Abstract

Sugarcane bagasse is a by-product from the sugar and ethanol industry which contains approximately 70 % of its dry mass composed by polysaccharides. To convert these polysaccharides into fuel ethanol it is necessary a pretreatment step to increase the enzymatic digestibility of the recalcitrant raw material. In this work, sugarcane bagasse was pretreated by an alkaline-sulfite chemithermomechanical process for increasing its enzymatic digestibility. Na2SO3 and NaOH ratios were fixed at 2:1, and three increasing chemical loads, varying from 4 to 8 % m/m Na2SO3, were used to prepare the pretreated materials. The increase in the alkaline-sulfite load decreased the lignin content in the pretreated material up to 35.5 % at the highest chemical load. The pretreated samples presented enhanced glucose yields during enzymatic hydrolysis as a function of the pretreatment severity. The maximum glucose yield (64 %) was observed for the samples pretreated with the highest chemical load. The use of 2.5 g l−1 Tween 20 in the hydrolysis step further increased the glucose yield to 75 %. Semi-simultaneous hydrolysis and fermentation of the pretreated materials indicated that the ethanol yield was also enhanced as a function of the pretreatment severity. The maximum ethanol yield was 56 ± 2 % for the sample pretreated with the highest chemical load. For the sample pretreated with the lowest chemical load (2 % m/m NaOH and 4 % m/m Na2SO3), adding Tween 20 during the hydrolysis process increased the ethanol yield from 25 ± 3 to 39.5 ± 1 %.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sugarcane bagasse is an agro-industrial by-product resulting from plant crushing to obtain a sucrose-rich juice used for sugar and ethanol production. In the Brazilian mills, the majority of sugarcane bagasse is used to produce steam and electricity; however, part of this sugarcane bagasse can be derived for producing second-generation ethanol due to increasing liquid fuel demand [1–3]. Sugarcane bagasse contains appreciable amounts of cellulose and hemicelluloses, which can be depolymerized by chemicals or enzymes into simple sugars such as glucose and xylose, respectively. The hydrolysis of sugarcane bagasse into fermentable sugars is a crucial stage, which mainly determines the overall process efficiency. Compared to chemical treatments, hydrolytic enzymes can be advantageously used to convert polysaccharides into monosaccharides because these enzymes require mild conditions in the process and avoid corrosion problems [4].

After polysaccharide hydrolysis, fuel ethanol production from biomass involves a fermentation step. However, pretreatment is necessary to increase enzymatic hydrolysis efficiency because it can break down the complex structure of the biomass, which increases its accessibility to cellulases [4, 5]. Alkaline-sulfite chemithermomechanical processing has been proposed to pretreat sugarcane bagasse since the process is very selective for delignification [6, 7]. The pretreated solids are delignified up to 50 % depending on the reaction conditions, retain most of the polysaccharide fraction, and present residual lignin partially sulfonated [6–8]. The main advantage of this physical–chemical treatment is that it is already practiced industrially, i.e. it has machinery available with basis on the pulping industry, with minor environmental and technological barriers for commercialization. Moreover, the liquor generated in the process, and the recovery of energy, chemicals, and lignin are steps already established [8].

The use of surface active additives, or surfactants, in enzymatic hydrolysis processes has increased the conversion efficiencies of several lignocellulosic substrates [9–14]. Surfactants are amphiphilic substances that usually contain a hydrophilic head and a hydrophobic tail. Non-ionic surfactants, such as fatty acid esters of sorbitan polyethoxylates (Tween 20, Tween 80), are the most effective additives evaluated for enhancing enzymatic hydrolysis of lignocellulosic materials. The surfactants tend to increase the enzymatic hydrolysis yield through hydrophobic interactions with the lignin, thus reducing unproductive adsorption or increasing desorption of cellulases in the substrate fibers, which allows the enzymes to catalyze another cycle of reactions [9, 11–13, 15]. In addition, it has been demonstrated that Tween 80 can reduce the inactivation of adsorbed cellulases on the substrate [14]. Recently, Morando et al. [16] evaluated alkaline hydrogen peroxide pretreatment of sugarcane bagasse followed by enzymatic hydrolysis in the presence of Tween 80. Under optimized conditions, a 29 % improvement in the glucose concentration compared to that without Tween 80 was observed. The effect of surfactants on enzymatic hydrolysis of alkaline sulfite-pretreated sugarcane bagasse and the subsequent fermentation of the sugar streams have not been investigated.

For the development of the present work, sugarcane bagasse samples were processed with three different loads of delignification agents (Na2SO3 and NaOH) to obtain sugarcane bagasse pulps that contain reduced lignin content. Then, milled bagasse samples and the pretreated materials were hydrolyzed with a commercial cellulase cocktail. For the different substrates, the use of non-ionic surfactants (Tween 20 or Tween 80) was assessed during the enzymatic hydrolysis steps to increase the glucose yield. Finally, selected samples were hydrolyzed and fermented with Saccharomyces cerevisiae for bioconversion into ethanol.

Materials and methods

Alkaline-sulfite chemithermomechanical processing of sugarcane bagasse

The raw material used in this work was sugarcane bagasse obtained from sugarcane cultivars commonly planted by small farmers in Brazil (Itajubá, MG). The mature sugarcane stalks were mechanically crushed to remove most of the sucrose juice. The collected sugarcane bagasse samples were then immersed in water and washed thoroughly to remove any residual sucrose. The washed samples were air-dried and stored under dry conditions until the samples were used in the pretreatment experiments. Pretreatment was performed with approximately 25 g of bagasse (on a dry mass basis) impregnated with alkaline-sulfite liquors at a bagasse/liquor ratio of 1:8 (m/v). Impregnation was performed by applying vacuum to the air-dried biomass contained in a Kitasato flask for 30 min. One hundred milliliters of liquor was then displaced in the flask, and an additional 15 min of vacuum was applied. After that, 100 ml of distilled water was added and vigorously mixed. The final alkaline-sulfite liquors corresponded to varied loads of 2 g/4 g, 3 g/6 g, or 4 g/8 g of NaOH/Na2SO3 per 100 g of bagasse. The impregnated biomass was cooked at 120 °C for 2 h. Then, the material was washed with distilled water, disaggregated in an industrial blender with 2.25 l of distilled water for 15 min, centrifuged (10 min, 3000×g at 10 °C), and further filtered on analytical filter paper.

Chemical characterization of sugarcane bagasse and pretreated samples

The bagasse samples were characterized for their extractive, polysaccharide, and lignin content according to Ferraz et al. [17]. The sugarcane bagasse and pretreated samples were milled to pass through a 0.5-mm screen and extracted with 95 % (m/m) ethanol for 6 h in a Soxhlet apparatus. The percentage of extractives was determined based on the dry mass of the extracted and non-extracted milled samples. Ethanol-extracted samples were hydrolyzed with 72 % m/m sulfuric acid at 30 °C for 1 h (300 mg of sample and 3 ml of sulfuric acid). The acid was diluted by adding 79 ml of distilled water, and the mixture was heated at 121 °C and 1 atm for 1 h. The resulting material was cooled and filtered through a porous glass filter number 3. The solids were dried to a constant mass at 105 °C, which was determined as the insoluble lignin. The soluble lignin in the filtrate was read in a standard UV cuvette (1-cm path length) at 205 nm. An absorptivity (extinction coefficient) value of 105 l g−1 cm was used to calculate the amount of acid-soluble lignin present in the hydrolysates. The 205-nm absorptivity reported for most lignocellulosic materials falls within the range of 88–113 l g−1 cm. The value of 105 l g−1 cm used in this protocol represents an average of the values found for different materials. Soluble sugars in the hydrolysates were quantified by HPLC using an HPX-87H column, heated at 45 °C and eluted with 5 mmol l−1 sulfuric acid at 0.6 ml min−1. Acetic acid and sugars were detected with a temperature-controlled refraction index detector. Glucan values were derived from acid-released glucose. C-5 polysaccharides values were derived from calculations, considering the acid-released monomers arabinose and xylose. Variation between analysis triplicates is shown as standard deviations in the “Results and discussion” section.

Enzymatic hydrolysis

The enzymatic hydrolysis experiments used an enzyme preparation produced by Trichoderma reesei (Multifect® CX 15L, Genencor/Danisco, Brazil), containing approximately 30 filter paper units (FPU) per ml of crude enzyme extract (cocktail). The total cellulase activity was determined according to the IUPAC recommendations [18]. Dosages of 20 or 60 FPU per gram of substrate were used during the hydrolysis steps. Each hydrolysis experiment was carried out in 125-ml Erlenmeyer flasks containing 1 g of substrate in 50 mmol l−1 sodium acetate buffer at pH 5.0 and the enzyme extract (final consistency of 5 % m/v). To avoid microorganism growth during the hydrolysis period, 0.01 % m/v sodium azide was added in the flasks. The flasks were incubated at 45 °C under reciprocal agitation of 120 cycles min−1. The reaction was sampled at defined periods from 14 to 96 h, and followed by centrifugation (3400×g) at 10 °C for 10 min. For each reaction time, two replicate experiments were performed. After centrifugation, hydrolysates were immediately analyzed to determine the glucose concentrations using the glucose oxidase kit (Bioclin-Quibasa, Brazil). The glucose yields were expressed as the percentage of the theoretical maximum glucose yield from the treated biomass. The effect of two surfactants, Tween 20 (polyoxyethylene sorbitan monolaurate) and Tween 80 (polyoxyethylene sorbitan monooleate), on enzymatic hydrolysis was evaluated. For this, 2.5 g l−1 surfactant (5 % m/m) [11] was added in the reaction medium before enzyme addition. The variation between the hydrolysis replicates is shown as error bars in the “Results and discussion” section.

Semi-simultaneous hydrolysis and fermentation (SSHF)

For ethanol production from alkaline-sulfite pretreated bagasse samples, SSHF was adopted in this study according to Franco et al. [19]. For this, the Erlenmeyer flasks containing the pretreated samples (containing approximately 90 % m/m humidity) were autoclaved at 1 atm, 120 °C for 15 min. The solids were suspended (final consistency of 5 % m/v) in 50 mmol l−1 sodium acetate buffer (pH 5), containing cellulase activity of 20 FPU g−1 and supplemented with 3 g l−1 yeast extract, 3 g l−1 peptone, 1 g l−1 ammonium chloride, 1 g l−1 KH2PO4, and 0.5 g l−1 magnesium sulfate. After 24 h of enzymatic hydrolysis at 45 °C, 4 g l−1 commercial S. cerevisiae was inoculated in the flasks, and the temperature was set to 30 °C.

The ethanol concentration was determined in each flask after 24 h fermentation. For this, a small liquid fraction was centrifuged (3400×g, 10 °C, 10 min), filtered on analytical filter paper and analyzed for ethanol concentration according to Majkic-Singh and Berkes [20] with modifications. Five microliters of alcohol oxidase preparation (Sigma, St. Louis, MO) was diluted in 5 ml of 50 mmol l−1 sodium phosphate buffer (pH 7.5). Horseradish peroxidase (HRP 2500 IU l−1, Sigma, St. Louis, MO) was also prepared in the same buffer containing 2 mmol l−1 2,2-azino-bis-(3-ethylbenzothiazoline-6-sulfonate) (ABTS). Afterward, 10 μl of the fermentation sample was reacted with 0.1 ml of diluted alcohol oxidase solution and 2.5 ml of solution containing ABTS and HRP. The mixture was left in a water bath at 37 °C for 30 min. The readings at 410 nm were performed using an UV–Vis spectrophotometer (Biochrom Libra S50). A calibration curve was prepared using pure standard-grade ethanol. The ethanol yield was expressed as the percentage of the theoretical maximum calculated from the glucose derived from the pretreated biomass samples.

The SSHF experiments were performed with samples pretreated at the three alkaline sulfite loads. In one of the SSHF experiments (the sugarcane bagasse sample pretreated at the lower alkaline-sulfite load), the SSHF was also carried out in the presence of 2.5 g l−1 Tween 20. Variation between the SSHF replicates is shown as deviations from the average values in the “Results and discussion” section.

Results and discussion

Sugarcane bagasse was used as a raw material to prepare fermentable C-6 sugars for subsequent ethanol production by S. cerevisiae. Untreated sugarcane bagasse contained 22.8 % total lignin, 41.2 % glucan, 21.4 % C-5 polysaccharides, and 2.9 % m/m acetyl groups. The acid hydrolysates of the C-5 polysaccharides were mainly composed of xylose (91.1 % of the total C-5) with minor amounts of arabinose (8.9 %) (Table 1). This chemical composition was consistent with data previously reported for sugarcane bagasse [6, 21, 22]. C-5 polysaccharide composition was characteristic of partially acetylated arabinoxylans already described as the major hemicellulose in sugarcane bagasse [21, 22].

Enzymatic hydrolysis of untreated sugarcane bagasse with a cellulase load of 20 FPU g−1 of substrate yielded a limited amount of glucose in solution. Enzymatic hydrolysis was not increased by using a higher cellulase load (60 FPU g−1) in the reaction medium, since both enzyme dosages produced the same maximum glucose yield of 25 % (Fig. 1). Another unsuccessful attempt to increase the glucose yield during enzymatic hydrolysis of the raw sugarcane bagasse involved the use of Tween 20 and Tween 80 surfactants in the hydrolysis medium (Fig. 2).

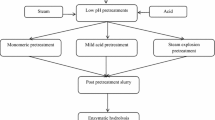

Low glucose yields during enzymatic hydrolysis of untreated sugarcane bagasse were expected owing to its high recalcitrance, which is characteristic of lignified grasses [22–25]. Moreover, the diffusion of surfactants is limited into non-pretreated materials [13]. To improve the glucose yields during the enzymatic hydrolysis step, sugarcane bagasse was submitted to a chemithermomechanical pretreatment at three increasingly alkaline sulfite loads (Table 1). Lignin removal increased with increased chemical loads in the pretreatment step. Maximum lignin removal corresponded to 35.5 % of the original amount present in the untreated sugarcane bagasse. Fiber bundles also disaggregated noticeably at the highest chemical loads. Mass balances for the polysaccharide fractions indicated that glucan and C-5 polysaccharides were almost completely retained in the pretreated materials (Table 1). In a biorefinery concept, C-5 polysaccharides could be recovered for production of high-value bioproducts, derived from typical C-5 fermenting processes [26] or even as polymeric xylan for use as additives in the pulp and paper industry [27]. Thus, the alkaline-sulphite pretreatment seems advantageous, since C-6 and also C-5 polysaccharides are preserved after pretreatment. High acetyl group removal was reached (around 90 %) during the pretreatment step owing to the alkali-labile acetyl ester groups present in the hemicellulose. This effect is interesting because the subsequent enzymatic hydrolysis step would not release toxic acetate/acetic acid [25, 28] to the fermentable monosaccharides stream.

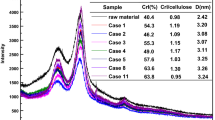

All pretreated sugarcane bagasse samples were hydrolyzed with commercial cellulases (Fig. 3). Increasing the chemical loads in the pretreatment caused more efficient delignification and increased digestibility of the substrates. Most of the glucose was released from the substrates in the first hours of hydrolysis. Hydrolysis rates decreased with the reaction time because the substrates become more recalcitrant. The residual cellulose should be enriched in crystalline portions [29] as well as more encapsulated by embedding lignin and hemicelluloses [30]. Sulfonation of residual lignin by the increased chemical load could also explain the increased digestibility of the pretreated materials [7]. del Rio et al. [31] also observed that adding sulfonic groups to lignin diminished the non-specific binding of the enzymes due to the probable electrostatic repulsion between lignin and cellulases. Thus, the sulfonation decreases the hydrophobicity of the pulp, reducing the unproductive adsorption of cellulases. In addition, previous works have demonstrated that CTMP pulps from sugarcane bagasse showed higher water retention due to the lower hydrophobicity of the samples [6, 7].

Glucose yields of pretreated sugarcane bagasse samples after enzymatic hydrolysis using 5 % m/v substrate, and 20 FPU g−1: pretreated samples with 2 % m/m NaOH plus 4 % m/m Na2SO3 (diamond); 3 % m/m NaOH plus 6 % m/m Na2SO3 (square); and 4 % m/m NaOH plus 8 % m/m Na2SO3 (triangle). The error bars represent variation between the two hydrolysis replicates. When not visible, the error bars were smaller than the symbol size

The maximum glucose yield obtained from the most severely pretreated sample was 64 %. A similar glucose yield was observed by Morando et al. [16]. Under optimized conditions, these authors obtained 64.8 % of glucose yield at 120-h hydrolysis from diluted acid-pretreated delignified sugarcane bagasse using 4.1 FPU g−1 substrate, 18.2 CBU g−1 substrate (β-glucosidase), and 0.95 % m/v Tween 80. Using wet oxidation (195 °C, 15 min and alkaline pH), Martin et al. [32] observed that the highest cellulose digestibility, around 75 %, was achieved after enzymatic hydrolysis of the pretreated material by using commercial preparations of T. reesei cellulases (25 FPU g−1 substrate) and β-glycosidase (0.46 CBU ml−1). This highest conversion of cellulose can be attributed to the high solubilisation of hemicelluloses in the pretreatment [32], whereas in the present work, C-5 polysaccharides were retained in the pretreated materials, probably diminishing the accessibility to the cellulases.

The effect of non-ionic surfactants on the hydrolysis of the pretreated materials is shown in Fig. 4 for hydrolysis periods of 48 h. The hydrolysis yield of the sample with the highest lignin content (23.2 %, resulting from the mildest pretreatment) was increased from 25 to 40 % by both surfactants (increase of 60 % in hydrolysis efficiency). According to the literature, the effect of surfactants depends on the substrate composition [11, 12, 15]. Interestingly, Eriksson et al. [11] reported that Tween 20 increased the enzymatic hydrolysis yield of steam-pretreated spruce much more than the conversions of lignin-free cellulose substrates (Avicel and delignified steam-pretreated spruce). They proposed that the surfactant adsorption to lignin prevents the unproductive binding of the enzyme to lignin, resulting in increased hydrolysis.

Glucose yields of pretreated sugarcane bagasse samples with 2 % m/m NaOH plus 4 % m/m Na2SO3 (white), 3 % m/m NaOH plus 6 % m/m Na2SO3 (gray), and 4 % m/m NaOH plus 8 % m/m Na2SO3 (black) after 48 h of enzymatic hydrolysis using 5 % m/v substrate, 20 FPU g−1, and 5 % m/m surfactants. The error bars represent variation between the two hydrolysis replicates

The maximum glucose yield obtained after 48 h of enzymatic hydrolysis in the evaluated data set was 75 %, an increase of 17 %, which resulted from the hydrolysis of the sugarcane bagasse sample pretreated under the highest chemical load and hydrolyzed in the presence of the Tween 20 surfactant. In a study with alkaline-pretreated maize straw, Chen et al. [33] found that the addition of 0.5 % m/v Tween 80 increased the hydrolysis yield from 81.2 to 87.3 % at 48 h of reaction (an enhancement of 7.5 %). Morando et al. [16] studied the enzymatic hydrolysis of diluted acid-pretreated delignified sugarcane bagasse in the presence of 0.95 % m/v Tween 80. The authors observed an enhancement of cellulose hydrolysis efficiency from 41.4 to 48.8 % at 48 h of reaction (an increase of 17.8 %). This value was similar to the increase observed in the present work.

A critical question in the hydrolysis studies of this type of pretreated samples is the fermentability of the prepared sugar streams. In the present work, S. cerevisiae was used to access the fermentability of the glucose present in the sugar streams prepared under four different experimental conditions. Table 2 presents the ethanol yields from the SSHF experiments. With increasingly chemical loads, the glucose yields were increased, and consequently, the ethanol yields increased from 25 to 56 %. The ethanol yield reported here was expressed based on maximum theoretical ethanol yield obtained from the C-6 polysaccharides present in the pretreated substrates. For all pretreated samples, only minimum amounts of glucose were not converted into ethanol, suggesting that the combined process produced a non-toxic sugar stream. The presence of the Tween 20 surfactant in the experiment that used the sample pretreated under the mildest condition showed a significant increase in the ethanol yield (from 25 to 39.5 %). This increase corresponds to a 56 % increase in the final ethanol yield, which could have been the result of improved saccharification during the hydrolysis step. This result also supports that S. cerevisiae’s ability to ferment the released glucose was not significantly affected by the presence of 2.5 g l−1 Tween 20 in the fermentation medium. In contrast, only 1 g l−1 of this surfactant inhibited Dekera clausenii [10]. Other published data also indicated that ethanol yields increased during the fermentation of biomass hydrolysates in the presence of surfactants. For example, Ooshima et al. [34] showed that the simultaneous hydrolysis and fermentation (SHF) rate of microcrystalline cellulose (Avicel) was slightly increased by the addition of Tween 20. In another study, Ballesteros et al. [35] observed that adding Tween 80 to SHF of steam-pretreated poplar increased the final ethanol yield by 6 % without affecting the yeast viability.

Conclusion

Alkaline-sulfite chemithermomechanical pretreatment was efficient for delignify sugarcane bagasse, and preserved the polysaccharide fraction. Increasingly chemical loads up to 4 % m/m NaOH/8 % m/m Na2SO3 intensified sugarcane bagasse delignification and consequently enhanced the glucose yields. The maximum glucose yield after 48 h of enzymatic hydrolysis was 64 and 75 % in the absence and presence of Tween 20, respectively. The semi-simultaneous hydrolysis and fermentation of pretreated samples yielded a maximum 56 % ethanol yield from the sample pretreated under the highest chemical load. Adding Tween 20 enhanced the enzymatic hydrolysis step and did not inhibit the glucose fermentation by S. cerevisiae.

References

Walter A, Ensinas A (2010) Combined production of second-generation biofuels and electricity from sugarcane residues. Energy 35:874–879

Dias MOS, Junqueira TL, Jesus CDF, Rossell CEV, Maciel-Filho M, Bonomi A (2012) Improving second generation ethanol production through optimization of first generation production process from sugarcane. Energy 43:246–252

Hofsetz K, Silva MA (2012) Brazilian sugarcane bagasse: energy and non-energy consumption. Biomass Bioenergy 46:564–573

Alvira P, Tomás-Pejó E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101:4851–4861

Sun Y, Cheng J (2002) Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour Technol 83:1–11

Mendes FM, Siqueira G, Carvalho W, Ferraz A, Milagres AMF (2011) Enzymatic hydrolysis of chemithermomechanically pretreated sugarcane bagasse and samples with reduced initial lignin content. Biotechnol Prog 27:395–401

Mendes FM, Laurito DF, Bazzeggio M, Ferraz A, Milagres AMF (2013) Enzymatic digestion of alkaline-sulfite pretreated sugar cane bagasse and its correlation with the chemical and structural changes occurring during the pretreatment step. Biotechnol Prog 29:890–895

Zhu JY, Pan XJ, Wang GS, Gleisner R (2009) Sulfite pretreatment (SPORL) for robust enzymatic saccharification of spruce and red pine. Bioresour Technol 100:2411–2418

Alkasrawi M, Eriksson T, Börjesson J, Wingren A, Galbe M, Tjerneld F, Zacchi G (2003) The effect of Tween-20 on simultaneous saccharification and fermentation of softwood to ethanol. Enzyme Microb Technol 33:71–78

Wu J, Ju LK (1998) Enhancing enzymatic saccharification of waste newsprint by surfactant addition. Biotechnol Prog 14:649–652

Eriksson T, Borjesson J, Tjerneld F (2002) Mechanism of surfactant effect in enzymatic hydrolysis of lignocellulose. Enzyme Microb Technol 31:353–364

Kim HJ, Kim SB, Kim CJ (2007) The effects of nonionic surfactants on the pretreatment and enzymatic hydrolysis of recycled newspaper. Biotechnol Bioprocess Eng 12:147–151

Seo DJ, Fujita H, Sakoda A (2011) Structural changes of lignocelluloses by a nonionic surfactant, Tween 20, and their effects on cellulase adsorption and saccharification. Bioresour Technol 102:9605–9612

Maohua Y, Aimin Z, Binbin L, Wangliang L, Jianmin X (2011) Improvement of cellulose conversion caused by the protection of Tween-80 on the adsorbed cellulase. Biochem Eng J 56:125–129

Eckard AD, Muthukumarappan K, Gibbons W (2013) A review of the role of amphiphiles in biomass to ethanol conversion. Appl Sci 3:396–419

Morando LEN, Gómez CXD, Zamora L, Uscanga MGA (2014) Statistical optimization of alkaline hydrogen peroxide pretreatment of sugarcane bagasse for enzymatic saccharification with Tween 80 using response surface methodology. Biomass Conv Bioref 4:15–23

Ferraz A, Rodríguez J, Freer J, Baeza J (2000) Estimating chemical composition of biodegraded pine and eucalyptus by DRIFT spectroscopy and multivariate analysis. Bioresour Technol 74:201–212

Ghose TK (1986) Measurement of cellulase activities. Pure Appl Chem 59:257–268

Franco H, Ferraz A, Milagres AMF, Carvalho W, Freer J, Baeza J (2012) Alkaline sulfite/anthraquinone pretreatment followed by disk refining of Pinus radiata and Pinus caribaea wood chips for biochemical ethanol production. J Chem Technol Biotechnol 87:651–657

Majkic-Singh N, Berkes I (1980) Spectrophotometric determination of ethanol by an enzymatic method with 2,2′-azino-di(3-ethylbenzthiazoline-6-sulfonate). Anal Chim Acta 115:401–405

Brienzo M, Siqueira AF, Milagres AMF (2009) Search for optimum conditions of sugarcane bagasse hemicellulose extraction. Biochem Eng J 46:199–204

Masarin F, Gurpilhares DB, Baffa DCF, Barbosa MHP, Carvalho W, Ferraz A, Milagres AMF (2011) Chemical composition and enzymatic digestibility of sugarcane clones selected for varied lignin content. Biotechnol Biofuels 4:55–64

Xu F, Shi YC, Wu X, Theerarattananoon K, Staggenborg S, Wang D (2011) Sulfuric acid pretreatment and enzymatic hydrolysis of photoperiod sensitive sorghum for ethanol production. Bioprocess Biosyst Eng 34:485–492

Jung YH, Kim S, Yang TH, Lee HJ, Seung D, Park YC, Seo JH, Choi IG, Kim KH (2012) Aqueous ammonia pretreatment, saccharification, and fermentation evaluation of oil palm fronds for ethanol production. Bioprocess Biosyst Eng 35:1497–1503

Karunanithy C, Muthukumarappan K (2011) Optimization of alkali soaking and extrusion pretreatment of prairie cord grass for maximum sugar recovery by enzymatic hydrolysis. Biochem Eng J 54:71–82

Chen X, Shekiro J, Pschorn T, Sabourin M, Tao L, Elander R, Park S, Jennings E, Nelson R, Trass O, Flanegan K, Wang W, Himmel ME, Johnson D, Tucker MP (2014) A highly efficient dilute alkali deacetylation and mechanical (disc) refining process for the conversion of renewable biomass to lower cost sugars. Biotechnol Biofuels 7:98–108

Carvalho W, Canilha L, Silva SS (2008) Semi-continuous xylose-to-xylitol bioconversion by Ca-alginate entrapped yeast cells in a stirred tank reactor. Bioprocess Biosyst Eng 31:493–498

Postma D, Chimphango AFA, Görgens JF (2014) Cationization of Eucalyptus grandis 4-O-methyl glucuronoxylan for application as a wet-end additive in a papermaking process. Holzforschung 68:519–527

Chen Y, Stipanovic AJ, Winter WT, Wilson DB, Kim YJ (2007) Effect of digestion by pure cellulases on crystallinity and average chain length for bacterial and microcrystalline celluloses. Cellulose 14:283–293

Siqueira G, Várnai A, Ferraz A, Milagres AMF (2013) Enhancement of cellulose hydrolysis in sugarcane bagasse by the selective removal of lignin with sodium chlorite. Appl Energy 102:399–402

del Rio LF, Chandra RP, Saddler JN (2011) The effects of increasing swelling and anionic charges on the enzymatic hydrolysis of organosolv-pretreated softwoods at low enzyme loadings. Biotechnol Bioeng 108:1549–1558

Martín C, Klinke HB, Thomsen AB (2007) Wet oxidation as a pretreatment method for enhancing the enzymatic convertibility of sugarcane bagasse. Enzyme Microb Technol 40:426–432

Chen M, Zhao J, Xia L (2008) Enzymatic hydrolysis of maize strawpolysaccharides for the production of reducing sugars. Carbohyd Polym 71:411–415

Ooshima H, Sakata M, Harano Y (1986) Enhancement of enzymatic hydrolysis of cellulose by surfactant. Biotechnol Bioeng 28:1727–1734

Ballesteros I, Olivia JM, Carrasco J, Cabanas A, Navarro AA, Ballesteros M (1998) Effect of surfactant and zeolites on simultaneous saccharification and fermentation of steamexploded poplar biomass to ethanol. Appl Biochem Biotechnol 70–72:369–381

Acknowledgements

The technical assistance of JS Canilha, JM Silva, and JC Tavares is acknowledged. This research was supported by CNPq (Process 480116/2010-5) and FAPESP (2008/56256-5, 2014/06923-6). JF Mesquita thanks CNPq and FAPEMIG for the student fellowships.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mesquita, J.F., Ferraz, A. & Aguiar, A. Alkaline-sulfite pretreatment and use of surfactants during enzymatic hydrolysis to enhance ethanol production from sugarcane bagasse. Bioprocess Biosyst Eng 39, 441–448 (2016). https://doi.org/10.1007/s00449-015-1527-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-015-1527-z