Abstract

Biodegradable nanoparticles loaded with anticancer drug paclitaxel and appropriately coated with polyvinyl alcohol (PVA), polyethylene glycol (PEG) as well as d-α-tocopheryl polyethylene glycol 1000 succinate (TPGS) were produced and characterised by various analysis techniques such as laser light scattering (LLS) for particle size and size distribution, scanning electron microscopy (SEM) and atomic force microscopy (AFM) for particle morphology, X-ray photoelectron spectroscopy (XPS) and Fourier Transform Infrared-Photoacoustic Spectroscopy (FTIR-PAS) for surface chemistry, and high performance liquid chromatography (HPLC) for drug encapsulation efficiency (EE) and in vitro release kinetics. The emphasis was given to the possible effects of surface coating on the physicochemical and pharmaceutical properties of paclitaxel loaded nanoparticles. It was found that the type and amount of the surfactant could significantly affect the drug EE in the nanoparticles, the particles characteristics and their in vitro release behaviour. The surfactants dominated on the nanoparticles’ surface and the coated nanoparticles displayed in spherical shape with relative smooth surface within the resolution scope of the equipment. The particle size and size distribution showed close relation to the surface coating, which may also be responsible for the drug encapsulation efficiency and the in vitro release kinetics. A favourable formulation of drug loaded nanoparticles of desired properties could be obtained by optimising the fabrication parameters.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Surfaces are important for both tissue engineering and controlled drug release systems, which affect the barrier layer, hydration effects, wettability control, biodegradation at surface and biocompatibility, drug distributions and release profiles, and so on. Although the polymeric nanoparticles have attracted considerable attention in view of their distinct advantages in the controlled delivery of various therapeutic agents like vaccines, human growth hormone, insulin, anti-tumour agents, contraceptives, proteins and peptides [1, 2], their application is compromised by the particles’ short residence time in the blood due to their recognition and capture by the macrophages in the mononuclear phagocyte system (MPS). The efficient prevention of the phagocytosis is to avoid or minimise the adsorption of blood components on the particle’s surface [3, 4, 5]. The surface modification can significantly influence the physicochemical and pharmaceutical properties of the nanoparticles including particle size, size distribution, particles morphology, surface chemistry, surface hydrophobicity, zeta potential, drug encapsulation efficiency (EE), and thus the accordant in vitro and in vivo behaviour of the encapsulated agent. Surface modification could be achieved during and after particle fabrication depending on the manufacturing technique. Polyethylene glycol (PEG) is widely used to cloak the particles and obtain stealthy properties. PEG coating can be obtained by its physical adsorption or its derivatives, and also can be directly prepared from the amphiphilic block copolymer [6, 7, 8, 9]. Further, our work has found that d-α-tocopheryl polyethylene glycol 1000 succinate (vitamin E TPGS or TPGS) which is water-soluble derivative of natural-source vitamin E and PEG could be a perfect emulsifier for making polymeric nanoparticles and also can be used as a component material of nanoparticle matrix when mixed with the synthetic biodegradable polymer poly (lactide-co-glycolide) (PLGA) [10]. More importantly, TPGS could be absorbed intact readily in the gastrointestinal tracts (GIT), and could inhibit P-glycoprotein (P-gp), the multidrug transporter, in the intestine to enhance the cytotoxicity of anticancer agents such as doxorubicin, vinblastine and paclitaxel which has low oral bioavailability [11, 12].

Paclitaxel is a well established antineoplastic drug which is originally extracted from the bark of Pacific yew or Western (Taxus brevifolid) [13]. It has excellent effects against a wide spectrum of cancers and its action mechanism has been intensively investigated [14]. Due to its very limited aqueous solubility, however, the only dosage form of paclitaxel available in its current clinical administration contains an adjuvant called Cremophor EL, which is a mixture of 50% polyoxyethylated castor oil and 50% dehydrated alcohol. This formulation has been demonstrated to cause some severe side effects including hypersensitivity reactions, nephrotoxicity, neurotoxicity, cardiotoxicity and so on [15, 16, 17]. Besides, this formulation can only be administered by intravenous (i.v.) infusion, which is inconvenient and irritating to patients and causes fluctuations of the drug concentration in the blood. The lack of optimal dosage form restricted further achievement of this novel drug and therefore the development of a safer and effective formulation devoid of Cremophor EL is an important investigational issue [18, 19]. Microencapsulation of paclitaxel in nanoparticles of biodegradable polymers and/or other mucoadhesive materials could provide an alternative dosage form for i.v. infusion and with further development for new administration route such as oral chemotherapy and for vascular tissue repair [20, 21]. The present work formed paclitaxel loaded polymeric nanoparticles by a modified solvent extraction/evaporation technique and appropriately coated with polyvinyl alcohol (PVA) which is one of the most commonly used surfactant stabiliser, PEG, as well as the TPGS. The perspective is given to the possible improvement of the surface coating in the physicochemical and pharmaceutical properties of paclitaxel loaded nanoparticles.

Amongst the techniques applied to form polymeric nanoparticles, the solvent extraction/evaporation method is widely adopted due to its being easy to manage and reproducible. In this method, a biodegradable polymer dissolved in an organic solvent is emulsified in an aqueous phase containing surfactant stabiliser, and the solvent evaporation leads to the formation of solid particles. Emulsifier or surfactant stabiliser plays a key role in separation of the two (oil/water) phases to form the emulsion or particles. The surfactant stabilises the dispersed-phase droplets formed during emulsification, inhibits coalescence of droplets and determines the particle size, size distribution, the morphological properties, the surface composition and the release property of the nanoparticles. Therefore, the key point related to this method is the possibility and status of surfactant binding on the particles’ surface. Since the surfactant molecules stay at the O/W interface during emulsification, there is a possibility of adsorption, attachment or chemical coupling of stabilisers onto the particles’ surface, which will alter the physicochemical properties of the surfaces. Surface modification of nanoparticles has been a useful strategy in achieving controlled and targeted release of active agent for a long circulation of period. However, improper coating of the surface may cause negative influence. For instance, nanoparticles with high amount of residual PVA may lower cellular uptake despite their smaller particle size [22]. It was normally considered that the attached hydrophilic PEG layer on particles surface provided a steric barrier to the adsorption of plasma components and as a consequence, opsonisation was greatly reduced. PEG coated particles thus had a long circulation time [23, 24]. TPGS is a new derivative from vitamin E and PEG. It is hydrophobic and hydrophilic, soluble in the oil and miscible with the water, and had a large molecular area. The unique nature made it act as a more efficient surfactant substance than PEG, which is hydrophilic only and often needs to be connected with some hydrophobic segment.

Materials and methods

Materials

Poly (dl-lactide-co-glycolide) (PLGA, L/G=75/25, MW 90,000–120,000) and polyvinyl alcohol (PVA, MW 30,000–70,000, with hydrolysis degree of 87 to 90%) were purchased from Sigma (Sigma Chemical Co., USA). Paclitaxel of 99.8% purity was purchased from Yunnan Hande Biotechnology Inc., China. d-α Tocopheryl polyethylene glycol 1000 succinate (TPGS) was purchased from Eastman Chemical Company, USA. Polyethylene glycol (PEG) 4000 was purchased from Fluka Chemie (Sigma Chemical Co.). Methylene chloride (dichloromethane, DCM, analytical grade) was purchased from Mallinckrodt (Mallinckrodt Laboratory Chemicals, Mallinckrodt Baker, Inc. USA). Acetonitrile used as mobile phase in high performance liquid chromatography (HPLC) was purchased from EM Science (ChromAR, HPLC grade, Mallinckrodt Baker, Inc. USA). Ultra-high pure water produced by UHQ Water Purification System (USF-ELGA lab water, Millipore Singapore Pte. Ltd.) was utilised for HPLC analysis. Deionised water was used throughout the experiment. All other chemicals used were of reagent grade.

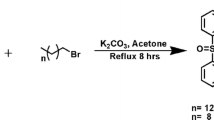

Nanoparticles preparation and coating

The nanoparticles were fabricated by a modified oil-in-water single emulsion solvent evaporation/extraction technique [10]. Typically, known masses of polymer, TPGS, and paclitaxel were dissolved in DCM, which was stirred until all materials were dissolved. The organic phase was poured into the aqueous solution containing one of the three surfactant substance TPGS, PVA or PEG and sonicated (Misonix Incorporated, USA). The formed o/w emulsion was stirred by magnetic stirrer continuously to evaporate off DCM. The resultant sample was separated and collected by centrifugation (12000 rpm, 15 min, 16 °C, 5810R, Eppendorf AG, 22331 Hamburg, Germany). The produced suspension was dried under lyophilisation (Alpha-2 Martin Christ Freeze Dryers, Germany) to obtain the fine powder of nanoparticles, which was kept in vacuum desiccators. Drug loading ratio was around 5% for the fabrication.

Nanoparticles characterisation

The size and size distribution were measured by laser light scattering (LLS, 90 Plus Particle Sizer, Brookhaven Instruments Corporation, USA). The dried powder samples were suspended in deionised water and sonicated slightly before measurement. The scanning electron microscopy (SEM, JSM-5600 LV, JEOL USA, Inc.) and atomic force microscopy (AFM, Multimode Scanning Probe Microscope, Digital Instruments, USA) were adopted to determine the shape and surface morphology of the nanoparticles. The amount of drug entrapped in the nanoparticles was determined in triplicate by HPLC (Agilent LC1100, Agilent Technologies, Singapore Pte Ltd, Singapore). Drug loaded nanoparticle powder (3 mg) were dissolved in 5 ml of pure acetonitrile and stirred by vortexer thoroughly. The resultant solution was filtered into vial for HPLC detection. Additionally, a recovery efficiency factor of the extraction procedure on the encapsulation efficiency was determined. The same amount of pure paclitaxel as loaded in the analysed nanoparticles and 3.0 mg of placebo nanoparticles or pure polymer were dissolved in 5 ml pure acetonitrile. The same procedure as above was carried out. The EE of paclitaxel was obtained as the mass ratio between the amount of paclitaxel incorporated in nanoparticles and that used in the nanoparticles preparation.

Surface analysis of nanoparticles

The X-ray photoelectron spectroscopy (XPS, Kratos Axis HSi, Kratos Analytical, Shimadzu Corporation, Japan) was utilised to analyse the surface composition. Peak curve fitting of the C1s envelope was performed using the software XPSPEAK Version 4.1. The Fourier transform infra-red spectroscopy (FTIR, Bio-Rad FTS-3500 FTIR, Excalibur Series, Bio-Rad Laboratories, Inc.) was also conducted with a photoacoustic spectroscopy technique (MTEC Model 300 Photoacoustic Detector System, MTEC Photoacoustic, Inc.). Nanoparticle powder samples were scanned in the IR range from 400 to 4000 cm−1, with a resolution of 8 cm−1 and carbon black reference. The detector was carefully purged by clean dry helium gas to increase the signal level and reduce moisture.

Paclitaxel in vitro release

The release rate of paclitaxel from the nanoparticles was determined in PBS medium (pH 7.4) by HPLC in triplicate. Paclitaxel loaded nanoparticles (5 mg) were suspended in 10 ml of buffer solution in a screw capped tubes and placed in an orbital shaker bath (GFL-1086, Lee Hung Technical Company, Bukit Batok Industrial Park A, Singapore), which was maintained at 37 °C and shaken horizontally at 110 min−1. At particular time interval, the tubes were taken out and centrifuged at 11,000 rpm for 15 min. The precipitated nanoparticles were re-suspended in 10 ml of fresh buffer before being put back into the shaker bath. The supernatant was taken for analysis of paclitaxel concentration. As with the measurement of EE, the extraction procedure needed to be analysed for the extraction recovery efficiency due to inefficient recovery.

Results and discussion

Three series of nanoparticle formulations were prepared with PVA, PEG and TPGS as the surfactant respectively. Furthermore, TPGS was also adopted to be a component material of nanoparticles matrix which was blended with PLGA at various molar ratios. The basic characters of various samples were outlined in Table 1. Samples P1 to P5 were PVA coated. Samples T1 to T5 were formed by applying TPGS as coating material. Samples G1 to G5 were coated with PEG.

Nanoparticles surface characterisation

XPS analysis

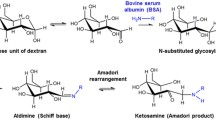

The envelope fit for the C1s regions was obtained by using the four main peaks corresponding to C-C/C-H (at about 283 eV), C-OH(R) (1.4–2.1 eV shift, the carbon next to the hydroxyl group), C-O-C=O (1.4–2.1 eV shift, the carbon of ester) and O-C=O (4.4±0.1 eV shift, the carbon in carboxylate) environments respectively [25, 26]. The chemical structures of the compounds encountered in the study were illustrated in Fig. 1. The comparison between synthesised nanoparticles and pure powder materials was done for analysis and the obtained results were summarised in Table 2. In the pure substances, PVA showed the expected presence of three carbon environments with 49.5% of the peak area contributed by the methylene (283.13 eV) groups, 43.4% methine α to the hydroxy (284.57 eV) and the remaining 9.9% of the C1s region derived from the nonhydrolysed acetate groups (287.63 eV). As for TPGS, three peaks can be observed, amongst which 46.9% referring to methyl/methylene groups (283.13 eV), 50.7% methine next to the hydroxy (284.57 eV) and 2.4% of the carbon in carboxylate (287.63 eV). It was noticeable that the difference in XPS spectra between PVA and TPGS was the opposite proportion of the peaks contributed by the methyl/methylene groups and the carbon next to hydroxy or hydroxyl group. The XPS data for PEG showed one peak from the ether carbons (284.47 eV). In the case of PLGA, the expected three peaks corresponded to the 39.7% methyl/methylene groups (283.23 eV), 35.1% carbon of ester group (284.93 eV) and 25.2% of the carbon in carboxylate (287.73 eV). After formulation, nanoparticle samples of various recipes gave all four peaks. In comparison with the XPS spectrum of pure PLGA, the data from all nanoparticles displayed a significant increase in the C1s region of C-OH(R) and decrease in both the C1s of C-O-C=O and that of O-C=O. This demonstrated that each of the surfactant substance was adsorbed or coated on the nanoparticle surface. The retaining of C1s envelope corresponding to C-O-C=O indicated the existence of PLGA at the particles surface. The result revealed that the surface of the nanoparticles was composed of both the matrix material PLGA and the surfactant stabiliser. By analysing the percentage of C1s envelopes corresponding to C-O-C=O (higher in pure PLGA) and C-OH(R) (higher in nanoparticles), it may be inferred that the distribution of PLGA on the particles surface was less than that of the surfactant coating substance, i.e. the nanoparticles’ surface is dominated by the surfactant molecules. Additionally, referring to the C-OH(R) envelope coming from coating substance, the ratio of this carbon environment percentage between the PVA coated nanoparticles and the pure PVA material was almost the same as that obtained for TPGS coated samples. However, it was higher than that for PEG coated nanoparticles. The result may suggest that the surfactant molecules of PVA or TPGS surrounding the particles surface were more than those of PEG. This may imply either PEG was easy to remove in the washing process, or it was not as efficient a coating surfactant as PVA and TPGS. Additionally, the ratio of TPGS to PLGA of matrix material had no significant influence on the surface coating.

For all samples, the elemental ratios of C and O were similar and did not seem to be affected significantly by the process. The O ratio for the PEG coated particles was notably lower than the pure material, which may indicate the less distribution of PEG on its coated nanoparticle surface. Moreover, several samples showed non-zero percentages for element N although the percentage was quite low, which may suggest a little presence of drug near or at the surface of nanoparticles randomly, which can influence the in vitro release behaviour by showing an initial burst. It is understandable, however, that the drug was more concentrated inside the nanoparticles as paclitaxel is highly hydrophobic and tends to stay away from aqueous environment.

FTIR analysis

To reach a better understanding of the surface chemistry of nanoparticles, the Fourier transform infra-red photoacoustic spectroscopy (FTIR-PAS) technique was employed, which can measure a sample’s absorbance spectrum rapidly and directly from a controllable sampling depth with little or no sample preparation. As a comparison, the pure materials in powder were also measured. It could be seen that there was a significant difference in the whole FTIR absorbance spectra amongst various pure materials both in the shape and in the position of the absorption peaks. The spectra of TPGS and PEG were similar except the latter lacks the peak corresponding to the carbonyl –C=O stretching vibrations (~1700 cm−1). All series of prepared nanoparticles were measured and the obtained spectra are illustrated in Fig. 2. In comparison of the absorbance spectra between the nanoparticles and the corresponding pure materials, it could be observed that the characteristic absorption peaks corresponding to both of the polymer material and the surface coating material appeared from all relevant particles. All samples showed the main peaks contributed by the functional groups of PLGA such as -CH, -CH2, -CH3 (2800–3000 cm−1), carbonyl -C=O (1650–1750 cm−1), C-O (1050–1250 cm−1), etc. The noted distinction between the nanoparticles and the PLGA came from the absorption feature in the region 2800–3500 cm−1. Also, the diversity amongst various nanoparticles could be related to this wave number range, although most of the absorption peaks overlapped to large extent. PEG coated nanoparticles gave strong peak absorbance corresponding to the functional groups of PEG such as C-O stretching (~1050 cm−1), -CH stretching of -CH2 (2800–2880 cm−1) and -CH bending regions of -CH2 (~1450 cm−1). TPGS coated nanoparticles showed all the features of PEG coated nanoparticles, for which the absorption peak of -CH stretching of -CH3 (2950–3000 cm−1) was strong. This agreed with the more -CH3 in the chemical structure of TPGS. As for the PVA coated nanoparticles, the strong and broad peak of -OH stretching vibrations (~3300 cm−1) was clearly different from the PEG and TPGS coated particles and quite close to the pure substance of PVA both in shape and in position. The FTIR analysis indicated that each coating material had distribution on the nanoparticles surface. It also showed the presence of the specific functional groups of both the polymer material and the surface coating material on the particles surface. The result confirmed that obtained from the XPS analysis.

Morphology and particle size

The AFM images showed in Fig. 3 indicated that TPGS coated nanoparticles displayed in spherical shapes. The distinct spherical nanoparticles could be observed either for the single nanoparticle or for a handful of the nanoparticles. The particles were sorted out well from each other without aggregation or cohesion. The surface was relatively smooth within the resolution. However, PEG coated particles appeared to be aggregated and not as homogenous (the image was not showed).

The mean size averaged by particle volume and polydispersity of all samples determined after freeze drying is included in Table 1. It could be seen that the size of particles coated with PVA was in the range from 299 to 545 nm with narrow polydispersity, particles coated with TPGS was 450 to 770 nm, and PEG coated was 671 to 869 nm with big polydispersity. This may imply again that PEG is not as effective for surfactant as PVA and TPGS regarding the fabricating technique applied. It is understandable as PEG is hydrophilic while TPGS is an amphiphilic substance which is not only possess bulky figure and large surface area, but also miscible with either the water or the oil phase. This is a characteristic of advantages which makes TPGS superior to many other surfactants such as PVA and PEG. On the other hand, the particle size was detected after freeze drying during which, there is a tendency for small nanoparticles to aggregate and generate a variety of freezing and drying stresses. This process may induce particle surface modification resulting in the formation of aggregates and it is one disadvantage of freeze-drying technique [27].

Drug encapsulation efficiency (EE) and in vitro release of paclitaxel

The EE data were listed in Table 1. Obviously, TPGS coated particles had highest EE while PVA coated ones got lower EE which was even lower than PEG coated particles. The result agreed with our previous work [10]. Another interesting thing might be referred to the PLGA/TPGS nanoparticles. When TPGS or PEG was used as surfactant, there was a trend to show that when the blending ratio of TPGS to PLGA in the matrix material was increased, the drug EE raised accordingly. This may indicate a favourable interaction amongst the polymer, TPGS/PEG, and the paclitaxel.

The cumulative release behaviour for all paclitaxel loaded nanoparticles was determined under in vitro condition and the typical profiles are shown in Fig. 4. Clearly, both of the surface coating and the TPGS blending into matrix material significantly influenced the in vitro release property. The release profiles showed three stages for all the formulations. The initial burst release was displayed in the first day and then the release kept a relatively slow increasing rate of a near zero order till a constant but retarded plateau stage. Similar to our preliminary work, the TPGS coated particles gave a slower release rate. With regard to the blend ratio of TPGS and PLGA encountered in the material matrix, when the amount of TPGS was more than that of PLGA, the release became faster than that for the TPGS/PLGA nanoparticles of less TPGS. Furthermore, in comparison of the release curves for various nanoparticles of the same TPGS/PLGA blend ratio, it was noticeable that the hydrophilic PEG coated particles displayed even faster release rate than both the PVA coated particles and TPGS coated particles. The explanation may also be referred to the interaction amongst the substances used in the formulation. Due to the special nature of TPGS, which was both hydrophobic and hydrophilic, soluble in both the oil and the water phase and had large molecular area and twice molecular weight of paclitaxel, its blending into the polymer matrix could affect or modulate the interaction among the drug and the matrix material and thus influence the release behaviour.

In vitro release profiles of paclitaxel from different nanoparticles formulations: a TPGS coated nanoparticles with different ratio of TPGS and PLGA as matrix material (ratio of TPGS-PLGA: T1 (3:1), T2 (1:1), T3 (1:3), T4 (1:10), T5 (0:1)); b TPGS-PLGA (1:3) nanoparticles coated with different surfactant (V3: PVA coating; T3: TPGS coating; G3: PEG coating))

Conclusion

The present paper proposed a few formulations of paclitaxel loaded PLGA nanoparticles of appropriate surface coating by PVA, PEG or a novel surfactant stabiliser—TPGS, which can also be blended with PLGA as the nanoparticle matrix material. XPS and FTIR study revealed that the surfactants do dominate on the nanoparticles surface. AFM and SEM observation indicated that the coated nanoparticles displayed in spherical shape with relative smooth surface within the resolution scope of the equipment. The particle size and size distribution showed close relation to the surface coating, which may also be responsible for the drug encapsulation efficiency and the in vitro release kinetics. The investigation confirmed our perspective that TPGS could be more efficient surfactant than PVA and PEG in emulsification to fabricate anticancer drug loaded polymeric nanoparticles.

References

Soppimath KS, Aminabhavi TM, Kulkarni AR, Rudzinski WE (2001) J Cont Rel 70:1

Moghimi SM, Hunter AC, Murray JC (2001) Pharmacol Rev 53:283

Bazile D, Ropert C, Huve P, Verrecchia T, Marlard M, Frydman A, Veillard M, Spenlehauer G (1992) Biomaterials 13:1093

Le Ray AM, Vert M, Gautier JC, Benoit JP (1994) Int J Pharm 106:201

Panagi Z, Beletsi A, Evangelatos G, Livaniou E, Ithakissios DS, Avgoustakis K (2001) Int J Pharm 221:143

Gref R, Domb A, Quellec P, Blunk T, Muller RH, Verbavatz JM, Langer R (1995) Adv Drug Deliv Rev 16:215

Torchilin VP, Papisov MI (1994) J Liposomes Res 4:725

Stolnik S, Dunn SE, Garnett MC, Davies MC, Coombes AGA, Taylor DC, Irving MP, Purkiss SC, Tadros TF, Davis SS, Illum L (1997) Pharm Res 14:657

Gref R, Minamitake Y, Peracchia MT, Trubetskoy V, Torchilin VP, Langer R (1994) Science 263:1600

Mu L, Feng SS (2003) J Controlled Release 86:33

Katrijn B, Francoise EB, Jochem A, Jurgen D (2003) J Pharm Sci 92:1250

Dintaman JM, Silverman JA (1999) Pharm Res 16:1550

Wani MC (1971) J Am Chem Soc 93: 2325

Horwitz SB (1992) Trends Pharmacol Sci 13:134

Weiss RB, Donehower RC, Wiernik PH, Ohnuma T, Gralla RJ, Trump DL, Baker JR, Van Echo DA, Von Hoff DD, Leyland-Jones B (1990) J Clin Onco l8:1263

Dorr RT (1994) Ann Pharmacother 28: S11

Sparreboom A, van Zuylen L, Brouiwr E, Loos WJ, de Bruijn P, Gelderblom H, Pillay M, Nooter K, Stoter G, Verweij J (1999) Cancer Res 59:1454

Terwogt JMM, Nuijen B, Huinink WWT, Beijnen JH (1997) Cancer Treatment Rev 23:87

Singla AK, Garg A, Aggarwal D (2002) Int J Pharm 235:179

Brannon-Peppas L (1995) Int J Pharm 116:1

Zeltner TB, Sweeney TD, Skornik WA, Feldman HA, Brain JD (1991) J Appl Physiol 70:1137

Sahoo SK, Panyam J, Prabha S, Labhasetwar V (2002) J Controlled Release 82:105

Harper GR, Davis SS, Davies MC, Norman ME, Tadros TF, Taylor DC, Irving MP, Walters JA, Watts JF (1995) Biomaterials 16:427

Stolnik S, Dunn SE, Garnett MC, Davies MC, Coombes AGA, Illum L, Davis SS, Taylor DC, Irving MP, Purkiss SC, Tadros TF (1994) Pharm Res 11:1800

Scholes PD, Coombes AGA, Illum L, Davis SS, Watts JF, Ustariz C, Vert M, Davies MC (1999) J Controlled Release 59:261

Briggs D, Seah MP (1990), Practical surface analysis by Auger and X-ray photoelectron spectroscopy. Wiley, Chichester

Konan YN, Gurny R, Allemann E (2002) Int J Pharm 233:239

Acknowledgment

The authors acknowledge with thanks the financial support of the Singapore-MIT Alliance (SMA) Programme: Innovation in Manufacturing Systems and Technology (IMST), Nanyang Technological University, Singapore; and the Research Grants R-397–000–001–112 from the Division of Bioengineering, National University of Singapore.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mu, L., Seow, PH., Ang, SN. et al. Study on surfactant coating of polymeric nanoparticles for controlled delivery of anticancer drug. Colloid Polym Sci 283, 58–65 (2004). https://doi.org/10.1007/s00396-004-1090-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-004-1090-7