Abstract

We investigated the abnormal reaction behavior of NCO units in micellar hydrophilic isocyanate in water through titration, particle size, FT-IR spectroscopy and GPC and mechanical properties. Hexamethylene diisocyanate (HDI) allophanate was modified with methoxy polyethyleneglycol (MPEG), yielding novel hydrophilic isocyanate, which formed stable and homogeneous micelles in water. The results we obtained showed that the rapid reduction of the NCO group took place at a specific time (with an induction period) after dispersing hydrophilic isocyanate into water. The induction period, which is equal to the lifetime of the NCO group, was largely dependent on the diameter of micelles determined by the content of MPEG introduced. The result of GPC measurement indicated that there are three types of reactions between NCO groups and water. The rapid reduction of NCO in water was explained by the stepwise progress of the reactions, according to the location of NCO units in the core-shell structure of hydrophilic isocyanate micelles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Polyurethane is a unique polymeric material with a wide range of physical and chemical properties and it has been used in various fields, such as foams, coatings, adhesives, and thermoplastic elastomers [1–4]. Polyurethane occupies an important position in many applications, especially in the coating industry, as the coating layer has some favourable qualities, such as, resistance to solvents, weather stability and mechanical properties.

There are two major systems in polyurethane coatings. One is called a one-component (1K) system in which the substrate is coated with high molecular weight polyurethane and dried physically. The other is a two-component (2K) system, which is a combination of hydroxyfunctional polymers and polyisocyanate hardeners containing NCO group. In the past, maximum performance and appearance were the main requirements, resulting in the development of solvent-borne 2K systems. In recent years, however, the demand has shifted to reduce volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) emissions. The waterborne polyurethane system is one of the options for reducing VOCs and HAPs [5–11].

Until the late 1980s, a waterborne 2K polyurethane system was unthinkable for two main reasons. First, the isocyanate hardener is usually hydrophobic and it is difficult to disperse into the water. Second, there is an undesired side reaction between the NCO group and water as shown in Scheme 1. The first problem was solved by the development of a novel type of isocyanate, which was modified with hydrophilic groups [12, 13]. For example, hydrophilic isocyanate hardeners were produced by reacting monohydroxy-functional polyethylene glycols with some of the NCO groups of the polyisocyanate. The NCO groups, however, are highly reactive and it is difficult to suppress the side reaction between NCO groups and water [14–20].

In the utilization of waterborne 2K polyurethane, it is important to keep NCO groups in water for a long time (to achieve long pot life) by suppressing the side reaction between NCO and water. To attain these purposes, we prepared hexamethylene diisocyanate (HDI) allophanate modified with the methoxy polyethylene glycols (MPEG) as a hydrophilic isocyanate in this research. Using this hydrophilic isocyanate, we investigated the reactivity of the NCO group in terms of the residual NCO group content in water, particle size, pH, molecular weight and mechanical properties. This new hydrophilic isocyanate could be dispersed into water in a simple way because of the very low viscosity. A long lifetime of NCO units could be attained by adjusting the MPEG content. In addition, we discuss the internal structure of the hydrophilic isocyanate micelles in relation to the NCO reactivity.

2 Experimental

2.1 Materials

Hexamethylene diisocyanate (HDI, Wako Pure Chemical Industries Ltd.), 2-methyl-1-propanol (Wako Pure Chemical Industries Ltd.), tris(tridecyl)phosphite (Johoku Chemical Co. Ltd.), lead 2-ethyl-hexanicacid (Wako Pure Chemical Industries Ltd.), benzoyl chloride (Wako Pure Chemical Industries Ltd.) were used without further purification. Methoxy polyethylene glycol (MPEG, NOF Corp.) was dried at 70 °C for 5 h under nitrogen bubbling.

The polyurethane emulsion for mechanical test was separately prepared with polytetramethylene oxide glycol (PTMG: Mn=2,000), triethylene glycol, dimethylol propionic acid (DMPA), 1,3-bis(isocyanatemethyl)cyclohexane, triethylamine and 2-(2-aminoethylamino)ethanol. This product contains 5,000 COOH groups and 3,800 OH groups equivalent.

2.2 Sample preparation

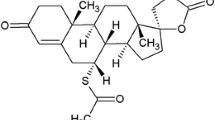

Hydrophilic isocyanates were synthesized in four steps as shown in Scheme 2. The first step is the urethane reaction between HDI and 2-methyl-1-propanol. Hexamethylene diisocyanate (5.77 mol), 2-methyl-1-propanol (0.405 mol) and tris(tridecyl) phosphite (0.795 mmol) were mixed at 20 °C under nitrogen atmosphere and heated at 80 °C for 2 h. This reaction was performed under excess amounts of NCO in order to leave one of the two NCO groups in HDI after the reaction with an OH group of 2-methyl-1-propanol.

The second step is the allophanate reaction. Lead 2-ethylhexanic acid (1.01 mmol) was added to the solution as a catalyst kept at 90 °C for 1 h, and then benzoyl chloride (0.711 mmol) was added as a termination agent.

The third step is distillation to remove unreacted HDI by using the thin membrane distillation method at 140 °C and 0.5 mmHg [21].

In the final step, a part of the NCO group of HDI allophanate reacted with the OH group of MPEG for 4 h at 70 °C. We prepared four hydrophilic isocyanate samples with different contents and molecular weights of MPEG as shown in Table 1. Samples were designated such that, for example in A400(20), the initial letter ‘A’ refers to allophanate, 400 to the molecular weight of MPEG, and 20 to the MPEG weight ratio (%) in this hydrophilic isocyanate. This final reaction proceeded under excess amounts of NCO group compared to OH group of MPEG so that the samples are a two-compound mixture; one is HDI allophanate modified with MPEG and the other is without MPEG as shown in Scheme 2. The content of HDI allophanate modified with MPEG was evaluated by NCO equivalent measurement and the results are shown in Table 1.

2.3 Dispersion preparation

To investigate the lifetime of NCO groups in water, the aqueous dispersion samples were prepared by addition of hydrophilic isocyanate into water with stirring, yielding stable dispersion of a 30 wt% concentration. The dispersion was left standing at 25 °C and a part of it was examined every 1 h after dispersing.

2.4 Mechanical test sample preparation

To study the influence of the NCO lifetime in water on the mechanical properties of a two-component (2K) polyurethane system, A400(20) was dispersed into water and kept for 10 min, 4 and 5 h, and then it was mixed with polyurethane emulsion. The ratio with NCO of A400(20) and OH of polyurethane emulsion is 1.2. Film samples for mechanical measurements were prepared by casting the mixed dispersions on a metal plate under ambient conditions. The films (about 0.1 mm thickness) were dried for more than 1 day and kept at 130 °C for 1 h to remove the remaining moisture.

2.5 Measurements

Isocyanate content was measured using the dibutylamine backtitration method as follows. The dispersion sample containing a NCO group was dissolved in THF. Dibutylamine was added to the THF solution with stirring and the amine group reacted with the NCO group immediately. This solution was diluted with isopropanol and the residual amine group of dibutylamine was titrated by 0.1 N HCl aq.

The average particle size was measured by light scattering (Coulter N4 Plus), where a He–Ne laser with wavelength of 632.8 nm was used. The sample was diluted in diionaized water to adequate concentration for measurement.

Infrared spectroscopic experiments were performed with a FT-IR spectrometer (HORIBA FT-710). The samples for IR measurements were diluted in THF to a 1% solution and coated on a NaCl disk. In order to remove the residual water and THF solvent, the disk was placed under a nitrogen stream at 25 °C for 10 min. The pH values were measured with a HORIBA M-13 pH meter. A part of this hydrophilic isocyanate dispersion was extracted and used for pH measurement.

The samples for GPC measurement were prepared by addition of each dispersion sample to methanol and heated at 50 °C for 24 h. Active NCO groups of the hydrophilic isocyanate terminated with OH groups of methanol and the residual methanol and water were removed by evaporation. The molecular weights of these samples were determined with Waters 410 system with DMF. The calibration curves for GPC were obtained by using polystyrene standard samples.

Mechanical properties were measured at room temperature using INTESCO Model 205 following the ASTM D412 specifications. A crosshead speed of 300 mm/min was used throughout these investigations to determine the ultimate tensile strength and elongation at break for all the samples. The values quoted are the average of five measurements.

3 Results and discussion

3.1 The lifetime of NCO group in water: MPEG content dependence

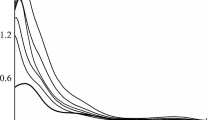

We selected three samples, A400(15), A400(20) and A400(25) (Table 1), in which the MPEG parts have the same molecular weight of 400 and 15, 20 and 25% weight fractions of MPEG, respectively. Figure 1 shows the residual NCO contents in water with the elapse of time after dispersing hydrophilic isocyanate into water. Here, the residual NCO content just after dispersing is regarded as 100%. As Fig. 1 shows, the reactivity is quite different among the three samples. For A400(15), the residual NCO content was about 70% even at 7 h after dispersing. On the other hand, that of A400(20) markedly decreased after 4 h and was found to be less than 10% at 5 h. In the case of A400(25), it started decreasing at 2 h and was almost nothing after 3.5 h. These results show that the reduction of NCO groups in water has an induction period and it is accelerated as the content of hydrophilic group increases.

Next, the average particle diameters of hydrophilic isocyanate dispersions were measured. Figure 2 shows the particle diameter after dispersion and the initial value is 265 nm for A400(15), 195 nm for A400(20), and 171 nm for A400(25). We found that the higher the content of MPEG is, the smaller the particle diameter is, due to the hydrophilic character of MPEG. As shown in Figs. 1 and 2, it is obvious that the smaller the particle diameter of this dispersion, the faster the reduction of NCO groups is, because the NCO groups in the smaller particles are easily attacked by water molecules and react with water. Furthermore, the particle diameter is found to change markedly at 5 h for A400(20) and at 3.5 h for A400(25). The rapid reduction of NCO groups in water has some influence on the particle diameter. It is worth noting that the bubbling of the solution was observed simultaneously with the rapid decrease of NCO content.

3.2 The lifetime of NCO group in water: MPEG molecular weight

The relationship between MPEG molecular weight and the lifetime of NCO group in water was examined using A400(20) and A550(20). These two samples have the same content of MPEG unit, but a different molecular weight, in other words, a different chain length. Figure 3 shows the residual NCO contents as a function of time after dispersing at 25 °C, where the residual NCO content just after dispersing hydrophilic isocyanate into water is regarded as 100%. The reactivity of NCOs in these samples was similar throughout the observation period. In both A400(20) and A550(20), the residual NCO contents were more than 70% at 4 h and remarkably decreased within the next 1 h. These results indicate that the reduction of NCO groups in water is independent of the chain length of polyoxyethylene. The average diameters of both dispersions are almost the same value of about 200 nm, suggesting that the lifetime is largely dependent on the diameter of the dispersion and the diameter is not determined by molecular weight, but by the content of MPEG in this hydrophilic isocyanate.

3.3 Reaction of hydrophilic isocyanate in water

The reaction between the NCO group and water was followed by FT-IR spectroscopy. A400(20) was selected as the sample for FT-IR measurement. Examples of FT-IR spectra collected at different times after dispersion are presented in Fig. 4: 10 min, 2, 4, 5, and 24 h from the top to bottom, respectively. The 2,270 cm−1 peak in the FT-IR spectra is assigned to NCO groups of hydrophilic isocyanate. As shown in Fig. 4, this 2,270 cm−1 peak is clearly perceived at 10 min, 2 and 4 h, but suddenly disappeared at 5 h. These results agree with the rapid decrease of NCO content as shown in Fig. 1. By contrast, the 3,340 cm−1 peak and the 1,645 cm−1 peak, which are assigned to the urea group formed by the reaction between NCO and water, gradually increased with the passage of the time. The pH values of A400(20) dispersion were also monitored as shown in Fig. 5. The pH values are stable around 6.0 until 3 h and then gradually increase between 3 and 5 h. These results also indicate that the rapid reaction between the NCO group and water influences the pH of this aqueous dispersion.

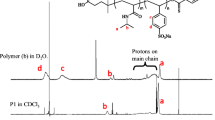

This reaction process between the NCO and water was examined by the GPC measurement in more detail. Figure 6 shows the GPC chromatograms at 10 min, 2, 4, 5, and 24 h after dispersing A400(20) into water. There are two main peaks at 10 min, of which one peak at the elution time of 35 min is assigned to the HDI allophanate without MPEG, and the other peak at 34 min is due to HDI allophanate modified with MPEG. With the elapse of time, the GPC chromatograms are slightly changed until 4 h. The new peaks at 32 and 33 min on the chromatogram appear with the decrease of the peaks at 34 and 35 min, while the peak at 35 min remains until 4 h. This GPC chromatogram changes drastically at 5 h. The peak at 35 min disappears completely and a broad peak, which means the production of much higher molecular weight molecules, appears at the shorter elution time. At 24 h, the broad peak is shifted to a shorter elution time compared to that at 5 h. These results of GPC measurements show that a large amount of A400(20) NCO groups react with water in the time range between 4 and 5 h and yield a high molecular weight compound.

This sudden reaction between the NCO and water is probably caused by the core-shell structure of this hydrophilic isocyanate micelle, as shown in Fig. 7. This hydrophilic isocyanate consists of two components, one is HDI allophanate without MPEG and the other is HDI allophanate with MPEG. HDI allophanate without MPEG exists near the center of this dispersion and forms the core of micelles. By contrast, HDI allophanate modified with MPEG exists near the surface of this dispersion and forms the shell. The reaction proceeds preferentially in the shell at the early stage, because the hydrophobic core region is protected from the penetration of water.

Taking into account these two components, three kinds of NCO reactions can be considered as shown in Scheme 3. A is a coupling reaction of two HDI allophanates bearing the MPEG unit, B is an extension reaction between HDI allophanates with MPEG and without MPEG, and C is a polymerization reaction of bifunctional HDI allophanates without MPEG. Because the HDI allophanate modified with MPEG exists near the surface of dispersion and easily comes in contact with water, reaction A mainly takes place and forms dimeric compounds in the early stage of reaction until 4 h. Reaction B also proceeds until 4 h, yielding the peak at 32 min on the chromatogram as the product. Until 4 h, almost all NCO groups existing in the shell layer has been consumed and HDI allophanates without MPEG start reacting with water. At this time point, the type of reaction changes to C, because water molecules reach the interface of the core region of this dispersion. Therefore, most HDI allophanates without MPEG rapidly react with water and form much higher molecular weight compounds after 4 h as shown in Fig. 6. The rapid change between 4 and 5 h is probably due to the difference in NCO concentration of the two layers. The NCO concentration is low in the shell layer, because HDI allophanate modified with MPEG is the main component of the shell. Therefore, the reaction between NCO and water proceeds slowly. On the other hand, the NCO concentration is high in the core, which is composed of HDI allophanates without MPEG. Consequently, the reaction between NCO and water proceeds very quickly.

3.4 Mechanical Properties of the film formed by A400(20) and polyurethane emulsion

The influence of the NCO lifetime in water on the mechanical properties of the two-component (2K) polyurethane system was studied. Table 2 shows the tensile strengths and ultimate elongation for each sample. Reference is the mechanical property of the film formed by polyurethane emulsion without A400(20). The ultimate elongation was decreased and the tensile strengths of 500 and 700% elongations were increased by adding A400(20). This result indicates that NCO group of A400(20) reacted with OH group of polyurethane emulsion and formed crosslinking structure. Furthermore, there is no big difference between the ultimate elongation of 10 min and 4 h samples. This indicates that almost all NCO groups of A400(20) are maintained for 4 h in water. We tried to mix A400(20) dispersion passed 5 h to polyurethane emulsion, but the two dispersions could not be mixed, and formed inhomogeneous film not suitable for measurement. This is due to the sudden reaction between NCO and water. After 5 h, the rapid progress of NCO reaction yields high molecular weight, which is not mixed with polyurethane dispersion any longer.

4 Conclusion

A novel hydrophilic isocyanate was synthesized by the reaction of HDI allophanate with MPEG. This hydrophilic isocyanate had a very low viscosity and formed stable dispersion with a simple mixing method into water. The NCO lifetime in water was closely related to the particle diameter of this dispersion, and the diameter was not determined by molecular weight but by the content of MPEG in this hydrophilic isocyanate. As the MPEG content increased, the diameters of this dispersion became small, resulting in the short NCO lifetime in water. The results of FT-IR and GPC measurements suggested that the types of reactions between the NCO and water molecules changed stepwise with the elapse of time, depending on the location of the reaction inside the micelles. The rapid consumption of NCO groups after a long induction period could be interpreted by the core-shell structure of micelles, in which the shell layer mainly consisted of HDI allophanate modified with MPEG and the core was composed of hydrophobic diisocyanates without MPEG. These results clearly indicate that NCO lifetime of hydrophilic isocyanate in water is adjustable by designing the micellar structure on the balance of hydrophobic HDI and hydrophilic MPEG components.

References

Sonnenschein MF, Rondan N, Wendt BL, Cox JM (2004) J Polym Sci A Polym Chem 42:271

Tang W, Farries RJ, Macknight WJ, Eisenbach CD (1994) Macromolecules 27:2814

Chen TK, Tien YI, Wei KH (2000) Polymer 41:1345

Consolati G, Levi M, Turri S (2001) Polymer 42:9723

Dieterich D (1981) Prog Org Coat 9:281

Rosthauser JW, Nachtkamp K (1986) J Coat Fabrics 16:39

Kim BK, Lee JC (1996) Polymer 37:469

Vogt-Birnbridh B (1996) Prog Org Coat 29:31

Mori Y, Yamazaki M, Shido H (2000) Prog Org Coat 40:119

Kim YB, Kim HK, Yoo JK, Hong JW (2002) Surf Coat Tech 157:40

Yang JE, Kong JS, Park SW, Lee DJ, Kim HD (2002) J Appl Polym Sci 86:2375

Jacobs PB, Yu PC (1993) J Coat Tech 65(822):45

Hrgedus CR, Gilicinski AG, Haney RJ (1996) J Coat Tech 68(852):51

Dorchak MJ (1997) J Coat Tech 69(866):47

Melchiors M, Sonntag M, Kobusch C, Jurgens E (2000) Prog Org Coat 40:99

Wicks ZW Jr, Wicks DA, Rosthauser JW (2002) Prog Org Coat 44:161

Collong W, Gobel A, Kleuser B, Lenhard W, Sonntag M (2002) Prog Org Coat 45:205

Bock M, Petzoldt J (1996) Mod Paint Coat 86:22

He ZA, Blank WJ, Picci ME (2002) J Coat Tech 74(930):31

Feng SX, Lunney P, Wargo R (1999) J Coat Tech 71(897):143

Nakashima T, Shimizu H, Hirata F (1996) Japanese patent H08-188566

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tawa, T., Ito, S. Preparation and reactions of hydrophilic isocyanate micelles dispersed in water. Colloid Polym Sci 283, 731–737 (2005). https://doi.org/10.1007/s00396-004-1213-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-004-1213-1