Abstract

In this paper, three identical membrane bioreactors (MBRs) were operated in parallel in order to specify the influence mechanism of hydraulic retention time (HRT) on MBR. The results showed that the removal efficiency of chemical oxygen demand (COD) was stable though it decreased slightly as HRT decreased, but biomass activity and dissolved oxygen (DO) concentration in sludge suspension decreased as HRT decreased. The filamentous bacteria grew easily with decreasing HRT. The extracellular polymeric substances (EPS) concentration and sludge viscosity increased significantly as filamentous bacteria excessively grew. The over growth of filamentous bacteria, the increase of EPS and the decrease of shear stress led to the formation of large and irregular flocs. Furthermore, the mixed liquid suspended solids (MLSS) concentration and sludge viscosity increased significantly as HRT decreased. The results also indicated that sludge viscosity was the predominant factor that affecting hydrodynamic conditions of MBR systems.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Membrane bioreactor (MBR) is a biological wastewater treatment process that uses membrane to replace the gravitational settling of the conventional activated sludge process for the solid–liquid separation of sludge suspension. MBRs, in which biomass is strictly separated by a membrane, offer several advantages over the conventional activated sludge process, including a higher biomass concentration, reduced footprint, low sludge production, and better permeate quality [1, 2]. But a major obstacle for the application of MBRs is the rapid decline of the permeation flux as a result of membrane fouling [3–5]. To establish strategies for fouling control, understanding of the fouling behavior is indispensable.

The organic loading rate (OLR) has significant relation with feed concentration, hydraulic retention time (HRT) and so on. In general, short HRT can induce large OLR. Thus, HRT is a very important operating parameter in MBR systems, which correlated not only to the treatment efficiency of the MBR systems [6, 7], but to the characteristics of biomass in an activated sludge system [8, 9]. Ren et al. [7] reported that when HRT was 5 h and the influent COD was less than 3,000 mg/L, the effluent quality could meet the accepted Chinese standards for water reclamation; when HRT was 3.2 h and the influent COD was smaller than 3,000 mg/L, the effluent quality could meet the normal Chinese discharged standard. Cho et al. [9] reported that in the short HRT and high flux condition, the nutrient removal efficiency increased compared to the long HRT and low flux condition, increasing HRT by 30% resulted in a decrease of nutrient removal efficiency by 10%. However, the short HRT or high OLR and high flux condition resulted in the acceleration of membrane fouling.

Much work has been performed to study the mechanisms of membrane fouling in MBRs, including the influence of biomass characteristics on membrane permeability. Chang and Kim studied the effect of biosolids concentrations on permeate flux during the membrane filtration of activated sludge suspensions with different MLSS concentrations, and found that the fouling cake resistance decreased as MLSS concentration decreased [10]. Yamamoto et al. [1] reported that the flux decreased abruptly if the MLSS concentration exceeded 40,000 mg/L in a submerged MBR. Bai and Leow [11] and Lim and Bai [12] examined the different size fractions of particles in the activated sludge wastewater, and found that the smaller particle size played a more important role on membrane fouling. The particle size distributions (PSD) of activated sludge suspensions have significant impacts on fouling cake layer permeability [13].

Recently, many MBRs studies have identified extracellular polymeric substances (EPS) as the most significant biological factor responsible for membrane fouling, which are microbial products due to metabolism and cell autolysis [14]. The quantitative analysis of EPS have performed because EPS have been reported not only as major sludge floc components keeping the floc together in a three-dimensional matrix, but also as key membrane foulants in MBR systems [15]. Accumulation of EPS both in the sludge suspension and on the membranes may cause an increase in the viscosity of the sludge suspension and an increase in the filtration resistance of the membrane [15]. It was also found that the filamentous bacteria concentration in MBRs had negative influence on MBR [16, 17]. Our previous work also showed that MLSS concentration, EPS and sludge particle size are the predominant factors affecting membrane fouling potential [13].

Since the MBR system includes living microorganisms and their metabolites, the operating conditions should have significant influence on sludge characteristics and membrane permeation. In fact, the HRT has no direct effect on membrane fouling, but the different HRT can cause various OLRs. In the present work, the influence of HRT on membrane fouling is analyzed, and the relationship between HRT and biomass characteristics and hydrodynamic conditions, including EPS, PSD, filamentous bacteria concentration, MLSS concentration, sludge viscosity, cross-flow velocity, and are studied systematically to specify how the HRT affects membrane permeability.

Materials and methods

Operation of MBRs

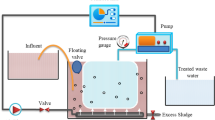

As shown in Fig. 1, the experimental system basically consisted of three activated sludge bioreactor (MBR-A, MBR-B, and MBR-C). The bioreactor was made of PVC. Two baffle plates divided the bioreactor into one riser zone and two down-comer zones. The membrane module was submerged in the riser. The area of riser zone was 6 × 20 cm2. In each MBR a membrane module with a total area of 0.1 m2 was submerged. The hollow fiber membrane module was made of polyethylene and had a normal pore size of 0.1 μm (DAIKI, Tokyo, Japan). In MBR-B and MBR-C, a secondary membrane module was submerged to obtain short HRTs. The role of the secondary membrane module was just to adjust the HRT. The secondary membrane module was cleaned every day to maintain the HRT of MBR-B and MBR-C. The fouling behavior of secondary membrane module was not investigated. The HRT of MBR-A was controlled at 10–12 h, and the HRTs of MBR-B and MBR-C were decreased to 6–8 and 4–5 h by the secondary modules. Thus, the decreased HRT can induce high OLR as shown in Table 1.

Three identical MBRs were operated continuously in parallel with the same feed wastewater. The composition of the feed water was as follows: Sucrose (350 mg/L), urea (91 mg/L) and dipotassium hydrogen phosphate (K2HPO4) (44 mg/L) were used as the main nutrition for activated sludge, and calcium chloride (CaCl2) was applied as microelement. Sodium bicarbonate (NaHCO3) was used as a buffer to adjust the mixed liquor pH to about 7.0. In order to investigate the membrane fouling degree accurately, a constant low pressure was used in the tests. During the operation of MBRs, the membrane module was driven by a fixed water head drop (WHD), ΔH = 40 ± 0.5 cm. The degree of membrane fouling was evaluated by membrane permeate flux. Activated sludge suspension was taken from the sedimentation tank of Dalian Chunliu Wastewater Treatment Plant. Prior to our experiments, the sludge suspension was acclimated for 30 days in other submerged MBRs.

In general, MBRs were thought to enable immense process intensifications through very high MLSS concentrations and resulting low footprint. In MBR process, however, higher MLSS concentrations give rise to high and non-Newtonian viscosities which impeded oxygen transfer and require more energy for pumping [18–20]. Therefore, lower biomass concentration is currently employed. So, the choice of the MLSS concentration is very important for the startup of the three MBRs. In this experiment, a moderate MLSS concentration of about 6,000 mg/L was used in order to avoid the disadvantage mentioned above. Other operating parameters are shown in Table 1.

Analytical methods

The extraction of bound EPS was based on a cation ion exchange resin (Dowex–Na form) method [21]. Bound EPS was normalized as the sum of carbohydrate and protein, which were analyzed using phenol/sulfuric-acid method and folin method [22], respectively.

The relative density of filamentous bacteria was evaluated by means of microscopic observation (Olympus, BH2-RFCA). The filament index (FI) was measured using the arbitrary scale recommended by Jenkins et al. [23]. The FI was rated on a scale of FI = 1–5, where FI = 1 represents little or no filamentous organisms, and FI = 5 represents excessive growth of filamentous organisms [24].

The size distributions of the sludge suspensions were determined by focused beam reflectance measurement (Model M400L, Lasentec, Redmond, WA, USA). The dissolved oxygen (DO) concentration was measured by a DO meter (55/12 FT, YSI Corporation, Owings Mills, MA, USA). The dynamic viscosity was determined using a rotational viscosity meter (Model NDJ-7, Shanghai, China). COD, MLSS, and specific oxygen uptake rate (SOUR) were analyzed in accordance with standard methods [25].

The membrane surface was observed with the help of a scanning electron microscope (SEM) (KYKY-2800B, Beijing, China). As the operation was terminated, a piece of membrane fiber was taken for SEM analysis. The sample was fixed with 3.0% glutaraldehyde in 0.1 M phosphate buffer at pH 7.2. The sample was dehydrated with ethanol, silver-coated by a sputter and observed in the SEM.

A propeller flow velocity meter (LS45, Chongqing Hydrological Apparatus Manufacture of the Hydraulic Ministry) was used to measure the cross-flow velocities of sludge suspension. The cross-flow velocities are average values of observed data at twenty measuring sites under the same aeration intensity.

Results and discussion

Performance of the MBRs

The mean COD removal efficiencies for about 2 months’ operation are summarized in Table 2. COD concentrations in supernatant and in effluent represented the removal efficiencies in the bioreactors and in the total MBR processes, respectively. The total COD removal efficiencies in the three MBRs could be kept over 94% regardless of HRT conditions. The bioreactors were responsible for ∼85–93% of COD removal. The COD removal efficiency slightly increased as HRT increased due to the lower OLR. It can be seen that the membrane showed a significant contribution (4–10%) to COD removal due to the complete retention of all particulate COD and macromolecular COD components by the membrane. It also has been shown that as the HRT decreased to 1.5 h and the COD of the feed wastewater reached up to 900 mg/L, the MBR could also obtain a COD reduction of 95–99% [26]. These results imply that the MBR system still had a high quality filtrate as it operates under high OLR or small HRT.

The DO concentrations with different HRT are illustrated in Table 2. As shown in Table 2, the DO concentration decreased dramatically as HRT decreased. The low HRT caused a high oxygen utilization rate to degrade pollutants. Additionally, this might be explained by an impeded transfer rate of both substrate and oxygen due to an increase of the sludge viscosity and MLSS concentration at short HRT or high OLR.

Specific oxygen uptake rate is an important parameter [27] for the characterization of biomass activity and it is in close association with biomass characteristics. HRT or OLR affects the metabolic activity of the sludge suspension in the bioreactor, as reflected by the SOUR. As shown in Table 2, SOUR had a similar change tendency with DO. The change of SOUR could be correlated with DO and biomass characteristics such as MLSS concentration, sludge viscosity and so on. The increase of MLSS concentration and sludge viscosity would lead to an increase of oxygen and substrate diffusion limitation in the sludge suspension, so the activities of biomass decreased.

The evolution of permeate flux during the membrane filtration of sludge suspension is presented in Fig. 2. It is important to note that large HRT resulted in a low fouling degree in the whole filtration time (MBR-A). Obviously, the curve of Fig. 2 can be roughly separated into two phases: from day 1 to day 35 (phase I), from day 35 to day 65 (phase II). From Table 3, it can be seen that the steady membrane flux declined rapidly after day 35, especially for MBR-B and MBR-C.

Nagaoka et al. [28] investigated the influence of OLR on membrane fouling in two parallel submerged MBR s, and found that the high OLR (1.5 g-TOC/L/day) showed a sudden increase of the pressure and a decrease of flux after 40th days, which could not be recovered even by membrane cleanings, while the low OLR (0.5 g-TOC/L/day) showed little increase of the pressure until 120th days. The data obtained from the current investigation, together with previous work in the literature, indicate that HRT or OLR was a very significant operating parameter that affects membrane performance in MBR systems.

SEM images were taken to determine the morphology of the foulants making up the fouling layer on the membrane surface. In Fig. 3, the SEM images show that a fouling cake layer built up on the membrane surface. It was found that the fouling cake layers formed on the membrane surfaces were mainly composed of filamentous bacteria or fungi with some bacillus attached on the surface. There were more filamentous bacteria in the cake layer of MBR-B and MBR-C than MBR-A. Even though the cake layers had much pores, the cake layers formed in MBR-B and MBR-C were much thicker than that formed in MBR-A. One possible reason for the difference of morphology of the formed layer is that the increase of filamentous bacteria concentration and EPS concentration led to an increase of bridge action among the deposited bacteria. Filamentous bacteria acted as the framework with cocci or bacilli as the matrix in the cake layer.

Except HRT, the three MBRs had the same operating parameters and the transmembrane pressure (TMP) is a constant value. Although HRT had no direct action on membrane fouling, HRT or OLR had impacts on the change of biomass characteristics for that it had close relation with DO concentration and SOUR of biomass (see Fig. 10).

Filamentous bacteria and floc size distribution

The over growth of filamentous bacteria have a negative influence on membrane permeability during the operation of MBR systems [16, 29, 30]. In this work, the filamentous bacteria concentration, which was quantified as FI, was evaluated to specify the influence of filamentous bacteria on membrane fouling and biomass characteristics. The results are presented in Fig. 4. It can be seen that there was an over growth of filamentous bacteria in MBR-C on day 27, then there was excessive filamentous bacteria in MBR-B on day 38.

The causes of sludge bulking are numerous and, to some degree, still unknown. It has been reported that nutrient imbalances and oxygen deficiency are often blamed for the bulking of sludge [31]. The growth of certain filamentous bacteria, such as Sphaerotilus and Haliscomenobacer hydrssis, is favored by relatively low DO concentrations [32]. However, it also has been reported that other filamentous bacteria, e.g. Microthrix parvicella can grow over a wide range of oxygen concentrations [33]. Deficiency of DO is believed to be one of the major causes responsible for most filamentous growth in activated sludge process. Filamentous bacteria have high surface-to-volume (A/V) ratio than non-filamentous bacteria. This high A/V ratio enables them to take up more nutrients as the bioreactor operates under high OLR. Therefore, we can conclude that the excessive growth of filamentous bacteria in MBR-C and MBR-B was mainly resulted from the low DO concentration and the high OLR.

The sludge floc size distributions of the three MBRs were measured on day 50 and showed in Fig. 5. It indicates that the sludge floc size increased with decreasing HRT (Fig. 5). The mean floc size for MBR-A, MBR-B, and MBR-C were 87.43, 118.85, and 127.34 μm, respectively. This result also can be explained from the over growth of filamentous bacteria. The excessive growth of filamentous bacteria would produce an abundance of filaments extending from the flocs into the bulk solution, producing a bridging lattice, which prevents the agglomeration of floc particles [34]. Therefore, as filamentous microorganisms started to grow, the sludge flocs became more irregularly shaped and porous [35], and the bound EPS increased sharply [16]. In addition, the shear stress or cross-flow velocity of the MBRs gave an order of MBR-A > MBR-B > MBR-C (see Hydrodynamic conditions section). In general, the decrease of shear stress will lead to the formation of larger sludge particles. Thus, the overgrowth of filamentous bacteria, the high EPS concentration and the low shear stress were the main reasons that lead to the increase of floc size in MBR-B and MBR-C.

Evolution of EPS in sludge suspension

Extracellular polymeric substances matrix is very heterogeneous, in which a variety of polymeric materials have been found: carbohydrates, proteins, lipids, and nucleic acids. In this work, the sum of total proteins and carbohydrates was considered to represent the total amount of EPS because these are the dominant components typically found in extracted EPS [36].

From Fig. 6, we can see that the sludge suspensions in MBR-B and MBR-C had higher EPS concentrations than that in MBR-A, indicating that the lower HRT condition could result in more EPS in the sludge flocs. It also can be seen that the EPS concentration especially in MBR-B and MBR-C increased abruptly on day 35.

Previous literatures demonstrated that the over growth of filamentous bacteria could result in much more release of EPS, and did great harm to membrane permeation [16, 29]. Therefore, it can be concluded that the sudden increase of EPS concentration in MBR-B and MBR-C was mainly resulted from the over growth of filamentous bacteria. Moreover, the filamentous bacteria caused the formation of irregularly shaped sludge flocs [16], which worsen the membrane permeability for the fixing action of filamentous bacteria. Therefore, many foulants deposited on the membrane surface and the filamentous bacteria used as the fixing type of adhering the membrane fouling material to increase the clinging intensity of the membrane foulants (see Fig. 3).

Results from recent reports indicate that EPS is the major membrane foulants during MBRs operation [37–40]. The composition and quantity of the organic fraction of the EPS would correlate to the membrane fouling [41]. Nagaoka reported that the high OLR could lead to much production of EPS and result in severe membrane fouling [28].

Evolution of MLSS concentration and dynamic viscosity

Significant increases of MLSS concentration and viscosity of the sludge suspension in an MBR have often been reported when municipal wastewater was treated [19, 42]. Figures 7 and 8 show the evolution of sludge concentration and sludge viscosity with operation time. From Fig. 7, it can be seen the MLSS concentration in MBR-A reached a steady value of about 7,500 mg/L. However, the MLSS concentration increased from 5,300 mg/L to 13,000 mg/L and 17,000 mg/L in MBR-B and MBR-C, respectively. Steady-state MLSS concentration in bioreactor was expected to decrease with longer HRT. Yoon et al. [43] revealed that as the HRT increases over 12 h, MLSS concentration in bioreactor will be stabilized at less than 15,000 mg/L, where stabilized MLSS concentration means no further sludge production.

Many researchers have given attention to the effects of MLSS concentration on membrane fouling [42]. Katayon et al. [44] investigated the impact of MLSS concentration on the performance of a MBR for treating food industry wastewater, and found that the mean flux value of process at low MLSS concentration (4,340–5,390 mg/L) was much higher than that at high MLSS concentration (6,330–10,780 mg/L). Various MBR studies showed that very little flux decline was observed for sludge concentrations smaller than 10,000 mg/L [45, 46]. The effect of MLSS concentration on membrane fouling varied from one study to another, because the experimental conditions were different from each other, and produced discrepant results. The data obtained from the current investigation, together with previous work in the literature, do not explain the exact membrane fouling mechanism caused by MLSS concentration, but do indicate that the MLSS concentration is an important factor affecting membrane permeability.

To investigate the impact of HRT or OLR on sludge viscosity, a rotational viscosity meter was used to determine the dynamic viscosity of sludge suspension. The dynamic viscosity of pure water at 20°C measured by this rotational viscosity meter was 1.0 mPas. From Fig. 8, it can be seen that MBR-B and MBR-C always had higher dynamic viscosity values than MBR-A, and the dynamic viscosity of the three MBRs increased suddenly on day 35. Xing et al. [47] found that there was a linear relation between sludge viscosity and sludge concentration in MBR systems. Nagaoka [48] found that there was a strong dependency of the filtration resistance on the dynamic viscosity. They also found that the accumulation of EPS in bioreactor caused the increase of dynamic viscosity, then led to rapid decline of membrane permeate flux. More polymers and small particles would accumulate on the membrane surface as a result of the higher dynamic viscosity.

The dynamic viscosity is a reflection of the magnitude of viscous substances, which may be considerably contributed by the polymers such as protein, carbohydrate, and so on. An increase of biopolymers in the sludge suspension will increase its viscosity, and hence reduce the MBRs permeate flux [49, 50]. Thus EPS has great contribution on the increase of the dynamic viscosity of the mixed liquor. In our previous work, we found that the sludge suspension with excessive filamentous bacteria had high viscosity for the presence of too much EPS [16]. The results, together with previous literatures, indicate that MLSS concentration EPS and filamentous bacteria were the major factors that cause the increase of sludge viscosity (please see Fig. 10).

In the membrane filtration, the deposition of sludge flocs is determined by two factors: the suction force generated from TMP and the shear force generated from aeration. With the suction force the sludge flocs presenting high viscosity can easily accumulate on the membrane surface and the filamentous bacteria has a fixing action on the membrane foulants, which adhere and penetrate between the membrane and membrane foulants. That is why the over growth of filamentous bacteria in sludge suspension resulted in severe membrane fouling.

Hydrodynamic conditions

Besides the sludge characteristics, the membrane fouling behavior also correlates significantly with the hydrodynamics of MBRs. In a submerged MBR, shear stress is created by aeration, which not only provides oxygen to the biomass, but also maintains the solids in suspension and scours the membrane surface and so alleviates membrane fouling. In the whole operation, the same aeration intensity, 0.2 m3/h, was used. It has been shown that the cross-flow velocity of sludge suspension has exponential relation with sludge viscosity [51].

From Fig. 9, it can be seen that as the sludge viscosity was smaller than 2.0 mPas, it had little influence on the cross-flow velocities, which could keep over 0.20 m/s. But, the cross-flow velocity of sludge suspension decreased sharply as the sludge viscosity was larger than 2.0 mPas. The cross-flow velocity was only 0.020 m/s as the sludge viscosity increased to 4.0 mPas. Liu et al. [52] reported that a critical cross-flow velocity of about 0.30 m/s appeared to exist. When the cross-flow velocity was lower than the critical value, the TMP, which was used to characterize membrane fouling potential, increased sharply with decreased cross-flow velocity. The flocs with high viscosity could easily deposit onto the membrane surface, but the lower cross-flow velocity under higher sludge viscosity could not scour the foulants effectively. Therefore, severe membrane fouling would occur as the sludge viscosity was too high.

As the long-term operation of the three MBRs was terminated, the membrane module was taken out and flushed with tap water to removal the cake layer or reversible fouling. After the hydraulic cleaning, the membrane flux of each MBR reached to 72, 81, and 75%. This result indicates that the HRT had little influence on irreversible fouling in our study. In addition, as shown in Fig. 10, the effect of HRT on membrane fouling and biomass characteristics can be summarized using a schematic relation.

Conclusions

This paper presents a comparative study of the effect of HRT on membrane permeate performance, biomass characteristics and hydrodynamic conditions (shown in Fig. 10). From the results reported here, the following conclusions can be drawn:

-

(1)

COD removal in the bioreactor slightly decreased with decreasing HRT, but total efficiency could be maintained over 94% regardless of HRT. DO and SOUR decreased as HRT decreased. This could be explained by impeded transfer rate of both substrate and oxygen due to high MLSS concentration and sludge viscosity.

-

(2)

The low HRT would result in high EPS concentration, high MLSS concentration and sludge viscosity. These factors had negative effect on membrane fouling. Therefore, too low HRT may have a negative effect on membrane permeate flux. The low HRT could cause excessive growth of filamentous bacteria in sludge suspension. Filamentous bacteria had great impacts on the performance of MBR systems because it led to more release of EPS, higher sludge viscosity and irregular shaped flocs. Filamentous bacteria used as the fixing type of adhering the membrane fouling material to increase the clinging intensity of the membrane foulants. In the case of our here experimental results, MLSS concentration, EPS, sludge viscosity, and filamentous bacteria had strong impacts on membrane fouling behavior.

-

(3)

Sludge viscosity was an important factor that affects the hydrodynamic conditions of MBRs. The cross-flow velocity of sludge suspension decreased sharply as sludge viscosity increased larger than 2.0 mPas. Under low cross-flow velocity, the shear stress induced by aeration could not scour the cake layer from membrane surface, thereby inducing severe membrane fouling. The HRT had little influence on irreversible fouling. Suitable HRT or OLR need to be maintained during the operation of MBR systems.

References

Yamamoto K, Hiasa M, Mahmood T, Matsuo T (1989) Water Sci Technol 21:43–54

van Dijk L, Roncken GCG (1997) Water Sci Technol 35:35–41

Chae S-R, Ahn Y-T, Kang S-T, Shin H-S (2006) J Memb Sci 280:572–581

Meng FG, Zhang HM, Li YS, Zhang XW, Yang FL, Xiao JN (2005) Sep Purif Technol 44:250–257

Zhang J, Chua HC, Zhou J, Fane AG (2006) Sep Sci Technol 41:1313–1329

Ren N, Chen Z, Wang A, Hu D (2005) Int Biodeterior Biodegradation 55:279–284

Ren N, Chen Z, Wang X, Hu D, Wang A (2005) Int Biodeterior Biodegradation 56:216–223

Yoon S-H, Kim H-S, Yeom I-T (2004) Water Res 38:37–46

Cho J, Song K-G, Hyup Lee S, Ahn K-H (2005) Desalination 178:219–225

Chang IS, Kim SN (2005) Process Biochem 40:1307–1314

Bai R, Leow HF (2002) Sep Purif Technol 29:189–198

Lim AL, Bai R (2003) J Memb Sci 216:279–290

Meng F, Zhang H, Yang F, Zhang S, Li Y, Zhang X (2007) Sep Purif Technol 51:95–103

Le-Clech P, Chen V, Fane TAG (2006) J Memb Sci 284:17–53

Nagaoka H, Ueda S, Miya A (1996) Water Sci Technol 34:165–172

Meng F, Zhang H, Yang F, Li Y, Xiao J, Zhang X (2006) J Memb Sci 272:161–168

Meng F, Yang F, Xiao J, Zhang H, Gong Z (2006) J Memb Sci 285:159–165

Drews A, Kraume M (2005) Chem Eng Res Des 83:276–284

Drews A, Evenblij H, Roenberger S (2005) Environ Prog 24:426–433

Rosenberger S, Kubin K, Kraume M (2002) Eng Life Sci 2:269–275

Fround B, Palmgren R, Keiding K, Nielsen PH (1996) Water Res 30:1749–1758

Lowery OH, Rosebrough NJ, Farr AL, Randall RJ (1951) J Bio Chem 193:265–275

Jenkins D, Richard MG, Daigger GT (1986) Manuel on the causes and control of activated sludge bulking and foaming. Ridgeline Press, Lafayette, CA

Eikelboom DH, van Bijisen HJ (1983) Microscopic sludge investigation manual. TNO Research Institute for Environmental Hygiene, The Netherlands

APHA (1995) Standard methods for the examination of water and wastewater. 19th edn. American Public Health Association, Baltimore, MD

Holler S, Trosch W (2001) J Biotechnol 92:95–101

Han SS, Bae TH, Jang GG, Tak TM (2005) Process Biochem 40:2393–2400

Nagaoka H, Yamanishi S, Miya A (1998) Water Sci Technol 38:497–504

Choi J-G, Bae T-H, Kim J-H, Tak T-M, Randall AA (2002) J Memb Sci 203:103–113

Shim JK, Yoo I-K, Lee YM (2002) Process Biochem 38:279–285

Gaval G, Pernelle J-J (2003) Water Res 37:1991–2000

Liu Y, Liu Q-S (2006) Biotechnol Adv 24:115–127

Rossetti S, Tomei MC, Nielsen PH, Tandoi V (2005) FEMS Microbiol Rev 29:49–64

Sezgin M, Jenkins D, Parker DS (1978) J WPCF 50:362–381

Wilen B-M, Balmer P (1999) Water Res 33:391–400

Lee W, Kang S, Shin H (2003) J Memb Sci 216:217–227

Chang I-S, Lee C-H (1998) Desalination 120:221–233

Rosenberger S, Kraume M (2002) Desalination 146:373–379

Drews A, Lee C-H, Kraume M (2006) Desalination 200:186–188

Drews A, Vocks M, Iversen V, Lesjean B, Kraume M (2006) Desalination 192:1–9

Ji L, Zhou J (2006) J Memb Sci 276:168–177

Gao M, Yang M, Li H, Wang Y, Pan F (2004) Desalination 170:177–185

Yoon SH, Kim HS, Yeom IT (2004) Water Res 38:37–46

Katayon S, Megat Mohd Noor MJ, Ahmad J, Abdul Ghani LA, Nagaoka H, Aya H (2004) Desalination 167:153–158

Hong SP, Bae TH, Tak TM, Hong S, Randall A (2002) Desalination 143:219–228

Meng F, Zhang H, Li Y, Zhang X, Yang F (2005) J Memb Sci 262:107–116

Xing CH, Qian Y, Wen XH, Wu WZ, Sun D (2001) J Memb Sci 191:31–42

Nagaoka H (1999) Water Sci Technol 39:107–114

Chang IS, Lee CH (1998) Desalination 120:221–233

Chang I-S, Bag S-O, Lee C-H (2001) Process Biochem 36:855–860

Liu R, Huang X, Sun YF, Qian Y (2003) Process Biochem 39:157–163

Liu R, Huang X, Wang C, Chen L, Qian Y (2000) Process Biochem 36:249–254

Acknowledgments

The project supported by National Natural Science Foundation of China, Grant No 50578024.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meng, F., Shi, B., Yang, F. et al. Effect of hydraulic retention time on membrane fouling and biomass characteristics in submerged membrane bioreactors. Bioprocess Biosyst Eng 30, 359–367 (2007). https://doi.org/10.1007/s00449-007-0132-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-007-0132-1