Abstract

The dissolved oxygen tension of 20% of air saturation, pH-shift from 4.0 to 5.5 on day 3, and a moderate shear stress (calculated as an impeller tip speed, \( V_{\text{tip}} = 0. 9 2 6- 2. 1 6 1 \, {\text{m}}/{\text{s}} \)) were identified to be the key factors in scaling-up the mated fermentation of Blakeslea trispora NRRL 2895 (+) and 2896 (−) for lycopene production from a shake flask to a stirred-tank fermenter. The maximal lycopene production of 183.3 mg/L was obtained in 7.5-L stirred-tank fermenter, and then the mated fermentation process was successfully step-wise scaled-up from 7.5- to 200-L stirred-tank fermenter. The comparability of the fermentation process was well controlled and the lycopene production was maintained during the process scale-up. Furthermore, with the integrated addition of 150 μmol/L abscisic acid on day 3, 0.5 g/L leucine and 0.1 g/L penicillin on day 4, the highest lycopene production of 270.3 mg/L was achieved in the mated fermentation of B. trispora in stirred-tank fermenter.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Constituted by 11 conjugated and 2 unconjugated double bonds, lycopene is a highly unsaturated open straight chain hydrocarbon. Lycopene has many important physiologic functions, such as preventing cancer [1–3], cardiovascular diseases [4, 5], osteoporosis [6], and strengthening immunity [7]. The production method of lycopene includes plant extraction, chemical synthesis, and microbial fermentation. Plant extraction does not satisfy the market need because of its low content in the plants. Chemical synthesis has many disadvantages, such as low yield, instability of product quality and high cost. Because of the decrease in the natural production of lycopene combined with the increase in worldwide demand, a new way to produce lycopene on a large scale is urgently needed and the submerged fermentation is viewed to be a potential solution to produce lycopene [8]. Blakeslea trispora [9], Streptomyces chrestomyceticus [10], Candida utilis [11], Phycomyces blakesleeanus [12], engineered Flavobacterium sp. [13], and engineered Escherichia coli [14] have been reported as lycopene-producing microorganisms.

B. trispora is an industrial microorganism for the production of β-carotene by microbial fermentation. Because lycopene is one of the intermediate metabolites in the pathway of mevalonic acid and it can be transformed into β-carotene by lycopene cyclase. So, to enhance lycopene accumulation, the activity of lycopene cyclase should be inhibited by adding the inhibitors of lycopene cyclase (e.g., piperidine and creatinine) into the fermentation medium [15, 16].

It should be noteworthy that a surprising inoculation method for the mated fermentation of B. trispora (+) and (−) strain in most of the present reports was inoculated directly from the spores of slant or Petri dish to fermentation medium without the first-stage and the second-stage liquid seed preculture process [17–19]. However, this inoculation method discourages industrial fermentation process, because it is difficult to prepare a large amount of spores for the mated fermentation process on a large scale. A process of Petri dishes preculture combining the first-stage and the second-stage liquid seed preculture was developed in our lab, and the ratio of (+)/(−) strain, the lycopene cyclase inhibitor, the trisporic acid analog, the HMG-CoA precursor and the mevalonate kinase promoter were identified to the key factors for the lycopene biosynthesis in a shake flask [20].

To date, the bioprocess of lycopene production at the scale of stirred-tank fermenter is rather limited and non-systematic, especially when compared with the β-carotene fermentation process by B. trispora. There were only a few reports about the batch fermentation of B. trispora for lycopene production in stirred-tank fermenter. A semi-industrial process (i.e., 800-L) for lycopene production by the mated fermentation of B. trispora F-816 (+) and F-744 (−) strains were reported, but the lycopene production was not shown [21].

Based on the above analysis, scale-up study on the mated fermentation of B. trispora NRRL 2895 (+) and 2896 (−) for the production of lycopene in the stirred-tank fermenter was done in this work. Firstly, the effects of DOT, pH and shear stress on the lycopene production by B. trispora in 7.5-L stirred-tank fermenter were investigated. Then, an integrated scale-up criterion by combining the best control strategy of DOT, pH-shift and shear stress was developed and its effectiveness was demonstrated by comparing the performances of B. trispora growth and metabolites biosynthesis (i.e., lycopene accumulation). Finally, the mated fermentation process of B. trispora was successfully scaled-up from shake flask to stirred-tank fermenter.

Materials and methods

Maintenance and preculture of B. trispora

The compatible mating strains of B. trispora NRRL 2895 (+) and 2896 (−) were kindly provided by Professor Guo-Lin Zou from Wuhan University (Wuhan, China). The cultures were maintained on potato-agar-dextrose slants. The slants were inoculated with mycelia/spores and incubated at 25 °C for 7 days, then stored at 4 °C for about 30 days.

Before the mated fermentation of B. trispora NRRL 2895 (+) and 2896 (−), the two stains were separately precultured by Petri dishes preculture, the first-stage seed preculture and the second-stage seed preculture. For Petri dishes preculture, the strain precultured on yeast phosphate soluble starch (YpSS) agar medium at 25 °C for 3 days in standard Petri dishes (diameter 9 cm). YpSS medium consisted of the following components (g/L): yeast extract, 4; K2HPO4, 1; MgSO4·7H2O, 0.5; starch, 15; agar, 20 (in this work, the chemical reagents were all purchase from China Sinopharm Chemical Reagent Co. Ltd.). For the first-stage seed preculture, the medium consisted of the following components (g/L): corn starch, 20; soybean flour, 20; corn flour, 30; corn steep liquor, 20; KH2PO4, 5; MnSO4, 0.05; FeSO4·7H2O, 0.09; CuSO4·5H2O, 0.08; CaC12, 0.05; MgSO4·7H2O, 0.41; and thiamine (VB1), 0.003. The 45-mL medium with nature pH was prepared in a 250-mL flask, and then 5-mL spores (with ca. 105 spores/mL) of the strain from Petri dish were inoculated, and followed by 12 h incubation at 28 °C on a rotary shaker (120 rpm). For the second-stage seed preculture, the medium was the same with the first-stage seed preculture. The 90-mL medium was prepared in a 500-mL flask, and inoculated with 10-mL first preculture broth, the inoculation density of the second-stage seed preculture was calculated as 300–350 mg dry cell weight (DW)/L, and then followed by 12 h incubation at 28 °C on a rotary shaker (120 rpm).

Fermentation process in shake flask

The B. trispora strains NRRL 2895 (+) and 2896 (−) were cultivated together (hereafter referred to as the mated culture) in the fermentation medium (with an initial pH of 4.0), which contained 59.4 g/L of glucose, 2.12 g/L of l-asparagine, 1.42 g/L of yeast extract, 1.26 g/L of KH2PO4, 0.4 g/L of MgSO4·7H2O, 1.0 g/L of vitamin A acetate, and 2.0 g/L of span 20. The fermentation was carried out in 250-mL shake flask with 45-mL medium and inoculated 5-mL second preculture broth, which included each mating type at the (+)/(−) strain ratio of 5:1 (v/v). The inoculation density of the mated fermentation was calculated as 300–350 mg dry cell weight (DW)/L, and then followed by 8 days incubation at 28 °C on a rotary shaker at 120 rpm. To accumulate lycopene, lycopene cyclase inhibitor (i.e., 2.0 g/L piperidine) was introduced to inhibit the transformation of lycopene into β-carotene by lycopene cyclase as described by Wang et al. [20].

Fermentation process in 7.5-, 20- and 200-L stirred-tank fermenter

The details about 7.5-, 20- and 200-L stirred-tank fermenter has been previously described [22, 23]. The slant culture, the first-stage and the second-stage seed preculture, the (+)/(−) strain ratio and the inoculation size, the fermentation medium and the culture temperature in 7.5- and 20-L stirred-tank fermenter were the same with those in the shake flask. For the fermentation in 200-L stirred-tank fermenter, the second-stage seed preculture of B. trispora NRRL 2895 (+) was conducted in 20-L stirred-tank fermenter. It was performed for 12 h at 28 °C with an agitation rate of 188 rpm. DOT level was controlled at 20% of air saturation by adjusting aeration rate (0–1.0 vvm) and vessel pressure (0–0.1 MPa). The second-stage seed preculture of B. trispora NRRL 2896 (−) and the other culture conditions in 200-L stirred-tank fermenter was the same with those in 7.5- and 20-L stirred-tank fermenter. Four cultures in 7.5-L and the process scaled-up were carried out with homogeneous cell source under well-controlled process conditions. The results presented were confirmed to be reproducible in another experiment (data not shown).

Effect of DOT

To enhance lycopene production, the significance of DOT on the B. trispora growth and lycopene accumulation was studied by setting DOT at 10, 20, 35 and 50% of air saturation and controlled by adjusting agitation speed, aeration rate and mixing with N2 and O2 in the inlet air, while time profiles of agitation speed (100–700 rpm) and culture pH (4.00 ± 0.01) were the same throughout the fermentation process in order to diminish the impact of shear stress and culture pH.

Effect of culture pH

The significance of culture pH on lycopene accumulation was studied. Firstly, the significance of initial culture pH, i.e., 4.0, 5.0, 6.0 and 7.0, was studied in shake flask. Secondly, based on the impact of initial culture pH, a pH-shift culture was developed by combining a 3-day culture at a culture pH of 4.0 (i.e., the first-stage) with the following culture at a culture pH of 5.0, 5.5 and 6.0 (i.e., the second-stage). The control experiment was conducted at an initial culture pH of 4.0 and then without pH control. From the viewpoint of lycopene accumulation, the above results indicated that the optimal DOT was 20% of air saturation, which was selected in the following experiment. To diminish the impact of shear stress and mixing, time profiles of agitation rate were the same during the fermentation.

Effect of shear stress

Based on the optimal results above, to investigate the significance of shear stress on the mated fermentation process of B. trispora, an agitation speed control strategy was developed under sufficient mixing without introducing too much agitation and aeration-related damage to B. trispora cells. Here, the agitation speed was converted to an impeller tip speed (i.e., \( V_{\text{tip}} \), m/s) which was expressed as the following equation:

where, \( \pi = 3. 1 4 2 \), N = agitation speed (rpm), D = impeller diameter (m). Here, for 7.5-, 20- and 200-L stirred-tank fermenter used in this work, the impeller diameter (D) was 5.9, 9.4 and 18 cm, respectively. For example, for 7.5-L stirred-tank fermenter, agitation speed was increased step-wise from 100 to 700 rpm (i.e., \( V_{\text{tip}} \) from 0.309 to 2.161 m/s) during the first 4.5 days (hereafter the agitation control strategy was referred to as strategy I). Based on the strategy I, the other three agitation speed control strategy was developed by increasing 200, 300 and 400 rpm agitation speed to 700 rpm on day 4.0, 3.5 and 3.0, and the corresponding \( V_{\text{tip}} \) was calculated to be 0.618 to 2.161, 0.926 to 2.161, and 1.235 to 2.161 m/s, respectively. After day 6, the agitation speeds were all decreased from 700 to 600 rpm, then was maintained until the end of the fermentation. During the mated fermentation process, a weak mixing situation (e.g., cell sedimentation) was observed with eye when the initial \( V_{\text{tip}} \) was lower than 0.309 m/s, so the minimal \( V_{\text{tip}} \) of 0.309 m/s was selected for this experiment.

Scale-up fermentation

Based on the information obtained above, DOT (20% of air saturation), pH-shift (shift from 4.0 to 5.5 after the culture of day 3), a moderate shear stress (\( V_{\text{tip}} \) from 0.926 to 2.161 m/s before the culture of day 3.5) were identified to be key factors during the mated fermentation of B. trispora in 7.5-L stirred-tank fermenter. Despite the stirred-tank fermenter scale, the other operational parameters (e.g., DOT, pH and \( V_{\text{tip}} \)) were maintained constant during scale-up. In 20- and 200-L stirred-tank fermenter, DOT level was adjusting by aeration rate (0.1–0.7 vvm) and vessel pressure (0.01–0.10 MPa), and pH was controlled by 5 M NaOH and 10% (v/v) H2SO4.

The lycopene cyclase inhibitor of piperidine (i.e., 2.0 g/L) was added on day 2 during the experiments above. However, based on the current legislative demands on food safety precautions and considering the toxicity of piperidine, a food grade with lower toxicity of creatinine (i.e., 6 g/L) was added as lycopene cyclase inhibitor after the culture of day 3 during the scale-up study. In addition, our previous study showed that the rate of inhibition lycopene transformed into β-carotene by adding 2.0 g/L piperidine on day 2 or 6 g/L creatinine on day 3 was quite similarly [20].

In addition, based on our previous work in shake flask, the trisporic acid analog (e.g., 150 μmol/L abscisic acid added on day 3), the HMG-CoA precursor (e.g., 0.5 g/L leucine added on day 4) and the mevalonate kinase promoter (e.g., 0.1 g/L penicillin added on day 4) were supplied during the scale-up fermentation [20].

Determination of dry biomass, β-carotene and lycopene content

The cell mass was filtered through muslin, washed thoroughly with distilled water, and dried in the vacuum freeze dryer at −75 °C under 45 Pa for 48 h. The dried cells were weighed to determine biomass.

The freeze-dried samples were pulverized and 40.0 mg sample powder was accurately weighed, and then extracted with 6 mL acetone by the ultrasonic cell disruption apparatus (J92-II, Ningbo Scientz Biotechnology Instrument, China) for 180 s (400 W power, 2 s ultrasound pulse, 3 s break, and 90 repetitions). The supernatant was filtrated through a 0.45 μm filter, and 20.0 μL was directly injected into the LC-UV for analysis.

The analysis of β-carotene and lycopene was preformed on the Waters 600E system (Waters, USA), equipped with an on-line degasser, a Waters 2487 UV detector. The column used for separation was Phenomsil C18 (250 × 4.6 mm i.d., 5 μm) fitted with a C18 guard column (Phenomsil, Tianjing, China). The optimized mobile phase was consisted of methanol (A), acetonitrile (B) and water (C), and the separation was carried on by the isocratic elution (A:B:C = 50:50:3, v/v). The column oven temperature was maintained at 40 °C and the flow rate was 1.0 mL min−1. The detection wave was fixed at 470 nm.

Quantitative analysis was performed by the method described by Xu et al. [24]. The β-carotene and lycopene content was calculated by the Eqs. 3 and 4, respectively:

where \( C_{\text{i}} \) and \( C_{\text{j}} \) is the β-carotene and lycopene content of sample, respectively; \( A_{\text{i}} \) and \( A_{\text{j}} \) is peak area of β-carotene and lycopene, respectively; \( C_{\text{s}} \) is the concentration of Sudan I; \( A_{\text{s}} \) is the peak area of Sudan I.

Image analysis

Samples for image analysis were prepared by adding 1 mL of fermentation broth to 20% (w/v) sucrose solution to dilute the sample to a final dry weight of about 0.2 g/L, to prevent artefacts from cell overlap [25]. Amounts of 10 μL of the diluted sample (100 amounts per sample in three replications) were placed on microscope slides and observed immediately. Image capture was carried out via CCD video camera mounted on an Olympus Research Stereo Microscope (SZX16) and digitized by a frame grabber card installed on a PC. Image analysis was performed with Image-Pro Plus 6.0 (Media Cybernetics, Inc.). The image analysis process included capture, enhancement, segmentation, object detection, measuring and analysis as described by Paul and Thomas [26] and Tucker et al. [27]. Clumps and freely dispersed mycelia (all elements) were measured together using projected area. The dispersed morphology consists of freely dispersed hyphae and clumps (aggregates) of different sizes on the basis of their projected area. The mean projected area of each class was the average of the experimentally obtained data. For clump morphology, perimeter was measured and combined with projected area to determine roughness, which describes the ruggedness of clump boundaries and is inversely related to circularity [27]. Means were calculated using a minimum of 250 mycelia (freely dispersed and clumps) for the projected area and 150 (clumps) for the roughness. The standard errors for the means were up to 11% for the projected area and up to 3% for the roughness.

Results and discussion

Effect of DOT

Lόpez-Nieto et al. [21] demonstrated that lycopene biosynthesis was significantly affected by air flow rate, and an enrichment of oxygen concentration (up to 25%) in the air stream increased the accumulation of lycopene, and the authors indicated high dissolved oxygen showed a positive effect on lycopene production. However, the DOT level and lycopene production was not mentioned in this report. Thus, the significance of DOT on the cell growth and lycopene accumulation should be studied. In this study, the DOT level was controlled at 10, 20, 35 and 50% of air saturation by adjusting agitation speed, aeration rate and mixing with N2 and O2 in the inlet air.

Figure 1a clearly shows that DOT significantly affected the cell growth of B. trispora. The maximal cell density of 16.74, 18.04, 19.23 and 20.07 g/L was obtained after the culture of day 5, 5, 4 and 3 when the DOT was controlled at 10, 20, 35 and 50%, respectively. The cell growth was almost inhibited during the first 2 days of fermentation when DOT was controlled at 10% of air saturation, while the cell grew more quickly when DOT was increased from 20 to 50% of air saturation. The results indicated that a higher DOT level (i.e., 50%) was favorable to the cell growth.

The contents of lycopene, β-carotene, γ-carotene, and phytoene had been detected. However, both the peak areas of γ-carotene and phytoene were too low to quantification. Therefore, the γ-carotene and phytoene were not considered to be the main by-products. Only the productions of lycopene and β-carotene were calculated. Figure 1b clearly shows that the specific lycopene biosynthesis (i.e., lycopene content) was significantly affected by DOT. The maximal lycopene content of 0.04, 0.29, 0.27 and 0.23 mg/100 mg DW was all obtained on day 7 when the DOT was controlled at 10, 20, 35 and 50% of air saturation, respectively. While, lycopene accumulation was significantly inhibited at 10% of air saturation during the fermentation process, and its maximal content was only 0.04 mg/100 mg DW, which was lower 4.75–6.25 times than that of obtained at 20–50% of air saturation. Figure 1c illustrates that lycopene production pattern was quite similar with that of lycopene content. The lycopene production was obviously inhibited when the DOT was controlled at 10% of air saturation, and its maximal lycopene production was only 7.0 mg/L. While, the lycopene production increased with an increase of DOT level, and the highest lycopene production of 49.4, 42.6 and 40.4 mg/L was all obtained on day 7 when the DOT was controlled at 20, 35 and 50% of air saturation, respectively. The results indicated that 20% of air saturation was favorable for the lycopene biosynthesis. To accumulate lycopene, 2.0 g/L piperidine was introduced as lycopene cyclase inhibitor to inhibit the transformation of lycopene into β-carotene by lycopene cyclase on day 3. In the all cases, the content of β-carotene was drastically decreased from day 3, and the highest content and its production were all lower than 0.1 mg/100 mg DW and 15.4 mg/L, respectively.

To conclude, the highest lycopene production (i.e., 49.4 mg/L) was obtained on day 7 when the DOT was controlled at 20% of air saturation, which was increased by 605% and 22.3% compared with that obtained at 10 and 50% of air saturation, respectively. Thus, 20% of air saturation was selected in the following experiments.

Effect of culture pH

Effect of initial culture pH in shake flask

Time profile of culture pH in the fermentation of B. trispora under various initial culture pH values was shown in Fig. 2a. In all cases, culture pH showed a bit decrease during the first day of fermentation. After that, at an initial pH of 7.0, culture pH remained relatively around 6.5 until the end of the fermentation. While at an initial pH of 4.0, 5.0 and 6.0, after a bit decrease during the first day, culture pH remained almost for 2 or 3 days and then quickly increased until the end of the fermentation.

Time courses of culture pH (a), biomass (b), lycopene content (c) and production (d) under various initial pH values during the mated fermentation of B. trispora in shake flasks. Symbols for initial culture pH: 4.0 (filled triangles), 5.0 (open triangles), 6.0 (filled circles), and 7.0 (open circles)

As shown in Fig. 2b, the maximum dry cell weight of 16.67 ± 0.63, 17.00 ± 0.34 and 16.59 ± 0.15 g/L was obtained on day 4, 3 and 4 at an initial pH of 5.0, 6.0 and 7.0, respectively. These results indicated that an initial pH of 5.0, 6.0 and 7.0 did not significantly affect the cell growth. While, a lower cell density of 14.36 ± 0.09 g/L was obtained on day 4 at an initial pH of 4.0, which indicated that an initial pH of 4.0 was not favorable to the cell growth.

Figure 2c and d show a similar pattern between lycopene content and lycopene production. The maximal lycopene content of 0.85 ± 0.13 mg/100 mg DW and lycopene production of 106.7 ± 16.7 mg/L were both attained on day 6 at an initial pH of 4.0. However, lycopene accumulation was obviously inhibited at the initial pH of 5.0, 6.0 and 7.0 during the whole mated fermentation process. As indicated in the kinetics of B. trispora cell growth (Fig. 2a) and lycopene biosynthesis (Fig. 2c), an initial pH of 4.0 was not favorable to the cell growth, but for lycopene accumulation, which indicated that the optimal culture pH for B. trispora cell growth was different from that for lycopene biosynthesis. In addition, the highest β-carotene content (0.16 ± 0.0 mg/100 mg DW) and production (21.9 ± 6.3 mg/L) were also obtained under the initial pH of 4.0. In the mated cultivation of B. trispora F-816 (+) and F-744 (−), Lόpez-Nieto et al. [21] reported the pH was adjusted to 7.5 before sterilization and without pH control was best for lycopene production in 800-L stirred-tank fermenter, while the lycopene production was not shown. Choudhari and Singhal [17] demonstrated that a higher yield of β-carotene (i.e., 99 ± 1 mg/L) by the mated fermentation of B. trispora NRRL 2895 (+) and 2896 (−) was obtained at an initial pH of 6.0–7.0 in shake flask.

To conclude, the highest lycopene production of 106.7 ± 16.7 mg/L was attained on day 6 at an initial pH of 4.0, which was 1.1–2.0 times higher than that obtained at an initial pH of 5.0, 6.0, and 7.0.

Effect of pH-shift

As shown in Fig. 2a, the time profiles of culture pH at the initial pH of 4.0 and 5.0 were quite similar after the culture of day 5. While the maximal lycopene content and production were obtained at an initial pH of 4.0 on day 6 (Fig. 2c, d), which was 150% and 110% higher than those obtained at an initial pH of 5.0, respectively. This suggested that the time course of pH at an initial pH of 4.0 might play an important role on the lycopene biosynthesis. Obviously, at an initial pH of 4.0, after a little decrease in the first day, the pH value remained relatively constant around 4.0 from day 2 to day 4, then the pH values quickly increased from 4.1 on day 4 to 6.2 on day 8. Based on this information, a pH-shift culture was proposed: culture pH was controlled at 4.0 during the first-stage culture and then shifted to a higher pH value (i.e., 5.0, 5.5, and 6.0) in the second-stage culture. Besides, at an initial pH of 4.0, a quickly increase of lycopene content from 0.30 ± 0.07 to 0.81 ± 0.12 mg/100 mg DW was observed from day 4 to day 5, then continuous slight increase to its peak value of 0.85 ± 0.13 mg/100 mg DW on day 6 (Fig. 2c). Therefore, it was supposed that pH should be shifted not later than day 4.

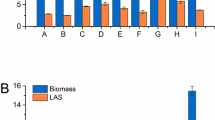

Based on the above analysis, the first 3 days culture at the pH of 4.0 (i.e., the first-stage) was shifted to the second-stage culture in which pH was controlled at 5.0, 5.5 and 6.0. As shown in Fig. 3a, the cell growth was remarkably affected by the second-stage culture pH. The maximal cell density was 14.30, 16.69 and 17.49 g/L as obtained all on day 5 at the second-stage culture pH of 5.0, 5.5 and 6.0, which was 1.7, 24.4 and 18.7% higher than the control, which was run at an initial pH of 4.0 and without pH control, respectively.

Time profiles of biomass (a), lycopene content (b) and production (c) of the pH-shift culture in 7.5-L stirred-tank fermenter by combining the 3-day culture at pH 4.0 (i.e., the first-stage) with the second-stage culture at the pH of 5.0 (open triangles), 5.5 (filled circles), 6.0 (open circles), and the control experiment (filled triangles) which was run at an initial pH 4.0 and without pH control

Time profiles of lycopene content and production under various second-stage culture pH values were compared in Fig. 3b and c. Not only the highest lycopene content (i.e., 0.9 mg/100 mg DW), but also the highest lycopene production (i.e., 131.8 g/L) were attained when pH was shifted from 4.0 to 5.5 on day 3. These results demonstrated that a pH-shift culture by combining the first 3 days at the pH of 4.0 (i.e., the first-stage) with the following the second-stage culture at the pH of 5.5 was beneficial for the cell growth and lycopene accumulation. In addition, the maximal β-carotene content (0.3 mg/100 mg DW) and production (37.2 mg/L) were also both obtained when pH was shifted from 4.0 to 5.5 on day 3.

Based on the above information, the effect of shift time (i.e., day 2.5, 3, 3.5 and 4) between the first-stage pH of 4.0 and the second-stage pH of 5.5 was investigated. The highest lycopene production of 136.5 mg/L was observed at the shift time of day 3, which was increased by 92.8, 22.1 and 57.4% compared with the shift time of day 2.5, 3.5 and 4, respectively (data not shown). Thus, a pH-shift from 4.0 to 5.5 after the culture of day 3 was beneficial for the lycopene biosynthesis. In the submerged fermentation of Ganoderma lucidum, Tang et al. [22] reported a pH-shift culture strategy for enhancing ganoderic acid production to 321.6 mg/L by shifting pH from 3.0 to 4.5 on day 4, which was 45% higher than constant pH (i.e., 3.0) fermentation.

To conclude, a pH-shift culture of B. trispora was successfully developed to enhance lycopene production. The highest lycopene production of 136.5 mg/L was obtained when pH was shifted from 4.0 to 5.5 after the culture of day 3, which was increased by 35.3 and 176% compared with the cultures at an initial pH of 4.0 without pH control (i.e., 100.9 mg/L) and at a constant pH of 4.0 (i.e., 49.4 mg/L), respectively.

Effect of shear stress

To achieve a highly effective process for the production of lycopene, the significance of shear stress (calculated as impeller tip speed, \( V_{\text{tip}} \)) on the B. trispora fermentation process was studied by setting an initial \( V_{\text{tip}} \) of 0.309, 0.618, 0.926 and 1.235 m/s. As observed, the fermentation broth mixed well in the stirred-tank fermenter even at a low shear stress of 0.309 m/s, and there was no apparent cell sedimentation and no serious cell adhesion at the stirred-tank fermenter wall in all cases during the fermentation process.

Figure 4a clearly shows the cell growth of B. trispora at an initial \( V_{\text{tip}} \) of 0.309, 0.618 and 0.926 m/s was quite similar, and the highest cell density was around 15.67 ± 0.35 g/L. While, at the highest initial \( V_{\text{tip}} \) of 1.235 m/s, the cell growth was obviously inhibited from day 1 to the end of fermentation and the maximal dry cell density was 11.07 g/L, which was 38–44% lower than the cultures at an initial \( V_{\text{tip}} \) from 0.309 to 0.926 m/s as investigated. These results demonstrated that a higher initial shear stress (i.e., \( V_{\text{tip}} \) of 1.235 m/s) was unsuitable to the B. trispora growth.

Effect of impeller tip speed on the cell growth (a), lycopene content (b) and production (c) during the mated fermentation of B. trispora in 7.5-L stirred-tank fermenter. Symbols for the impeller tip speed: 0.309–2.161 m/s (filled triangles), 0.618–2.161 m/s (open triangles), 0.926–2.161 m/s (filled circles) and 1.235–2.161 m/s (open circles)

Dynamic profiles of lycopene content and production were compared in Fig. 4b and c. The highest lycopene content (i.e., 1.15 mg/100 mg DW) and production (i.e., 183.3 mg/L) were obtained at an initial \( V_{\text{tip}} \) of 0.926 m/s. While, lycopene accumulation was significantly inhibited at an initial \( V_{\text{tip}} \) of 0.618 and 1.235 m/s (Fig. 4b, c), and the maximal cell growth of the latter was 42.7% lower than that of former (Fig. 4a). In addition, the maximal β-carotene content (0.3 mg/100 mg DW) and production (32.9 mg/L) were also both obtained at an initial \( V_{\text{tip}} \) of 0.926 m/s. By dynamic monitoring the morphology, bigger clumps (i.e., expressed with projected area above 8,000,000 μm2) and a greater percentage of these clumps (i.e., expressed with frequency, 30.4%) were found at the initial \( V_{\text{tip}} \) of 0.618 m/s compared with the cultures at an initial \( V_{\text{tip}} \) of 0.309, 0.926 and 1.235 m/s (data not shown). These indicated that these clumps were not favorable to the lycopene biosynthesis. While, the formation of these clumps could be inhibited by a suitable shear stress of the initial \( V_{\text{tip}} \) of 0.926 m/s without introducing too much agitation damage to B. trispora cell, and the frequency of these clumps was only about 11% at an initial \( V_{\text{tip}} \) of 0.926 m/s. This might be the reason for the highest cell density and lycopene accumulation were both observed under the initial \( V_{\text{tip}} \) of 0.926 m/s.

Lόpez-Nieto et al. [21] demonstrated that shorter hyphae led a higher lycopene production at a constant speed of 300 rpm during the fermentation process, but lycopene production and biomass decreased because of a higher shear stress (i.e., above 300 rpm). In this study, it was unsuitable to maintain a constant agitation speed during the fermentation process. Because the hyphae of B. trispora were easy to aggregate under a constant agitation speed, which could lead to the big clumps and then the cell was sedimented and adhered at the stirred-tank fermenter wall. Therefore, a step-wise increase agitation speed was developed. In the submerged fermentation of G. lucidum, Tang et al. [23] also demonstrated an agitation speed control strategy to investigate the significance of shear stress by setting a low initial \( V_{\text{tip}} \)(i.e., 0.154 m/s) step-wise increase to a high \( V_{\text{tip}} \)(i.e., 1.234, 1.543, 1.853 or 2.161 m/s), and it was observed that a lower \( V_{\text{tip}} \) of 1.234 m/s was the best for the G. lucidum fermentation.

To conclude, a moderate shear stress, i.e., a \( V_{\text{tip}} \) gradient increases from 0.926 to 2.161 m/s before the culture of day 3.5, was the best for the lycopene production. The highest lycopene production of 183.3 mg/L was obtained, which was increased by 34 and 161% compared with that at an initial \( V_{\text{tip}} \) of 0.309 and 0.618 m/s, respectively.

Scale-up fermentation

Based on the above results, DOT, pH-shift and a moderate shear stress were identified as key factors affecting the cell growth and lycopene production. An integrated scale-up criterion by combining the DOT (i.e., 20% of air saturation), pH-shift from 4.0 to 5.5 after the culture of day 3 with a moderate shear stress (i.e., \( V_{\text{tip}} = 0. 9 2 6- 2. 1 6 1\, {\text{m}}/{\text{s}} \)) was proposed. Instead of taking a direct scale-up from 7.5- to 200-L, a more conservative approach was taken, in which a medium-sized step of 20-L was included. At the first step, the process was scaled-up from 7.5- to 20-L scale, and followed by further scale-up from 20- to 200-L scale. This step-wise approach reduces the risks by early diagnosing problems at a medium scale, and can refine the criterion for the next step [28]. Here, the cell growth and lycopene accumulation were compared to evaluate the scale-up criterion for the mated fermentation of B. trispora.

The cell growth and lycopene accumulation at each scale were quantitatively evaluated by directly comparing the time profiles of B. trispora growth and lycopene biosynthesis (Fig. 5). The maximal cell density was all attained on day 6 at the scale of 7.5, 20 and 200-L stirred-tank fermenter. Because of good mixing capacity of stirred-tank fermenter, apparent cell sedimentation was not observed during the B. trispora fermentation process. Figure 5b compared the specific lycopene biosynthesis (i.e., lycopene content) profiles at different scales of stirred-tank fermenter. A similar lycopene content variation at various scales of stirred-tank fermenter was observed and the maximal lycopene content was about 1.76 mg/100 mg DW at all scales. A fluctuation of the maximal total lycopene production at various scales of stirred-tank fermenter was observed in Fig. 5c, and the maximal lycopene production was around 270.3 mg/L at all scales. In addition, lycopene began to accumulate from day 3 (Fig. 5b, c), while in Figs. 1b and c, 2c and d, 3b and c, 4b and c, lycopene began to accumulate from day 2. And the maximal β-carotene content and production was all around 0.3 mg/100 mg DW and 33 mg/L, respectively.

Overall, the time profiles of B. trispora cell growth, lycopene accumulation and the corresponding kinetic parameters were quite similar in the three scales. These demonstrated that the DOT, pH-shift and a moderate shear stress were identified to be the key factors in scaling-up B. trispora fermentation process from 7.5- to 200-L stirred-tank fermenter for the lycopene production.

Conclusions

The DOT of 20% of air saturation, pH-shift from 4.0 to 5.5 after the culture of day 3 and a moderate shear stress (i.e., a \( V_{\text{tip}} \) gradient increases from 0.926 to 2.161 m/s before the culture of day 3.5) were identified as the key factors in the scaling-up B. trispora fermentation process. Based on the integrated scale-up criterion, the B. trispora fermentation was successfully scale-up from 7.5- to 200-L stirred-tank fermenter. This work is very useful to the large-scaled mated fermentation of B. trispora for lycopene production toward industrial application. The information obtained may be also beneficial to the other filamentous fungi fermentation process.

References

Palozza P, Colangelo M, Simone R, Catalano A, Boninsegna A, Lanza P, Monego A, Ranelletti FO (2010) Lycopene induces cell growth inhibition by altering mevalonate pathway and Ras signaling in cancer cell lines. Carcinogenesis 31(10):1813–1821

Huang CS, Liao JW, Hu ML (2008) Lycopene inhibits experimental metastasis of human hepatoma SK-Hep-1 cells in athymic nude mice. J Nutr 138:538–543

Tang FY, Shih CJ, Cheng LH, Ho HJ, Chen HJ (2008) Lycopene inhibits growth of human colon cancer cells via suppression of the Akt signaling pathway. Mol Nutr Food Res 52:646–654

Rao AV (2002) Lycopene, tomatoes, and the prevention of coronary heart disease. Exp Biol Med 227:908–913

Bansal P, Gupta SK, Ojha SK, Nandave M, Mittal R, Kumari S, Arya DS (2006) Cardioprotective effect of lycopene in the experimental model of myocardial ischemia-reperfusion injury. Mol Cell Biochem 289:1–9

Rao LG, Mackinnon ES, Josse RG, Murray TM, Strauss A, Rao AV (2007) Lycopene consumption decreases oxidative stress and bone resorption markers in postmenopausal women. Osteoporosis Int 18:109–115

Watzl B, Bub A, Brandstetter BR, Rechkemmer G (1999) Modulation of human T-lymphocyte functions by the consumption of carotenoid-rich vegetables. British J Nutr 82:383–389

Liu QN, Zhu LW, Wang YH, Li DS, Wan DJ, Tang YJ (2009) Advance on the production of lycopene by microbial fermentation. Food Ferment Ind 35(6):157–161 (In Chinese)

Mehta BJ, Obraztsova IN, Cerdá-Olmedo E (2003) Mutants and intersexual heterokaryons of Blakeslea trispora for production of β-carotene and lycopene. Appl Environ Microbiol 69:4043–4048

Bianchi ML, Francheschi G, Marnati MP, Spalla C (1969) Microbiological process for the production of lycopene. US patent 3,467,579

Miura Y, Kondo K, Saito T, Shimada H, Fraser PD, Misawa N (1998) Production of the carotenoids lycopene, β-carotene, and astaxanthin in the food yeast Candida utilis. Appl Environ Microbiol 64:1226–1229

Murillo FJ, Calderόn IL, Lόpez-Díaz I, Cerdá-Olmedo E (1978) Carotene-superproducing strains of Phycomyces. Appl Environ Microbiol 36:639–642

Hohmann HP, Pasamontes L, Tessier M, van Loon A (2000) Fermentative carotenoid production. US patent 6,124,113

Alper H, Miyaoku K, Stephanopoulos G (2005) Construction of lycopene-overproducing E. coli strains by combining systematic and combinatorial gene knockout targets. Nat Biotechnol 23(5):612–616

Choudhari SM, Ananthanarayan L, Singhal RS (2008) Use of metabolic stimulators and inhibitors for enhanced production of β-carotene and lycopene by Blakeslea trispora NRRL 2895 and 2896. Bioresour Technol 99:3166–3173

Mantzouridou F, Tsimidou MZ (2008) Lycopene formation in Blakeslea trispora chemical aspects of a bioprocess. Trends Food Sci Technol 19:363–371

Choudhari S, Singhal R (2008) Media optimization for the production of β-carotene by Blakeslea trispora: a statistical approach. Bioresour Technol 99:722–730

Mantzouridou F, Roukas T, Kotzekidou P (2002) Effect of the aeration rate and agitation speed on β-carotene production and morphology of Blakeslea trispora in a stirred tank reactor: mathematical modeling. Biochem Eng J 10:123–135

Nanou K, Roukas T, Kotzekidou P (2007) Role of hydrolytic enzymes and oxidative stress in autolysis and morphology of Blakeslea trispora during β-carotene production in submerged fermentation. Appl Environ Microbiol 74:447–453

Wang JF, Liu XJ, Liu RS, Li HM, Tang YJ (2011) Optimization of the mated fermentation process for the production of lycopene by Blakeslea trispora NRRL 2895 (+) and NRRL 2896 (−). Biopro Biosys Eng. doi: 10.1007/s00449-011-0628-6

Lόpez-Nieto MJ, Costa J, Peiro E, Méndez E, Rodríguez-Sáiz M, De la Fuente JL, Cabri W, Barredo JL (2004) Biotechnological lycopene production by mated fermentation of Blakeslea trispora. Appl Microbiol Biotechnol 66:153–159

Tang YJ, Zhang W, Liu RS, Zhu LW, Zhong JJ (2011) Scale-up study on the fed-batch fermentation of Ganoderma lucidum for the hyperproduction of ganoderic acid and Ganoderma polysaccharides. Process Biochem 46:404–408

Tang YJ, Zhang W, Zhong JJ (2009) Performance analyses of a pH-shift and DOT-shift integrated fed-batch fermentation process for the production of ganoderic acid and Ganoderma polysaccharides by medicinal mushroom Ganoderma lucidum. Bioresour Technol 100:1852–1859

Xu F, Yuan QP, Dong HR (2006) Determination of lycopene and β-carotene by high-performance liquid chromatography using Sudan I as internal standard. J Chromatogr B 838:44–49

Jüsten P, Paul G, Nienow A, Thomas C (1996) Dependence of mycelial morphology on impeller type and agitation intensity. Biotechnol Bioeng 52:634–648

Paul G, Thomas C (1998) Characterization of mycelial morphology using image analysis. Adv Biochem Eng Biotechnol 60:1–59

Tucker K, Kelly T, Delgrazia P, Thomas C (1992) Fully-automatic measurement of mycelial morphology by image analysis. Biotechnol Prog 8:353–359

Yang JD, Lu C, Stasny B, Henley J, Guinto W, Gonzalez C, Gleason J, Fung M, Collopy B, Benjamino M, Gangi J, Hanson M, Ille E (2007) Fed-batch bioreactor process scale-up from 3-L to 2, 500-L scale for monoclonal antibody production from cell culture. Biotechnol Bioeng 98(1):141–154

Acknowledgments

Financial support from the National Natural Science Foundation of China (NSFC, Project Nos. 20976038 and 21176059), the Key Project of Chinese Ministry of Education (Project No. 210132), Hubei Provincial Natural Science Foundation for Innovative Research Team (Project No. 2008CDA002), Scientific Research Key Project of Hubei Provincial Department of Education (Project No. Z20101401), Discipline Leader Project of Wuhan Municipality (Project No. 200951830553), Key Technology R&D Program of Wuhan Municipality (Project No. 201120822280-2), the Open Project Programs for the Key Laboratory of Fermentation Engineering (Ministry of Education), the National Key Laboratory of Biochemical Engineering (Project No. 2010KF-06), and the State Key Laboratory of Bioreactor Engineering are gratefully acknowledged. Ya-Jie Tang also thanks the Chutian Scholar Program (Hubei Provincial Department of Education, China) (2006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, XJ., Liu, RS., Li, HM. et al. Lycopene production from synthetic medium by Blakeslea trispora NRRL 2895 (+) and 2896 (−) in a stirred-tank fermenter. Bioprocess Biosyst Eng 35, 739–749 (2012). https://doi.org/10.1007/s00449-011-0654-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-011-0654-4