain, by retrieving data from 1016 questionnaires.

Another technique, which can assist the decision making, is represented by the fuzzy comprehensive evaluation method. This method transforms qualitative evaluation into quantitative evaluation according to certain membership degrees, that is, using fuzzy mathematics to make an overall evaluation of objects subject to several factors. The method is suitable for solving several non-deterministic problems (e.g., Zou et al. 2006). There are two papers using this method in the context of AFSCs, i.e., Tian et al. (2015), jointly with fuzzy AHP, for cold chain performance evaluation and Qiao et al. (2015) for evaluation of service ability of an AFSC. Differently from Zou et al. (2006), the problem of cold chain was considered in terms of inhibitors and a fuzzy interpretive structural model (FISM) was used. The FISM represents an extension of the interpretive structural modeling (ISM), which is an interactive learning process where a set of directly and indirectly related elements are structured into a comprehensive systemic model. It is the case to recall that a typical cold generally consists of pre-cooling facilities, cold storage, refrigerated carriers, packaging, warehouse, traceability, retailer, and consumers. An efficient management of the cold chain aims at preventing unnecessary losses.

To complete this subsection, a few very different approaches have to be mentioned. It was proposed in Perez-Salazar et al. (2019), where a Mexican green coffee supply chain was considered and an agent-based model was discussed for a scheduling and rescheduling problem. The decision support agent used Mamdani inference systems for coffee growing yield, quality scoring of different kind of coffee samples, sorting process scheduling of different kind of coffee. It is well known that fuzzy logic models deal with variables which have linguistic values, to take into account the uncertainty coming from the human language. From that perspective, they are interpretable, that is human-readable, and they look more appropriate to deal with farmers’ decision making. We recall that the core of a fuzzy inference system is a fuzzy rule base consisting of IF-THEN propositions. Fuzzy systems can be developed in a data-driven way, in an expert-driven way (where experts help to build appropriate IF-THEN rules), or in a combination of the two ways. It is the case to mention the variables of the fuzzy system modeling the coffee growing yield, because they can be referred to any product: nutrition, rainfall, control of pests, control of diseases, planting density, pruning, temperature. For each variable, there were from two to four attributes, according to the case. A fuzzy inference system was also used in Lambert et al. (2014), where it was part of an expert system aiming at a better synchronization between the first two links of a supply chain, i.e., production in the orchard and citrus fruit exporting company.

In Wang (2013), a fuzzy neural network algorithm for supply chain performance evaluation of fresh agricultural products is presented. In Suharajito (2012), a fuzzy regression model was used for risk balancing in order to formulate a fair pricing mechanism for farmers. The model was validated in the corn supply chain management to determine the corn price at farmer level using the risk constraints for each stakeholder.

4 Fuzzy versus non-fuzzy techniques

As discussed in Govindan et al. (2015), the most popular non-fuzzy approach for green supplier evaluation and selection in other sectors is AHP. The conventional AHP is based on a hierarchical structure of goal, criterion and alternative. The criteria are assessed by the goal, and each alternative is assessed by each criterion, giving a final value by means of suitable weights. AHP can be seen as an easily understandable approach to determine the performance of a supplier with respect to each criterion. The utilization and integration of fuzzy techniques may be advantageous for some settings, but it has attracted also some criticism. In fact, according to some studies analyzed in Govindan et al. (2015), the ultimate decisions from fuzzified AHP models seem not to provide any significant differences against regular AHP. This might lead practitioners to choose basic AHP approaches over fuzzified approaches since regular AHP approaches may look easier. A concrete clarification in this regard can be found in Mulubrhan et al. (2004), where the authors presented a comparative analysis of AHP and fuzzy AHP. The authors showed that the main difference between the conventional and fuzzy version of the method is that in the latter it seems clearer when a criterion is not significant in the decision-making process. Besides, maybe even more important, they showed that when the information/evaluations are certain, the classical methods perform well, while when the information/evaluations are uncertain, then the fuzzy method is preferable. A graphical scheme illustrating the difference between the two methods, in terms of steps, can also be found in Mulubrhan et al. (2004).

To our best knowledge, the only article dealing with AFSCs, where a comparison between fuzzy and non-fuzzy approaches was discussed, is Meena et al. (2019). In Meena et al. (2019), the case of the Indian agri-food supply chain was considered to perform a SWOT-AHP analysis. While the most important factor in SWOT-AHP was from the strength group, in the SWOT fuzzy AHP the most important factor was from the weaknesses group, which is reasonably consistent with making decisions in an uncertain environment.

Regarding the other popular MCDM method, that is TOPSIS, a comparison between its classical and fuzzy version for supplier selection (even though in the context of a manufacturing company) can be found in Sevkli et al. (2010), where a related graphical scheme is also provided. The two methods suggested a different choice of supplier, which is not a surprising finding. In fact, most supplier selection decisions are made in complex environments, where the criteria (e.g., quality performance, price/cost, delivery, management capacity and financial reputation) cannot be quantitatively and precisely measured using traditional decision-making tools such as the classical TOPSIS. Since there is intrinsic ambiguity in human judgment, the classical TOPSIS fails to provide a suitable solution.

As it was also pointed out in Chen et al. (2006), supplier selection problems adhere to uncertain and imprecise data, and fuzzy-set theory is a proper choice to deal with them, thanks to the use of linguistic variables. The use of such variables in decision making is highly beneficial when performance values (e.g., for assessing possible suppliers) cannot be adequately expressed by means of numerical values.

For the green supplier selection problem, as for the supplier selection, the fuzzy set theory helps to minimize the effects of imprecise data (Banaeian et al. 2018), confirming the findings of the above-mentioned papers.

5 Conclusions

AFSCs represent the important sequence of operations from the production of food to its distribution and consumption. There are many important problems in this sector which lie in the broad area of optimization and decision making, e.g., supplier selection and routing problems, by taking into account green constraints.

Most fuzzy techniques employed for AFSCs are fuzzy decision-making techniques. AFSCs are complex and uncertain systems. Since it is acquired from the former literature the fact that fuzzy set theory provides the optimal setting for solving problems in uncertain and imprecise environments, there is a lack of comparisons with classical techniques. Also, there is a lack of applications of fuzzy techniques at the level of data-driven model. As pointed out in Sharma et al. (2020a), there is a huge amount of data generated throughout the AFSC which would enable the involved actors to draw valuable insights and to enhance productivity through data-driven decision making. However, in such case there may be challenges in terms of data storage, data collection and data visualization.

References

Banaeian N et al (2018) Green supplier selection using fuzzy group decision making methods: a case study from the agri-food industry. Comput Oper Res 89:337–347

Belauda J-P, Prioux N, Vialle C, Sablayrolles C (2019) Big data for agri-food 4.0: application to sustainability management for by-products supply chain. Comput Ind 111:41–50

Blanco-Mesa F, Merigo JM, Gil-Lafuente AM (2017) Fuzzy decision making: a bibliometric-based review. J Intell Fuzzy Syst 32:2033–2050

Cavaliere D, Loia V, Senatore S (2020) Towards a layered agent-modeling of IoT devices to precision agriculture. FUZZ-IEEE 1–8

Chen C-T, Lin C-T, Huang S-F (2006) A fuzzy approach for supplier evaluation and selection in supply chain management. Int J Prod Econ 102:289–301

Chen X, Wang H, Tian B (2020) Multidimensional agro-economic model with soft-IoT framework. Soft Comput 24:12187–12196

Cruz L, Pires-Ribeiro J, Barbosa-Povoa A (2019) Design and planning of agri-food supply chains. Comput Aided Chem Eng 46:55–60

Dai M, Liu L (2020) Risk assessment of agricultural supermarket supply chain in big data environment. Sustain Comput Inform Syst 28:100420

Dai L, Bai S (2020) An approach to selection of agricultural product supplier using pythagorean fuzzy sets. Math Probl Eng Article ID 1816028

D’Aniello G, Gaeta A, Loia V, Orciuoli F (2016) Integrating GSO and SAW ontologies to enable situation awareness in green fleet management. In: 2016 IEEE international multi-disciplinary conference on cognitive methods in situation awareness and decision support (CogSIMA). IEEE, pp 138–144

D’Aniello G, Gaeta M, Hong TP (2017) Effective quality-aware sensor data management. IEEE Trans Emerg Top Comput Intell 2(1):65–77

D’Aniello G, Gaeta M, Loia F, Reformat M, Toti D (2018) An environment for collective perception based on fuzzy and semantic approaches. J Artif Intell Soft Comput Res 8(3):191–210

Demir E, Koca G (2021) Green supplier selection using intuitionistic fuzzy AHP and TOPSIS methods: a case study from the paper mills. Adv Intell Syst Comput 1197:666–673

Esteso A, Alemany MME, Ortiz A (2017) Deterministic and uncertain methods and models for managing agri-food supply chain. Dir Organ 62:41–46

Esteso A, Alemany MME, Ortiz A (2018a) Conceptual framework for designing agri-food supply chains under uncertainty by mathematical programming models. Int J Prod Res 56(13):4418–4446

Esteso A, del Mar E Aleman M, Ortiz A, Guyon C (2018b) A collaborative model to improve farmers’ skill level by investments in an uncertain context. In: Camarinha-Matos L, Afsarmanesh H, Rezgui Y (eds) Collaborative networks of cognitive systems. PRO-VE 2018. IFIP advances in information and communication technology, vol 534. Springer, Cham

European Council (2014) Brussels. Retrieved from http://www.consilium.europa.eu/uedocs/cms_data/docs/pressdata/en/ec/145397.pdf

Fahimnia B, Sarkis J, Davarzani H (2015) Green supply chain management: a review and bibliometric analysis. Int J Prod Econ 162:101–114

FAO. World Agriculture: Towards 2015/2030. www.fao.org/3/y4252e/y4252e00.htm

Feng H et al (2020) Applying blockchain technology to improve agri-food traceability: a review of development methods, benefits and challenges. J Clean Prod 260:121031

Fritz M, Schiefer G (2008) Food chain management for sustainable food system development: a European research agenda. Agribusiness 24(4):440–452

Fuchigami HY, Severino MR, Yamanaka L, de Oliveira MR (2019) A literature review of mathematical programming applications in the fresh agri-food supply chain. In: Reis J, Pinelas S, Melão N (eds) Industrial engineering and operations management II. IJCIEOM 2018. Springer proceedings in mathematics and statistics, vol 281. Springer, Cham

Gabus A, Fontela E (1972) World problems, an invitation to further thought within the framework of DEMATEL. Battelle Geneva Research Center, pp 1–8

Giallanza A, Puma GL (2020) Fuzzy green vehicle routing problem for designing a three echelons supply chain. J Clean Prod 259:120774

Govindan K, Rajendran S, Sarkis J, Murugesan P (2015) Multi criteria decision making approaches for green supplier evaluation and selection: a literature review. J Clean Prod 98(1):66–83

Haoran S, Wen D, Ling Z (2014) A fuzzy TOPSIS based approach for distributor selection in supply chain management: an empirical study of an agricultural enterprise in China. Adv J Food Sci Technol 6(1):112–118

Hasuike T, Kashima T, Matsumoto S (2017) Robust agricultural supply chain management with various random and fuzzy parameters. In: 2017 6th IIAI international congress on advanced applied informatics (IIAI-AAI), Hamamatsu, pp 11–16

Hosseini-Motlagh S et al (2020) A novel hybrid approach for synchronized development of sustainability and resiliency in the wheat network. Comput Electron Agric 168:105095

Huang X et al (2020) Real-time emergency management mode of cold chain logistics for agriculturalproducts under the background of “Internet+’’. J Intell Fuzzy Syst 38(6):7461–7473

Hwang CL, Yoon K (1981) Multiple attribute decision making: methods and applications. Springer, New York

Jakhar M, Srivastava MK (2018) Prioritization of drivers, enablers and resistors of agri-logistics in an emerging economy using fuzzy AHP. Br Food J 120(9):2166–2181

Jie G (2017) Two echelon supply chain model of agricultural products based on stochastic fuzzy process of cost demand. Int J Reason Based Intell Syst 9(3/4):110–123

Jie C (2020) Empirical analysis of the impact index of agricultural product supply chain risk on agricultural economic development. Revista de la Facultad de Agronomia 37(2):1001–1011

Joshi R, Banwet DK, Shankar R (2009) Indian cold chain: modeling the inhibitors. Br Food J 111(11):1260–1283

Kahraman C, Cevik Onar S, Oztays B (2015) Fuzzy multicriteria decision-making: a literature review. Int J Comput Intell Syst 8(4):637–666

Kamble SS, Gunasekaran A, Gawankar SA (2020) Achieving sustainable performance in a data-driven agriculture supply chain: a review for research and applications. Int J Prod Econ 219:179–194

Lambert GF et al (2014) An expert system for predicting orchard yield and fruit quality and its impact on the Persian lime supply chain. Eng Appl Artif Intell 33:21–30

Lezoche M, Hernandez JE, del Mar Eva Alemany Diaz M, Panetto H, Kacprzyk J (2020) Agri-food 4.0: a survey of the supply chains and technologies for the future agriculture. Comput Ind 117:103187

Lima Junior FR, Osiro L, Ribeiro Carpinetti LC (2014) A comparison between Fuzzy AHP and Fuzzy TOPSIS methods to supplier selection. Appl Soft Comput 21:194–209

Liu Y, Eckert C, Yannou-Le Brisc G, Petite G (2019) A fuzzy decision tool to evaluate the sustainable performance of suppliers in an agrifood value chain. Comput Ind Eng 127:196–212

Liu Z et al (2020) Selecting the optimal green agricultural products supplier: a novel approach based on GBWM and PROMETHEE II. Sustainability 12:6703

Mangla K et al (2018) Enablers to implement sustainable initiatives in agri-food supply chains. Int J Prod Econ 203:379–393

Mansor M, Kamarulzaman NH (2020) Seaweed supply chain risk identification in sabah using fuzzy failure mode and effect analysis. 2020 IOP conference on series: earth environment science, vol 549, p 012096

Meena SR et al (2019) Strategic analysis of the Indian agri-food supply chain. OPSEARCH 56(3):965–982

Moher D et al (2009) Preferred reporting items for systematic reviews and meta-analyses: the PRISMA statement. PLoS Med 6(7):e1000097

Mulubrhan F, Akmar Mokhtar A, Muhammad M (2004) Comparative analysis between fuzzy and traditional analytical hierarchy process. MATEC Web Conf 13:01006

Opricovic S, Tzeng GH (2004) The compromise solution by MCDM methods: a comparative analysis of VIKOR and TOPSIS. Eur J Oper Res 156(2):445–55

Paksoy T, Pehlivan NY, Ozceylan E (2012) Application of fuzzy optimization to a supply chain network design: a case study of an edible vegetable oils manufacturer. Appl Math Model 36:2762–2776

Perez-Salazar MR et al (2019) An agent-based model driven decision support system for reactive aggregate production scheduling in the green coffee supply chain. Appl Sci 9(22):4903

Petrovic D, Roy R, Petrovic R (1999) Supply chain modeling using fuzzy sets. Int J Prod Econ 59:443–453

Qiang L, Jiuping X (2008) A study on vehicle routing problem in the delivery of fresh agricultural products under random fuzzy environment. Int J Inf Manag Sci 19(4):673–690

Qiao L, Dawei Z, Xin S (2015) Evaluation on service ability of agri-food supply chain. Open Cybern Syst J 9:986–991

Septifani R, Santoso I, Rodhiyah BN (2019) Risk mitigation strategy of rice seed supply chains using fuzzy-FMEA and fuzzy-AHP. In: International conference on green agro-industry and bioeconomy, IOP conference series: earth and environmental science vol 230, p 012059

Sevkli M, Zaim S, Turkyılmaz A, Satır M (2010) An application of fuzzy topsis method for supplier selection. In: International conference on fuzzy systems, Barcelona, pp 1–7

Sharma R et al (2020a) A systematic literature review on machine learning applications for sustainable agriculture supply chain performance. Comput Oper Res 119:104926

Sharma R, Darbari JD, Yadavalli VSS, Agarwal V, Jha PC (2020b) Analytical structural model for implementing innovation practices in sustainable food value chain. Adv Intell Syst Comput 1048:699–710

Shi H, Liu K, Peng H, Yao Y (2016) Fuzzy TOPSIS-based supply chain optimization of fresh agricultural products. Adv Model Anal A 53(1):186–203

Singh A, Kumari S, Malekpoor H, Mishra N (2018) Big data cloud computing framework for low carbon supplier selection in the beef supply chain. J Clean Prod 202:139–149

Suharajito M (2012) Risks balancing model of agri-supply chain using fuzzy risks utility regression. J Theor Appl Inf Technol 41(2):134–144

Tian F et al (2015) Evaluation research on performance of Chinese agri-food cold-chain logistics company. In: 2015 12th international conference on service systems and service management (ICSSSM), Guangzhou, pp 1–6

Tian ZP et al (2018) Green supplier selection using improved TOPSIS and best-worst method under intuitionistic fuzzy environment. Informatica 29(4):773–800

UN. World Population Prospects, the 2012 Revision; United Nation: New York, NY, USA (2013)

Van Laarhoven PJ, Pedrycz W (1983) A fuzzy extension of Saaty’s priority theory. Fuzzy Sets Syst 11:229–241

Wang H (2013) Research on supply chain performance evaluation of fresh agricultural products. INMATEH Agric Eng 40(2):35–42

Wang CN, Nguyen VT, Duong DH, Tuong Do H (2018) A hybrid fuzzy analytic network process (FANP) and data envelopment analysis (DEA) approach for supplier evaluation and selection in the rice supply chain. Symmetry 10:221

WCED U (1987) Our common future. World commission on environment and development. Oxford University Press, Oxford

Yazdani M, Wang ZX, Chan FTS (2020) A decision support model based on the combined structure of DEMATEL, QFD and fuzzy values. Soft Comput 24:12449–12468

Yu J, Gan M, Ni S, Chen D (2018) Multi-objective models and real case study for dual-channel FAP supply chain network design with fuzzy information. J Intell Manuf 29:389–403

Zhao G et al (2020) Risk analysis of the agri-food supply chain: a multi-method approach. Int J Prod Res 1–26

Zhu Y-X, Lee S-J, Zhang J-Q (2016) Performance evaluation on supplier collaboration of agricultural supply chain. Int J Inf Syst Change Manag 8(1):130–140

Zongxin X, Dawei Z (2013) Research on risks evaluation of the agricultural products supply chain. J Appl Sci 13(14):2735–2739

Zou Z, Yun Y, Sun J (2006) Entropy method for determination of weight of evaluating indicators in fuzzy synthetic evaluation for water quality assessment. J Environ Sci 18:1020–1023

Acknowledgements

Dr. Tomasiello acknowledges support from the IT Academy program. Ms. Alijani has been supported by the Estonian Research Council Grant PRG864.

Author information

Authors and Affiliations

Contributions

S.T. was involved in the conceptualization, investigation and methodology; S.T. and Z.A. were involved in writing–original manuscript; and S.T. was involved in writing—revised manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Human participants or animals performed

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Fuzzy decision-making techniques

Appendix: Fuzzy decision-making techniques

In order to offer a clear vision to the readers, in this section we recall the steps of the main fuzzy decision-making techniques mentioned in this survey.

1.1 Fuzzy AHP

Fuzzy analytic hierarchy process (fuzzy AHP) is a decision-making tool which has been used in several problems since it was introduced (Van Laarhoven and Pedrycz 1983). Let \(C_i=\{c_1,...,c_i\}\) be the criteria set and \(M=[{\tilde{M}}_{ij}]\) be the pairwise comparison matrix

The method foresees the following steps

-

Step 1 compute \(S_k=(S_{k,l}, S_{k,m}, S_{k,u})\) values for each row as follows:

$$\begin{aligned}&S_k=\sum _ {j=1}^n M_{kj} \times \left[ \sum _{i=1}^n \sum _ {j=1}^ n M_{ij}\right] ^{-1} \nonumber \\&\quad {for} \ \ k=1,...,n; \end{aligned}$$(2) -

Step 2 deduce the degree of possibility of \(S_k\ge S_k'\) and \( k\ne k'\) through the following equations; Let \( S_1=(S_{1,l}, S_{1,m}, S_{1,u})\) and \( S_2=(S_{2,l}, S_{2,m}, S_{2,u})\) then:

$$\begin{aligned} \left\{ \begin{array}{ll} V(S_1 \ge S_2) \quad {if} \ \ S_{1,m} \ge S_{2,m} \\ V(S_1 \ge S_2)= \frac{S_{1,u}-S_{2,l}}{(S_{1,u}-s_{2,l})+(S_{2,m}-S_{1,m})} \end{array} \right. \end{aligned}$$(3) -

Step 3 calculate the criteria weight by

$$\begin{aligned}&W'(c_i)=\min \{V(S_i\ge S_k)\} \ \ k=1,...,n \quad {and} \nonumber \\&\ \ k\ne i. \end{aligned}$$(4)and arranged into a vector

$$\begin{aligned} W'=[W'(c_1),...,W'(c_n)] \end{aligned}$$(5) -

Step 4 compute the normalized weight

$$\begin{aligned} W_i=\frac{W'(c_i)}{\sum _{i=1}^n W'(c_i)}. \end{aligned}$$(6)

1.2 Fuzzy DEMATEL

Decision-making trial and evaluation laboratory (DEMATEL) is considered as an efficient method for the identification of cause–effect of a complex system (Gabus and Fontela 1972). The categorization of the criteria helps to have a better understanding of the criteria. Moreover, it is used to assign importance weights to each of them. If the problem is consisting of n criteria, \(C=\{C_1,C_2,...,C_n\}\), by the following steps we can compute importance weight of each of the criterion based on fuzzy DEMATEL.

-

Step 1 The pairwise influence matrix of the criteria is as following equation. Each of the influence matrix components describes the level of influence the criterion of that row has on the values of the criterion in that column.

$$\begin{aligned} {\widetilde{IM}}_{kh}= \left[ \begin{array}{ccc} {\widetilde{IM}}_{11} &{} \cdots &{} {\widetilde{IM}}_{1n}\\ \vdots &{} \ddots &{} \vdots \\ {\widetilde{IM}}_{n1} &{} \cdots &{} {\widetilde{IM}}_{nn} \\ \\ \end{array} \right] \end{aligned}$$(7) -

Step 2 Normalizing the influence matrix IM by equation and obtaining the normalized influence matrix of NM:

$$\begin{aligned} {\widetilde{NM}}_{kh}= \left[ \begin{array}{ccc} {\widetilde{NM}}_{11} &{} \cdots &{} {\widetilde{NM}}_{1n}\\ \vdots &{} \ddots &{} \vdots \\ {\widetilde{NM}}_{n1} &{} \cdots &{} {\widetilde{NM}}_{nn} \\ \\ \end{array} \right] \end{aligned}$$(8)where, \({\widetilde{NM}}_{kh}=\frac{{\widetilde{IM}}_{kh}}{{\tilde{R}}}=(\frac{{\widetilde{IM}}_{kh,l}}{{\tilde{R}}_l}, \frac{{\widetilde{IM}}_{kh,m}}{{\tilde{R}}_m}, \frac{{\widetilde{IM}}_{kh,u}}{{\widetilde{R}}_u})\) and

$${\tilde{R}}=(\max ({\widetilde{IM}}_{kh,l}), \max ({\widetilde{IM}}_{kh,m}), \max ({\widetilde{IM}}_{kh,u})).$$ -

Step 3 Obtaining the total-relation fuzzy matrix \( {\tilde{T}}\) by:

$$\begin{aligned} {\widetilde{T}}_{kh}= & {} \lim _{w \rightarrow \infty }({\widetilde{NM}}^1_{kh}+ {\widetilde{NM}}^2_{kh}+...+{\widetilde{NM}}^w_{kh}) \nonumber \\= & {} {\widetilde{NM}}_{kh}(1-{\widetilde{NM}}_{kh})^{-1} \end{aligned}$$(9)where \({\tilde{T}}_{kh}\) is a fuzzy number

$$\begin{aligned} {\tilde{T}}_{kh}= \left[ \begin{array}{ccc} {\tilde{T}}_{11} &{} \cdots &{} {\tilde{T}}_{1n}\\ \vdots &{} \ddots &{} \vdots \\ {\tilde{T}}_{n1} &{} \cdots &{} {\tilde{T}}_{nn}. \\ \\ \end{array} \right] \end{aligned}$$(10) -

Step 4 Computing the sum of rows and columns of the total relation matrix and calling them \(\tilde{D_i}\) and \(\tilde{R_i}\).

-

Step 5 Obtaining the weights \({\tilde{w}}_i=(w_{i,l}, w_{i,m}, w_{i,u})\) through

$$\begin{aligned} w_{i,l}= & {} \sqrt{({\tilde{D}}_{i,l}+{\tilde{R}}_{i,l})^2+({\tilde{D}}_{i,l}-{\tilde{R}}_{i,l})^2} \end{aligned}$$(11)$$\begin{aligned} w_{i,m}= & {} \sqrt{({\tilde{D}}_{i,m}+{\tilde{R}}_{i,m})^2+({\tilde{D}}_{i,m}-{\tilde{R}}_{i,m})^2} \end{aligned}$$(12)$$\begin{aligned} w_{i,u}= & {} \sqrt{({\tilde{D}}_{i,u}+{\tilde{R}}_{i,u})^2+({\tilde{D}}_{i,u}-{\tilde{R}}_{i,u})^2} \end{aligned}$$(13) -

Step 6 Defuzzification of fuzzy weights through equation:

$$\begin{aligned} w_i=\frac{w_{i,l}+2w_{i,m}+w_{i,u}}{4}. \end{aligned}$$(14)

1.3 Fuzzy TOPSIS

The technique for order of preference by similarity to ideal solution (TOPSIS) is a multi-criteria decision method based on the concept that the chosen alternative should have the shortest distance from the positive ideal solution and the longest distance from the negative ideal solution (Hwang and Yoon 1981). The Euclidean distance measure is used to this end. Let \(A=(l_1, p_1, u_1)\) and \(B=(l_2, p_2, u_2)\) two triangular fuzzy numbers (TFNs). We recall that the distance between two TFNs is calculated by:

Fuzzy TOPSIS works as follows. Potential alternatives (suppliers in the above-mentioned supplier selection problem) and evaluation factors (criteria) are created based on expert preferences (decision makers). Let m and n be the number of alternatives and criteria through which the performance of criteria is going to be evaluated, respectively. Let \({\tilde{X}}\in {\mathbb {R}}^{m\times n}\) be the fuzzy decision matrix. It is first normalized to form the normalized decision matrix \({\tilde{R}}\) as follows:

Weighted normalized decision matrix \({\tilde{U}}\) is computed by multiplying the weights of criteria \({\tilde{W}}=[{\tilde{w}}_1,\ldots ,{\tilde{w}}_n]\) by the corresponding elements of the normalized decision matrix \({\tilde{R}}\).

where \( {\tilde{u}}_ {ij}\) is formulated as \({\tilde{u}}_{ij }= {\tilde{r}}_ {ij} \times {\tilde{w}}_j\). The positive ideal solution (PIS) is determined by the largest normalized and weighted score for each criterion. Similarly, the negative ideal solution (NIS) is determined by selecting the least normalized and weighted score of each criterion as follows:

The distances of each alternative to the positive ideal solution \(d^+ \) and negative ideal solution \(d^-\) for alternative \(i = 1, 2,..., m\) are calculated according to (15) as

Using these distance values, closeness index CI for each alternative is:

The values of CI range from 0 to 1, and an alternative with the highest CI is selected as the best alternative.

1.4 Fuzzy VIKOR

VIseKriterijumska Optimizacija I Kompromisno Resenje (VIKOR) is the Serbian translation of multi-criteria optimization and compromise solution (Opricovic and Tzeng 2004). The VIKOR method first establishes a compromise ranking-list, then a compromise solution, and finally the weight stability intervals for the compromise solution. Fuzzy VIKOR works as follows. The fuzzy best value \( {\tilde{f}}_j^* = (l_j^*, m_j^*,u_j^*)\) and fuzzy worst value \( {\tilde{f}}_j^\circ = (l_j^\circ , m_j^\circ ,u_j^\circ )\) are determined, respectively, as

The fuzzy difference \({\tilde{d}}_{ij}\) between \({\tilde{x}}_{ij}\) and fuzzy best value \({\tilde{x}}_{ij}\) and \({\tilde{f}}_j^*\) (respectively, worst value \({\tilde{f}}_j^\circ )\) is obtained by

The separation \({\tilde{S}}_ i\) of supplier \(A_i\) from the fuzzy best value \({\tilde{f}}_j^*\), and the separation of \(R_i\) of supplier \(A_i\) from the fuzzy worst value \({\tilde{f}}_j^\circ \) can be obtained from

where \({\tilde{S}}_i\) is a fuzzy weighted sum that is the separation measure of \(A_i\) from the fuzzy best value, \({\tilde{R}}_j\) is a fuzzy operator max denoting the separation measure of \(A_i\) from the fuzzy worst value, and \(w_i\) is the average importance weight of criterion \(C_j\). The relation \({\tilde{Q}}_i = (l_i , m_i , u_ i )\) is given by

where \(K= \frac{n+1}{2n}\) is the criteria weight and \(\oplus \) is the fuzzy sum. The value of \({\tilde{S}}_i, {\tilde{R}}_i \) and \({\tilde{Q}}_i\) can be defuzzified and converted into crisp numbers \(S_i, R_i\) and \(Q_ i\). Consequently, alternatives are ranked in ascending order of S, R and Q. If the following two conditions are satisfied, the compromise solution \((A^{(1)})\) is proposed as the best ranked by measure Q:

-

I.

sustainable advantage, \(Q(A^{ (2)} ) -Q(A^{ (1)} ) \ge \frac{1}{m-1} \), where \(A^{(2)}\) is the alternative with second position;

-

II.

sustainable stability in decision making, alternative \(A^{(1)}\) must also be the best ranked by S and/or R; this may imply “voting by majority rule” (when \(K> 0.5\) is needed), or “by consensus \(K\approx 0.5\) , or “with veto” (\(K< 0.5\)), where K denotes the weight of decision-making strategy of the maximum group utility.

In case that one condition is not satisfied, then a set of compromise solutions is developed, such as:

-

III.

alternatives \(A^{(1)}\) and \(A^{(2)}\), if condition II is not satisfied;

-

IV.

alternatives \(A^{ (1) }, A^{ (2)},..., A^{ (M)}\), if condition I is not satisfied. \(A^{(M)}\) is determined by the relation \(Q(A^{(M)}) -Q(A^{(1)}) < \frac{1}{m-1} \) for maximum M.

Rights and permissions

About this article

Cite this article

Tomasiello, S., Alijani, Z. Fuzzy-based approaches for agri-food supply chains: a mini-review. Soft Comput 25, 7479–7492 (2021). https://doi.org/10.1007/s00500-021-05707-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00500-021-05707-3