Abstract

High-purity fructooligosaccharides (FOS) were produced from sucrose by an innovative process incorporating immobilized Aspergillus japonicus and Pichia heimii cells. Intracellular FTase of A. japonicus converted sucrose into FOS and glucose, and P. heimii fermented glucose mainly into ethanol. The continuous production of FOS was carried out using a tanks-in-series bioreactor consisting of three stirred tanks. When a solution composed of 1 g L−1 yeast extract and 300 g L−1 sucrose was fed continuously to the bioreactor at a dilution rate of 0.1 h−1, FOS at a purity of up to 98.2 % could be achieved and the value-added byproduct ethanol at 79.6 g L−1 was also obtained. One gram of sucrose yielded 0.62 g FOS and 0.27 g ethanol. This immobilized dual-cell system was effective for continuous production of high-purity FOS and ethanol for as long as 10 days.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fructooligosaccharides (FOS), which are important prebiotics [1], can stimulate the proliferation of bifidobacteria in the intestine [2], enhance dietary calcium absorption [3], lower blood cholesterol [4], and thus improve human health. FOS produced from sucrose falls into three categories: inulo-, levan- and neo-type of oligosaccharides [5]. Among these oligosaccharides, only the inulo-type FOS which comprises 1-kestose, nystose, and 1F-fructosyl nystose is currently available. Generally, this FOS is produced from sucrose through a reaction catalyzed by 1F-fructosyltransferase (EC 2.4.1.99; FTase). During the reaction large amounts of glucose as well as FOS are produced [6]. Furthermore, because glucose is a competitive inhibitor of the fructosyl-transferring reaction, a portion of the sucrose remains unreacted. Thus, the product is low-purity FOS consisting of 50–60 % FOS, 30–40 % glucose, and 10–20 % sucrose. Because high-purity FOS is non-cariogenic, low in calories, and may be ingested by diabetic patients, two methods for producing high-purity FOS from sucrose have been developed: (1) a mixed-enzyme system of FTase and glucose oxidase and (2) a mixed-culture consisting of Aspergillus japonicus having FTase activity and Gluconobacter oxydans having glucose dehydrogenase activity [7–10]. In both, the byproduct glucose is converted into gluconic acid, which is rendered insoluble by mixing with a calcium carbonate suspension. Furthermore, because glucose is eliminated, the sucrose is almost completely consumed and high-purity FOS is obtained. However, when a membrane reactor containing a single stirred tank was used for the continuous production of high-purity FOS, the reaction was incomplete [10]. It has also been reported that high-purity FOS can be obtained via successive fermentation with Pichia pastoris following the catalytic reaction of FTase on sucrose [11]. Recently, a high-purity neo-FOS has been directly obtained by fermentation of sucrose with yeast Xanthophyllomyces dendrorhous having 6G-FTase activity [12]. Neo-FOS comprises neokestose and neonystose, in which fructosyl units are bound to glucose moiety of sucrose by β-(2 → 6) linkages [13]. During the fermentation with X. dendrorhous, sucrose was converted into neo-FOS, 1-kestose, glucose and fructose. Meanwhile, the monosaccharides were consumed by the yeast cells. Therefore, total FOS (neo-FOS and 1-kestose) at a content of 90.2 % on a dry weight basis was achieved.

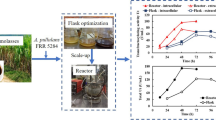

Since the oxidation catalyzed by glucose oxidase or glucose dehydrogenase of G. oxydans for the removal of glucose requires large amounts of oxygen and the carrier for immobilization of the enzyme or microbial cells is a barrier for mass transfer of oxygen, neither immobilized enzyme nor immobilized cells were investigated for the production of high-purity FOS. In this work, a tanks-in-series bioreactor containing calcium alginate-immobilized cells of A. japonicus and P. heimii was used for the continuous production of high-purity FOS and ethanol (Fig. 1). Through the catalytic reaction of intracellular FTase of A. japonicus, sucrose was converted into FOS and glucose. Meanwhile, the yeast P. heimii fermented the glucose into alcohols and organic acids, with ethanol as the primary product.

Materials and methods

Microorganisms and chemicals

Aspergillus japonicus TU 21 was derived from A. japonicus TIT-KJ 1 by monospore culture and selective isolation [14], and it was capable of producing an intracellular FTase with superior activity in the submerged culture medium containing >150 g L−1 sucrose. A. japonicus TU 21 was cultured on agar plates (10 g L−1 yeast extract, 50 g L−1 sucrose, and 15 g L−1 agar) at 25 °C and transferred every month. P. heimii BCRC 20410 (ATCC 22387) was obtained from the Culture Collection and Research Center, Taiwan. In our preliminary experiment, it was found this yeast strain was unable to directly metabolize sucrose nor hydrolyze sucrose into glucose and fructose. Sodium alginate (80–120 cP), fructose, glucose, sucrose, 1-kestose, nystose, and fructosyl nystose were purchased from Wako. Culture media, substrate solution, alginate suspension, and water were autoclaved at 121 °C for 15 min.

Immobilization of A. japonicus

In a 500-mL Erlenmeyer flask, 200 mL culture medium containing 150 g L−1 sucrose, 20 g L−1 yeast extract, 5 g L−1 KH2PO4, and 0.2 g L−1 MgSO4·7H2O (pH 6) were inoculated with spores of A. japonicus at a dose of 107 mL−1. After 72 h of incubation in a shaker at 150 rpm and 30 °C, the culture was mixed with 3 volumes of water and homogenized using an IKA T-18 disruption system. It was then mixed thoroughly with an equal volume of 40 g L−1 sodium alginate. The mixture was dripped through a needle (ID 1.0 mm) into 10 g L−1 CaCl2 solution using a peristaltic pump. After 2 h of stirring, the calcium alginate beads formed were stored in a 4 °C refrigerator. These white beads of immobilized A. japonicus with diameters of 2.5–3.5 mm were used for further experiments within 24 h.

Immobilization of P. heimii

A loopful of P. heimii cells grown on agar plate (20 g L−1 glucose, 10 g L−1 yeast extract, 2 g L−1 KH2PO4, 0.2 g L−1 MgSO4·7H2O, and 15 g L−1 agar, pH 6) at 25 °C for 2–5 days was inoculated to a 500-mL Erlenmeyer flask containing 200 mL of culture medium composed of 50 g L−1 glucose, 10 g L−1 yeast extract, 2 g L−1 KH2PO4, and 0.2 g L−1 MgSO4·7H2O (pH 6.0). After incubating in a shaker at 160 rpm and 25 °C for 36 h, the mixture was inoculated into a 5-L jar fermenter with a working volume of 3 L. For mass production of the yeast cells, cyclic batch fermentation was carried out at 30 °C, 400 rpm, and 1 vvm with the pH controlled at around 5.5 by the automatic addition of 5 N NaOH solution. A 2.5-L yeast culture was harvested every 24 h and 2.5 L fresh medium was fed to the fermenter for the next batch fermentation. Yeast cells were obtained by centrifugation and were then mixed throughly with an equal volume of 40 g L−1 sodium alginate solution. The mixture was dripped through a needle (ID 1.0 mm) into 10 g L−1 CaCl2 solution using a peristaltic pump. After 2 h of stirring, the calcium alginate beads formed were stored at 4 °C in a solution containing 20 g L−1 glucose, 1 g L−1 yeast extract, and 10 g L−1 CaCl2. The pale yellow beads of immobilized P. heimii with diameters of 2–3 mm were used for further experiments.

HPLC analysis of saccharides

Saccharides in the reaction mixture were determined by HPLC on a Chromatorex NH2 column (4.6 × 250 mm, Fuji Silysia Chemical Ltd., Japan) with a refractive index detector. The mobile phase was acetonitrile:water (65:35) and the flow rate was 0.5 mL min−1. Prior to HPLC analysis, the reaction mixture was adequately diluted with water and then passed through a syringe filter with a pore size of 0.2 μm. Twenty microliters of sample was injected for analysis. Retention times for fructose, glucose, sucrose, 1-kestose, nystose, and fructosyl nystose were 12.0, 12.8, 14.9, 19.7, 24.5, and 30.5 min, respectively.

Determination of ethanol, glycerol, and organic acids by HPLC

Ethanol, glycerol, and organic acids were analyzed by HPLC according to the method described by Holcroft and Kader with some modifications [15]. An ICSep Ion-300 column (7.8 × 300 mm, Transgenomic Ltd. USA) with a refractive index detector was used. The mobile phase was 1 g L−1 phosphoric acid at a flow rate of 0.4 mL min−1. Retention times for lactic acid, glycerol, acetic acid, and ethanol were 20.6, 21.2, 24.5, and 31.4 min, respectively.

Assay of FTase activity of immobilized A. japonicus

FTase activity was determined based on the formation of 1-kestose. About 1 g of immobilized A. japonicus beads, which had been spread on filter paper to remove excessive water, were added to a 250-mL Erlenmeyer flask containing 100 mL of 300 g L−1 sucrose solution (in 0.1 M sodium acetate buffer, pH 5.5). After the reaction was carried out in a water bath shaker at 150 rpm and 30 °C for 30 min, 1 mL of reaction solution was carefully withdrawn from the reaction mixture and diluted with water by a factor of 100. The amount of 1-kestose in the reaction mixture was determined by HPLC. One unit of FTase activity was defined as the amount of enzyme required to produce one micromole of 1-kestose per minute under the above-mentioned conditions.

Assay of glucose-consuming rate of immobilized P. heimii

About 20 g of immobilized P. heimii beads, which had been spread on filter paper to remove excessive water, were mixed with 0.2 M sodium acetate buffer (pH 5.5) to reach a total volume of 50 mL. The reaction was started by mixing this immobilized cell suspension with 50 mL of 200 g L−1 glucose in a 250-mL Erlenmeyer flask. The reaction proceeded in a water bath shaker at 30 °C for 60 min. The glucose concentration in the reaction mixture was determined by HPLC. One unit of glucose-consuming rate was defined as a decrease of one micromole of glucose per minute under the above-mentioned conditions.

Batch reaction for the production of high-purity FOS by immobilized A. japonicus and immobilized P. heimii

Nine hundred grams of sucrose and 5,000 U (about 1,800 g) of immobilized P. heimii were added to a 5-L bioreactor. Then water was added to a volume of 2.8 L. After the sucrose was completely dissolved by stirring, the reaction was initialized by adding 3,000 U (about 200 g) of immobilized A. japonicus. Water was again added to reach a total volume of 3.0 L. The reaction was carried out at 30 °C and 100 rpm, and the pH of the reaction mixture was controlled at around 5.5 by automatic addition of a mixture of 100 g L−1 NaOH and 10 g L−1 Ca(OH)2. The batch-wise reaction was allowed to continue for 24 h.

Continuous production of high-purity FOS by immobilized A. japonicus and immobilized P. heimii using a tanks-in-series bioreactor

As shown in Fig. 1, the tanks-in-series bioreactor consisted of three stirred tanks. Each tank had a working volume of 3 L. Each of the first two tanks contained 5,000 U of immobilized P. heimii, 3,000 U of immobilized A. japonicus, and 900 g of sucrose. The third tank contained 5,000 U of immobilized P. heimii only. After 10 and 20 h of batch operation in tank 1 and tank 2, respectively, the two tanks were connected together with a peristaltic pump. To start the continuous reaction, a solution composed of 300 g L−1 sucrose and 1 g L−1 yeast extract was fed to tank 1 at a rate of 5 mL min−1 (dilution rate = 0.1 h−1). At the same dilution rate material was transferred from tank 1 to tank 2, and tank 2 to tank 3. The operation of tank 3 was started as the reaction mixture was received. The liquid levels in the tanks were checked every 4 h. The pumping rates were slightly adjusted if necessary. After 3 days of continuous operation, the reactor system achieved a steady state. After that, continuous operation was sustained for 25 days. In order to maintain living microorganisms in the system, 0.5 % volume of 200 g L−1 yeast extract was daily added to tanks 2 and 3.

Results and discussion

Batch reaction for the production of high-purity FOS

As shown in Fig. 2, during the batch reaction catalyzed by immobilized A. japonicus and immobilized P. heimii, 1-kestose is formed first, peaks at 3 h and then gradually declines because of the conversion of 1-kestose into nystose. Nystose increases rapidly during the first 6 h and then remains constant. Fructosyl nystose increases very slowly and achieves nearly the same concentration as 1-kestose after 24 h of reaction. The amounts of 1-kestose and nystose are equal at 5.5 h, which is much earlier than for the mixture of free cells of A. japonicus and Gluconobacter oxydans used in the previous work [10]. This is because a 3.7 times higher dose of FTase activity than the previous work is used in the present immobilized cell system. The high dosage of FTase also causes the hydrolysis of sucrose and a small amount of fructose is found in the reaction mixture. The elimination of glucose during the reaction is much slower than when G. oxydans was used [10], not only because calcium alginate is a barrier to the mass transfer of saccharides but also because the metabolic patterns of P. heimii and G. oxydans are quite different. Yeast cells take up glucose and ferment it into ethanol, glycerol, organic acids, biomass and others, whereas G. oxydans oxidizes glucose into gluconic acid through the catalytic reaction of a membrane-bound glucose dehydrogenase [16]. This is a one-step reaction and the glucose turnover rate is much higher than for P. heimii. However, G. oxydans requires large amounts of oxygen to complete the reaction, which may not be available for an immobilized cell system due to the difficulty of transferring oxygen through the alginate gel. In the present experiment, glucose and small amounts of fructose are almost eliminated in 24 h and it was accompanied by the formation of large amounts of ethanol (~90 g L−1). The HPLC chromatograms of the saccharides in the reaction mixtures after 2, 8, and 24 h of reaction, respectively, are shown in Fig. 3.

HPLC chromatograms of saccharides in the reaction mixtures at different reaction times during the batch reaction for production of FOS from sucrose using immobilized cells of A. japonicus and P. heimii as biocatalysts (F fructose, G glucose, GF sucrose, GF 2 1-kestose, GF 3 nystose, GF 4 fructosyl nystose)

Continuous production of high-purity FOS and ethanol

Table 1 shows the carbohydrate compositions of the reaction mixtures in the individual tanks of the tanks-in-series reactor operated at a dilution rate of 0.1 h−1. Most of the sucrose has been consumed at 83 % in tank 1. From tank 1 to tank 2, the content of FOS on a dry weight basis increases from 70.2 to 95.9 %. More than 99 % of the initial sucrose has been converted into FOS and monosaccharides. The decreases in glucose and fructose are due to the metabolism of the yeast P. heimii. From tank 2 to tank 3, fructose decreases and glucose is completely consumed. The other saccharides remain the same because tank 3 has immobilized yeast cells only. Thus, FOS at high purity of up to 98.2 % has been obtained. The immobilized cells in this system are effective for several weeks if 0.5 % volume of 200 g L−1 yeast extract is daily added to tanks 2 and 3 to sustain the microbial cells in this system.

Table 2 compares the carbohydrate compositions of the FOS products from various studies. A membrane reactor containing A. japonicus and G. oxydans has been employed for the continuous production of high-purity FOS from sucrose, wherein the byproduct glucose is converted into calcium gluconate precipitate [10]. This reaction is carried out in a single stirred tank and only 87 % FOS content was achieved. A successive fermentation with free cells of P. pastoris after the catalytic reaction of β-fructofuranosidase on sucrose has been used to produce high-purity FOS [11]. The byproduct glucose was converted mainly into glycerol. FOS accounted for 93.8 % on a dry weight basis of the total saccharides in the product.

In the tanks-in-series reactor with the immobilized cells of A. japonicus and P. heimii as presented in this work, the byproduct glucose is converted mainly into ethanol. Ethanol can be readily recovered by mean of distillation. The final FOS syrup consisted of the following ingredients (g L−1): FOS 186, ethanol 79.6, glycerol 11.2, acetic acid 2.5 and lactic acid 1.1.

If glycerol is taken into account as has been reported [11], the FOS content may be decreased. As shown in Table 3, the content of FOS produced in this work is higher than that in other studies. The concentration of ethanol in the tanks-in-series reactor is slightly lower than in batch reaction (Fig. 2). This is because the batch reaction is always more complete than the continuous reaction under the similar reaction conditions. Table 4 shows the conversion yields of 1-kestose, nystose and fructosyl nystose from sucrose, respectively. The higher DP of FOS, the lower conversion yield of FOS. Higher dose of FTase or longer period of reaction time results in a FOS product with much higher DP of FOS, thus more glucose is released. In this dual-cell system, if the reaction proceeds more towards completion, the conversion yield of FOS decreases and more glucose is liberated for the ethanol fermentation by the yeast; therefore, more ethanol is produced. On the other hand, the hydrolytic reaction of FTase on sucrose also affects the total conversion yield of FOS and ethanol production. The ratio of hydrolytic activity to fructosyl-transferring activity of FTase depends on the nature of the enzyme and reaction conditions such as pH and concentration of sucrose. During the reaction the amount of sucrose hydrolyzed can be calculated as follows:

where 0.74, 0.65 and 0.61 are conversion yields of GF2, GF3 and GF4 from sucrose, respectively (Table 4). The initial concentration of sucrose is 300 g L−1. According to Table 1 (tank 3), the amount of sucrose hydrolyzed is to be: 300–63.6/0.74–94.6/0.65–27.8/0.61–2.3 = 20.6 (g L−1). This accounts for 6.9 % of initial sucrose.

The results of 25 days operation for continuous production of high-purity FOS are shown in Fig. 4. FOS and ethanol were produced at a constant rate during the first 10 days and then declined slightly. Glucose and fructose levels remained at approximately zero, indicating that the yeast cells were effective in removing the monosaccharides generated in the reaction mixture. However, after 10 days of operation a continuous increase in sucrose reveals that FTase activity has decayed, because the fungal cells had died. During the process of cell immobilization, most of the mycelia cells of A. japonicus were disrupted by the homogenizer. Furthermore, it was difficult for the fungal cells to survive under the anaerobic conditions of operation.

Time courses for FOS, ethanol, glucose, fructose and sucrose during continuous production of high-purity FOS over 25 days via the tanks-in-series bioreactor operated at a dilution rate of 0.1 h−1, using 300 g L−1 sucrose as substrate and immobilized cells of A. japonicus and P. heimii as biocatalysts (F fructose, G glucose, GF sucrose)

Compared to the mixed-enzyme systems for the production of high-purity FOS as previously reported [7–9], the present work using the immobilized cells is cost-saving because of the reuse of the biocatalysts. Yeast extract is the life-sustaining nutrient for immobilized cells in this system, though this may appear that it will increase the cost; in fact it only accounts for a small portion of the total cost. This system requires 2,160 g of sucrose and 13.2 g of yeast extract daily. The cost of yeast extract is 20 times higher than that of sucrose. The overall cost of yeast extract is 12.2 % of sucrose. Furthermore, ethanol, a value-added byproduct can be obtained from the system.

Conclusions

Immobilized cells of A. japonicus and Pichia heimii could be used for producing FOS in very high yield. Through the catalytic reaction of the intracellular FTase of A. japonicus, sucrose was converted into FOS and glucose. Meanwhile, P. heimii fermented the glucose mainly into ethanol. A tanks-in-series bioreactor was employed for the continuous production of high-purity FOS and the value-added byproduct ethanol. A solution composed of 1 g L−1 yeast extract and 300 g L−1 sucrose was fed continuously to the bioreactor at a dilution rate of 0.1 h−1. FOS of up to 98.2 % purity was obtained and ethanol was the primary byproduct. One gram of sucrose yielded 0.62 g of FOS and 0.27 g of ethanol. This immobilized dual-cell system was effective for 10 days in producing high-purity FOS.

Abbreviations

- F:

-

Fructose

- G:

-

Glucose

- GF:

-

Sucrose

- GF2 :

-

1-Kestose

- GF3 :

-

Nystose

- GF4 :

-

1F-Fructosyl nystose

- DP of FOS:

-

Degree of polymerization of FOS

- Yc of FOS:

-

Conversion yield of FOS (g FOS produced/g sucrose consumed)

References

Yun JW (1996) Fructooligosaccharides—occurrence, preparation, and application. Enzyme Microb Technol 19:107–117

Sangeetha PT, Ramesh MN, Prapulla SG (2005) Recent trends in the microbial production, analysis and application of fructooligosaccharides. Trends Food Sci Technol 16:442–457

Zafar TA, Weaver CM, Zhao Y, Martin BR, Wastney ME (2004) Nondigestible oligosaccharides increase calcium absorption and suppress bone resorption in ovariectomized rats. J Nutr 134:399–402

Ooi LG, Liong MT (2010) Cholesterol-lowering effects of probiotics and prebiotics: a review of in vivo and in vitro findings. Int J Mol Sci 5:37–50

Monsan PM, Ouarné F (2010) Oligosaccharides derived from sucrose. In: Charalampopoulos D, Rastall A (eds) The prebiotics and probiotics science and technology. Springer, Berlin

Duan KJ, Chen JS, Sheu DC (1994) Kinetic studies and mathematical model for enzymatic production of fructooligosaccharides from sucrose. Enzyme Microb Technol 16:334–339

Jung KH, Kim JH, Jeon YJ, Lee JH (1993) Production of high fructo-oligosaccharide syrup with two enzyme system of fructosyltransferase and glucose oxidase. Biotechnol Lett 15:65–70

Yun JW, Lee MG, Song SK (1994) Batch production of high-content fructo-oligosaccharides from sucrose by the mixed-enzyme system of β-fructofuranosidase and glucose oxidase. J Ferment Bioeng 77:159–163

Sheu DC, Lio PJ, Chen ST, Lin CT, Duan KJ (2001) Production of fructooligosaccharides in high yield using a mixed enzyme system of β-fructofuranosidase and glucose oxidase. Biotechnol Lett 23:1499–1503

Sheu DC, Duan KJ, Cheng CY, Bi JL, Chen JY (2002) Continuous production of high-content fructooligosaccharides by a complex cell system. Biotechnol Prog 18:1283–1286

Yang YL, Wang JH, Teng D, Zhang F (2008) Preparation of high-purity fructo-oligosaccharides by Aspergillus japonicus β-fructofuranosidase and successive cultivation with yeast. J Agric Food Chem 56:2805–2809

Sheu DC, Chang JY, Chen YJ, Lee CW (2013) Production of high-purity neofructooligosaccharides by culture of Xanthophyllomyces dendrorhous. Biores Technol 132:432–435

Linde D, Rodríguez-Colinas B, Estévez M, Poveda A, Plou FJ, Fernández-Lobato M (2012) Analysis of neofructooligosaccharides production mediated by the extracellular β-fructofuranosidase from Xanthophyllomyces dendrorhous. Biores Technol 109:123–130

Duan KJ, Sheu DC, Chen JS (1993) Purification and characterization of β- fructofuranosidase from Aspergillus japonicus TIT-KJ1. Biosci Biotech Biochem 57:1811–1815

Holcroft DM, Kader AA (1999) Controlled atmosphere-induced changes in pH and organic acid metabolism may affect color of stored strawberry fruit. Postharvest Biol Tec 17:19–32

Krajewski V, Simic P, Mouncey NJ, Bringer S, Sahm H, Bott M (2010) Metabolic engineering of Gluconobacter oxydans for improved growth rate and growth yield on glucose by elimination of gluconate formation. Appl Environ Microbiol 76:4369–4376 109:123–130

Acknowledgments

This work was supported by the National Science Council (NSC), Taiwan, under Contract NSC 99-2221-E-036-019.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sheu, D.C., Chang, J.Y., Wang, C.Y. et al. Continuous production of high-purity fructooligosaccharides and ethanol by immobilized Aspergillus japonicus and Pichia heimii . Bioprocess Biosyst Eng 36, 1745–1751 (2013). https://doi.org/10.1007/s00449-013-0949-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-013-0949-8