Abstract

Optimal conditions for enzymatic synthesis of biodiesel from palm oil and ethanol were determined with lipase from Pseudomonas fluorescens immobilized on epoxy polysiloxane–polyvinyl alcohol hybrid composite under a microwave heating system. The main goal was to reduce the reaction time preliminarily established by a process of conventional heating. A full factorial design assessed the influence of ethanol-to-palm oil (8:1–16:1) molar ratio and temperature (43–57 °C) on the transesterification yield. Microwave irradiations varying from 8 to 15 W were set up according to reaction temperature. Under optimal conditions (8:1 ethanol-to-oil molar ratio at 43 °C), 97.56 % of the fatty acids present in the palm oil were converted into ethyl esters in a 12-h reaction, corresponding to a productivity of 64.2 mg ethyl esters g−1 h−1. This represents a sixfold increase from the process carried out under conventional heating, thus proving to be a potential tool for enhancing biochemical modification of oils and fats. In general, advantages of the new process include: (1) microwaves speed up the enzyme-catalyzed reactions; (2) there are no destructive effects on the enzyme properties, such as stability and substrate specificity, and (3) the microwave assistance allows the entire reaction volume to be heated uniformly. These bring benefits of a low energy demand and a faster conversion of palm oil into biodiesel.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Microwaves are electromagnetic waves with frequencies ranging from 300 MHz to 300 GHz. Microwaves induce molecular rotation of dipolar species accompanied by intermolecular friction and energy dissipation, resulting in volumetric heating without affecting the molecular structure. Microwave heating is a process of direct energy absorption by the irradiated material (liquid) with a uniformly distributed heat sources which prevents convection due to thermal gradients, a common phenomenon in conventional heating. Microwave heating is selective and depends mainly on the dielectric properties and the relaxation frequency of the treated material [1, 2].

In recent years, microwave irradiation has become an increasingly popular heating method, because it proves to be clean, cheap and convenient. Reduction in reaction times, enhancement in conversions and sometimes also in selectivity have been reported concerning mainly solvent-free reactions conducted in a microwave field [2, 3].

The first report on microwave-assisted organic syntheses appeared in 1986 in two independent works carried out by Gedye and Guigere [4]. The authors performed reactions in sealed flasks and compared the obtained data to those from experiments with conventional heating. The significant reduction in the reaction time boosted the application of this heating technique [4–7]. Several review articles and books provide extensive coverage on this subject and demonstrate that its large reaction diversity could be favorable by this heating method [1–6]. Besides other uses in several chemical organic synthesis [8] and biological reactions [9], microwaves are currently being used to assist enzymatic hydrolytic and synthetic reactions by lipases and proteases [10–13].

Lipases (triacylglycerol ester hydrolases E.C. 3.1.1.3) are hydrolytic enzymes that catalyze the acylglycerol hydrolysis preferentially at the oil/water interface. The hydrolytic reactions for lipases are essentially reversible and the potential of these enzymes in the organic synthesis has been well documented [14]. The versatility of the lipase as a catalyst is also evident by the number of industrial processes being set up [14–17], where there is an interest in controlling the physical, functional and organoleptic properties of the products. The potential of the enzymatic technology for developing new or well-known products at more competitive costs meets the need of this industrial segment in achieving its goals [18, 19].

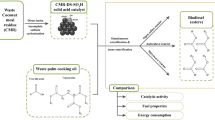

In this context, the objective of the present work was to improve the enzymatic process for vegetable oil modification, aiming at a higher yield, lower energy consumption and waste reduction. Particular emphasis was given to the effects of high-frequency electromagnetic fields (microwaves) to develop biotransformation processes using lipase as a catalyst, in view of the its great versatility to mediate typical reactions in the oleochemical industry. More specifically, the target reaction is the ethanolysis of palm oil to produce biodiesel. This is an exceptional option for the Brazilian biodiesel production, since both palm oil and ethanol are readily available in the country. In addition, previous results indicated that the product obtained from the enzymatic transesterification process has properties in accordance with the standard specifications for biofuel [20]. Nevertheless, the reaction productivity is still low compared to the conventional chemical route. Therefore, in this work, an attempt was made to reduce the reaction duration of a previously established process performed under conventional heating using Pseudomonas fluorescens lipase immobilized on epoxy polysiloxane–polyvinyl alcohol hybrid composite (SiO2–PVA) as a catalyst [20]. For this, a full 22 factorial design leading to a set of 7 runs with different molar ratio and temperature combinations was performed to attain the optimal conditions for the microwave-assisted enzymatic synthesis of biodiesel.

Materials and methods

Materials

Commercial lipase P. fluorescens (Lipase AK—20715TD from Amano Pharmaceuticals-Nagoya, Japan) was used as received without further purification. Tetraethoxysilane was acquired from Aldrich Chemical Co. (Milwaukee, WI, USA). Epichlorohydrin, hydrochloric acid (minimum 36 %), ethanol (minimum 99 %), polyvinyl alcohol (MW 72,000) and polyethylene glycol (MW 1,500) were supplied by Reagen (Rio de Janeiro, RJ, Brazil). Palm oil was a kind gift from Agropalma (Para, Brazil) having the following composition in fatty acids (wt): 0.1 % lauric, 1.2 % mirystic, 46.8 % palmitic, 3.8 % stearic, 37.6 oleic and 10.5 % linoleic, with 849.0 g mol−1 average molar mass. Standard chromatography (ethyl esters) previously synthesized by chemical route [21]. All the other reagents were of analytical grade.

Support synthesis and lipase immobilization

SiO2–PVA composite was prepared by the hydrolysis and polycondensation of tetraethoxysilane according to the methodology previously described by Santos et al. [22] attaining particles having the following properties: average pore diameter (22.91 Å), surface area BET (461.00 m2 g−1) and porous volume (0.275 cm3 g−1). Activation of SiO2–PVA particles was carried out with epichlorohydrin and used to immobilize the lipase AK. To perform this work, four batches of immobilized derivatives were prepared and average measured hydrolytic activity was 1,500 ± 138 U g−1 biocatalyst. Additional properties of this immobilized derivative can be found elsewhere [22].

Biodiesel synthesis

Reactions were performed in a microwave reactor (Model Discover/University-Wave, Cem Corporation). The cylindrical design assures homogeneous irradiation of the working volume that, for instance, is missing in the conventional microwave ovens available on the market and frequently used in experiments without modifications. A magnetic stirrer was used to attain at three levels of the liquid mixing qualitatively classified as low, medium, or high. Temperature was controlled with compressed air blown into the chamber and monitored by an infrared sensor located in the lower part of the chamber. This chilling air was designed to operate at different levels of pressure and either on continuous or intermittent flow mode. ChemDriver software was used to record data for each run, including variation in the microwave flux and temperature [7]. The working volume was designed as a 100-ml spherical glass reactor containing 12 g of substrate consisting of palm oil and anhydrous ethanol at different molar ratios in the absence of solvents. The reaction medium was incubated with the immobilized derivative at a fixed proportion of 20 % (w/w) in relation to the total weight of reactants involved in the reaction. For the time course studies, an aliquot of reaction medium was taken at various time intervals and diluted in n-heptane for GC analysis.

Experimental design and data treatment

The influence of the variables (molar ratio and temperature) on biodiesel formation was studied using a 22 full factorial design. Runs were performed at random. Three experiments were carried out at the center point level, for experimental error estimation. Results were analyzed using Statistica version 5 (StatSoft Inc., USA) and Design-Expert 6.0 (Stat-Ease Corporation, USA) softwares. The statistical significance of the regression coefficients was determined by Student’s t test, the second-order model equation was evaluated by Fischer’s test and the proportion of variance explained by the model obtained was given by the multiple coefficient of determination (R 2) [17].

Downstream procedure

When the reaction was completed, the lipase was separated from the medium and the organic phase was washed twice with one volume of water to remove both the remaining ethanol and the free glycerol as a by-product. The residual water was removed by evaporation to attain the final fatty acid ethyl ester product. The specific gravity of the product was determined in accordance with the recommendations of ASTM1298.

Analytical methods

GC analysis

Ethyl esters derived from ethanolysis of palm oil were analyzed using gas chromatography Varian CG 3800 model (Varian Inc., Corporate Headquarters, Palo Alto, CA, USA) equipped with flame-ionization detector and 5 % DEGS CHR-WHP 80/100 mesh 6 ft 2.0 mm ID and 1/8 in. OD (Restek, Frankel Commerce of Analytic Instruments Ltd., SP, Brazil) according to methodology previously described by Urioste et al. [21]. Data collection and analyses were performed using the software Galaxie Chromatography Data System version 1.9. The calibration curves were measured from standard ethyl esters using hexanol as an internal standard. The reaction yield was calculated by taking into account the mass of ester content obtained by GC analysis and the total theoretical ester mass based on the initial amount of both oil and ethanol [21].

Biodiesel viscosity determination

The biodiesel viscosity was determined by LVDV-II cone and plate spindle Brookfield viscosimeter (Brookfield Viscometers Ltd, England). Biodiesel samples of 0.5 mL were used and the measurements were replicated three times. A circulating water bath was used to maintain temperature at 25 or 40 °C (±0.1 °C) during the assays.

Thermal stability of immobilized derivative in the microwave reactor

For the thermal stability tests, samples of the immobilized lipase preparation were incubated in n-heptane at 60 °C under microwave irradiations for 3 h under. Samples were removed and assayed for residual activity as previously described [20, 23], taking an unheated control to be 100 % active. The rate of deactivation (k d) and half-life time (t 1/2) was calculated by Eqs. 1 and 2, respectively.

where A 0 is the initial activity, while A is the activity after t min of heating.

Results and discussion

Thermal stability of the immobilized derivative under microwave irradiation

Different agents, such as temperature and chemicals, promote enzyme inactivation. Inactivation by chemicals can often be avoided rather easily by keeping them out of the reaction medium. Temperature, however, produces opposite effects on enzyme activity and stability and is, therefore, a key variable in any biocatalytical process [24].

Under microwave irradiation, a direct energy transfer between the electromagnetic field and the polar protein’s domains could induce modification in enzyme flexibility, consequently changing the enzymatic properties, but there are differences depending on the reaction medium. In an aqueous medium, the properties of the irradiated enzyme are identical to those obtained under conventional heating. In an organic medium, where only polar species absorb the microwave energy, the enzyme activity, selectivity and stability can be improved by microwave heating. Some authors envisage [2, 9] the existence of a specific effect of the microwave irradiation on the structural and functional properties of enzymes. Moreover, a direct absorption of the microwave energy by the polar substrates of the enzyme could lead to a higher reactivity of the functional groups involved in the enzymatic reaction [25].

In this context, an important preliminary step was to estimate the thermal stability of the P. fluorescens lipase immobilized on SiO2–PVA under microwave irradiation. This allowed determining the temperature range that could be used to perform the biodiesel synthesis. Thermal stability assays were carried out by incubating this specific lipase preparation in n-heptane at 60 °C and submitting to 100 W microwave irradiation over a maximum period of 3 h.

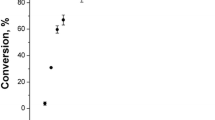

Figure 1 displays values for residual activities of the immobilized derivative as a function of time and microwave irradiation. These data were then used to estimate the thermal inactivation constant (k d) and the biocatalyst half-life time (t ½) as 0.084 h−1 and 8.22 h, respectively. The estimated half-life time could be considered as a highly promising value as compared to the data reported for other immobilized lipase preparations described in the literature [25].

Microwave-assisted biodiesel synthesis

Experimental design was used as a tool to study the combined effect of ethanol-to-oil molar ratio and temperature in the transesterification yield of the biodiesel synthesis. The range of molar ratio and temperature was between 8–16 and 43–57 °C, respectively. In all the experiments, the immobilized derivative was used at 20 % (w/w) in relation to the total weight of reactants involved in the reaction media. Runs were performed at random and three experiments were carried out at the center point level, coded as “0” and allowing estimation of the experimental error.

The experimental matrix and the transesterification yields (%) are shown in Table 1. The profile for the ethyl esters formation as a function of time is displayed in Fig. 2.

Profile for ethyl esters formation in the transesterification reaction of the palm oil with ethanol catalyzed by Pseudomonas fluorescens lipase immobilized on SiO2–PVA under different conditions. The reactions were carried out according to 22 full factorial design (runs 1–7). Ethyl esters from lauric acid (full line); myristic acid (open circle); palmitic acid (open square); stearic acid (open triangle); oleic acid (filled triangle); linoleic acid (filled square) and total esters (filled circle)

The results revealed that the immobilized derivative was able to produce the main FAEE (fatty acid ethyl esters) under all evaluated conditions. The highest ethyl ester concentrations were related to palmitate and oleate ethyl esters, followed by ethyl linoleate with the other esters being produced at lower amounts. This profile was as expected by considering the palm oil fatty acid composition and was similar for all experiments performed. The transesterification yield was strongly affected by both variables and varied from 62.9 to 86.5 %.

The results showed in Table 1 were used to estimate the effects of the main variables and their interactions. According to the Student’s t test (Table 2), both variables and their interaction were significant at 95 % of confidence level.

The significant effect of the temperature (p = 0.0234) is an expected result, since enzymes are temperature-sensitive macromolecules. However, the microwave-specific effect could have a non-thermal origin, although this is still a controversial matter. According to Rejasse et al. [2], the microwave effects on the specific activity due to the structural modification of the irradiated enzyme show uncertainty about a non-thermal effect.

Concerning the influence of medium polarity given in this work by the molar ratio variable (x 1), results show a strong influence of this variable (p = 0.0337) on the transesterification yield. Table 1 shows that for lipase AK the highest oil yield to the FAEE could be achieved when a lower excess of alcohol was utilized (run 1). Although both variables were significant and showed negative effects, the interaction between them revealed a strong and significant positive effect (p = 0.0144). The most important factor in this process was the dielectric properties of the reactants. In this work, runs were carried out using the following substances and/or products: palm oil and anhydrous ethanol as starting materials; lipase and ethyl esters and glycerol as main products; and other intermediary products, such as mono and diglycerides.

The association between microwave irradiations and these compounds is essentially determined by dielectric properties [26–28]. Thus, the ability of a substance to convert microwave energy into heat at a given frequency and temperature can be determined by a parameter known as loss tangent or tangent delta (δ) which represents the dielectric losses in the irradiated material to attenuation and is defined as the ratio of dielectric loss factor to dielectric constant.

where ε′ and ε″ are defined as dielectric constant and dielectric loss, respectively.

Table 3 shows differences in these three dielectric parameters, definitively indicating that the dielectric loss factor is the most indicative parameter concerning the heating of the irradiated material [26, 29, 30]. Water, e.g., has the highest dielectric constant (78.2), but its dielectric loss factor (10.3) is approximately two times lower than ethanol (22.9). Hence, ethanol heats faster in the microwave chamber than water. This simple physical fact explains the reduction in the reaction yields when the ethanol-to-oil molar ratio increases. Moreover, the water molecules are much smaller than those of the oils, which simply mean that the dielectric constants and loss factors of oil–water blends are much lower when compared to free water.

Dielectric properties of oil feedstock mixed with different solvents were measured and analyzed by Terigar et al. [30]. Results indicated that dielectric constants were relatively unchanged throughout the frequency range, but were strongly dependent on solvent type. The dielectric constant of the soy flour with hexane mixture decreased (2.92) in comparison to the soy flour with ethanol mixture (8.7) due the polarity of each solvent dielectric loss of the mixture with ethanol was 5.4, while the mixture with hexane had virtually zero dielectric loss.

On the other hand, the enzymatic reactions are quite complex and the microwave effects raise many questions concerning the irradiation effects on the reaction system. Definite interpretations require additional experimental data and further studies, and this is an area of intensive investigations.

Table 4 shows the analysis of variance (ANOVA) for a linear model from experimental results by multiple regression analysis and curvature check (0.2511). The best fitting response function can be written by Eq. 4.

where \( \hat{y} \) is the transesterification yield (%) and x 1 and x 2 are molar ratio and temperature, respectively.

The statistical significance of this model was evaluated by the F test (Table 4), which revealed that this regression is statistically significant at a 95 % probability level. The model did not show lack of fit and the determination coefficient (R 2 = 0.9862) indicates that the model can explain 98.62 % of the variability.

A numeric optimization of the transesterification yield as a function of the molar ratio and temperature was carried out using the software Design-Expert 6.0. According to this study, the maximum transesterification yield can be obtained at the lowest levels of both variables (8:1 ethanol-to-oil molar ratio and 43 °C temperature) as displayed in the response surface (Fig. 3) corresponding to the model described in Eq. 4.

Response surface described by the statistical coded model that represents the transesterification yield in the formation of biodiesel from palm oil catalyzed by Pseudomonas fluorescens lipase immobilized on SiO2–PVA as a function of molar ratio (x 1) and temperature (x 2) according to Eq. 4

To confirm this model, experiments were carried out under the established condition and the differences between the experimental and theoretical values were lower than 1 %. The run conducted to confirm the model attained a greater than 80 % conversion of palm oil fatty acids into ethyl esters, over an 8 h reaction. However, the kinetic study carried out at up to 12 h of reaction time resulted in 76.90 wt % of ethyl esters formed, which corresponded to a yield of 97.56 % (Fig. 4).

Ethyl esters profile in the transesterification of palm oil using Pseudomonas fluorescens lipase immobilized on SiO2–PVA under the predicted conditions (ethanol-to-oil molar ratio of 8:1 at 43 °C). Ethyl esters from lauric acid (full line); myristic acid (open circle); palmitic acid (open square); stearic acid (open triangle); oleic acid (filled triangle); linoleic acid (filled square) and total esters (filled circle)

The purified biodiesel presented kinematic viscosity of 4.75 cSt at 40 °C in accordance with ASTM D5761 (United States) and EN 14214 (Europe) biodiesel standards, which require viscosities in the range of 1.9–6.0 cSt and 3.0–5.0 cSt, respectively.

Conventional heating versus microwave irradiation

To demonstrate the effect of microwave irradiation in the ethanolysis of palm oil, a comparison between the transesterification reaction under conventional heating and microwave irradiation was performed. Data summarized in Table 5 indicate that almost complete oil conversion was achieved under microwave irradiation in about 12 h. In contrast, the conventional heating allows only 61.30 % of oil conversion to be attained in 24 h. Hence, the microwave-assisted reaction rate was about six times higher than that under conventional heating (productivity of 64.2 mg ethyl esters g−1 h−1).

In the context of the reported results, it may be suggested that the process developed would be economically beneficial, since it reduces time and energy. Some advantages in relation to the conventional ethanolysis include: (1) an increase in yield and the enzyme-catalyzed reaction rate; (2) the method of the substrate heating by microwaves is not harmful. This conclusion mainly refers to the alteration in the enzyme properties (enzyme stability) and the substrate specificity. In addition, (3) microwave assistance allows the entire volume of the substrate to be heated uniformly, which can increase biocatalyst activity.

Conclusion

Microwave technology is emerging as an alternative energy source to perform enzymatic reactions. In the context of this trend, ethanolysis of palm oil for biodiesel production was carried out as a model study. The formation of ethyl esters was highly influenced by the variables (x 1, x 2) molar ratio and temperature, respectively. The proposed mathematical model was validated experimentally and confirmed that a low molar ratio 8:1 (ethanol:oil) and a temperature of 43 °C result in a greater than 80 % conversion of palm oil fatty acids into ethyl esters, over an 8-h reaction. However, the kinetic study carried out at up to 12 h resulted in 76.90 wt % of ethyl esters formed, which corresponded to a yield of 97.56 %.

The experiments performed confirm that the main effect of the microwaves is thermal rather than the alteration in the enzyme properties. In this context, all alterations in the enzymatic properties observed in this study could be attributed to thermal effects, as those observed under conventional heating ethanolysis. The results reported suggest that the proposed process would be economically beneficial since it reduces time and energy, and has some advantages in relation to conventional ethanolysis.

References

Kubrakova IV, Toropchenova ES (2008) Microwave heating for enhancing efficiency of analytical operations (review). Inorg Mater 44:1509–1519

Rejasse B, Lamare S, Legoy MD, Besson T (2007) Influence of microwave irradiation on enzymatic properties: applications in enzyme chemistry. J Enzym Inhib Med Chem 22:518–526

Bassyouni FA, Abu-Bakr SM, Rehim MA (2012) Evolution of microwave irradiation and its application in green chemistry and biosciences. Res Chem Intermed 38:283–322

Lindstrom P, Tierney J, Wathey B, Westman J (2001) Microwave assisted organic synthesis—a review. Tethahedron 57:9255–9283

Oghbaei M, Mirzaee O (2010) Microwave versus conventional sintering: a review of fundamentals, advantages and applications. J Alloy Compd 494:175–189

Gupta MN, Roy I (2004) Enzymes in organic media: forms, functions and applications. Eur J Biochem 271:2575–2583

Da Rós PCM, de Castro HF, Carvalho AF, Soares CMF, Moraes FF, Zanin GM (2012) Microwave-assisted enzymatic synthesis of beef tallow biodiesel. J Ind Microbiol Biotechnol 39:529–536

Gupta M, Paul S, Gupta R (2009) General characteristics and applications of microwaves in organic synthesis. Acta Chim Sloven 56:749–764

Leadbeater NE, Stencel LM, Wood EC (2007) Probing the effects of microwave irradiation on enzyme-catalysed organic transformations: the case of lipase-catalysed transesterification reactions. Org Biomol Chem 5:1052–1055

Wan H, Sun S, Hu X, Xia Y (2012) Nonthermal effect of microwave irradiation in nonaqueous enzymatic esterification. Appl Biochem Biotechnol 166:1454–1462

Costa ICR, Leite SGF, Leal ICR, Miranda LSM, de Souza ROMA (2011) Thermal effect on the microwave assisted biodiesel synthesis catalyzed by lipases. J Braz Chem Soc 22:1993–1998

Yu D, Wang Z, Chen P, Jin L, Cheng Y, Zhou J, Cao S (2007) Microwave-assisted resolution of (R, S)-2-octanol by enzymatic transesterification. J Mol Catal 48:51–57

Fang Y, Huang W, Xia Y (2008) Consecutive microwave irradiation induced substrate inhibition on the enzymatic esterification. Process Biochem 43:306–310

Hasan F, Shah AA, Hameed A (2006) Industrial applications of microbial lipases. Enzyme Microb Tech 39:235–251

Rufino AR, Biaggio FC, Santos JC, de Castro HF (2009) Chemoenzymatic synthesis: a strategy to obtain xylitol monoesters. J Chem Technol Biotechnol 84:957–960

Lee M, Lee D, Cho JK, Cho J, Han J, Park C, Kim S (2012) Improved high-pressure enzymatic batch synthesis in near-critical carbon dioxide. Bioprocess Biosyst Eng 35:105–113

Freitas L, Da Ros PCM, Santos JC, De Castro HF (2009) An integrated approach to produce biodiesel and monoglycerides by enzymatic interestification of babassu oil (Orbinya sp). Process Biochem 44:1068–1074

Li N, Zong M, Wu H (2009) Highly efficient transformation of waste oil to biodiesel by immobilized lipase from Penicillium expansum. Process Biochem 44:685–688

Shah S, Gupta MN (2007) Lipase catalyzed preparation of biodiesel from Jatropha oil in a solvent free system. Process Biochem 42:409–414

Moreira ABR, Perez VH, Zanin GM, De Castro HF (2007) Biodiesel synthesis by enzymatic transesterification of palm oil with ethanol using lipases from several sources immobilized on silica-PVA composite. Energ Fuel 21:3689–3694

Urioste D, Castro MBA, Biaggio FC, De Castro HF (2008) Synthesis of chromatographic standards and establishment of a method for the quantification of the fatty ester composition of biodiesel from babassu oil. Quim Nova 31:407–412

Santos JC, Paula AV, Nunes GFM, De Castro HF (2008) Pseudomonas fluorescens lipase immobilization on polysiloxane-polyvinyl alcohol composite chemically modified with epichlorohydrin. J Mol Catal B-Enzym 52–3:49–57

Soares CMF, Castro HF, Moraes FF, Zanin GM (1999) Characterization and utilization of Candida rugosa lipase immobilized on controlled pore silica. Appl Biochem Biotech 77–9:745–757

Polizzi KM, Bommarius AS, Broering JM, Chaparro-Riggers JF (2007) Stability of biocatalysts. Curr Opin Chem Biol 11:220–225

Réjasse B, Lamare S, Legoy MD, Besson T (2004) Stability improvement of immobilized Candida antarctica lipase B in an organic medium under microwave radiation. Org Biomol Chem 2:1086–1089

Schubert H, Regier M (2005) The microwave processing of foods. CRC Press, Taylor and Francis, ISBN-13: 978 1 85573 964 2

Nelson SO (1978) Frequency and moisture dependence of dielectric properties of high- moisture corn. J Microwave Power EE 13:213–218

Venkatesh MS, Raghavan GSV (2004) An overview of microwave processing and dielectric properties of agri-food materials. Biosystems Eng 88:1–18

Hayes BL (2002) Microwave synthesis: chemistry at the speed of light. CEM Publishing, Matthews, p 296

Terigar BG, Balasubramanian S, Boldor D (2010) An analysis of the microwave dielectric properties of solvent-oil feedstock mixtures at 300–3000 MHz. Bioresource Technol 101:6510–6516

Acknowledgments

The authors are grateful for the financial support provided by CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico) and FAPESP (Fundação de Amparo à Pesquisa do Estado de São Paulo) Brazil.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Da Rós, P.C.M., Freitas, L., Perez, V.H. et al. Enzymatic synthesis of biodiesel from palm oil assisted by microwave irradiation. Bioprocess Biosyst Eng 36, 443–451 (2013). https://doi.org/10.1007/s00449-012-0801-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-012-0801-6