Abstract

In this study, we carried out sodium hydroxide and sonication pretreatments of rapeseed straw (Brassica napus) to obtain monosugar suitable for production of biofuels. To optimize the pretreatment conditions, we applied a statistical response-surface methodology. The optimal pretreatment conditions using sodium hydroxide under sonication irradiation were determined to be 75.0 °C, 7.0 % sodium hydroxide, and 6.8 h. For these conditions, we predicted 97.3 % enzymatic digestibility. In repeated experiments to validate the predicted value, 98.9 ± 0.3 % enzymatic digestibility was obtained, which was well within the range of the predicted model. Moreover, sonication irradiation was found to have a good effect on pretreatment in the lower temperature range and at all concentrations of sodium hydroxide. According to scanning electron microscopy images, the surface area and pore size of the pretreated rapeseed straw were modified by the sodium hydroxide pretreatment under sonication irradiation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The application of lignocellulosic feedstocks, the most abundant energy sources, offers numerous benefits to biofuels production. Development of these fuels, however, still faces economic as well as technical obstacles [1]. Biological conversion of lignocellulose into biofuels requires, prior to fermentation, hydrolysis of polysaccharides into monosugars [2]. Lignocellulose hydrolysis depends on characteristics such as porosity and crystallinity [1, 3]. Various pretreatment processes can improve hydrolysis rates and biomass yields by modifying the physical and chemical structures of the biomass [4]. But because pretreatment effectiveness differs according to the biomass composition and characteristics, pretreatment condition must be optimized for each biomass [1, 2]. Generally, pretreatment disrupts the carbohydrate–lignin complex that limits the accessibility of cellulose and hemicellulose to enzymes or chemicals [4, 5].

Classical alkaline pretreatment of lignocellulose, involving alkaline solutions such as sodium, potassium, calcium, and ammonium hydroxides, reduces the substitutions of lignin and various uronic acids in lignocellulosic materials. For alkali, it is recommended that pretreatment time and temperature be lower than for acids [6]. The main effect of alkaline pretreatment is delignification by breakage of the ester bonds in the cross-linking of lignin and xylan. This increases biomass porosity by swelling, thereby effecting an increase of the internal surface area, a separation of structural linkages between lignin and carbohydrates, a decrease of crystallinity, and disruption of the lignin structure [3, 6–9].

Rapeseed straw (Brassica napus) is an attractive bioenergy resource. For many years, rapeseed crops around the world have been cultivated as sources of food as well as oil and biodiesel [9–13]. Rapeseed straw, which is an agricultural waste, is an appealing source of biofuel feedstock due to its high (more than 60 %) carbohydrate content [9, 13]. Early pretreatment work on bioethanol production from rapeseed straw mainly involved hydrothermal [10], dilute acid [12], H2SO4-catalyzed hydrothermal [11], sodium hydroxide [9] and soaking in aqueous ammonia (SAA) pretreatments [13].

There have been investigations on the application of sodium hydroxide to the pretreatment of several biomass resources such as hardwood, softwood, corn stover, cotton stalk, rapeseed straw, and wheat straw [3, 6, 7, 9, 14–16]. As for published data, the enzymatic digestibility of hardwood after dilute-NaOH pretreatment was increased from 14 to 55 %, with a lignin decrease of 24–55 to 20 % [14]. After 2 % NaOH pretreatment of wheat straw, rice straw and bagasse, hydrolysis rates effectively increased to 33.0, 25.5, and 35.5 %, respectively [15]. High lignifications of 63.5 % under the conditions of 2 % NaOH for 90 min at 121 °C/15 psi and 60.8 % conversion of cellulose were observed for NaOH pretreatment of cotton stalk [7].

There have been several pretreatments performed for conversion of rapeseed straw to biofuel [9–11, 13]. In a hydrothermal pretreatment, nearly 100 % of enzymatic hydrolysis was obtained at 210–220 °C for 30–50 min; however, only 65 % of glucose hydrolysis was obtained at 193 °C for 27 min [10]. Lu et al. [11] reported 63.17 % total glucan conversion of high-solid-content (20 %) rapeseed straw for pretreatment with 1 % sulfuric acid at 180 °C for 10 min. Elsewhere, after SAA pretreatment, 60.7 % of enzymatic digestibility was achieved, specifically under the conditions of 69.0 °C, 19.8 % aqueous ammonia, and 14.2 h [13]. Another study, reporting on NaOH pretreatment, obtained 95.7 % enzymatic digestibility under 68.4 °C, 7.9 % (w/w) sodium hydroxide and 5.5 h conditions [9]. As the above-noted results indicate, thermal and acid pretreatments require high-severity condition such as high temperature. Alkaline pretreatment, by contrast, requires moderate temperature and long duration [2, 10–13].

Ultrasound pretreatment of lignocellulosic feedstocks is a relatively new modality [4, 17, 18]. Ultrasonication has been widely applied within the food, medicine, and pulp and paper industries, as well as to biomass fractionation processes [17, 19–22]. In the biomass fractionation field, ultrasonication seems a promising technology that can be easily introduced to the biorefinery processes at the pretreatment, fractionation, extraction, separation and purification stages [17, 23–25]. Ultrasound can be categorized into three frequency ranges: power (16–100 kHz), high frequency (100 kHz–1 MHz) and diagnostic (1–10 MHz) [18]. Low-frequency ultrasound waves generate cavitations and acoustic streaming in a liquid. The cavitation disintegrates nearby particles, and improves diffusivity or mass transfer by strong hydro-mechanical shear forces [17, 18, 26, 27]. Ultrasonication enhances the extractability of hemicellulose, cellulose, and lignin in lignocellulosic biomasses. Also, it has fewer impurities and more selectivity in linkage breaking, which affects the physicochemical properties of the products [4, 17, 21]. Nevertheless, it does not hydrolyze a biomass to monosugars. Material pretreated by ultrasound is more easily hydrolyzed by increasing the accessible surface area and, thereby, affecting the crystallinity [4, 28].

Pretreatment of rapeseed straw under ultrasound irradiation had not been investigated prior to the present study. Specifically, we investigated the effect of sonification and optimization of pretreatment conditions with sodium hydroxide under ultrasound irradiation. For pretreatment condition optimization, we utilized the response-surface methodology, by which the five-level three-factor effects and their reciprocal interactions on sodium hydroxide pretreatment under ultrasound irradiation were predicted.

Materials and methods

Materials

Rapeseed straw (B. napus) was obtained from the Bioenergy Crop Research Center of the National Institute of Crop Science (Muan, Korea). The composition of the rapeseed straw was 33.93 % cellulose, 18.52 % hemicellulose, 33.32 % lignin and 6.9 % ash [13]. The straw was washed with distilled water to remove dust, and was then dried at 40 °C for 2 days. The dried straw was ground and fractionated to a particle size of 0.71–1.40 mm using sieves. Cellulase (Cellulaclast® 1.5 L, 98 FPU/mL, Novo Inc., Denmark) and β-glucosidase (Novozyme 188, 430 CBU/mL, Sigma-Aldrich Co., Ltd., USA) were used for enzymatic hydrolysis. Avicel® PH-101 (~97 %, Sigma-Aldrich Co., Ltd., USA) was used in the enzymatic hydrolysis as a reference. Sodium hydroxide (Duksan Chemical Co., Ltd., Korea) and the other chemicals were of analytical grade.

Sodium hydroxide pretreatment under ultrasound irradiation

Ten grams of rapeseed straw were treated with 1–9 % (w/w) sodium hydroxide in 250 mL screw-capped laboratory Pyrex bottles (Duran, Germany) at 30–80 °C for 1–9 h under sonication irradiation. Ultrasound irradiation was conducted using a sonicator (JAC-2010, Kodo Technical Research Co., Ltd, Korea), offering an ultrasonic frequency of 40 kHz (300 W). The solid-to-liquid ratio was 1:10. After pretreatment, the remaining solids were separated by filter paper (porosity: coarse; Fisherbrand®) and washed with deionized water until the pH [using pH meter, a PHM210 (MeterLab®, France) of waste water reached about 7. The pretreated solid residues were maintained in a plastic container at 4 °C for further use.

Experimental design and statistical analysis

Five-level three-factor central-composite rotatable design of response-surface methodology was introduced to optimize the pretreatment conditions, requiring 20 runs including eight factorial points, six axial points, and six central points [9, 13, 29]. The pretreatment conditions were pretreatment temperature, sodium hydroxide concentration, and pretreatment time. Table 1 lists the coded and uncoded independent conditions (X i ), the levels, and the experimental design. The experimented results (Table 1) were analyzed using Design-Expert 7 (Stat-Ease Inc., USA) for prediction of the quadratic response-surface model

where Y is the response factor (biomass recovery, lignin removal, or enzymatic digestibility), X i is the ith independent factor, β0 is the intercept, β i is the first-order model coefficient, β ii is the quadratic coefficient for factor i, and β ij is the linear model coefficient for the interaction between factors i and j [2, 9, 13, 29].

Enzymatic hydrolysis

The enzymatic hydrolysis of the pretreated rapeseed straw was performed according to the standard National Renewable Energy Laboratory (NREL) chemical analysis and testing procedures [30]. The operating conditions were 50 °C, pH 4.8 (using 0.05 M sodium citrate buffers), and a shaking incubator operated at 150 rpm for 72 h. The initial glucan concentration was 1 g [1 % (w/v)], based on 100 mL of total liquid and solid. Enzymes loaded 30 FPU of cellulase and 30 CBU of β-glucosidase. Hydrolyzed samples were periodically taken for glucose-concentration analysis purposes. Avicel® PH-101 and raw rapeseed straw were employed as the reference and control, respectively [9, 13, 30].

Analytical methods

To determine the sugar contents in the pretreated biomass samples and enzymatic hydrolysates, high-performance liquid chromatography (HPLC) equipped with a refractive index detector (RID-10A, Shimadzu Corp., Japan) and SUPELCOGEL™ Pb columns (SUPELCO™ Analytical, USA) was used. The operation conditions were 85 °C oven temperature and 0.6 mL/min flow rate (with deionized water). The enzymatic digestibility was calculated as follows [9, 13]

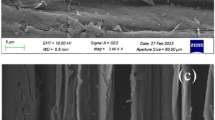

Scanning electron microscopy of pretreated rapeseed straw

To compare the physical surface characteristics of the post-pretreatment rapeseed straw, scanning electron microscopy (SEM; JSM-5400, JEOL Ltd., Japan) was used. Preliminarily, the samples were coated with a thin layer of gold [9, 13].

Results and discussion

The results of lignocellulose biomass pretreatment depend on the pretreatment conditions [4]. In the present study, the optimization of pretreatment conditions under ultrasound irradiation focused on three aspects: biomass recovery, lignin removal, and enzymatic digestibility.

Effect of pretreatment condition on biomass recovery

The effects of the sonication irradiation pretreatment conditions on the biomass recovery of rapeseed straw were investigated using the response-surface methodology. The biomass recovery yield, as based on the initial biomass weight, ranged between 54.24 and 87.11 %. The following quadratic equation (Eq. 3) was calculated from a regression analysis using Design-Expert 7. This model presents 0.88 of R 2 and 0.78 of Adj. R 2. The coefficients of the predicted model, based on the coded condition level and probability values (p values), are listed in Table 3.

where X 1, X 2 and X 3 represent the pretreatment temperature, pretreatment time and sodium hydroxide concentration, respectively, and Y is the biomass recovery. Table 3 indicates the analysis of variance (ANOVA) results for the response-surface quadratic model. The p values of most of the coefficients (X 1, X 3, and \( X_{2}^{2} \)) were less than 0.05. It is presenting that predicted model was adequate to compare the actual relationship among the selected conditions. p values greater than 0.1 meant that the model terms were not significant.

In the relationship between the actual values of biomass recovery and the predicted values, the predicted values relative to the actual values were within the model’s designed ranges (data not shown). Figure 1 shows the effects of the pretreatment conditions on the biomass recovery. As indicated in Fig. 1a, the biomass recovery sharply decreased relative to the increase of the pretreatment temperature with 3 or 7 % NaOH at 5 h. The biomass recovery with 7 % NaOH showed a higher slope than that with 3 % NaOH. The biomass recovery manifested as a concave curve for the increase of pretreatment time at 55 °C (Fig. 1b). Pretreatment with 3 % NaOH showed a higher biomass recovery than that with 7 % NaOH. Figure 1c shows that the biomass recovery was sharply decreased by the increase of temperature over 3 or 7 h at 5 % NaOH. The effect of time on biomass recovery was reduced by higher temperature.

Figure 2 provides response-surface plots representing the effects (and reciprocal interactions) of pretreatment temperature, pretreatment time and sodium hydroxide concentration on the biomass recovery when all other conditions were constant at the zero level. As shown in Fig. 2a, the biomass recovery was increased linearly by the increase of pretreatment temperature over all of the time ranges. By contrast, at 5 h for all of the temperature ranges, the biomass recovery was sharply curtailed. Figure 2b shows the effects and reciprocal interaction of the pretreatment temperature and sodium hydroxide concentration at 5 h. At low temperatures, biomass recovery was slightly decreased in the range of 7 % NaOH and below. At high temperatures, the biomass recovery was sharply decreased by the increase of the NaOH concentration. Also, the linear-increase slope of biomass recovery, due to the decrease of pretreatment temperature, was steeper than that of the low NaOH concentration. Figure 2c represents the effects and reciprocal interaction of pretreatment time and sodium hydroxide concentration at the zero level (55 °C). The biomass recovery manifested as a concave curve in all ranges of sodium hydroxide concentration and pretreatment time. From Figs. 1 and 2, it is evident that in NaOH pretreatment under ultrasound irradiation, pretreatment time is a less important condition than pretreatment temperature or sodium hydroxide concentration.

Response-surface plots representing effects of reaction temperature, reaction time and sodium hydroxide concentration on biomass recovery of pretreated rapeseed straw. a Sodium hydroxide concentration was fixed at 21 % (w/w), b reaction time was fixed at 5 h, c reaction temperature was fixed at 55 °C

Effect of pretreatment condition by RSM on lignin removal

As the Table 2 data indicate, the amount of lignin removal ranged from 38.72 to 60.86 % of the initial lignin in the untreated rapeseed straw. The highest lignin removal (60.86 %) was obtained under the 80 °C, 5 % (w/w) sodium hydroxide for 5 h pretreatment conditions, which also resulted in low biomass recovery yields (Run 6). The effects of pretreatment temperature, pretreatment time and sodium hydroxide concentration (under sonication irradiation) on the lignin removal of rapeseed straw were investigated by response-surface methodology using Design-Expert 7. In the result of the predicted model, the regression analysis had 0.67 of R 2 and 0.38 of Adj. R 2. R 2 and Adj. R 2 values were too low, and so the analysis of lignin removal data is not suitable for model prediction.

Figure 3 plots the relationship between lignin removal and biomass recovery/enzymatic digestibility under NaOH pretreatment with ultrasound irradiation. The increase of lignin removal caused a decrease of biomass recovery (R 2 = 0.762). However, the lignin removal increased the enzymatic digestibility (R 2 = 0.673). These results reflect the fact that NaOH pretreatment of rapeseed straw diminishes the lignin content in biomass by enhancing the accessibility of cellulose to enzymes. Similarly, the most significant effect of NaOH pretreatment was on delignification, the concentration of NaOH being the significant factor for cotton stalk. Lignin reduction linearly increased with the increase of NaOH pretreatment severity [7].

Optimization of pretreatment conditions by RSM on enzymatic digestibility

The effects of sonication-irradition pretreatment on the enzymatic digestibility of rapeseed straw were investigated. The values obtained ranged from 39.7 (Run 12) to 91.7 % (Run 11) (Table 2). As the result of a regression analysis using Design-Expert 7, the following quadratic equation (Eq. 4), which had 0.97 of R 2 and 0.95 of Adj. R 2, was obtained as

where \( X_{1}^{'} \), \( X_{2}^{'} \), \( X_{3}^{'} \) represent the pretreatment temperature, pretreatment time and sodium hydroxide concentration, respectively, and Y is the enzymatic digestibility of the pretreated rapeseed straw.

The predicted model was evaluated using the coefficients of determination and ANOVA [2, 9, 13, 29]. The coefficients of the predicted model, as based on the coded factor level and probability values, are shown in Table 4. Table 4 also lists the ANOVA results for the response-surface quadratic model with sodium hydroxide pretreatment under sonication irradiation. The p values of most of the coefficients (\( X_{1}^{'} \), \( X_{2}^{'} \), \( X_{3}^{'} \), \( X_{1}^{'} X_{2}^{'} \), \( X_{2}^{'} X_{3}^{'} \) and \( X_{1}^{'2} \)) were less than 0.05, which indicates that the predicted model properly showed the actual relationship among the selected conditions. All of the linear coefficients were more significant than their quadratic and cross-product terms. However, to minimize prediction error, all of the coefficients were considered in this designed model.

Figure 4 plots the effect of pretreatment conditions on the enzymatic digestibility. As shown in Fig. 4a, the enzymatic digestibility of the pretreated rapeseed straw linearly increased according to the increase of pretreatment temperature under the 5 % NaOH and 5 h conditions. That is, high pretreatment temperature (80 °C) improved the enzymatic digestibility. In a comparable study on NaOH pretreatment of rapeseed straw [9], the enzymatic digestibility was sharply increased relative to pretreatment under ultrasound irradiation. Relative to NaOH pretreatment without ultrasound irradiation, the enzymatic digestibility was increased about 27 % at low temperature (30 °C) [9]. However, at high temperature (80 °C), the difference in enzymatic digestibility was diminished. These results indicate that ultrasound irradiation has a significant effect on enzymatic digestibility at low temperature.

Figure 4b shows the effects of pretreatment time on the enzymatic digestibility at 55 °C and 5 % NaOH. For a short pretreatment time, below 5 h, the enzymatic digestibility showed a slight linear increase. However, over 5 h, it was not affected. Compared with NaOH pretreatment of rapeseed straw [9], pretreatment under ultrasound irradiation showed an increasing enzymatic digestibility pattern. Specifically, ultrasound irradiation enhanced enzymatic digestibility by about 11 % over NaOH pretreatment. Nevertheless, the pretreatment time did not show a significant effect on the enzymatic digestibility increase [9].

Figure 4c plots the effects of sodium hydroxide concentration on enzymatic digestibility at 55 °C and 5 h. As is apparent, the enzymatic digestibility was sharply linearly increased by the increase of NaOH concentration. Relative to Kang et al.’s [9] results, the present study showed a similar enzymatic digestibility pattern. The enzymatic digestibility was increased by about 7.2–11 % by ultrasound irradiation in the experimental range of the NaOH concentration compared with the NaOH pretreatment [9].

From the experimental data, we can conclude that the most significant conditions for enzymatic digestibility in NaOH pretreatment under ultrasound irradiation were pretreatment temperature and NaOH concentration. Moreover, we can conclude that ultrasound irradiation has a good effect on pretreatment in the lower temperature range and for all concentrations of sodium hydroxide.

Figure 5a provides a response-surface plot of the effects of pretreatment temperature and pretreatment time, along with their reciprocal interaction effects on the enzymatic digestibility of rapeseed straw under ultrasound irradiation when the level of sodium hydroxide concentration was fixed at 5 % (w/w). A positive interaction between pretreatment temperature and time was observed. At a low pretreatment temperature (30 °C), the pretreatment time showed a negative effect on the enzymatic digestibility. But at a high pretreatment temperature (over 55 °C), the enzymatic digestibility sharply increased with time duration. Also, with a short pretreatment time (1 h), the enzymatic digestibility did not significantly increase with the rise of pretreatment temperature. However, with a long pretreatment time, the increase of pretreatment temperature had a strong effect on the improvement of enzymatic digestibility. A high enzymatic digestibility was obtained under the conditions of high pretreatment temperature and long treatment time.

Response-surface plots representing effects of reaction temperature, reaction time and sodium hydroxide concentration on enzymatic digestibility of pretreated rapeseed straw. a Sodium hydroxide concentration was fixed at 21 % (w/w), b reaction time was fixed at 5 h, c reaction temperature was fixed at 55 °C

Similarly, Kang et al. [9] reported that high temperature and long treatment time resulted in high enzymatic digestibility under the 5 % (w/w) NaOH pretreatment condition. Under the SAA with 15 % (w/w) condition, the enzymatic digestibility was increased by temperature rises above 90 °C over the entire pretreatment period [13].

Figure 5b is a response-surface plot representing the effects of pretreatment temperature and sodium hydroxide concentration, along with their reciprocal interaction effects on the enzymatic digestibility at 5 h under ultrasound irradiation. Under the low sodium hydroxide concentration condition, the increase of temperature (over 60 °C) slightly enhanced the enzymatic digestibility. However, for 5–9 % (w/w) sodium hydroxide, the enzymatic digestibility dramatically increased in the 55–80 °C range. The increase of sodium hydroxide concentration also effected a linear increase of enzymatic digestibility at low pretreatment temperatures. Over the entire temperature range, the enzymatic digestibility was enhanced by the increase of sodium hydroxide concentration. As a similar result, the pretreatment of rapeseed straw with 5–9 % NaOH resulted in a dramatic increase in enzymatic digestibility when the temperature ranged from 55 to 80 °C at 5 h. Under this condition, the temperature and NaOH concentration had a more significant effect on enzymatic digestibility than time [9]. Moreover, for all of the ammonia concentrations, the rising of temperature showed a drastic increase in enzymatic digestibility under the SAA pretreatment condition [13].

A response-surface plot representing the effects of pretreatment time and sodium hydroxide concentration, along with their reciprocal interaction effects on the enzymatic digestibility of rapeseed straw under the zero level (55 °C) ultrasound-irradiation condition is provided in Fig. 5c. Over the entire sodium hydroxide concentration range, the increase of pretreatment time did not significantly affect the enzymatic digestibility. However, the pretreatment time had a strongly enhancing effect on the enzymatic digestibility. It was evident that reaction time is a less important factor than reaction temperature or sodium hydroxide concentration. Similarly, in a previous study, at 55 °C the enzymatic digestibility was strongly increased at high NaOH concentrations as time passed. However, the increase of NaOH with a short reaction time only slightly increased the enzymatic digestibility [9]. In another study, the pretreatment of rapeseed straw with SAA and a high ammonia concentration only slightly increased the enzymatic digestibility with time at 50 °C [13].

To optimize the NaOH pretreatment conditions for rapeseed straw under sonication irradiation, we focused on economic alternatives in the forms of low pretreatment temperature, time and sodium hydroxide concentration ranges. The optimal conditions of NaOH pretreatment under sonication irradiation were selected by a regression analysis using Design-Expert 7 software. They were 75.0 °C pretreatment temperature, 6.5 h pretreatment time, and 7.0 % (w/w) sodium hydroxide with a solid:liquid ratio of 1:10 under sonication irradiation. At these optimal points, a 97.3 % enzymatic digestibility was obtained. To determine the validity of the model’s predicted value, repeated experiments were carried out under the predicted conditions. In the result, a 98.9 ± 0.3 % enzymatic digestibility was obtained. This well represented the optimized condition ranges of the model.

Figure 6 shows the results of a comparison of the enzymatic digestibilities of the cellulose and the raw and pretreated rapeseed straw. The raw rapeseed straw did not properly hydrolyze below 20 %. Cellulose (Avicel) was hydrolyzed at about 91 %. The pretreated rapeseed straw under the optimal conditions was about 98 % hydrolyzed. The obtained results indicated that NaOH pretreatment of rapeseed straw under ultrasound irradiation is effective for biofuel production purposes.

SEM photo of sodium hydroxide-pretreated rapeseed straw

The various pretreatment techniques change the physical and chemical structures of lignocellulosic biomass [4]. Figure 7 shows the morphology change of rapeseed straw after pretreatment as observed by SEM. Figure 7a, b (unpretreated rapeseed straw) provides the views of the small-pore, compact and rigid structure of raw rapeseed straw. Figure 7c, d (pretreated rapeseed straw) shows that the pretreated straws were well broken and that the pore size was enlarged. It was speculated that the partial removal of hemicellulose and lignin broke the crystallized structure of cellulose–hemicellulose–lignin. Available surface area, as related to the accessibility of cellulose to enzymes, is one of the major limiting factors for enzymatic hydrolysis in industrial processes [13].

SEM images of NaOH-pretreated rapeseed straw under sonication irradiation. a Inside of raw rapeseed straw, b outside of raw rapeseed straw, c inside of pretreated rapeseed straw, d outside of pretreated rapeseed straw. Pretreated rapeseed straws (c, d) are pretreated in the condition of 75 °C pretreatment temperature, 7.0 % (w/w) sodium hydroxide and 6.5 h pretreatment time with a solid-to-liquid ratio of 1:10 under sonication irradiation (40 kHz, 300 W)

Conclusions

In this study, sodium hydroxide pretreatment of rapeseed straw by response-surface methodology under ultrasound irradiation was carried out. Sonication had a good effect on pretreatment at the lower temperature range and at all sodium hydroxide concentration ranges. Also, pretreatment time was a less important factor than other parameters. For the optimum pretreatment conditions of 75 °C, 7.9 % sodium hydroxide, and 5.5 h under sonication irradiation, 97.3 % enzymatic digestibility was predicted. After sodium hydroxide pretreatment of rapeseed straw under sonication irradiation, physical surface characteristics such as the surface area and pore size were enhanced, thereby accelerating the enzymatic hydrolysis.

References

Alvira P, Tomas-Pejo E, Balesteros M, Negto MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101:4851–4861

Jeong GT, Park DH (2010) Production of sugars and levulinic acid from marine biomass Gelidium amansii. Appl Biochem Biotechnol 161:41–52

Fang LT, Gharpuray MM, Lee YH (1987) Cellulose hydrolysis biotechnology monographs. Springer, Berlin 55

Yunus R, Salleh SF, Abdullah N, Biak DRA (2010) Effect of ultrasonic pre-treatment on low temperature acid hydrolysis of oil palm empty fruit bunch. Bioresour Technol 101:9792–9796

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple M, Ladisch M (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96:673–686

Balat M (2011) Production of bioethanol from lignocellulosic materials via the biochemical pathway: a review. Energy Conversat Manag 52:858–875

Silverstein RA, Chen Y, Sharma-Shivappa RR, Boyette MD, Osborne J (2007) A comparison of chemical pretreatment methods for improving saccharification of cotton stalks. Bioresour Technol 98:3000–3011

Tarkov H, Feist WC (1969) A mechanism for improving the digestibility of lignocellulosic materials with dilute alkali and liquid ammonia. Adv Chem Ser 95(1):197–218

Kang KE, Jeong GT, Park DH (2012) Pretreatment of rapeseed straw by sodium hydroxide. Bioprocess Biosyst Eng 35:705–713

Díaz MJ, Cara C, Ruiz E, Romero I, Moya M, Castro E (2010) Hydrothermal pre-treatment of rapeseed straw. Bioresour Technol 101(7):2428–2435

Lu X, Zhang Y, Angelidaki I (2009) Optimization of H2SO4-catalyzed hydrothermal pretreatment of rapeseed straw for bioconversion to ethanol: focusing on pretreatment at high solids content. Bioresour Technol 100(12):3048–3053

Castro E, Díaz MJ, Cara C, Ruiz E, Romero I, Moya M (2011) Dilute acid pretreatment of rapeseed straw for fermentable sugar generation. Bioresour Technol 102(2):1270–1276

Kang KE, Jeong GT, Sunwoo C, Park DH (2012) Pretreatment of rapeseed straw by soaking in aqueous ammonia. Bioprocess Biosyst Eng 35:77–84

Millet MA, Baker AJ, Scatter LD (1976) Physical and chemical pretreatment for enhancing cellulose. Appl Microbiol Biotechnol 29:462–468

Akhtar MS, Saleem M, Akhtar MW (2001) Saccharification of lignocellulosic materials by the cellulases of Bacillus subtilis. Int J Agr Biol 3:199–202

Li Y, Ruan R, Chen PL, Liu Z, Pan X, Lin X (2004) Enzymatic hydrolysis of corn stover pretreated by combined dilute alkaline treatment and homogenization. Trans ASAE 47:821–825

García A, Alriols MG, Llano-Ponte R, Labidi J (2011) Ultrasound-assisted fractionation of the lignocellulosic material. Bioresour Technol 102(10):6326–6330

Nikolic′ S, Mojovic′a L, Rakin M, Pejin D, Pejin J (2010) Ultrasound-assisted production of bioethanol by simultaneous saccharification and fermentation of corn meal. Food Chem 122:216–222

Vilkhu K, Mawson R, Simons L, Bates D (2008) Applications and opportunities for ultrasound assisted extraction in the food industry—a review. Innov Food Sci Emerg 9:161–169

Shaw LE, Lee D (2009) Sonication of pulp and paper effluent. Ultrason Sonochem 16:321–324

Sun RC, Tomkinson J (2002) Comparative study of lignins isolated by alkali and ultrasound-assisted alkali extractions from wheat straw. Ultrason Sonochem 9:85–93

Sun RC, Tomkinson J, Ye J (2003) Physico-chemical and structural characterization of residual lignins isolated with TAED activated peroxide from ultrasound irradiated and alkali pre-treated wheat straw. Polym Degrad Stabil 79:241–251

Romdhane M, Gourdon C (2002) Investigation in solid-liquid extraction: influence of ultrasound. Chem Eng J 87:11–19

Koberg M, Cohen M, Ben-Amotz A, Gedanken A (2011) Bio-diesel production directly from the microalgae biomass of Nannochloropsis by microwave and ultrasound radiation. Bioresour Technol 102:4265–4269

Patist A, Bates D (2008) Ultrasonic innovations in the food industry: from the laboratory to commercial production. Innov Food Sci Emerg 9(2):147–154

Ebringerová A, Hromádková Z (2002) Effect of ultrasound on the extractability of corn bran hemicelluloses. Ultrason Sonochem 9:225–229

Liu CF, Sun RC, Quin MH, Zhang AP, Ren JL, Xu F, Ye J, Wu SB (2007) Chemical modification of ultrasound-pretreated sugarcane bagasse with maleic anhydride. Ind Crops Prod 26:212–219

Toma M, Vinatoru M, Paniwnyk L, Mason TJ (2007) Investigation of the effects of ultrasound on vegetal tissues during solvent extraction. Ultrason Sonochem 8:137–142

Jeong GT, Park DH (2009) Optimization of biodiesel production from castor oil using response surface methodology. Appl Biochem Biotechnol 156:431–441

Selig M, Weiss N, Ji Y (2008) Enzymatic saccharification of lignocellulosic biomass in laboratory analytical procedure. National Renewable Energy Laboratory, Golden

Acknowledgments

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology (2012R1A1A2006718).

Author information

Authors and Affiliations

Corresponding authors

Additional information

G.-T. Jeong and D.-H. Park have equally contributed as corresponding author to this work.

Rights and permissions

About this article

Cite this article

Kang, K.E., Jeong, GT. & Park, DH. Rapeseed-straw enzymatic digestibility enhancement by sodium hydroxide treatment under ultrasound irradiation. Bioprocess Biosyst Eng 36, 1019–1029 (2013). https://doi.org/10.1007/s00449-012-0854-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-012-0854-6