Abstract

The paper presents a novel nonlocal strain gradient isogeometric model for functionally graded carbon nanotube-reinforced composite (FG-CNTRC) nanoplates. To observe the length scale and size-dependency effects of nanostructures, the nonlocal strain gradient theory (NSGT) is considered. The present model is efficient to capture both nonlocal effects and strain gradient effects in nanoplate structures. In addition, the material properties of the FG-CNTRC are assumed to be graded in the plate thickness direction. Based on the higher order shear deformation theory (HSDT), the weak form of the governing equations of motion of the nanoplates is presented using the principle of virtual work. Afterward, the natural frequency and deflection of the nanoplates are made out of isogeometric analysis (IGA). Thanks to higher order derivatives and continuity of NURBS basic function, IGA is suitable for the weak form of NSGT which requires at least the third-order derivatives in approximate formulations. Effects of nonlocal parameter, strain gradient parameter, carbon nanotube (CNT) volume fraction, distributions of CNTs and length-to-thickness ratios on deflection and natural frequency of the nanoplates are examined and discussed in detail. Numerical results are developed to show the phenomenon of stiffness-softening and stiffness-hardening mechanisms of the present model.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Due to superior features, carbon nanotubes (CNTs) are considered as “new materials for the twenty-first century” [1] and a potential constituent of reinforcement for nanocomposites, and the strongest and the most prevalent and resilient material. Therefore, CNTs have many attached attentions from scientists and open a new research direction in nanotechnology.

With the advantageous of functionally graded/composites materials, a lot of numerical methods has been devised to study these materials such as smoothed finite element methods [2,3,4], isogeometric analysis [5, 6]. To study mechanical behaviors of CNTs, two popular models including continuum mechanics (CM) and molecular dynamics (MD) are often used. The MD can predict micro/nanostructures with the high precision, but there are some limitations to computationally expensive costs and calculating on too short time scale. Therefore, it must currently be left to CM for simulating of longer times and large systems. To overcome these shortcomings, several CM theories have been developed and used such as the first- and second-order strain gradient theory of Mindlin [7, 8], the nonlocal elasticity theory [9], the first-order strain gradient theory [10, 11], the second-order strain gradient theory [12,13,14], couple stress theory [15], modified couple stress theory [16] and modified strain gradient elasticity theory [17], etc. In those models, effect of nonlocal elasticity or strain gradient is only considered. Hence, Lim et al. [18] combined nonlocal elasticity and strain gradient effects to propose the nonlocal strain gradient theory (NSGT). Xu et al. [19] studied analytical solutions of bending and buckling analyses of Euler–Bernoulli beams using NSGT. Size-dependent analysis based NSGT and finite element method for bending, buckling, and free vibration responses of nanobeams was developed by Rajasekaran and Khaniki [20]. Li and Hu [21] used NSGT to investigate analytical solutions of nonlinear bending deflections and free vibration frequency of functionally graded nanobeams. Bending and buckling analyses of nanobeams using analytical methods based on NSGT [22] were reported. In their model, both Euler–Bernoulli and Timoshenko nanobeams were considered. Free vibration analysis of isotropic nanoplates [23] and buckling analysis of orthotropic nanoplates in thermal environment [24] using NSGT and analytical solutions was also developed. Arefi et al. [25] studied bending analysis of a sandwich porous nanoplate integrated with piezoelectric. Transient responses of porous functionally graded nanoplates under various pulse loads were reported in Ref. [26]. Geometrically nonlinear vibration analysis of sandwich nanoplates was performed by Nematollahi and Mohammadi [27]. Jalaei and Thai [28] studied the dynamic stability of viscoelastic porous FG nanoplate under longitudinal magnetic field. For nanoshell structures, buckling and post-buckling behaviors [29], wave dispersion analysis [30], and free vibration analysis [31] have also examined.

In sum, available studies have only focused on using analytical methods based on NSGT to calculate and simulate nanostructures. As we have known, analytical solutions are suitable for the problems with simple geometries and boundary conditions. It is very difficult to apply real structures in practices. So, numerical methods have been developed and considered as a potential candidate to perform the real structures. To the best of author’s knowledge, a combination of NSGT and numerical methods has not been studied and published in the literature so far. Hence, this topic is very potential and interesting for researchers to explore. Due to that lack of the researches, the authors intend to fill this gap in the literature by developing a size-dependent numerical model using NSGT theory for nanoplate structures and plate structures. In nanoplates and plate structures, it always requires higher order continuity of basic functions for higher order derivative of approximate variables. IGA with NURBS basis functions proposed by Hughes and coworkers [32] can be considered as a very strong candidate to study plate structures. Nguyen et al. [33] reported an overview and computer implementation aspects of IGA. To express local refinement, an approach to generalize the geometry independent field approximation approach [34,35,36,37] was also proposed. This provides greater flexibility in the choice of the discretisation for the geometry and the field variables, hence allow accounting for localisation and local refinement without refining the patch in all coordinate directions and shows good convergence of IGA compared to alternatives [5, 6, 38]. The IGA has been successfully developed and applied to investigate size-dependent plate problems such as nonlocal theory [39,40,41,42,43], modified strain gradient elasticity theory [44, 45], modified couple stress theory [46, 47], structures with cutout [38, 48,49,50], locking free in plate/shell structures [38, 51,52,53,54] etc. Therefore, in this study, a novel size-dependent nonlocal strain gradient isogeometric model for static and free vibration analyses of functionally graded carbon nanotube-reinforced composites is developed.

2 Theoretical formulation

2.1 Functionally graded carbon nanotube-reinforced composite materials

Four configurations of CNTs including UD, FG-V, FG-O, and FG-X can be formulated as

where

in which \(w_{{{\text{CNT}}}}\) is the mass fraction of CNTs.

Based on the rule of mixtures, the effective material properties are expressed as

where \(\nu_{{{12}}}^{{{\text{CNT}}}} ,\,\,\rho_{{}}^{{{\text{CNT}}}}\) and \(\nu^{{\text{m}}} ,\,\,\rho^{{\text{m}}}\) are Poisson’s ratio and density of CNTs and matrix, respectively; \(E^{{\text{m}}}\) and \(G^{{\text{m}}}\) are the Young’s modulus and shear modulus of the isotropic matrix; \(E_{{{11}}}^{{{\text{CNT}}}}\), \(E_{{{22}}}^{{{\text{CNT}}}}\) and \(G_{{{12}}}^{{{\text{CNT}}}}\) are the Young’s and shear modulus of CNTs; \(\eta_{1} ,\,\,\eta_{2}\) and \(\eta_{3}\) are CNT efficiency parameters listed in Table 1; \(V_{{{\text{CNT}}}}\) and \(V_{{\text{m}}}\) are the CNTs and matrix volume fractions, in which \(V_{{{\text{CNT}}}} + V_{{\text{m}}} = 1\).

2.2 Nonlocal strain gradient theory (NSGT)

Equations of motion of nonlocal elastic solids are given as follows

where \(t_{ij}\) is the total nonlocal stress components; fi and \(g_{i} \, \) are the body force and traction components, respectively; \(\rho\) is density mass; \(\ddot{u}_{i}\) is the acceleration field; V is the volume and S is the Neumann boundary.

Based on the NSGT [18], the nonlocal stress tensor is expressed by

where

in which \(t_{ij}^{0}\) and \(t_{ij}^{1}\) are the nonlocal stress and higher order stress tensors; \(\alpha \left( {\left| {{\mathbf{x^{\prime}}} - {\mathbf{x}}} \right|} \right)\) is the nonlocal kernel function; \({\mathbf{x}}\) is a reference point in the body; l is the material length scale parameter; \(\nabla = \frac{\partial }{\partial x} + \frac{\partial }{\partial y}\) is the differential operator; \(\sigma_{ij}\) is the local Cauchy stress tensors of classical elasticity theory and satisfies

where \(\varepsilon_{kl}\) is strain components; \(C_{ijkl}\) is elastic modulus coefficients and \(u_{k}\) is displacements.

Using the special Helmholtz averaging kernel, the nonlocal constitutive in Eq. (11) can be rewritten as [55]

where \(L = \left( {1 - \mu \nabla^{2} } \right)\) defines the linear differential operator, in which \(\nabla^{2} = \frac{{\partial^{2} }}{{\partial x^{2} }} + \frac{{\partial^{2} }}{{\partial y^{2} }}\) and \(\lambda = l^{2}\).

Similarly, Eq. (8) can be represented by

Substituting Eq. (13) into Eq. (14), the equilibrium equation is performed as

Applying the principle of virtual displacement, Eq. (15) can be presented

where \(\delta u_{i}\) is the virtual displacement.

The first term in Eq. (16) can be given by applying the integration by parts and divergence theorem

Similarly, the second term in Eq. (16) can be rewritten as

Substituting Eqs. (17) and (18) into Eq. (16), the final equation is expressed as

The traction on the Neumann boundary in this study is ignored, Eq. (19) is rewritten as

Using the symmetric condition, the virtual displacement vector can be defined as

Substituting Eq. (21) into Eq. (20), the final form is described as

3 Displacement field

Based on HSDT [56], the displacement components can be formulated as

where

in which u, v and w are the in-plane and transverse displacement components, respectively; \(\theta_{x}\) and \( \, \theta_{y}\) are two rotations; \( \beta _{x} = w_{{,x}} {\text{ and }}\beta _{y} = w_{{,y}} \); \(f\left( z \right) = z - 4z^{3} /3h^{2}\) [57].

The bending and shear strain components are defined as

where

in which \(f^{\prime}(z) = 1 - 4z^{2} /h^{2}\).

The constitutive relations can be defined as

where

Substituting Eqs. (25) and (27) into Eq. (22), the discrete equations for bending analysis of the nanoplates subjected to a transverse load \(f_{0}\) can be described as [58]:

where

Similarly, the discrete equations for free vibration analysis are expressed as

where

where \({\mathbf{I}}_{3x3}\) is the identity matrix of size 3 × 3.

3.1 The NSGT formulation using NURBS basis function

The displacements using NURBS basis functions can be expressed as

where \({\mathbf{q}}_{I}\) is a vector that contains degrees of freedom combined with the control point I; NI is the shape function defined as in Ref. [32].

Substituting Eq. (33) into Eq. (26), Eq. (26) can be rewritten as:

where

Inserting Eq. (33) into Eq. (24), Eq. (24) can be performed

where

Inserting Eqs. (34) and (36) into Eqs. (29) and (31), respectively, the final compact forms are expressed as follows:

where \({\mathbf{K}}\), \({\mathbf{M}}\) and \({\mathbf{f}}\) are the global stiffness matrix, mass matrix and force vector defined as

in which \(\omega\) and \({\overline{\mathbf{q}}}\) are the natural frequency and modes shape, respectively.

4 Numerical examples

4.1 Verification

4.1.1 Strain gradient effect

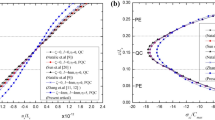

We now consider an isotropic square plate (length a = 10, thickness h). Material properties can be given as Young’s modulus E = 30 × 106, Poisson’s ratio v = 0.3 and density mass \(\rho = 2300\) kg/m3. Without nonlocal effects, the present model is Aifantis’s pure strain gradient theory [10]. Analytical and finite element solutions based on Kirchhoff theory were investigated by Babu and Patel [59]. Effects of length scale parameter on convergence studies of the normalized first natural frequency and central deflection of the isotropic plate are listed in Tables 2 and 3, respectively. According to Ref. [59], FEM-C and FEM-NC were conforming and nonconforming finite elements. We see that the convergence of the proposed method is really good and the present results match very well with reference solutions. Besides, an increase of length scale parameter leads to a rise of the natural frequency and a decrease of the central deflection of the plate. Hence, it can be found that using strain gradient theory makes the stiffness of the plate rise.

4.1.2 Nonlocal effect

In this section, nonlocal effect on FG-CNTRC nanoplates is studied. The matrix is made of PmPV with \(E^{m} = 2.1\,\,{\text{GPa,}}\) \(\nu^{m} = 0.34,\) \(\rho^{m} = 1.16\,\,{\text{g/cm}}^{{2}}\), and the reinforcements are (10,10) SWCNTs with \(E_{{{11}}}^{{{\text{CNT}}}} \, = 5.6466\,{\text{(TPa),}}\,\,E_{{{22}}}^{{{\text{CNT}}}} \, = 7.08\,{\text{(TPa),}}\,\,G_{{{12}}}^{{{\text{CNT}}}} \, = 1.9445\,{\text{(TPa),}}\,\,\alpha_{{{11}}}^{{{\text{CNT}}}} = 3.4584{,}\,\,\alpha_{{{22}}}^{{{\text{CNT}}}} = 5.1682\), and G23 = G13 = G12.

First, a simply supported (SSSS) square nanoplate (length a = 1, µ = 1.5) is considered. Without strain gradient effects, the proposed model becomes Erigen’s nonlocal elasticity theory model. Table 4 shows the first three non-dimensional frequencies of the FG-CNTRC nanoplate. We observe that the present results match very well with reference solutions [43] for all cases of a/h and \(V_{{{\text{CNT}}}}^{*}\).

Next, the central deflection of SSSS FG-CNTRC square nanoplate (length a = 1, a/h = 50) under a uniform load f0 = 0.1 × 104 is investigated. Effect of nonlocal parameter on defection of the nanoplate is indicated in Table 5. Again, we can see that an excellent agreement between the present results and reference ones [43] is obtained. Besides, the deflection of the nanoplate increases with a rise of the nonlocal parameter. So, we also find that the stiffness of the plate decreases once using the Erigen’s nonlocal elasticity theory.

4.2 Square plate

To consider both strain gradient and nonlocal effects in nanoplates, a FG-CNTRC square nanoplate (length a = 1) is exampled.

First, effect of length scale and nonlocal parameters on free vibration analysis of the nanoplate is investigated. Table 6 shows the first five frequencies of the fully clamped (CCCC) nanoplate. It can be seen that the natural frequencies decrease with a rise of the nonlocal parameter and increase with a rise of both the length scale parameter and length-to-thickness ratio. Table 7 lists the first natural frequency of the SSSS FG-CNTRC square nanoplate with a/h = 50. Again, we can see that when the length scale parameter increases the natural frequency increases as well, while the natural frequency reduces when the nonlocal parameter rises.

Next, effect of length scale and nonlocal parameters on deflection of the SSSS square nanoplate (length a = 1, a/h = 50) subjected to a uniform load f0 = 0.1 × 104 is examined. Deflections of the SSSS FG-CNTRC square nanoplate are indicated in Table 8. We can see that the deflection increases with a rise of the nonlocal parameter and decreases with an increase of the length scale parameter. Besides, we can see the smallest deflection in FG-X case and the largest deflection in FG-O case. So, the FG-X pattern can be considered the best reinforcement.

As obtained in results of static and free vibration analyses of the plates, it is observed that mechanical characteristics of the nanoplates including stiffness-softening and stiffness-hardening mechanisms are significantly influenced using the NSGT.

4.3 Circular plate

A fully clamped FG-CNTRC circular nanoplate with radius R is now considered. Effects of length scale and nonlocal parameters on the first natural frequency of the nanoplate with R/h = 10 and 20 are listed in Tables 9 and 10, respectively. Again, the non-dimensional natural frequency of the nanoplate decreases with an increase of the nonlocal parameter and increases with a rise of the length scale parameter. Therefore, it can be observed that the phenomenon of stiffness-softening and stiffness-hardening mechanisms is found using the NSGT.

5 Conclusions

In this paper, a novel nonlocal strain gradient isogeometric model for FG-CNTRC nanoplates was proposed. The material properties of the FG-CNTRC are assumed to be graded in the thickness direction. To consider the length scale and size-dependency effects of nanostructures, the nonlocal strain gradient theory (NSGT) was considered. Through the numerical results, it can be withdrawn some interesting points:

-

1.

The proposed model is capable of capturing both nonlocal effects and strain gradient effects in nanoplate structures.

-

2.

The governing equation is approximated using isogeometric analysis (IGA) which easily satisfy at least the third-order derivatives in weak form of nanoplates.

-

3.

Phenomenon of stiffness-softening and stiffness-hardening mechanisms of the proposed model was fully observed.

-

4.

The distribution of CNTs has a lot of influence the stiffness of the plate.

References

Harris P (2001) Carbon nanotubes and related structures: new materials for the twenty-first century. Cambridge University Press, Cambridge

Nguyen-Xuan H, Liu G, Thai-Hoang C, Nguyen-Thoi T (2010) An edge-based smoothed finite element method (ES-FEM) with stabilized discrete shear gap technique for analysis of Reissner-Mindlin plates. Comput Methods Appl Mech Eng 199(9–12):471–489

Phung-Van P, Nguyen-Thoi T, Le-Dinh T, Nguyen-Xuan H (2013) Static and free vibration analyses and dynamic control of composite plates integrated with piezoelectric sensors and actuators by the cell-based smoothed discrete shear gap method (CS-FEM-DSG3). Smart Mater Struct 22(9):095026

Phung-Van P, Nguyen-Thoi T, Luong-Van H, Lieu-Xuan Q (2014) Geometrically nonlinear analysis of functionally graded plates using a cell-based smoothed three-node plate element (CS-MIN3) based on the C0-HSDT. Comput Methods Appl Mech Eng 270:15–36

Nguyen-Xuan H, Tran LV, Thai CH, Kulasegaram S, Bordas SPA (2014) Isogeometric analysis of functionally graded plates using a refined plate theory. Compos B Eng 64:222–234

Thai CH, Nguyen-Xuan H, Bordas SPA, Nguyen-Thanh N, Rabczuk T (2015) Isogeometric analysis of laminated composite plates using the higher-order shear deformation theory. Mech Adv Mater Struct 22(6):451–469

Mindlin RD, Eshel NN (1968) On first strain-gradient theories in linear elasticity. Int J Solids Struct 4(1):109–124

Mindlin RD (1965) Second gradient of strain and surface-tension in linear elasticity. Int J Solids Struct 1(4):417–438

Eringen AC (1972) Nonlocal polar elastic continua. Int J Eng Sci 10(1):1–16

Aifantis EC (1992) On the role of gradients in the localization of deformation and fracture. Int J Eng Sci 30(10):1279–1299

Aifantis EC (1999) Strain gradient interpretation of size effects. Int J Fract 95(1):299

Polizzotto C (2003) Gradient elasticity and nonstandard boundary conditions. Int J Solids Struct 40(26):7399–7423

Polizzotto C (2013) A second strain gradient elasticity theory with second velocity gradient inertia—part I: constitutive equations and quasi-static behavior. Int J Solids Struct 50(24):3749–3765

Polizzotto C (2013) A second strain gradient elasticity theory with second velocity gradient inertia—part II: dynamic behavior. Int J Solids Struct 50(24):3766–3777

Toupin RA (1962) Elastic materials with couple-stresses. ARCH RATION MECH AN 11(1):385–414

Yang F, Chong ACM, Lam DCC, Tong P (2002) Couple stress based strain gradient theory for elasticity. Int J Solids Struct 39(10):2731–2743

Lam DCC, Yang F, Chong ACM, Wang J, Tong P (2003) Experiments and theory in strain gradient elasticity. J Mech Phys Solids 51(8):1477–1508

Lim CW, Zhang G, Reddy JN (2015) A higher-order nonlocal elasticity and strain gradient theory and its applications in wave propagation. J Mech Phys Solids 78:298–313

Xu X-J, Wang X-C, Zheng M-L, Ma Z (2017) Bending and buckling of nonlocal strain gradient elastic beams. Compos Struct 160:366–377

Rajasekaran S, Khaniki HB (2017) Bending, buckling and vibration of small-scale tapered beams. Int J Eng Sci 120:172–188

Li L, Hu Y (2016) Nonlinear bending and free vibration analyses of nonlocal strain gradient beams made of functionally graded material. Int J Eng Sci 107:77–97

Lu L, Guo X, Zhao J (2017) A unified nonlocal strain gradient model for nanobeams and the importance of higher order terms. Int J Eng Sci 119:265–277

Farajpour A, Yazdi MRH, Rastgoo A, Mohammadi M (2016) A higher-order nonlocal strain gradient plate model for buckling of orthotropic nanoplates in thermal environment. Acta Mech 227(7):1849–1867

Nematollahi MS, Mohammadi H, Nematollahi MA (2017) Thermal vibration analysis of nanoplates based on the higher-order nonlocal strain gradient theory by an analytical approach. Superlattices Microstruct 111:944–959

Arefi M, Kiani M, Rabczuk T (2019) Application of nonlocal strain gradient theory to size dependent bending analysis of a sandwich porous nanoplate integrated with piezomagnetic face-sheets. Compos B Eng 168:320–333

Mirjavadi SS, Afshari BM, Barati MR, Hamouda AMS (2019) Transient response of porous FG nanoplates subjected to various pulse loads based on nonlocal stress-strain gradient theory. Eur J Mech A Solids 74:210–220

Nematollahi MS, Mohammadi H (2019) Geometrically nonlinear vibration analysis of sandwich nanoplates based on higher-order nonlocal strain gradient theory. Int J Mech Sci 156:31–45

Jalaei MH, Thai H-T (2019) Dynamic stability of viscoelastic porous FG nanoplate under longitudinal magnetic field via a nonlocal strain gradient quasi-3D theory. Compos B Eng 175:107164

Sahmani S, Fattahi AM (2018) Small scale effects on buckling and postbuckling behaviors of axially loaded FGM nanoshells based on nonlocal strain gradient elasticity theory. Appl Math Mech 39(4):561–580

Karami B, Janghorban M, Tounsi A (2018) Variational approach for wave dispersion in anisotropic doubly-curved nanoshells based on a new nonlocal strain gradient higher order shell theory. Thin-Walled Struct 129:251–264

Ghorbani K, Mohammadi K, Rajabpour A, Ghadiri M (2019) Surface and size-dependent effects on the free vibration analysis of cylindrical shell based on Gurtin-Murdoch and nonlocal strain gradient theories. J Phys Chem Solids 129:140–150

Hughes TJR, Cottrell JA, Bazilevs Y (2005) Isogeometric analysis: CAD, finite elements, NURBS, exact geometry and mesh refinement. Comput Methods Appl Mech Eng 194(39):4135–4195

Nguyen VP, Anitescu C, Bordas SPA, Rabczuk T (2015) Isogeometric analysis: An overview and computer implementation aspects. Math Comput Simulat 117:89–116

Atroshchenko E, Tomar S, Xu G, Bordas SPA (2018) Weakening the tight coupling between geometry and simulation in isogeometric analysis: From sub- and super-geometric analysis to Geometry-Independent Field approximaTion (GIFT). Int J Numer Meth Eng 114(10):1131–1159

Marussig B, Zechner J, Beer G, Fries T-P (2015) Fast isogeometric boundary element method based on independent field approximation. Comput Methods Appl Mech Eng 284:458–488

Videla J, Anitescu C, Khajah T, Bordas SP, Atroshchenko E (2019) h-and p-adaptivity driven by recovery and residual-based error estimators for PHT-splines applied to time-harmonic acoustics. Comput Math Appl. 2019:8

Hu Q, Chouly F, Hu P, Cheng G, Bordas SP (2018) Skew-symmetric Nitsche’s formulation in isogeometric analysis: Dirichlet and symmetry conditions, patch coupling and frictionless contact. Comput Methods Appl Mech Eng 341:188–220

Valizadeh N, Natarajan S, Gonzalez-Estrada OA, Rabczuk T, Bui TQ, Bordas SP (2013) NURBS-based finite element analysis of functionally graded plates: static bending, vibration, buckling and flutter. Compos Struct 99:309–326

Phung-Van P, Ferreira AJM, Nguyen-Xuan H, Abdel WM (2017) An isogeometric approach for size-dependent geometrically nonlinear transient analysis of functionally graded nanoplates. Compos B Eng 118:125–134

Phung-Van P, Thai CH, Nguyen-Xuan H, Abdel WM (2019) Porosity-dependent nonlinear transient responses of functionally graded nanoplates using isogeometric analysis. Compos B Eng 164:215–225

Phung-Van P, Thai CH, Abdel-Wahab M, Nguyen-Xuan H (2020) Optimal design of FG sandwich nanoplates using size-dependent isogeometric analysis. Mech Mater 142:103277

Phung-Van P, Thai CH, Nguyen-Xuan H, Abdel-Wahab M (2019) An isogeometric approach of static and free vibration analyses for porous FG nanoplates. Eur J Mech A/Solids. 2019:103851

Phung-Van P, Lieu QX, Nguyen-Xuan H, Wahab MA (2017) Size-dependent isogeometric analysis of functionally graded carbon nanotube-reinforced composite nanoplates. Compos Struct 166:120–135

Thai CH, Ferreira AJM, Nguyen-Xuan H (2018) Isogeometric analysis of size-dependent isotropic and sandwich functionally graded microplates based on modified strain gradient elasticity theory. Compos Struct 192:274–288

Thai CH, Ferreira AJM, Phung-Van P (2019) Size dependent free vibration analysis of multilayer functionally graded GPLRC microplates based on modified strain gradient theory. Compos Part B-Eng 169:174–188

Nguyen HX, Nguyen TN, Abdel-Wahab M, Bordas SPA, Nguyen-Xuan H, Vo TP (2017) A refined quasi-3D isogeometric analysis for functionally graded microplates based on the modified couple stress theory. Comput Methods Appl Mech Eng 313:904–940

Thai CH, Ferreira AJM, Tran TD, Phung-Van P (2019) A size-dependent quasi-3D isogeometric model for functionally graded graphene platelet-reinforced composite microplates based on the modified couple stress theory. Compos Struct 2019:111695

Nguyen-Thanh N, Nguyen-Xuan H, Bordas SPA, Rabczuk T (2011) Isogeometric analysis using polynomial splines over hierarchical T-meshes for two-dimensional elastic solids. Comput Methods Appl Mech Eng 200(21–22):1892–1908

Natarajan S, Chakraborty S, Ganapathi M, Subramanian M (2014) A parametric study on the buckling of functionally graded material plates with internal discontinuities using the partition of unity method. Eur J Mech A/Solids 44:136–147

Natarajan S, Manickam G, Bordas S (2013) Supersonic flutter analysis of functionally graded material plates with cracks. Front Aerospace Eng 2(2):91–97

Phung-Van P, Nguyen LB, Tran LV, Dinh TD, Thai CH, Bordas S et al (2015) An efficient computational approach for control of nonlinear transient responses of smart piezoelectric composite plates. Int J Non-Linear Mech 76:190–202

Phung-Van P, Tran LV, Ferreira A, Nguyen-Xuan H, Abdel-Wahab M (2017) Nonlinear transient isogeometric analysis of smart piezoelectric functionally graded material plates based on generalized shear deformation theory under thermo-electro-mechanical loads. Nonlinear Dyn 87(2):879–894

Phung-Van P, Ferreira A, Nguyen-Xuan H, Wahab MA (2017) An isogeometric approach for size-dependent geometrically nonlinear transient analysis of functionally graded nanoplates. Compos B Eng 118:125–134

Yin S, Hale JS, Yu T, Bui TQ, Bordas SP (2014) Isogeometric locking-free plate element: a simple first order shear deformation theory for functionally graded plates. Compos Struct 118:121–138

Lu P, Zhang PQ, Lee HP, Wang CM, Reddy JN (2007) Non-local elastic plate theories. Proc R Soc A Math Phys Eng Sci 463(2088):3225–3240

Thai CH, Phung-Van P (2020) A meshfree approach using naturally stabilized nodal integration for multilayer FG GPLRC complicated plate structures. Eng Anal Bound Elem 117:346–358

Reddy JN (1984) A simple higher-order theory for laminated composite plates. J Appl Mech 51(4):745–752

Thai CH, Ferreira AJM, Phung-Van P (2020) A nonlocal strain gradient isogeometric model for free vibration and bending analyses of functionally graded plates. Compos Struct 251:112634

Babu B, Patel BP (2019) A new computationally efficient finite element formulation for nanoplates using second-order strain gradient Kirchhoff’s plate theory. Compos B Eng 168:302–311

Acknowledgements

This research is funded by Vietnam National Foundation for Science and Technology Development (NAFOSTED) under Grant no. 107.02-2019.09.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Phung-Van, P., Thai, C.H. A novel size-dependent nonlocal strain gradient isogeometric model for functionally graded carbon nanotube-reinforced composite nanoplates. Engineering with Computers 38 (Suppl 3), 2027–2040 (2022). https://doi.org/10.1007/s00366-021-01353-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-021-01353-3