Abstract

Cheese whey fermentation with Kluyveromyces marxianus was carried out at 40 °C and pH 3.5 to examine simultaneous single-cell protein production and chemical oxygen demand (COD) removal, determine the fate of soluble whey protein and characterize intermediate metabolites. After 36 h of batch fermentation, the biomass concentration increased from 2.0 to 6.0 g/L with 55 % COD reduction (including protein), whereas soluble whey protein concentration decreased from 5.6 to 4.1 g/L. It was confirmed through electrophoresis (SDS-PAGE) that the fermented whey protein was different from native whey protein. HPLC and GC–MS analysis revealed a change in composition of organic compounds post-fermentation. High inoculum concentration in batch fermentation resulted in an increase in biomass concentration from 10.3 to 15.9 g/L with 80 % COD reduction (including protein) within 36 h with residual protein concentration of 4.5 g/L. In third batch fermentation, the biomass concentration increased from 7.3 to 12.4 g/L with 71 % of COD removal and residual protein concentration of 4.3 g/L after 22 h. After 22 h, the batch process was shifted to a continuous process with cell recycle, and the steady state was achieved after another 60 h with biomass yield of 0.19 g biomass/g lactose and productivity of 0.26 g/L h. COD removal efficiency was 78–79 % with residual protein concentration of 3.8–4.2 g/L. The aerobic continuous fermentation process with cell recycle could be applied to single-cell protein production with substantial COD removal at low pH and high temperature from cheese whey.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cheese whey is a by-product of the cheese-producing industry, which is considered as an environmental pollutant due to its high biological oxygen demand (BOD) of 40–60 g/L and chemical oxygen demand (COD) of 60–80 g/L. The main components of cheese whey are lactose (4.5–5.0 % w/v), soluble proteins (0.6–0.8 % w/v), lipids (0.4–0.5 % w/v) and mineral salts (0.8–1.0 % w/v) [1, 2]. The whey protein is the second dominant component in cheese whey. Whey protein is a mixture of different proteins which are composed of β-lactoglobulin (40–50 % w/w), α-lactalbumin (12–15 % w/w), immunoglobulin’s (8 % w/w), bovine serum albumin (5 % w/w), lactoferrin (1 % w/w), lactoperoxidase (0.5 % w/w), proteose-peptone and glycomacropeptide (12 % w/w) [3].

Production of cheese whey is on the rise due to increase in demand of milk and milk-derived products. As per Food and Agriculture Organization (FAO) 2005 report, the worldwide annual production of cheese whey was around 139 billion kilograms of which 35.2 and 3.1 billion kilogram were generated in USA and Canada, respectively, with a global annual growth rate of 2 % [4–6]. Around half of the whey is either dumped into sewers or disposed on the land [4]. The disposal and land application have detrimental impact on health and environment [4, 7]. The availability of surplus amount of cheese whey provides an opportunity to apply various biotechnological processes to convert it into value-added products such as ethanol, lactic acid, enzymes, biopolymer, biogas and single-cell protein (SCP) [1, 2]. Bioconversion of whey into SCP has become one of the best solutions and is carried out in many countries [1, 2, 8]. The use of whey for the production of proteinaceous yeast biomass has several advantages such as it is a simple treatment process (i.e., reduction of cheese whey COD) and the final discharge of the whey is facilitated, since the pollutant load is significantly reduced and the whey lactose is converted into proteinaceous yeast biomass.

The SCP is generally produced using yeasts such as Kluyveromyces, Candida and Trichosporon species as they can naturally metabolize whey lactose [9]. Kluyveromyces marxianus species have been the most widely studied for SCP production from cheese whey and categorized as generally regarded as safe (GRAS) microorganism for food and feed applications [9–11]. SCP production is a good alternative for whey treatment; however, there are some challenges during processing: (1) economy of the process and contamination problem; (2) low efficiency of COD removal; (3) fate and recovery of soluble whey protein after fermentation (when raw whey is fermented without protein removal). On-site production of SCP as animal feed using cheese whey is not commercialized due to contamination problems and poor economic return [12–15]. The fermentation at extreme conditions such as low pH (3–4) and high temperature (40 to 45 °C) has been suggested to prevent the contamination problem [1, 16]. Few large-scale industries are able to remove the whey proteins before fermentation through membrane separation technology (ultrafiltration and nanofiltration); however, application of membrane technology is not possible for small- and medium-scale industries due to economic reasons [15, 17]. Till date, most of the studies and trends for SCP production use whey permeate (after removal of whey protein by ultrafiltration) [2, 18–20]. Therefore, there is a need of an alternative process, which could efficiently tackle the problems with on-site utilization of cheese whey.

The SCP production and COD removal can be carried out employing basic bioprocess engineering principle through running different modes of fermentation, such as batch, fed-batch or continuous process. However, each process has its own advantage and disadvantage. The choice of the mode depends on the objective, i.e., production or treatment or both. However, batch process information is always essential before running the continuous or fed-batch process. Moreover, continuous process is usually preferred on industrial scale due to economic reasons [21].

Thus, the aim of the present research was to study a fermentation strategy for yeast SCP production, with high COD removal using raw cheese whey (with protein) as substrate, at low pH and high temperature to minimize contamination. Further, the study was also undertaken to characterize the residual soluble whey protein and intermediate compounds produced during fermentation.

Materials and methods

Cheese whey

Fresh cheese whey was obtained from the cheese-producing industry in Quebec, Canada, and stored at −20 °C until use. The major composition of cheese whey is presented in Table 1. Higher lactose concentration in the whey increases the chances of ethanol formation [22]. Therefore, the cheese whey with COD of 68.0 ± 2.0 g/L was diluted to COD of approximately 50.0 g/L, and the diluted one was used in batch and continuous fermentation processes.

Microorganism

A strain of yeast K. marxianus was isolated from cheese whey and identified by biochemical and molecular methods in our laboratory (accession number GQ 506972). The culture was subcultured on de Man, Rogosa and Sharpe (MRS) agar plates and incubated at 35 °C for 24 h and preserved at 4 °C for future use.

Inoculum preparation

MRS broth was prepared and sterilized at 121 °C for 15 min. A loopful of K. marxianus grown on MRS agar plates was used to inoculate 100 mL Erlenmeyer flask containing 20 mL of MRS media. The flask was incubated in an incubator shaker at 150 rpm and 35 °C for 12 h. The actively grown cells from the flask were used as a pre-culture to inoculate 2 L Erlenmeyer flask containing 500 mL of pasteurized cheese whey and incubated under conditions as described above. The actively grown cells from the flask were used as the inoculum to inoculate 10 L medium in the bioreactor.

Fermentation

Fermentation was carried out in a stirred tank 15 L bioreactor (working volume: 10 L, Biogenie, Quebec, Canada) equipped with accessories and programmable logic control (PLC) system for dissolved oxygen (DO), pH, anti-foam, impeller speed, aeration rate and temperature. The software (iFix 3.5, Intellution, USA) allowed automatic set-point control and integration of all parameters via PLC. Before each sterilization cycle, the polarographic pH electrode (Mettler Toledo, USA) was calibrated using buffers of pH 4 and 7 (VWR, Canada). The oxygen probe was calibrated to zero (using N2 gas) and 100 % (air saturated water). Fresh cheese whey (10 L) with initial COD 50.0 g/L was transferred to a 15 L bioreactor followed by pasteurization for 15 min at 80 °C and pH 3.5 (original pH of the whey). After pasteurization, the temperature was reduced to 40 °C and the DO probe was re-calibrated. The fermentation was conducted at low pH (3.5) and high temperature (40 °C) to minimize the chances of contamination, which is one of the most common problems in industries [1, 16]. The bioreactor was inoculated with appropriate inoculum as described below. Three fermentation runs were conducted with normal, high and medium-cell-density inoculums as described below.

Fermentation with normal cell density inoculum

The first batch bioreactor was inoculated with 5 % (v/v) inoculum (initial suspended solids concentration 2.0 g/L) of K. marxianus which was prepared as described earlier. To keep the DO above 25 % saturation (critical DO for K. marxianus), air flow and agitation rates were appropriately adjusted. The pH 3.5 was maintained using 4 N H2SO4 or 4 N NaOH and polypropylene glycol (PPG, Sigma-Canada) (0.1 % v/v) solution was used to control foam during fermentation. The fermentation was carried out for 36 h.

Fermentation with high-cell-density inoculum

The second batch fermentation was carried out with high-cell-density inoculum (initial suspended solids concentration 10.3 g/L). The inoculum was prepared by growing K. marxianus in a 10 L (working volume) bioreactor for 24 h. To obtain rapid growth of K. marxianus, the fermentation (inoculum production) was conducted at pH 5.5 and temperature 35 °C using diluted cheese whey (initial COD 50.0 g/L) as substrate. The fermented broth was centrifuged aseptically to obtain a concentrated biomass, which was used as the inoculum.

The bioreactor preparation and feed pasteurization for the second batch was similar to the first batch fermentation, except that the second batch fermentation feed (cheese whey) was supplemented with urea (0.22 % w/v, which was optimized in the shake flask study) as extra nitrogen source to minimize nitrogen limitation. Urea as nitrogen supplement was chosen because it is cheaper compared to other nitrogen sources and its consumption, unlike ammonium sulfate, does not change the pH of the medium [23]. The fermentation was conducted at pH 3.5 and 40 °C for 36 h.

Batch fermentation with medium-cell-density inoculum followed by changing to continuous fermentation

The third batch fermentation was conducted with medium-cell-density inoculum (initial suspended solids concentration 7.3 g/L). The inoculum was prepared similarly to the second batch. The batch fermentation process in this case was changed to a continuous process with hydraulic retention time (HRT) 24 h, after 22 h of batch operation. The bioreactor preparation and feed (fortified with 0.22 % w/v of urea) pasteurization were similar to the second batch fermentation.

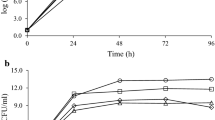

In batch fermentation, the specific growth rate (μ) was calculated by the slope of the line of a semi log plot of cell concentration versus time. For the continuous fermentation with cell recycle system, at steady state the following equations were derived using mass balance [21] in the bioreactor (Fig. 1) to calculate the specific growth rate (μ):

In which X and X r are the biomass concentration in the bioreactor and centrifuged biomass (recycle stream), respectively; F, F r , F 1, r, V and D represent the feed flow rate (L/h), recycle flow stream (L/h), total flow in the reactor (L/h), recycle ratio, working volume of the reactor (L) and the dilution rate (1/h). X 0 and X 2 represent the biomass concentration in feed and supernatant, respectively (Fig. 1). The high-cell-density biomass (between 12.0 and 13.0 g/L) during the continuous fermentation was maintained by recycling the centrifuged biomass. The raw cheese whey feeding (fortified with 0.22 % w/v urea), sampling, and biomass recycling feed flow were controlled using an external peristaltic pump (Masterflex, Cole-Palmer, USA). The recycled biomass was prepared by centrifuging the fermented effluent of the bioreactor and the volume was maintained as desired. When the system reached a steady state, it was operated continuously for 8 days (192 h) at 24 h HRT.

Analytical methods

The samples were withdrawn at regular intervals (in all three runs) and analyzed for cell concentration (colony forming unit—CFU), yeast biomass (suspended solids), reducing sugar (lactose), COD and soluble protein. The total cell count (CFU/mL) was determined by a standard agar plate technique. The appropriately diluted samples were plated on MRS agar plates and incubated at 35 °C for 24 h to get the isolated colonies. Suspended solids were measured using APHA Standard Methods [24]. Reducing sugar (lactose) concentration was measured by using dinitro salicylic acid (DNS) method [25]. 1 mL of appropriately diluted sample, 2 mL of distilled water and 2 mL of DNS solution were transferred to a test tube, followed by incubation in a water bath at 100 °C for 5 min. After that, 15 mL of distilled water (to cool down the reaction mixture and thus to stop the reaction and to dilute the color) was added to the reaction mixture. Absorbance of the solution was read by a spectrophotometer at 540 nm, which was compared to the standard curve. COD was measured according to APHA Standard Methods [24] using a closed reflex, colorimetric method. Soluble protein concentration was determined by Lowry et al.’s [26] method using 1 mg/mL bovine serum albumin (BSA) as standard.

The protein content in the biomass at the end of first batch fermentation was determined using the method described by Lopez et al. [27] with some modification. The biomass was treated with lysis buffer, which contains 5 mL/L of Triton X-100, 0.372 g/L of ethylenediaminetetraacetic acid (EDTA) and 0.035 g/L of phenylmethylsulfonyl fluoride (PMSF). Then the biomass suspension was incubated for 20 min under shaking condition at room temperature. After incubation, the sample was sonicated for 5 min with ultrasonic homogenizer Autotune 750W (Cole-Parmer Instruments, Vernon Hills, Illinois, US) to increase lysis of the cells and release the protein. The protein concentration was measured by Lowry et al.’s [26] method.

All the analyses were carried out in triplicate and the average values are presented (with standard error less than 5 % of the mean).

Characterization of residual protein and intermediate compounds

Electrophoresis of native whey and fermented whey protein

The nature of the residual protein in the centrifuged supernatant of the first batch yeast-fermented cheese whey was evaluated using electrophoresis and was compared with the native whey protein. Sodium dodecyl polyacrylamide gel electrophoresis (SDS-PAGE) was carried out according to the protocol of Laemmli [28]. Acrylamide/bis-acrylamide gel 10 % was used to prepare resolving gel, whereas 5 % acrylamide/bis-acrylamide gel was used as stacking gel. Samples were prepared with sample loading buffer and heated for 3 min at 100 °C before loading to the gel. One lane was also loaded with molecular weight (MW) marker (Sigma, USA) to evaluate the approximate MW of the proteins. After loading the samples, gel electrophoresis was conducted in VWR electrophoresis unit and was run at a constant voltage of 100 mV for 4 h. Then gel was rinsed with water and stained with coomassie blue solution for 45 min followed by de-staining overnight.

Evaluation of sugar and intermediate compounds in whey and fermented whey

The cheese whey and centrifuged fermented whey (supernatant) were characterized for their sugars and intermediate compounds (produced during fermentation) to evaluate the components responsible for residual COD in the supernatant. The analysis was carried out by HPLC and GC–MS.

HPLC analysis

The analysis of sugar and intermediate compounds produced during fermentation was performed using HPLC. The samples of cheese whey and fermented broth were centrifuged at 5,000 rpm for 10 min to remove the suspended particles. The collected supernatants from centrifuged samples were filtered to obtain a clear liquid with Nanosep MF Centrifugal Devices purchased from Pall Life Sciences, USA. The following conditions were used for sugar analysis by HPLC: mobile phase solvent, 480 mM sodium hydroxide solution; isocratic flow rate 0.4 mL/min, analytical column 4 × 250 mm dimension (Carbopack™ MA1) from Dionex, Dionex ED40 Electrochemical Detector (ED); the data were analyzed using Chromeleon software [29]. The retention time of the standard sugars were determined by running the standard glucose, galactose and lactose (Sigma Chemicals, USA). After determination of the retention time of standards, the samples were run through the HPLC under optimum conditions to obtain the sugars and other intermediates profile.

GC–MS analysis

The cheese whey and centrifuged fermented whey supernatant samples were extracted for analysis of intermediate compounds in two different ways. Firstly, the samples were directly extracted with solvent and, secondly, the samples were distilled and the distillate was extracted by solvent. The two extraction methods were used because precipitation occurred during direct solvent extraction, whereas there were chances of loss of some volatile compounds during distillation. The whey and the supernatant samples (original and distillate) were extracted with dichloromethane (CH2Cl2). 100 mL of samples (whey and supernatant) were extracted five times with 5 mL of CH2Cl2 each time. The extracted samples in CH2Cl2 were concentrated with liquid nitrogen, followed by filtration through 0.4 μm filter. The filtered samples were used for analysis of the intermediate compounds through GC–MS. GC–MS analysis was carried out by some modification in the Dragone et al. [30] protocol. PerkinElmer Clarus-500 GC–MS system was used. Separations of different compounds were performed on a fused silica capillary Innowax column (length-30 m, I.D 0.25 mm, film 0.25 μm, Agilent Technology) with 1 μL of injected sample. The injection was performed in split mode (10:1). Helium was used as the carrier gas at constant flow of 1 mL/min. The oven temperature was programmed from 60 to 250 °C at a rate of 5 °C/min with an initial 5 min hold time and a final hold time of 20 min. The detector was set to electronic impact mode (70 eV), with an acquisition range from m/z 29 to m/z 360. Identification of volatile and semi-volatile compounds was performed using the software Turbo Mass with National Institute of Standard and Technology (NIST) library.

Result and discussion

Variation of different parameters during cheese whey fermentation with K. marxianus

The first batch fermentation was conducted without supplementation of external nitrogen source due to the fact that previous research report did not use extra nitrogen when cheese whey was used as a growth medium for Kluyveromyces species [7, 31]. Furthermore, this allows us to evaluate the protein consumption profile and the fate of protein without addition of an external nitrogen source. The nitrogen source was supplemented only when whey permeate was used as the growth medium [13, 20].

The results of the cell count, biomass (suspended solids), lactose, COD and soluble protein concentrations during fermentation are presented in Fig. 2. The cell count (CFU/mL) of K. marxianus increased with time and reached maximum (4.60 × 108 CFU/mL) in 30 h. Yeast biomass (suspended solids) concentration during fermentation was also increased and reached 6.0 g/L at 24 h of fermentation. The values of specific growth rate (μ m), productivity (g/L h) of the biomass and the yield (Y x/s ) were found to be 0.20 h−1, 0.16 g/L h and 0.12 g biomass/g lactose consumed, respectively. The specific growth rate (μ m) 0.37 h−1, biomass yield Y x/s 0.37 g/g, biomass concentration 15.0 g/L and biomass productivity 1.27 g/L h of K. marxianus at pH 5.0 and temperature 30 °C have been reported by Lukondeh et al. [32] with 40.0 g/L initial lactose concentration in the synthetic medium. Comparatively lower biomass yield and productivity in the present work might be due to two reasons: (a) extreme fermentation conditions (i.e., low pH 3.5 and high temperature 40 °C) used in this work to minimize the contamination problem and (b) deficiency of easily assimilable nitrogen in the medium, because external nitrogen was not supplemented and very low quantity of protein (26 % of the initial protein) present in the medium was consumed by the yeast (as presented below). However, nitrogen deficiency may not be very important as Ghaly and Kamal [7] reported higher yield (0.44 g/g), but low specific growth rate (0.15 h−1) (Table 3) during the production of SCP using undiluted cheese whey at 31 °C and pH 4.4 without external nitrogen supplement. To eliminate this possibility, we conducted shake flasks experiments (initial pH 3.5 not controlled during the experiments) at different concentrations of urea and found that a 0.22 % w/v urea concentration was optimum with 10 % improvement of the biomass yield. On the other hand, maximum yield and productivity of Kluyveromyces species have been reported at pH 4.4 and 5.8 and temperature 31 and 30 °C in batch processes while cultivating K. marxianus on cheese whey [7] and whey permeate [20], respectively (Table 3). Thus, the yeast cells cultivated at higher temperature and low pH, used in this study, needed higher maintenance energy (diverting higher amount of lactose toward catabolism), which led to a decrease in the biomass yield [33].

The protein content of the yeast biomass (or suspended solids) at the end of fermentation was found to be 42 % w/w, which was higher than the required minimum protein content (40 % w/w) of the yeast biomass (animal feed) as per the guidelines of Association of American Feed Control Officials (AAFCO) [34].

Most of the lactose (30.0 g/L) was consumed within 18 h and the final residual lactose concentration was less than 1.0 g/L (Fig. 2). The soluble whey protein concentration decreased up to 12 h (Fig. 2) and slightly increased from 12 to 18 h, which may be due to the excretion of cellular proteins and enzymes. After that, the soluble protein concentration remained almost constant until the end of the fermentation process (36 h). A similar trend in protein consumption has been reported [22]. Decrease in soluble protein concentration during the first 12 h of fermentation could be due to its consumption by microorganisms as nitrogen source. This hypothesis was supported by the fact that K. marxianus and Lactobacillus species are known to have proteolytic activity on whey proteins [35, 36]. K. marxianus is known to possess serine carboxypeptidase and lysine aminopeptidase [37]. The stable concentration of soluble protein after 18 h might be due to the partial consumption of protein and simultaneous secretion of extracellular enzymes by K. marxianus (such as inulinase and lipase), as this yeast is known to produce various enzymes [11].

COD decreased rapidly up to 18 h (Fig. 2) of fermentation followed by a slow reduction. This could be due to a rapid increase in the yeast biomass concentration which consumed most of the lactose during the first 18 h. However, COD continued to decrease from 18 h until the end of fermentation (36 h), which could be due to the consumption of intermediate compounds that might have formed during the first 18 h or was already present in the cheese whey. COD reduction of 55 % was achieved at the end of fermentation. High residual COD (21.8 g/L) in the fermented whey supernatant was due to residual soluble protein (4.1 g/L) and other residual organic compounds (present in cheese whey as well as those produced during fermentation) [38]. Intermediate metabolites such as organic acids (pyruvic acid, malic acid, acetic acid, citric acid, propionic acid, fumaric acid and others) were reported to be produced during whey fermentation by K. marxianus [30, 32]. Moreover, it has been reported that the production of intermediate metabolites increased with high initial lactose concentration during fermentation due to a change in the metabolic pathways of K. marxianus from oxidative to mixed oxidative [13].

Characteristics of native whey protein and fermented whey protein

SDS-PAGE was carried out for native whey protein and supernatant (centrifuged fermented broth) containing residual whey protein (Fig. 3). Results clearly demonstrated that the nature of whey protein changed during fermentation. Native whey proteins (lanes 1 and 2) have higher molecular weight (MW) range (mostly above 29 kDa), while the supernatant proteins mostly had lower MW range (below 29 kDa). Thus, the SDS-PAGE results confirmed that the whey protein was partially hydrolyzed and produced lower MW range of proteins from native whey protein during fermentation. The proteolysis of goat whey protein has also been reported by K. marxianus and Lactobacillus species [35, 36].

Sugar and intermediate compounds in whey and fermented whey

HPLC analysis

The results of HPLC analysis of cheese whey and the supernatant of the fermented whey are presented in Fig. 4. The retention times were determined for the three sugars: glucose (24.7 min), galactose (27.63 min) and lactose (29.32 min) (chromatograms have not been shown). This method was found to be good for the analysis of the three sugars at a time with clear separated peaks. The main sugar component of cheese whey is lactose, which is also evident in the HPLC analysis (Fig. 4). The HPLC chromatogram of the supernatant (Fig. 4) indicates that there is no residual lactose in the supernatant after fermentation; however, many other peaks indicate the presence of secondary metabolites generated during fermentation. These intermediate compounds were responsible for the residual COD after fermentation. It was difficult to identify all these unknown compounds in the supernatant by HPLC (because standard compounds are required to detect the unknown compounds). Therefore, further identification of intermediate compounds was carried out using GC–MS.

GC–MS analysis

The individual separated compounds were identified by GC–MS on the basis of the NIST library and the results are presented in Figs. 5 and 6 and Table 2. The obtained GC–MS chromatogram for cheese whey and the fermented whey supernatant samples is presented; both were directly extracted with CH2Cl2. Cheese whey as well as supernatant contains different groups of volatile compounds such as carbonyls, alcohols, esters, acids, furan and phenols. A comparison of the organic compounds of cheese whey before and after fermentation reveals that some compounds (such as 2-methyl propanol, formic acid and isomaltol) were degraded and some new intermediate metabolites (such as 2,3-butanediol, 2-furanmethanol, butyrolactone and glycerin) were generated during fermentation. The degradation of original cheese whey compounds might be responsible for COD reduction after lactose utilization. The volatile organic compounds (VOCs) and semi-VOCs identified during this study (fermentation conducted at a lower pH and higher temperature) in cheese whey (Table 2) are similar to those identified (in cheese whey or whey powder) by other researchers [38, 39]. This study also confirmed that some valuable compounds (like phenylethyl alcohol, an aroma compound) are produced during fermentation. The production of aroma compounds (like fruit ester, carboxylic acids, ketones, furans alcohols and isoamyl acetate) by K. marxianus has also been documented [11].

GC–MS chromatogram of cheese whey with retention time (RT) of acetic acid hydrazide (9.82), acetic acid (13.94), formic acid (15.40), octanol-1 internal standard (16.39), 2-furanmethanol (18.91), 2-cyclohexene-1-ol (22.10), maltol (25.33), 2-propanone 1,3-dihydroxy (27.72), 2-hydroxy propionic acid (29.78), 4-H-pyran-4-one-2,3-dihydro-3,5-dihydroxy-6-methyl (31.09), 2-furan carboxaldehyde 5-hydroxy methyl (35.08) and 2(3H)-furanone dihydro-4-hydroxy (36.60), respectively, from the left

GC–MS chromatogram of supernatant with retention time (RT) of 2-butanone 3-hydroxy (9.40), acetic acid hydrazide (9.80), acetic acid (13.97), 2,3-butanediol (16.02), octanol-1 internal standard (16.39), 2-furan methanol (18.92), pentanoic acid 3-methyl (19.23), maltol (25.33), 2-propanone-1,3-dihydroxy (27.71), 4-H-pyran-4-one 2,3-dihydro-3,5-dihydroxy-6-methyl (31.09), 2-furan carboxaldehyde 5-hydroxy methyl (35.07) and 2(3H)-furanone,dihydro-4-hydroxy (36.59), respectively, from left

Fermentation with high-cell-density inoculum

The first batch results revealed low COD reduction (55 %) and low biomass yield. To obtain higher COD reduction, the second fermentation batch was conducted with higher initial cell density inoculum (high initial biomass concentration) considering the fact that high cell concentration can lower the diversion of K. marxianus metabolic pathway toward mixed oxidative metabolism and thus low intermediates will be formed. Further, higher degradation of intermediate metabolites was expected at higher cell concentration.

The variation in cell count, biomass, lactose, soluble protein and COD concentration during the fermentation with high-cell-density inoculum (10.3 g/L initial suspended solids) is presented in Fig. 7. The cell count (CFU/mL) increased from an initial (1.03 × 109 CFU/mL) to maximum (1.70 × 109 CFU/mL) in the first 12 h. Initially, the cell count increased rapidly followed by slow growth (Fig. 7). After 12 h, increase in cell concentration was not observed, which could be due to deficiency of growth-limiting substrate lactose. A similar profile for biomass (suspended solids) increase was also observed; biomass increased from an initial 10.3 g/L to a maximum 17.1 g/L at 12 h (Fig. 7); thereafter, the biomass started decreasing. The overall increase in biomass (15.9 − 10.3 = 5.6 g/L) at the end of fermentation (36 h) was 39 % higher compared to the first batch (biomass increase 4.0 g/L) and the yield of biomass was also increased by 58 % (Table 3). The increase in biomass concentration and biomass yield could be attributed to two reasons: (a) utilization of more whey lactose for oxidative metabolism and (b) availability of easily assimilable nitrogen source as urea. However, the yield of biomass was still lower than when the process was performed at pH 4.4 and temperature 31 °C (Table 3) using cheese whey as growth medium. This is due to the higher maintenance energy required to maintain the cell life at low pH and higher temperature. The maintenance energy requirement further increased due to higher cell concentrations used in this batch [31, 40]. The specific growth rate (μ), productivity (g/L h) of the biomass and yield (Y x/s ) are presented in Table 3.

Lactose consumption was rapid during the first 18 h (Fig. 7) and approximately more than 98 % of lactose was consumed during this period with residual lactose concentration less than 0.7 g/L. The soluble protein concentration decreased during the first 6 h followed by a slight increase at 12 h, which might be due to excretion of some extracellular protein or enzymes, and remained almost constant during the rest of the fermentation process with residual protein concentration of 4.5 g/L. This again indicates that the protein could not be utilized after a certain extent. Though urea was supplemented in this batch, however, the addition of urea did not show any effect on protein consumption trend (i.e., first decreased, followed by a slight increase and then stayed constant as observed in the first batch).

The COD reduction of 80 % was obtained at the end of 36 h of fermentation. COD and lactose decreased (consumed) rapidly during the first 18 h of fermentation and was attributed to the high cell density. After lactose consumption (i.e., after 18 h), COD reduction continued up to 36 h of fermentation and was due to consumption of intermediate metabolites produced, similar to the first batch of fermentation (Table 2). The residual COD at the end of fermentation was 9.6 g/L. The residual COD was due to residual soluble protein (5.4 g/L) and lactose (0.8 g/L). The rest, 3.3 g/L COD, could be due to the intermediate compounds, which K. marxianus produced (as characterized in first batch fermentation). The value of COD due to intermediate metabolites is much lower compared to the COD observed in the first batch (15.8 g/L). The COD reduction of 80 % at the end of fermentation was 25 % higher than the first batch fermentation (which was operated with 2.0 g/L initial biomass concentration as inoculum). The results revealed that the degradation of organic compounds (original whey and those produced during fermentation by K. marxianus) was higher with high-cell-density inoculum (initial suspended solids 10.3 g/L), which resulted in low residual COD. The consumption of intermediate metabolites as carbon source by Kluyveromyces species has been reported as diauxic metabolic nature [41]. The second reason for low residual COD might be the low intermediates production due to lower lactose to cell (biomass) ratio that resulted in increased oxidative metabolism [13]. The finding of this batch study, i.e., higher COD reduction could be applied to bioconversion of whey into SCP for the continuous process employing a similar cell concentration.

Batch fermentation with medium-cell-density inoculum and shift to continuous fermentation

The second batch fermentation results revealed that the fermentation with higher cell density increased the COD degradation efficiency. However, it may be difficult to maintain (15.0–17.0 g/L) a high cell concentration during the fermentation process. Therefore, the third batch fermentation was started with a comparatively lower cell concentration compared to the second batch. The variations in different parameters during the batch fermentation with medium-cell-density inoculum (7.3 g/L initial suspended solids), such as cell count, biomass, lactose, soluble protein and COD, are presented in Fig. 8. The cell count (CFU/mL) of K. marxianus increased from initial (6.20 × 108 CFU/mL) to maximum (1.44 × 109 CFU/mL) at 22 h. Similar to the second batch fermentation, the increase in cell count (CFU/mL) was rapid. A similar profile for biomass increase was also noticed, which increased from 7.3 to 12.4 g/L at 22 h (Fig. 8). Lactose concentration decreased from 32.4 to 0.7 g/L and COD removal of 71 % was obtained at 22 h. The soluble protein content decreased from 5.7 to 4.3 g/L and there was no further change or little change in the protein concentration.

After 22 h, batch fermentation was changed to continuous mode with 24 h HRT. The cell recycle system was used to keep high biomass concentration (12.0–13.0 g/L, almost close to the cell concentration in the 2nd batch), so that COD degradation remained high. The steady state during the continuous process was obtained after 60 h of operation. The variations in lactose, COD and soluble protein concentration during batch and continuous fermentation are shown in Fig. 8. The lactose concentration increased from 0.7 to 4.3 g/L when the batch process was shifted to continuous mode and then slowly decreased to 0.8 g/L. The lactose consumption at steady state was 97.5 %, whereas the effluent COD concentration varied between 10.0 and 12.0 g/L (Fig. 8). The soluble protein concentration in the effluent at steady state ranged between 3.8 and 4.2 g/L. The values of specific growth rate (h−1), biomass yields (Y x/s ), biomass productivity (g/L h) and % of COD reduction during the continuous process are shown in Table 3.

The results of continuous fermentation with cell recycle system showed that higher COD reduction (up to 78–79 %) could be achieved during fermentation conducted at low pH (3.5) and high temperature (40 °C). The productivity of biomass 0.26 g/L h was comparable to the batch process (2nd run). However, batch process productivity does not include the downtime required for inoculum preparation, harvesting, cleaning and recharging of the bioreactor. This will lower the batch productivity of a real-world process. The other advantage of low pH and high temperature operating conditions will provide an opportunity to run the continuous process with cell recycle system for a long time without contamination, which is one of the main obstacles of a continuous process for large-scale operations [21].

Studies by others researchers [7, 20, 31, 42, 43] for SCP production and COD removal during batch and continuous process have been presented in Table 3, which showed little higher yields and COD removal efficiency (in batch processes). These studies were conducted at favorable fermentation conditions (pH 4.5–6.0 and temperature 30–35 °C) where chances of contamination were higher. Thus, to run the process without contamination while using cheese whey without sterilization, a little loss of yield could be sacrificed. Moreover, most of the existing studies were conducted using whey permeate (Table 3) and reported higher COD removal. This was due to the absence of the residual protein in the whey permeate. In the present case, COD removal up to 95 % could be achieved if the residual soluble protein was recovered from the supernatant. The recovered protein could be mixed with the biomass to increase the overall SCP production.

This study provides an alternative continuous process for the biotransformation of raw cheese whey into SCP without removing the whey protein before fermentation, which will reduce the whey management problem. Also, the residual soluble protein (3.9 g/L) could be recovered from the fermented whey supernatant and mixed with the biomass (SCP). This could increase the protein content in the final product and further reduce the effluent COD (4.8 g/L). However, this requires further study to optimize the protein recovery process.

Conclusions

The biomass concentration was increased from 2.0 to 6.0 g/L after 24 h in the case of batch fermentation with low-cell-density inoculum. The COD reduction after 36 h of fermentation was 55 % with a residual soluble protein concentration of 4.1 g/L. The SDS-PAGE results revealed that the residual protein was different (low molecular weight) from native whey protein. The HPLC and GC–MS analysis indicated that there was no residual lactose in the supernatant, but other intermediate compounds present were responsible for residual COD along with residual protein. The fermentation with high-cell-density inoculum resulted in higher COD removal (up to 80 %) with a biomass productivity of 0.25 g/L h. The protein consumption trend was similar during all batch fermentations with residual concentration between 4.1 and 4.5 g/L. The finding of higher COD removal from the batch process was applied in continuous process using cell recycle system. The continuous fermentation with cell recycle system gave a COD reduction of up to 78.5 % with biomass productivity of 0.26 g/L h. Thus, this study established that the continuous fermentation with cell recycle system could be applied to produce SCP with simultaneous high COD removal. Further studies are required on recovering residual soluble protein and thus decreasing residual COD concentration.

References

González Siso MI (1996) The biotechnological utilization of cheese whey: a review. Bioresour Technol 57:1–11

Panesar PS, Kennedy JF (2012) Biotechnological approaches for the value addition of whey. Crit Rev Biotechnol 32:327–348

Madureira AR, Pereira CI, Gomes AMP, Pintado ME, Xavier Malcata F (2007) Bovine whey proteins—overview on their main biological properties. Food Res Int 40:1197–1211

Ghaly AE, Mahmoud NS, Rushton DG, Arab F (2007) Potential environmental and health impacts of high land application of cheese whey. Am J Agric Biol Sci 2:106–117

Agustriyanto R, Fatmawati A (2009) Model of continuous cheese whey fermentation by Candida pseudotropicalis. World Acad Sci Eng Technol 33:281–285

Smithers GW (2008) Whey and whey proteins—From ‘gutter-to-gold’. Int Dairy J 18:695–704

Ghaly AE, Kamal MA (2004) Submerged yeast fermentation of acid cheese whey for protein production and pollution potential reduction. Water Res 38:631–644

Mawson AJ (1994) Bioconversions for whey utilization and waste abatement. Bioresour Technol 47:195–203

Mansour MH, Ghaly AE, Benhassan RM, Nassar MA (1993) Modeling batch production of single cell protein from cheese whey. Appl Biochem Biotechnol 43:1–14

Grba S, Stehlik-Tomas V, Stanzer D, Vahčić N, Škrlin A (2002) Selection of yeast strain Kluyveromyces marxianus for alcohol and biomass production on whey. Chem Biochem Eng Q 16:13–16

Fonseca GG, Heinzle E, Wittmann C, Gombert AK (2008) The yeast Kluyveromyces marxianus and its biotechnological potential. Appl Microbiol Biotechnol 79:339–354

Çinar Ö, Hasar H, Kinaci C (2006) Modeling of submerged membrane bioreactor treating cheese whey wastewater by artificial neural network. J Biotechnol 123:204–209

Cristiani-Urbina E, Netzahuatl-Munoz AR, Manriquez-Rojas FJ, Juarez-Ramrez C, Ruiz-Ordaz N, Galndez-Mayer J (2000) Batch and fed-batch cultures for the treatment of whey with mixed yeast cultures. Process Biochem 35:649–657

Chatzipaschali AA, Stamatis AG (2012) Biotechnological utilization with a focus on anaerobic treatment of cheese whey: current status and prospects. Energies 5:3492–3525

Spălăţelu C (2012) Biotechnological valorisation of whey. Innov Romanian Food Biotechnol 10:1–8

Pacheco FP, Galindo AB (2010) Microbial safety of raw milk cheeses traditionally made at a pH below 4.7 and with other hurdles limiting pathogens growth. In: Mendez-Vilas A (ed) Current research, technology and education topics in applied microbiology and microbial biotechnology, Formatex, pp 789–1620

Fernández A, Menéndez V, Riera FA (2012) α-Lactalbumin solubilisation from a precipitated whey protein concentrates fraction: pH and calcium concentration effects. Int J Food Sci Technol 47:467–474

Mollea C, Marmo L, Bosco F (2013) Valorisation of cheese whey, a by-product from the dairy industry. ISBN 978-953-51-0911-2

Paul D, Mukhopadhyay R, Chatterjee B, Guha A (2002) Nutritional profile of food yeast Kluyveromyces fragilis biomass grown on whey. Appl Biochem Biotechnol 97:209–218

Schultz N, Chang L, Hauck A, Reuss M, Syldatk C (2006) Microbial production of single-cell protein from deproteinized whey concentrates. Appl Microbiol Biotechnol 69:515–520

Michael L, Shuler FK (2002) Bioprocess engineering: basic concepts. Prentice Hall: Upper Saddle River, New York

Parrondo J, García LA, Díaz M (2009) Nutrient balance and metabolic analysis in a Kluyveromyces marxianus fermentation with lactose-added whey. Braz J Chem Eng 26:445–456

Ugalde UO, Castrillo JI (2002) Single cell proteins from fungi and yeasts. In: Dilip KA, George GK (eds) Applied mycology and biotechnology. Elsevier, Amsterdam

American Public Health A, Eaton AD, American Water Works A, Water Environment F (2005) Standard methods for the examination of water and wastewater, APHA-AWWA-WEF, Washington, DC

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275

López CVG, del Carmen Cerón García M, Fernández FGA, Bustos CS, Chisti Y, Sevilla JMF (2010) Protein measurements of microalgal and cyanobacterial biomass. Bioresour Technol 101:7587–7591

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685

Dionex the determination of carbohydrates, alcohols, and glycols in fermentation broths. pp 1–11

Dragone G, Mussatto SI, Oliveira JM, Teixeira JA (2009) Characterisation of volatile compounds in an alcoholic beverage produced by whey fermentation. Food Chem 112:929–935

Ghaly AE, Kamal M, Correia LR (2005) Kinetic modelling of continuous submerged fermentation of cheese whey for single cell protein production. Bioresour Technol 96:1143–1152

Lukondeh T, Ashbolt NJ, Rogers PL (2005) Fed-batch fermentation for production of Kluyveromyces marxianusFII 510700 cultivated on a lactose-based medium. J Ind Microbiol Biotechnol 32:284–288

Verduyn C (1991) Physiology of yeasts in relation to biomass yields. Antonie Van Leeuwenhoek 60:325–353

AAFCO (2010) Association of American feed control official incorporated

Didelot S, Bordenave-Juchereau S, Rosenfeld E, Piot JM, Sannier F (2006) Peptides released from acid goat whey by a yeast–lactobacillus association isolated from cheese microflora. J Dairy Res 73:163–170

Hamme V, Sannier F, Piot JM, Didelot S, Bordenave-Juchereau S (2009) Crude goat whey fermentation by Kluyveromyces marxianus and Lactobacillus rhamnosus: contribution to proteolysis and ACE inhibitory activity. J Dairy Res 76:152–157

Ramírez-Zavala B, Mercado-Flores Y, Hernández-Rodríguez C, Villa-Tanaca L (2004) Purification and characterization of a serine carboxypeptidase from Kluyveromyces marxianus. Int J Food Microbiol 91:245–252

Mahajan SS, Goddik L, Qian MC (2004) Aroma compounds in sweet whey powder. J Dairy Sci 87:4057–4063

Karagül-Yüceer Y, Drake MA, Cadwallader KR (2003) Aroma-active components of liquid cheddar whey. J Food Sci 68:1215

Boender LGM, De Hulster EAF, Van Maris AJA, Daran-Lapujade PAS, Pronk JT (2009) Quantitative physiology of Saccharomyces cerevisiae at near-zero specific growth rates. Appl Environ Microbiol 75:5607–5614

Fonseca GG, Gombert AK, Heinzle E, Wittmann C (2007) Physiology of the yeast Kluyveromyces marxianus during batch and chemostat cultures with glucose as the sole carbon source. FEMS Yeast Res 7:422–435

Ben-Hassan RM, Ghaly AE (1995) Continuous production of single cell protein from cheese whey lactose using Kluyveromyces fragilis. Am Soc Agric Eng 38:1121–1127

Anvari M, Khayati G (2011) Submerged yeast fermentation of cheese whey for protein production and nutritional profile analysis. Adv J Food Sci Technol 3:122–126

Acknowledgments

The authors are sincerely thankful to the Natural Sciences and Engineering Research Council of Canada (Grant A4984, RDCPJ379601-08, and Canada Research Chair) for their financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yadav, J.S.S., Bezawada, J., Elharche, S. et al. Simultaneous single-cell protein production and COD removal with characterization of residual protein and intermediate metabolites during whey fermentation by K. marxianus . Bioprocess Biosyst Eng 37, 1017–1029 (2014). https://doi.org/10.1007/s00449-013-1072-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-013-1072-6