Abstract

Inexpedient vibration between cutting tool and work piece promotes regenerative chatter in turning process. Generally, acquired chatter signals are contaminated with ambient noise. In this study, experimentally recorded raw chatter signals have been denoised using wavelet transform. Further, in order to quantify the chatter severity a new parameter called chatter index has been evaluated considering aforesaid denoised signals at different levels of cutting parameters as inputs. Moreover, these input and output parameters have been considered to train the chatter phenomenon using adaptive neuro-fuzzy inference system. Developed technique has been validated by performing more experiments. Hence, a new idea for identification and quantification of chatter has been proposed which will be very efficient in suppression of chatter.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In turning process, tool chatter results in excessive noise, poor surface finish, breakage of machine tool components and tool wear. Tool chatter is defined as the self-excited unavoidable relative motion between the cutting tool and work piece (Quintana and Ciurana 2011; Siddhpura and Paurobally 2012; Taylor 1907). Researchers have developed various methods in order to overcome the problem of chatter. Previous researchers have presented tool chatter mathematically in the form of delay differential equation (Berger et al. 1998). In some works, the delay differential equation is associated with structural nonlinearities (Hanna and Tobias 1974). Recently, some researchers have adopted spindle speed variation technique (Otto and Radons 2013) and use of multiple tuned mass damper (Yang et al. 2010) to mitigate the chatter effect. Moreover, researchers have developed various methods to control chatter by increasing the stiffness and damping coefficient of mechanical components (Duncan et al. 2005). Furthermore, researchers found that the depth of cut, feed rate, cutting speed and chip thickness influences chatter phenomenon. Clancy and Shin (2002) proposed that by reducing the depth of cut and feed rate, chatter can be minimised to a great extent. They also established that the cutting stability is greatly increased at low cutting speeds. Khorasani et al. (2011) have performed turning experiments with cutting speed, feed rate and depth of cut as cutting parameters. They observed that the influence of depth of cut on surface roughness is not regular and has a variable character. Tobias and Fishwick (1958) in their research work ascertained that the chip thickness affects the cutting forces dynamically. This instability in cutting forces results in regenerative tool chatter. Altintas and Weck (2004) observed that the dynamic cutting force depends not only on chip thickness but also on the shear angle oscillation and tool flank wavy surface contact mechanism. In the present work, depth of cut, feed rate and spindle speed have been considered as input parameters in order to predict the chatter stability in turning process.

In the last few decades some researchers have tried to explore the mechanism of chatter phenomenon through processing of acquired raw chatter signals. Recently, chatter mechanism has been investigated based on Fourier transform (FT) analysis of process signals such as force (Tobias 1961), displacement (Wu and Du 1996) and torque (Choi and Shin 2003). FT technique analyses the signal globally but not locally and thus is not suitable to extract inherent information of nonstationary chatter signals. To extract the signal features locally a new short-time Fourier transform (STFT) was developed. However, in STFT technique it is not possible to obtain high resolution in both time and frequency domains (Mallat 2008) simultaneously. In recent years wavelet transform (WT) has been developed as a new tool to study the dynamic characteristics of cutting process (Taylor et al. 2010; Yao et al. 2010). In comparison with FT and STFT, WT has some advantages such as performing local analysis, handling both stationary and nonstationary signals and also providing efficient time-frequency analysis (Wang and Liang 2009). Moreover, raw chatter signals are contaminated with ambient noises and WT technique proves to be an efficient tool to denoise these noisy signals. In the present work, this technique has been adopted to pre-process the raw chatter signal by denoising it.

Some researchers have tried to investigate the effects of cutting parameters on tool chatter considering the artificial intelligence approach such as artificial neural network (ANN), fuzzy inference system (FIS), adaptive neuro-fuzzy inference system (ANFIS). Lange and Abu-Zahra (2002) used a multi-layer preceptor ANN to correlate the response of the ultrasound sensor to the accelerometer measurement of tool chatter. Multi-layer preceptor ANN with three inputs and one hidden layer was found to be the optimum network architecture based on the least error squares and minimum network complexity. Chae et al. (2006) used neural network technique in micromachining of steel and aluminium in order to estimate the tool condition. Du et al. (1992) presented a study on tool condition monitoring in turning using the fuzzy set theory and found that results from the proposed fuzzy method indicated an overall 90% reliability for detecting tool conditions. Tansel et al. (2006) used fuzzy logic controllers for automatic chatter detection in their research work. Moreover, chatter phenomenon is very close to surface roughness because it results in poor surface finish and various researchers have utilised ANN and FIS to create a prediction model for surface roughness. Pal and Chakraborty (2005) and Kohli and Dixit (2005) have developed a back-propagation neural network model for surface roughness considering feed rate, cutting forces and depth of cut in turning process. They also observed that the proposed methodology was quite effective and utilises fewer training and testing data. Xavior and Vinayagamoorthy (2014) adopted FIS technique for model prediction considering depth of cut, feed, cutting speed and nose radius in turning process. They observed that results predicted by FIS were highly accurate and precise.

Moreover, ANN system is appropriate if adequate numbers of measurable data are present in a given process and this may be one of the limitations of ANN. Saeed et al. (2012) worked on identification of cracks in curvilinear beams by using both ANN and ANFIS. He found that ANFIS can improve the precision and provide better results. On the other hand, FIS depends on the expert knowledge for fuzzy rule generation and design of the nonadaptive fuzzy sets. In fuzzy logic, the shape of the membership functions depends on the input parameters and variation in these parameters will change the shape of the membership function. However, dependence on the expertise of fuzzy rule generation and design of nonadaptive fuzzy sets are the limitations of FIS. Recently, a merged technique (ANFIS) has been developed by the researchers to overcome the limitations of the aforesaid techniques.

ANFIS technique is the ensemble of FIS and ANN, thus utilising the advantage of both the techniques. Researchers have observed that ensemble technique is better because of its remarkably improved prediction accuracy and stability. In this technique, multiple base models are used to predict the results and so the overall prediction error of the system is reduced considerably. Hino and Yoshimura (2000) used fuzzy neural network model to develop a new method in order to predict chatter vibration in high-speed end milling operation. After comparing the experimental and predicted results, they observed that the numerical simulation can predict the chatter vibration very well. They also proposed that this technique can be reasonable and practical for other machining processes such as turning. Lin et al. (2002) proposed a complex ANN fuzzy inference model to explore the chatter phenomenon in cutting operation. Further, they also suggested that ANN fuzzy system can also be utilised for chatter problem identification in other machining processes. Lo (2003) utilised an adaptive network-based fuzzy inference system to create a prediction model for surface roughness considering spindle speed, feed rate and depth of cut. Furthermore, some researchers have done a comparative study of ANFIS with statistical methods such as regression modelling as well as response surface methodology (RSM). Jiao et al. (2004) utilised an adaptive network-based fuzzy inference system to create a prediction model for surface roughness and observed that ANFIS is better as compared to regression modelling of complex systems such as turning. Porhemmat et al. (2017) observed that ANFIS model provided much more accurate results as compared to RSM. There is no learning process in fitting the regression and RSM model for improving their performance. ANFIS is able to extract the complex nonlinear relationships between inputs and the output. Moreover, the model developed by RSM shows the greater deviation than the ANFIS. As compared to RSM, an artificial intelligent technique does not require a standard experimental design to build the model and different experimental designs can be used. In addition, ANFIS model is flexible and permits the addition of new experimental data to build a better ANFIS model. Various researchers have also used neuro-fuzzy network in order to predict an earthquake phenomenon (Zheng et al. 2015) and state the early warning of industrial accidents (Zheng et al. 2017). Moreover, limited research work has been reported till date regarding the use of ANFIS for investigation of chatter mechanism in turning process. This is the motivation of considering ANFIS over other prediction techniques.

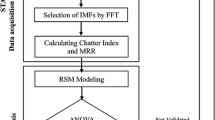

In the present work, ANFIS approach has been adopted to explore the relation between cutting parameters and chatter severity and is outlined as follows: firstly, the raw chatter signals have been acquired experimentally during turning process considering different process parameters. Secondly, the wavelet denoising technique has been used to eliminate the ambient noise present in raw signal. Further, a new parameter denoted as chatter index (CI) has been evaluated to quantify the chatter severity. Thereafter, the input process parameters and corresponding chatter indexes have been considered to train the chatter phenomenon using ANFIS. This ANFIS model has been used to predict the influence of control parameters on chatter severity. Finally, the developed ANFIS model has been validated by comparing the trained data with the experimental ones.

2 Theoretical analysis

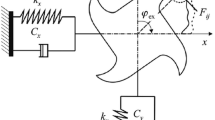

In the present work, a single degree of freedom (SDoF) turning operation with a flexible tool and rigid work piece has been considered as shown in Fig. 1. Mathematical model for turning operation has been represented by a SDoF equation as given by (Siddhpura and Paurobally 2012; Zhang et al. 2012)

where

-

\(F_\mathrm{f} (t)\) is the dynamic cutting force in feed direction, m is the mass of tool, c represents the damping coefficient, and k is the stiffness.

-

\(q(t)=\) Displacement with respect to time (t),

-

\(F_\mathrm{f} (t)=\) dynamic cutting force in feed direction with respect to time (t),

-

\({\dot{q}}(t)=\) first-time differentiation with respect to time (t) known as velocity,

-

\(\ddot{q}(t)=\) second-time differentiation with respect to time (t) known as acceleration.

Equation (1) has been further written as

\(F_\mathrm{f} (t)\) is given by

where b is the chip width, \(k_\mathrm{f}\) is the cutting force coefficient, \(d_0\) is nominal chip thickness, and \(\tau \) is the time delay between current time and previous time. Here, \(\tau =\frac{60}{N}\); N is the spindle speed in rpm.

In above equation d(t) is the dynamic chip thickness due to tool vibration and is equal to \(\left[ {d_0 +q(t-\tau )-q(t)} \right] \)

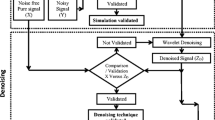

For apparent understanding, a framework of the proposed chatter detection is shown in Fig. 2.

3 Experimentation

Turning test has been performed on ASTM A36 mild steel by using high-speed precision lathe NH22 (Hindustan Machine Tool Ltd.) with different sets of cutting parameters. Chemical composition of work piece is listed in Table 1. Schematic diagram of the experimental set-up is presented in Fig. 3. A single-point cutting carbide tool has been for turning of mild steel bars. An accelerometer [Make: PCB Piezotronics and Model: 356A16] and data acquisition system [Make: OROS group and Model: OR35-multi analyser] have been used to acquire the chatter vibration signals.

For each set of turning, a new bar of ASTM A36 has been used. Work piece of 200 mm length and 40 mm diameter has been used. Here, 140 mm length of work piece has been used for turning, while remaining 60 mm length was used for holding purpose in chuck. In total, 80 runs of turning have been performed considering the cutting parameters: depth of cut (d), feed rate (f) and spindle speed (N). The various levels of cutting parameters considered are shown in Table 2.

The experiments have been performed in order to acquire the raw chatter signals, and some of the recorded signals are shown in Figs. 4, 5 and 6. Here, the raw signals have been recorded at “d = 1.5 mm, f = 0.05 mm/rev and N = 700 rpm”, “d = 2.5 mm, f = 0.1 mm/rev and N = 700 rpm” and “d = 2 mm, f = 0.05 mm/rev and N = 1000 rpm”, respectively. These recorded raw signals have severe noise inclusions. In the present study, wavelet denoising has been done using MATLAB software and hybrid thresholding rule has been adopted to acquire much smoother results.

4 Wavelet-based denoising

The inclusion of noise in the signal interrupts the identification of exact chatter. Several approaches such as kernel estimators, spline estimators and Fourier-based signal processing have been considered by different researchers. But these techniques have certain limitations and imperfections. Therefore, more appropriate novel approach is required for denoising, which motivated this research. In this study, wavelet denoising technique has been done. In wavelet denoising technique the noisy signal is first decomposed using wavelet transform, where the level of decomposition depends upon the length of the signal. After decomposition, the thresholding of the coefficients has been done. If the wavelet coefficient is smaller than the threshold level, it is then set as zero and if the coefficient is larger than threshold level, it is either adapted or kept as it is.

4.1 Wavelet decomposition

The aforesaid denoising technique has been implemented two steps, i.e. wavelet decomposition and wavelet thresholding. In wavelet decomposition technique, the acquired signal of finite energy is passed through low-pass filter and high-pass filter. Low-pass filter will result in approximate coefficient, while high-pass filter will yield detailed coefficient. The methodology of signal decomposition is shown in Fig. 7. The level of decomposition depends on the length of the signal. In Figs. 8, 9 and 10, \(d_{1}, d_{2}, d_{3}\) and \(d_{4}\) are stationary detailed coefficients acquired at decomposition levels 1, 2, 3 and 4, respectively. A detailed coefficient has been obtained when raw signal is passed through high-pass filter, while approximated coefficient “\(a_{4}\)” has been obtained at lower frequency.

In this study, Daubechies 5 (db5) wavelet with decomposition level of 4 has been selected. Selection of decomposition level depends on the length of the signal \(({N}_{\mathrm{s}})\). For example, \({N}_{\mathrm{s}}= 256 = 2^{8}\) indicates that the decomposition level should be 8. In the present work, decomposition level “4” has been considered to reduce computing time and enhance chatter responsiveness. The wavelet which supremely matches the signal has been detected by several trials, and it has been found that Daubechies 5 (db5) is the best option.

4.2 Wavelet thresholding rule

Generally, hard or soft thresholding rules have been adopted for denoising purpose. If the wavelet coefficient values are greater than the given threshold level, then hard thresholding function will retain all wavelet coefficients above threshold level and rest are set as zero (Debnath 2012). The hard thresholding is defined as

where W is noisy wavelet coefficient and T is the threshold.

In soft thresholding, if the wavelet coefficient values are greater than given threshold, then soft thresholding function shrinks the wavelet coefficient and the rest are set as zero (Debnath 2012). The soft thresholding is defined as

However, hard thresholding is based on keep or remove approach; hence, it classifies a true signal as noise and vice versa. On the other hand, soft thresholding shrinks the wavelet coefficients. Due to these difficulties, both the rules are unable to denoise the signal accurately and may leave the chatter undetected. In order to overcome the limitations of the aforesaid thresholding methods, an adaptive hybrid thresholding approach has been developed recently (Wang and Liang 2009) and is given by

Here, sgn (W) is the signum function of W and W is noisy wavelet coefficient, \(\zeta \) is a parameter in the range of (0, 1), and T is the customised thresholding level (Donoho 1995) given by

where n is length of signal, and \(\sigma \) is standard deviation of noise.

In the present study, hybrid thresholding rule has been adopted to acquire much smoother results. The detailed coefficients and denoised signals are shown in Figs. 8, 9 and 10. Further, a new parameter denoted as chatter index (CI) has been evaluated to quantify the chatter severity.

5 Chatter quantification

Cutting parameters plays prominent role in producing chatter in turning process. Several researchers have investigated the effect of cutting parameters in turning operation, but their investigation was based on raw signals. These raw signals are contaminated with noisy signals. Hence, their results on chatter identification were not so much accurate. Till date no work has been reported yet, on investigation of chatter information considering the denoised signals. In the present work, chatter severity has been explored by evaluating a new parameter called chatter index (CI) considering aforesaid denoised signals.

In turning operation chatter index indicates the prominence of particular set of parameters in generating chatter. Higher the value of chatter index more will be the resultant chatter. Thus, chatter index helps in identifying the severity of chatter. Chatter index is evaluated using the given relation

where CI is the chatter index, n is the length of signal, and \(\mu \) is the mean.

The values of chatter indexes obtained at different set of cutting parameters are shown in Table 3. In this study, 80 experiments have been performed and some of the experimental results are shown in Table 3.

6 Prediction methodology

A lot of research works have been carried out by researchers to develop techniques for chatter identification. Some researchers have tried to investigate the effects of cutting parameters on tool chatter considering the artificial intelligence approach (ANN and FIS). Individual and combined effect of input parameters d, f and N on chatter index can be easily predicted with help of these intelligent systems. In the present work, a hybrid approach (ANFIS) has been used as chatter prediction methodology as discussed in the next article.

6.1 Adaptive neuro-fuzzy inference system (ANFIS)

ANFIS is the combination of fuzzy logic and neural networks. ANN system is appropriate if adequate measurable data are present in a given process and this may be one of the limitations of ANN. On the other hand, FIS depends on the expert knowledge for fuzzy rule generation and design of the nonadaptive fuzzy sets. Further, in fuzzy logic the shape of the membership functions depends on parameters and variation in these parameters will change the shape of the membership function. The application of a neuro-fuzzy inference system is used for the purpose of prediction and eliminates the limitations of the aforesaid techniques. Furthermore, ANFIS controller can evolve automatically to acquire desired membership functions of the fuzzy if-then rules to achieve goals. It can be trained to develop if-then fuzzy rules and determine membership functions for input and output variables of the system. In ANFIS, the membership function parameters can be tuned using back-propagation algorithm or combination of back-propagation with a least squares method.

ANFIS model includes the following steps:

-

1

Based on linguistic statement define the input and output variables.

-

2

Fuzzy partition of variables.

-

3

Selection of membership functions (MF’s).

-

4

Fuzzy if-then rules.

-

5

Design fuzzy reasoning (inference mechanism).

-

6

Defuzzification.

6.2 ANFIS modelling for chatter

In this study, the ANFIS technique has been adopted for training and prediction of chatter index (CI) in turning process. Here, MATLAB has been used for training, analysis and testing purpose. The architecture of ANFIS model, MF’s and fuzzy rule viewer is shown in Figs. 11, 12 and 13, respectively. ANFIS architecture comprises of three-node input layer, 80 nodes in hidden layers and one node in output layer. However, ANFIS architecture consists of five layer discussed as;

Layer 1: It is also known as fuzzification. This layer consists of input variable which converts input data into fuzzy set by means of membership functions given by (Asilturk 2011; Daoming and Jie 2006)

where i is node of layer, \(\left( \mathrm{OP} \right) _{1,i} \) is output of 1\({\mathrm{st}}\) layer, \(\mu _{a_i }\) and \(\mu _{b_i }\) are membership function. This layer supplies the input values to next layer.

Layer 2: It is also known as multiplication or membership layer. It receives the input values from 1\({\mathrm{st}}\) layer and acts as a membership function. The output of this layer is the product of all incoming signals from layer 1 and is expressed as (Asilturk 2011; Daoming and Jie 2006)

where \(\omega _i \) is output signal of 1\({\mathrm{st}}\) output layer \(\left( \mathrm{OP} \right) _{2,i} \) and denotes the firing strength of rule. Firing strength means the degree to which the antecedent part of fuzzy rule is satisfied and it shapes the output function for rule.

Layer 3: It is also known as rule layer or normalisation. In layer 3 the \({i}{\mathrm{th}}\) node calculates the ratio of an each \({i}{\mathrm{th}}\) rule firing strength to the sum of all rules firing strength, expressed as,

where \(\left( \mathrm{OP} \right) _{3,i} \) is the output of 3\({\mathrm{rd}}\) layer and \(\bar{{\omega }}_i \) is normalised firing strength.

Layer 4: It is also known as defuzzification layer which performs defuzzification by means of fuzzy rule operation. Every node i in this layer is an adaptive node. Input and output relation of this layer has been defined as (Asilturk 2011; Daoming and Jie 2006);

where \(\left( \mathrm{OP} \right) _{4,i}\) is output of 4\({\mathrm{th}}\) layer and \(Z_{i}\) is constant parameter used to minimise the error between ANFIS output and computed result. \(P_{i}, Q_{i}\) and \(R_{i}\) are constant parameters of model.

Layer 5: It is also known as output layer or summation layer, which adds up all input coming from layer 4 and transforms each fuzzy result in to crisp output (Asilturk 2011; Daoming and Jie 2006) given by;

The ANFIS structure has been tuned by least-square estimation and back-propagation algorithm. In this study, based on back-propagation neural network (BPNN) a first-order Sugeno ANFIS has been used. Here, BPNN algorithm performs two phases of data flow for a given input–output data pairs. Firstly, the input parameter pattern has been propagated from input to output layer and thereafter that the network output (CI) has been back-propagated from output layer to the previous layer in order to update the weight. Weights are internal parameters associated with each node.

Furthermore, the fuzzy set is completely characterised by its membership functions (MF’s). In this study Gaussian-shaped five MFs have been used for each input parameters as shown in Fig. 12. Due to its smoothness and versatility, Gaussian MFs are employed to identify fuzzy variables and specify the degree of membership. Moreover, if the component “depth of cut” is considered as fuzzy variable, then its membership function might be very low (VL), low (L), medium (M), high (H) and very high (VH). Similarly, the MFs for feed rate and spindle speed have been considered as very low, low, medium, high and very high.

After selection of MF’s for input parameters, the fuzzy if-then rules have been written. Some of the fuzzy if-then rules are shown in Table 4. Fuzzy if-then rules are backbone of fuzzy inference system and mathematically represent the linguistic relationship between input and output variables.

To describe ANFIS architecture in brief, consider two fuzzy if-then rules considering first-order Sugeno model expressed as;

-

Rule 1: if (X is \({a}_{1})\) and (Y is \({b}_{1})\), then (\({F}_{1} = {P}_{1}{X} +{Q}_{1}{Y} + {R}_{1})\);

-

Rule 2: if (X is \({a}_{2})\) and (Y is \({b}_{2})\), then (\({F}_{2} = {P}_{2}{X} +{Q}_{2}{Y} + {R}_{2})\); . . .

-

Rule n: if (X is \({a}_{{n}})\) and (Y is \({b}_{{n}})\), then (\({F}_{{n}} = {P}_{{n}}{X} +{Q}_{{n}}{Y} + {R}_{{n}})\);

where X and Y are inputs, \({a}_{{n}}\) and \({b}_{{n}}\) are appropriate fuzzy sets, \({P}_{{n}}, {Q}_{{n}}\) and \({R}_{{n}}\) are correlation parameters, and \({F}_{{n}}\) contributes to the output of the system.

Figures 19, 20 and 21 show the three-dimensional surface model developed to study the interaction between process parameters and chatter index. On the other hand, Fig. 22 shows the two-dimensional surface model for better understanding the effect of each parameter on chatter index.

7 Results and discussion

7.1 Model validation (training and checking)

In the present study, ANFIS model is used to predict the CI in turning process. Hence, it is essential to have proper training and checking of data set which is used to generate the ANFIS model. Improper selection of data sets will not validate the model. For training and checking purpose different sets of data have been taken. Here the training data set included 80 observations and checking data set involved 30 observations. These training and checking data sets were uniformly sampled from input range and used. In this study for FIS training, hybrid optimisation method is used, which is combination of least-square and back-propagation gradient descent methods. This hybrid method involves forward and backward learning algorithm. Figures 14, 15 and 16 show the training and checking result of different data sets.

Figure 14 shows the data set training purpose. Training the ANFIS system with training data set and FIS output is shown in Fig. 15. Here, the average testing error is found to be 0.000000197 and is quite acceptable, while training error found to be 0.0642 is also acceptable.

Figure 16 shows the ANFIS validation diagram with checking data sets and FIS output. It clearly shows that checking data look fine enough against the trained FIS. The average testing error for checking data set is found to be 0.1479 and is satisfactory.

7.2 Model accuracy and error

To assess the accuracy and error in prediction of chatter, twelve new experiments have been performed as shown in Table 5. This includes the experimental CI values, predicted CI values, percentage of individual error \(({e}_{{ai}})\) and accuracy of model \(({A}_{{i}})\). The percentage of individual error has been obtained by using Eq. (14), while average individual accuracy of model has been calculated by using equation (15).

where \(e_{ai}\) represents average individual error, \(A_\mathrm{c}\) represents average individual accuracy, \(V_\mathrm{E}\) and \(V_\mathrm{P}\) show the experimental and predicted values, respectively, n is the total number of data set test, and i represents the number of experimental runs (\(i = 1, 2, 3 \ldots n\)).

The average percentage of error of ANFIS model has been found to be 6.5%, while accuracy of ANFIS model is 93.5%. This indicates that the proposed model could be successfully used to predict the CI in turning process. A good agreement between experimental and predicted data validates the developed ANFIS training model and is shown in Fig. 17.

7.3 Comparative study of ANFIS, ANN and RSM

Comparative studies of ANFIS have been done with artificial neural network (ANN) and response surface methodology (RSM) for the prediction of chatter severity. More number of experiments has been performed considering cutting parameters as mentioned in Table 2. Further, experimental results were analysed using ANN and RSM. Here, RSM and ANN modelling has been done by taking the range of cutting parameters in coded form \((-1 \mathrm{to} +1)\) by the given relation:

7.3.1 ANN modelling

ANN training has been done using MATLAB software. 3-5-1 ANN architecture comprised of 3-neurons in input layer (d, f and N), 5-neurons in hidden layer (A to E) and 1-neuron in output layer (CI) as shown in Fig. 18. The training function “TRAINLM” and learning function “LEARNGDM” have been used. Further, activation function “TANSIG” has been invoked to obtain the desired output. Final optimal weights between the input and hidden layers; hidden and output layers are listed in Table 6.

7.3.2 RSM modelling

RSM has been adopted to develop the quadratic model for chatter severity. As per estimated regression coefficient, the model equation for chatter index (CI) is as follows;

To assess the accuracy in prediction of chatter using the three techniques, percentage deviation of experimental results and individual predicted results have been calculated using equation (14) and are presented in Table 7. From Table 7, it is evident that ANFIS (5.6%) has less average error in prediction of chatter as compared to ANN (6.1%) and RSM (7.0%). Thus, it is inferred that ANFIS is better as compared to ANN and RSM for predicting chatter severity in turning process.

7.4 Chatter severity plots

In order to understand the relative dependency of chatter severity on cutting parameters, 2D and 3D graphs have been plotted with respect to the chatter index and cutting parameters. From Table 3 it has been noted that the chatter index CI is maximum when depth of cut is 2 mm, feed rate 0.05 mm/rev. and spindle speed 100 rpm, while at depth of cut 1 mm, feed rate 0.15 mm/rev and spindle speed 1000 rpm chatter index is minimum.

From the 3D plots, it is inferred that the dependency of chatter index on the cutting parameters is not monotonous. To represent the nonmonotonous behaviour of CI, surface plots have been drawn as shown in Figs. 19, 20 and 21. These plots represent the variation of chatter index considering two cutting parameters at a time. Figure 19 shows the interaction effect of feed rate and depth of cut on CI, at holding spindle speed of 1000 rpm. Here, minimum CI is obtained at a depth of cut 1 mm and feed rate between 0.2 and 0.25 mm/rev. Moreover, at the depth of cut of 2 mm CI is 3.8. Figure 20 shows the interaction effect of depth of cut and spindle speed on CI at fixed feed rate of 0.15 mm/rev. Here, CI is minimum at depth of cut of 2 and 0.5 mm and spindle speed of 700 and 1000 rpm. From the above discussion it has been inferred that at same depth of cut (d= 2 mm) the chatter can be maximum or minimum. This reflects the nonmonotonous behaviour of CI with respect to the cutting parameters. Furthermore, Fig. 21 shows the interaction effect of spindle speed and feed rate on CI while keeping the depth of cut fixed at 1.5 mm. Here, minimum CI has been found at 1000 rpm and 0.25 mm/rev.

The relative influence of various cutting parameters on CI can be established with the help of 2D graph as shown in Fig. 22.

Experiments have been performed by varying each parameter at a time and keeping the other two parameters constant. These results have been plotted in a 2D graph as shown in Fig. 22. From Fig. 22a it is evident that depth of cut is the most influencing parameter. In the considered range of depth of cut, CI \((= 2.4)\) is maximum at \(d = 2\) mm. Spindle speed is the next most influencing cutting parameter. CI \((= 2)\) is maximum at \(N = 700\) rpm as shown in Fig. 22b. Furthermore, maximum value of CI is 1.45 at feed rate of 0.05 mm/rev. as shown in Fig. 22c.

From the above analysis, it is quite clear that depth of cut is the most influencing parameter in chatter phenomenon. The reason is with the increase in depth of cut keeping other parameters constant, the associated radial force increases prominently as compared to the other cutting forces. This increase in radial force results in increased waviness and unevenness along the surface of the work piece. This waviness leads to further time delay between the two corresponding turning passes along the job surface. So, ultimately increase in depth of cut results in pronounced tool chatter as compared to the rest of the cutting parameters.

Furthermore, the experimental results indicate that, even for identical depth of cut, the turning process can be either stable or unstable depending on spindle speed and feed rate. From Table 3, in experiment run 2, the value of CI is 0.52 when depth of cut, speed and feed rate are 2.5 mm, 850 rpm and 0.25 mm/rev., respectively. However, for the same depth of cut, in experimental run 66, CI is 3.04 at spindle speed of 1300 rpm and feed rate 0.05 mm/rev.

In the present work, it is concluded that variation of chatter with respect to the cutting parameters is not monotonic. In this study, chatter phenomenon has been categorised into two phases. Firstly, stable chatter, i.e. if the value of CI is in the range of 0–1. Secondly, unstable chatter, when CI is greater than 1.

8 Conclusions

In the present work, experiments have been conducted at different cutting parameters and the corresponding raw chatter signals have been acquired. These raw signals are pre-processed using wavelet denoising technique. These denoised signals are trained using an ANFIS model. Further, more experiments have been conducted to validate the developed training model. From the analysis of chatter severity it has been inferred that depth of cut is the most influencing cutting parameter. The key findings of the present research are enumerated as follows:

-

Chatter index reflects the random nature of turning process.

-

Chatter index of denoised signal reveals that the chatter dependence on cutting parameters is not monotonic in nature.

-

Wavelet transformation is a powerful tool used for pre-processing the raw chatter signal.

-

ANFIS training is quite apt in predicting the nature of chatter phenomenon.

References

Altintas Y, Weck M (2004) Chatter stability of metal cutting and grinding. CIRP Ann Manuf Technol 53(2):619–642

Asilturk I (2011) On-line surface roughness recognition system by vibration monitoring in CNC turning using adaptive neuro-fuzzy inference system (ANFIS). Int J Phys Sci 6(22):5353–5360

Berger BS, Minis I, Harley J, Rokni M, Papadopoulos M (1998) Wavelet based cutting state identification. J Sound Vib 213(5):813–827

Chae J, Park SS, Freiheit T (2006) Investigation of micro-cutting operations. Int J Mach Tools Manuf 46:313–332

Choi T, Shin YC (2003) On-line chatter detection using wavelet-based parameter estimation. Trans Am Soc Mech Eng J Manuf Sci Eng 125(1):21–28

Clancy BE, Shin YC (2002) A comprehensive chatter prediction model for face turning operation including tool wear effect. Int J Mach Tools Manuf 42(9):1035–1044

Daoming G, Jie C (2006) ANFIS for high-pressure waterjet cleaning prediction. Surf Coat Technol 201(3):1629–1634

Debnath L (2012) Wavelets and signal processing. Springer, Berlin

Donoho DL (1995) De-noising by soft-thresholding. IEEE Trans Inf Theory 41(3):613–627

Du RX, Elbestawi MA, Li S (1992) Tool condition monitoring in turning using fuzzy set theory. Int J Mach Tools Manuf 32:781–796

Duncan GS, Tummond MF, Schmitz TL (2005) An investigation of the dynamic absorber effect in high-speed machining. Int J Mach Tools Manuf 45(4):497–507

Hanna NH, Tobias SA (1974) A theory of nonlinear regenerative chatter. ASME J Eng Ind 96(1):247–255

Hino J, Yoshimura T (2000) Prediction of chatter in high-speed milling by means of fuzzy neural networks. Int J Syst Sci 31(10):1323–1330

Jiao Y, Lei S, Pei ZJ, Lee ES (2004) Fuzzy adaptive networks in machining process modeling: surface roughness prediction for turning operations. Int J Mach Tools Manuf 44(15):1643–1651

Khorasani AM, Aghchai AJ, Khorram A (2011) Chatter prediction in turning process of conical workpieces by using case-based resoning (CBR) method and taguchi design of experiment. Int J Adv Manuf Technol 55(5–8):457–464

Kohli A, Dixit US (2005) A neural-network-based methodology for the prediction of surface roughness in a turning process. Int J Adv Manuf Technol 25(1):118–129

Lange JH, Abu-Zahra NH (2002) Tool chatter monitoring in turning operations using wavelet analysis of ultrasound waves. Int J Adv Manuf Technol 20:248–254

Lin B, Zhu MZ, Yu SY, Zhu HT, Lin MX (2002) Study of synthesis identification in the cutting process with a fuzzy neural network. J Mater Process Technol 129(1):131–134

Lo SP (2003) An adaptive-network based fuzzy inference system for prediction of workpiece surface roughness in end milling. J Mater Process Technol 142(3):665–675

Mallat S (2008) A wavelet tour of signal processing: the sparse way. Academic press, New York

Otto A, Radons G (2013) Application of spindle speed variation for chatter suppression in turning. CIRP J Manuf Sci Technol 6(2):102–109

Pal SK, Chakraborty D (2005) Surface roughness prediction in turning using artificial neural network. Neural Comput Appl 14(4):319–324

Porhemmat S, Ghaedi M, Rezvani AR, Azqhandi MHA, Bazrafshan AA (2017) Nanocomposites: synthesis, characterization and its application to removal azo dyes using ultrasonic assisted method: modeling and optimization. Ultrason Sonochem 38:530–543

Quintana G, Ciurana J (2011) Chatter in machining processes: a review. Int J Mach Tools Manuf 51(5):363–376

Saeed RA, Galybin AN, Popov V (2012) Crack identification in curvilinear beams by using ANN and ANFIS based on natural frequencies and frequency response functions. Neural Comput Appl 21(7):1629–1645

Siddhpura M, Paurobally R (2012) A review of chatter vibration research in turning. Int J Mach Tools Manuf 61:27–47

Tansel IN, Wang X, Chen P, Yenilmez A, Ozcelik B (2006) Transformations in machining. Part 2. Evaluation of machining quality and detection of chatter in turning by using s-transformation. Int J Mach Tools Manuf 46:43–50

Taylor FW (1907) On the art of cutting metals. The American Society of Mechanical Engineers, New York

Taylor CM, Turner S, Sims ND (2010) Chatter, process damping, and chip segmentation in turning: a signal processing approach. J Sound Vib 329(23):4922–4935

Tobias SA (1961) Machine tool vibration research. Int J Mach Tool Des Res 1(1–2):1–14

Tobias SA, Fishwick W (1958) The chatter of lathe tools under orthogonal cutting conditions. Trans ASME 80(2):1079–1088

Wang L, Liang M (2009) Chatter detection based on probability distribution of wavelet modulus maxima. Robot Comput Integr Manuf 25(6):989–998

Wu Y, Du R (1996) Feature extraction and assessment using wavelet packets for monitoring of machining processes. Mech Syst Signal Process 10(1):29–53

Xavior MA, Vinayagamoorthy R (2014) Fuzzy inference system for prediction during precision turning of Ti-6al-4v. Procedia Eng 97:308–319

Yang Y, Munoa J, Altintas Y (2010) Optimization of multiple tuned mass dampers to suppress machine tool chatter. Int J Mach Tools Manuf 50(9):834–842

Yao Z, Mei D, Chen Z (2010) On-line chatter detection and identification based on wavelet and support vector machine. J Mater Process Technol 210(5):713–719

Zhang L, Wang X, Liu S (2012) Analysis of dynamic stability in a turning process based on a 2-DOFs model with overlap factor. J Mech Sci Technol 26(6):1891–1899

Zheng YJ, Ling HF, Chen SY, Xue JY (2015) A hybrid neuro-fuzzy network based on differential biogeography-based optimization for online population classification in earthquakes. IEEE Trans Fuzzy Syst 23(4):1070–1083

Zheng YJ, Chen SY, Xue Y, Xue JY (2017) A Pythagorean-type fuzzy deep denoising autoencoder for industrial accident early warning. IEEE Trans Fuzzy Syst 25(6):1561–1575

Acknowledgements

The authors gratefully acknowledge the Mechanical Engineering Department, IIT Indore, India, for their help in conducting experiments.

Funding

This research received no specific grant from any funding agency in the public or commercial sector.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declared that they have no conflict of interest.

Research involving human participants and/or animals

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

Informed consent was obtained from all authors included in this study.

Additional information

Communicated by V. Loia.

Rights and permissions

About this article

Cite this article

Kumar, S., Singh, B. Chatter prediction using merged wavelet denoising and ANFIS. Soft Comput 23, 4439–4458 (2019). https://doi.org/10.1007/s00500-018-3099-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00500-018-3099-8