Abstract

Micro-drilling using lasers finds widespread industrial applications in aerospace, automobile, and bio-medical sectors for obtaining holes of precise geometric quality with crack-free surfaces. In order to achieve holes of desired quality on hard-to-machine materials in an economical manner, computational intelligence approaches are being used for accurate prediction of performance measures in drilling process. In the present study, pulsed millisecond Nd:YAG laser is used for micro drilling of titanium alloy and stainless steel under identical machining conditions by varying the process parameters such as current, pulse width, pulse frequency, and gas pressure at different levels. Artificial intelligence techniques such as adaptive neuro-fuzzy inference system (ANFIS) and multi gene genetic programming (MGGP) are used to predict the performance measures, e.g. circularity at entry and exit, heat affected zone, spatter area and taper. Seventy percent of the experimental data constitutes the training set whereas remaining thirty percent data is used as testing set. The results indicate that root mean square error (RMSE) for testing data set lies in the range of 8.17–24.17% and 4.04–18.34% for ANFIS model MGGP model, respectively, when drilling is carried out on titanium alloy work piece. Similarly, RMSE for testing data set lies in the range of 13.08–20.45% and 6.35–10.74% for ANFIS and MGGP model, respectively, for stainless steel work piece. Comparative analysis of both ANFIS and MGGP models suggests that MGGP predicts the performance measures in a superior manner in laser drilling operation and can be potentially applied for accurate prediction of machining output.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Lasers find wide range of applications in various sectors such as manufacturing, aerospace and aviation, automobile, electrical and electronics and medical sectors. Lasers are used in various material processing techniques like laser peening, laser forming, laser welding, laser cutting, laser milling, laser drilling and laser-assisted machining due to its benefits such as less machining time, high precision and repeatability of the processes. Among all laser beam machining processes, laser drilling has engrossed attention recently [1, 2]. Due to the short interface time between the materials and laser, millisecond laser and ultrafast lasers have been considered as the preeminent techniques for drilling of brittle and hard-to-machine materials such as Inconel, titanium alloys and stainless steels. Stainless steel and titanium alloys are widely used in various fields such as electrical and electronics, petrochemical, shipping, aviation and aerospace, automobile and manufacturing industries and medical science due to their favorable mechanical, thermal and chemical properties. However, laser drilling of such materials is difficult because it induces various defects viz. micro-cracks, spatter, heat-affected zone, circularity and taper. Extensive research works have been carried out for optimization of process parameters so as to improve the performance measures, e.g. geometric and surface quality and heat-induced characteristics of laser-drilled holes [3,4,5]. Since laser drilling process is a costly process, development of such defects causes loss in economy. To overcome such difficulties, it is imperative to develop predictive models based on artificial intelligence techniques embedded with meta-heuristic approaches for optimization of the quality characteristics.

Casalino [5] have presented potential application of computational intelligence techniques for prediction, modeling and optimization of various laser material processing methods. The study shows that computational intelligence algorithms are capable of determining the hidden knowledge from experimental data to make complex decisions without human intervention. Hajihassani et al. [6] have proposed artificial and meta-heuristic approaches for prediction and optimization of the construction processes. Parandoush and Hossain [7] have presented a detailed study on scope for prediction and optimization of machining responses during laser beam machining (LBM) using artificial intelligence techniques such as artificial neural network, genetic algorithm and fuzzy expert system. The study states that artificial intelligence techniques have good potential to understand the machining behavior with less human effort. As laser drilling, especially micro- and nano-scale machining process, is a complicated process, prediction of process behavior makes the way to understand the difficult process behavior for the practitioners. Vijayaraghavan et al. [8] have proposed genetic programming (GP) and artificial neural network (ANN) approach for predicting the quality characteristics during drilling of grapheme sheets. The study shows that results obtained using genetic programming have good agreement with the experimental results as compared to ANN approach. Sibalija et al. [9] have conducted laser drilling on nickel-based super alloys having thickness of 1.2 mm using Nd:YAG laser varying two process parameters such as pulse frequency and pulse duration to analyze the seven drilling responses. Sibalija et al. [9] have proposed artificial intelligence method like artificial neural network technique and statistical approach such as Taguchi’s quality loss function, gray relation analysis (GRA) and principal component analysis (PCA) for prediction and optimization of the seven process outputs in laser drilling of nimonic alloy. The results suggest that prediction capability of ANN is superior to statistical methods. Bello et al. [10] have reported that artificial intelligence techniques are potentially suitable to be applied in the field of drilling. Gill and Singh [11] have proposed adaptive neuro-fuzzy inference system (ANFIS) to develop a predictive model for estimation of material removal rate (MRR) during drilling of ceramic alloys. Pérez et al. [12] have adopted adaptive neuro-fuzzy inference system for modeling of quality measures in laser surface treatment process.

As drilling is a complex process, researchers have proposed various computational approaches such as regression analysis, support vector machine (SVM) and artificial neural network [13] to achieve better prediction capability. Garg et al. [13] have proposed a predictive model based on multi gene genetic programming (MGGP) to estimate the burr height in drilling of AISI 316L and compared the results with regression analysis, support vector machine and artificial neural network. The results suggest that MGGP possesses reasonable potential to be treated as a good predictive model. Abhishek et al. [14] have demonstrated prediction capability of genetic programming (GP) and ANFIS models in drilling of composites. Abidin et al. [15] have used various soft computing approaches to obtain optimum parametric setting for estimating drilling path in various drilling methods.

Desai and Shaikh [16] have conducted a comparative study on prediction capability of different predictive models such as artificial neural network, semi-analytical technique and genetic programming while measuring the depth of cut in laser micro milling of thermoplastics. The study shows that GP produces less prediction error as compared to other models although all the techniques have reasonable accuracy in predicting the depth of cut. To predict the performance measures during turning of stainless steel, Garg and Tai [17] have preferred computational techniques using fuzzy logic, support vector regression, regression analysis, artificial neural network and genetic programming over physics-based models for predicting the performance measures. It is stated that genetic programming is quite robust in prediction over other methodologies. González et al. [18] have proposed an ANN model for predicting the dimensional error during ball end milling process. Khandelwal et al. [19] have proposed two different predictive models such as non-linear multi regression model and genetic programming for the estimation of properties of rock and suggest the superiority of the GP model over non-linear multi regression model. Asiltürk and Çunkaş [20] have used artificial neural network and multiple regression analysis for prediction of surface roughness during turning of stainless steel. It is observed that artificial neural network predicts the output with greater accuracy as compared to statistical method.

Extensive literature survey indicates that prior works are limited to identify the significant process parameters and their effect on the performance measures, predict quality characteristics and optimize the process parameters using statistical, computational and meta-heuristic approaches in different machining processes. However, potential of application of computational intelligence and meta-heuristic approaches is hardly explored for prediction and optimization of performance measures in laser drilling operation. With growth in miniaturization of existing products, there is rapid demand in production of micro machined products with high geometric quality and crack-free surfaces. To achieve the desired quality holes for hard-to-machine materials in an economical manner, it is imperative that computational intelligence approaches can predict the process behavior in an effective manner. The purpose of the present study was to propose a model to predict quality characteristics of micro holes made on hard-to-machine materials like AISI 316 and Ti6Al4V using pulsed Nd:YAG laser. Pulsed millisecond Nd:YAG laser is used for micro drilling of Ti6Al4V and AISI 316 under identical machining conditions (same parametric setting) varying the process parameters such as current, pulse width, pulse frequency and gas pressure at three different levels to determine the performance measures, e.g. circularity at entry and exit, heat affected zone, spatter area and taper. Artificial intelligence techniques such as adaptive neuro-fuzzy inference system (ANFIS) and multi-gene genetic programming (MGGP), are used not only to predict the performance measures but also to analyze the variation of performance measures with the change in process parameters beyond experimental domain once the proposed models are converged.

2 Methodology

Artificial and computational intelligence generally involves use of computer algorithms to capture the hidden knowledge from data and uses them for training “intelligent machine” to make decisions without human intervention [5]. As simulation is becoming more prevalent from product design and planning manufacturing operations point of view, laser material processing can also be benefit from the computer generating knowledge through soft computing [5]. Laouissi et al. [21] have proposed statistical approach using response surface methodology (RSM) and artificial intelligence like ANN for predicting the machining outputs during turning of EN-GJL-250 cast iron. Laouissi et al. [21] have also optimized machining outputs using genetic algorithm (GA) after prediction of machining outputs using RSM and ANN. The study shows the scope for implementation of heuristic approach for optimization after prediction through statistical and artificial intelligence techniques during high-speed machining. Bustillo and Correa [22] have proposed artificial intelligence method for predicting surface roughness in high-speed machining process. Bayesian network approach is used to predict the surface roughness of the work piece in dry and lubricating (using minimum quantity lubrication) conditions and the predicted results are quite closer to experimented values.

2.1 Adaptive neuro-fuzzy inference system (ANFIS)

Adaptive neuro-fuzzy inference system is widely applied for predicting quality characteristics in the field of manufacturing engineering. Gholami et al. [23] have proposed a hybrid technique using meta-heuristic approach like particle swarm optimization algorithm embedded adaptive neuro-fuzzy inference system for prediction and optimization of threshold bank profile shape using digital laser. The study suggests that results obtained using meta-heuristic approach embedded with predictive technique have less uncertainty in nature. Petković et al. [24] have adopted adaptive neuro-fuzzy inference system to develop a predictive model to forecast the heat-affected zone (HAZ) during laser cutting of glass fiber reinforced plastic. Abdulshahed et al. [25] and Abdulshahed et al. [26] have proposed adaptive neuro-fuzzy inference system to predict the thermal error developed in the machine tool during computerized numerical control (CNC) milling process. Al-Ghamdi and Taylan [27] have adopted an adaptive neuro fuzzy inference system for predicting the material removal rate in electrical discharge machining (EDM) process. Sohrabpoor [28] have proposed a response model based on ANFIS and meta-heuristic approach known as imperialist competitive algorithm (ICA) to optimize process parameters in laser cladding process. Sohrabpoor [29] have adopted ANFIS to predict the performance of graphene-metal alloys in laser cladding process.

Adaptive neuro fuzzy inference system (ANFIS) is a mixed pattern of two artificial intelligence techniques known as artificial neural network (ANN) and fuzzy inference system (FIS). Fuzzy logic and neural network are two complementary techniques. Neural network has the capability of learning from both data and feedback without getting involved in understanding the pattern in the data sets. But, fuzzy logic model patterns are easy to comprehend because they use linguistic terms in the form of IF–THEN rules. A neural network with their learning proficiencies can be used to learn the fuzzy decision rules; this helps in development of a hybrid intelligent system network.

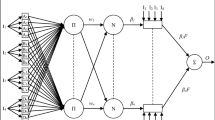

The fuzzy system provides expert knowledge to be used by the neural network. ANFIS consists of five layers and each layer consists of some nodes like artificial neural network (ANN). Figure 1 indicates the adaptive network structure for ANFIS. The structure for adaptive neuro-fuzzy inference system is characterized as follows. The details of each layer have been already discussed in the past literature [11, 23,24,25,26,27,28, 30]:

-

Layer 1 consists of fuzzification layer.

-

Layer 2 is known as product layer.

-

Layer 3 is called as normalized layer.

-

Layer 4 is the defuzzification layer.

-

Layer 5 is known as output layer.

2.2 Multi gene genetic programming (MGGP)

In the present study, multi gene genetic programming is proposed for development of a predictive model for prediction of quality measures in laser drilling process. Genetic programming (GP) is first introduced by Koza in early 1990s [31,32,33]. GP is probably the most general approach of evolutionary computation methods and applied for simple and complex systems in all aspects of engineering problem [34]. Sharma et al. [35] have proposed Taguchi method embedded with genetic programming method for prediction of compaction strength in powder metallurgy (PM) process. Panda et al. [36] have used genetic programming-based model for predicting the bead dimensions in wire and arc additive manufacturing. Kok et al. [37] have proposed a predictive model for estimation of surface roughness using genetic expression programming. Garg and Lam [38] have proposed multi gene genetic programming approach to develop an empirical relationship between input parameters and performance measures such as surface roughness, tool life and power consumption while turning of stainless steel and aluminum alloy. Brezocnik et al. [39] have proposed genetic programming to develop a model for prediction of surface roughness of drilled holes produced through milling process.

Multi gene genetic programming is a robust modified version of genetic programming. It successfully integrates the model structure selection ability of the standard GP with the parameter estimation power of classical regression [34]. Instead of complex rules and mathematical routines, MGGP is able to learn the key information patterns within the multidimensional information domain with high speed [34]. The steps (pseudo code) for the MGGP have been illustrated as follows (Table 1). The more detailed explanations about multi gene genetic programming (MGGP) are available in literature [13, 34, 36, 38].

3 Materials and methods

3.1 Materials

Laser beam micro-drilling is performed on commercially available stainless steel (AISI 316) and titanium alloy (Ti6Al4V) having dimension of 50 × 50 × 0.45 mm3. The materials have been procured from Manohar Metal Corporation (Mumbai, India) for laser beam drilling purpose. The selection of materials and thickness is based on applications, commercial availability and economic reasons. Field emission scanning electron microscopy with energy dispersive spectroscopy (FESEM-EDS) has been performed to obtain the weight percentage of constituents present in the work piece and confirms the chemical composition of the as received work piece of AISI 316and Ti6Al4V. Figures 2 and 3 indicate the weight percentage of constituents available in work piece 1 (AISI 316 stainless steel) and work piece 2 (Ti6Al4V titanium alloy), respectively, and confirms the material composition of the available materials.

3.2 Methods

Laser beam micro drilling is a thermal ablation process in which high-intensity energy beam is focused at a point. This laser guided beam helps in melting and evaporation of molten material from the focus zone of the work piece. The molten materials from the drilled area are flushed away with the help of assistant gas pressure. Since laser guided beam can be focused on a very small diameter with high accuracy, it helps in attaining precise micro-drilled holes [5]. In the present study, laser drilling is performed on a pulsed millisecond (ms) Nd:YAG laser machine developed at Raja Ramanna Centre for Advanced Technology (RRCAT), Indore, India. Pulsed Nd:YAG laser system with 250 W average power, 5 kW maximum peak power, 1–20 ms pulse duration and 1–100 Hz repetition rate has been used for micro-drilling process. Laser beam has been delivered through a 200 µm-core diameter and 0.22 numerical aperture (NA) silica–silica fiber. Argon gas is used as an assistant gas to protect the laser lens from any damage and flushing of molten material during laser beam micro-drilling process. Schematic layout for the present experimentation (laser drilling process) has been shown in Fig. 4. Here, offset distance of 3 mm has been considered. The process parameters considered after extensive literature survey [40,41,42,43] and control parameters available with the laser drilling setup in RRCAT, Indore.

The process parameters considered for the laser beam micro-drilling process are current, pulse frequency, pulse width and gas pressure and each at three levels (low, medium and high) as shown in Table 2. The laser beam drilling setup and their parametric levels are discussed in Table 2 below. If all the probable factor combinations would have been considered, it would require 34 experimental runs. To determine the influence of process parameters on performance measures with less number of experimental runs, Taguchi method has been employed. Taguchi’s L27 orthogonal array is used to design the experimental matrix (Tables 3 and 4) and each experimental trial is repeated twice.

4 Results and discussion

Laser beam micro drilling is a thermal ablation process in which high-intensity energy beam is focused at a point. Laser guided beam helps in melting and evaporation of molten material from the focused zone on the work piece. The remaining molten material from the machined area is flushed away using assistant gas pressure. The improper flushing of molten materials may cause expelled materials to be deposited on the surface area of the drilled holes leading to several irregularities in terms of circularity at entry and exit, heat-affected zone, spatter area and taper. Drilled samples are tested under optical and scanning electron microscope (SEM) to determine the quality characteristics such as circularity at entry (Cent), circularity at exit (Cexit), heat-affected zone (HAZ), spatter area (SA) and taper of laser drilled micro holes. The experiments have been conducted according to experimental layout using Taguchi’s L27 orthogonal array. The experimental conditions are shown in Tables 3 and 4 for AISI 316 and Ti6Al4V, respectively. Each experiment is repeated twice and average value is noted down. The normalized values of performance measures under each treatment combination are shown in Tables 3 and 4. The normalization of performance measures is carried out using Eqs. 1 and 2. Let xij be the experimental response value for jth response in ith trial and xmin and xmax are the maximum and minimum experimental response for jth response.

Normalization:

“Larger the better” characteristic is preferred for performance measures like circularity at entry and exit, whereas “Lower the better” characteristic is recommended for heat affected zone, spatter area and taper.

Improper flushing of molten materials may cause expelled material to be deposited on the surface area of the drilled holes, known as spatter area. Spatter area is calculated as shown in Fig. 5. The surface area of the total molten material deposited on the surface of each hole, known as spatter area, is calculated for both the materials.

For the calculation of circularity at entry, circularity at exit and HAZ, spatter deposition on the surface of the laser drilled samples are removed by emery polishing with paper III grade 1/0 (Kohinoor Products, India). To calculate the circularity of the hole and its dimensions, the drilled samples are taken under optical microscope (Carl Zeiss, GERMANY) and analyzed. The circularity is defined as the ratio of minimum diameter (Dminimum) to maximum diameter (Dmaximum) of Ferret’s hole diameter as expressed in Eq. 3. Figure 6a and b indicates the calculation of circularity of laser drilled holes for AISI 316 and Ti6Al4V, respectively, using Ferret’s hole diameter concept:

Figure 7a and b indicates the pictographic representation of laser drilled holes at entry and exit, respectively, for AISI 316 for experiment number 5. Similarly, Fig. 7c and d indicates the pictographic representation of laser drilled holes at entry and exit, respectively, for Ti6Al4V for experiment number 5. From the figures, difference of hole diameter at entry and exit for both the work pieces can be clearly observed. This indicates that the presence of taper on laser drilled micro-holes. Taper of the drilled holes is calculated by Eq. 4 stated below:

After analysis of geometrical features of the laser drilled hole, the samples are cloth polished and etched to reveal the HAZ of each hole for both the materials. Scanning electron microscope (SEM) (JEOL JSM-6480LV, USA) has been used to calculate the HAZ. In laser beam drilling process, a high amount of thermal energy is developed during machining operation. The thermal energy leads to change in microstructure near the drilled holes, known as heat affected zone (HAZ). Figure 8a and b indicates the HAZ for AISI 316 and Ti6Al4V work piece, respectively. While comparing Fig. 8a with Fig. 8b, it is observed that HAZ value is higher for Ti6Al4V work piece as compared to AISI 316 work piece under identical experimental conditions (experiment number 5). Higher value of HAZ is observed in case of titanium alloy work piece. It may be attributed to low thermal conductivity of titanium alloys as compared to stainless steel. As heat is not properly dissipated and localized near the machining zone, it results in higher HAZ value at parametric setting at 4 ms of pulse width, 230 A of laser current, 4 Hz of pulse frequency and 8 bar gas pressure (experiment number 5). Figure 8c indicates formation of burrs and surface erosion in drilled hole for AISI 316 workpiece. The formation of burrs may occur due to insufficient flushing pressure. Surface cracking may be due to prolonged heating effect on the material. Figure 8d indicates development of micro-cracks in the HAZ of the micro-drilled holes for Ti6Al4V alloy. As thermal conductivity of Ti6Al4V is low, it leads to localization of heat near the machined area resulting in development of thermal stress near the drilled region. The thermal stresses cause formation of micro-cracks (distortion) near the drilled zone. It is clearly observed that the hole quality differs for both the materials during laser beam drilling of AISI 316 and Ti6Al4V under same experimental parametric setup (experiment number 5).

The development of micro-cracks in the machining zone of Ti6Al4V is an important issue that needs to be addressed. The present study is further extended to analyze the formation micro-cracks near the drilling zone. Figure 9 helps to understand the parametric effect on formation of micro-cracks near the drilled area of Ti6Al4V alloy. Figure 9 indicates that thermal input energy (due to factor A and B), pulse frequency (C) and assistant gas pressure (D) have huge contribution in development of micro-cracks near the drilled holes. It is clearly observed that drilled hole with less thermal input energy, less crack intensity is observed as compared to drilled holes with higher thermal input energy. The development of micro-cracks and their propagation occur due to several reasons like development of thermal stress in machined zone, gas pressure, increment of pulse frequency and fracture toughness. Increase in thermal input energy causes increase in thermal stress within the machined region. When thermal stress exceeds the limit of ultimate strength of the workpiece, it results in development of cracks in the machined zone. Increase in pulse frequency leads to reduction of pulse-off-time and escalation of rate of heat input during laser beam drilling process. If thermal conductivity of the material is less and the developed thermal energy is not easily dissipated (or concentrated near the machining zone), it may lead to distortion near machined zone in form of cracks. Increase in gas pressure leads to increase in cooling rate. Change in sudden temperature difference leads to increase the crack intensity [44].

4.1 Prediction of hole quality through ANFIS

To predict the performance measures such as circularity at entry (Cent), circularity at exit (Cexit), heat affected zone (HAZ), spatter area (SA) and taper for laser beam drilling on AISI 316 and Ti6Al4V, adaptive neuro fuzzy inference system (ANFIS) toolbox available with MATLAB 2017b has been used. Sugeno model has been used for the analysis (Fig. 10). The ANFIS analysis has been performed in two phases, namely training and testing. 70% experimental data (20 sets of data) considered for training and remaining 30% (7 data) which are not included in training of the network taken for testing of the developed network. The four input parameters and Gaussian type membership function (gaussmf) are considered for prediction model in ANFIS. Subtractive clustering has been selected for generating the fuzzy inference system (FIS). In training phase, the model become stable after three iterations where 0.01 is the error tolerance value (20 experimental data are taken). This states that the model is well developed. Now to check the adequacy of the developed model, the testing of the model has been performed using seven experimental data from experiment numbers 21 to 27 (Tables 6, 7). The proposed steps for the ANFIS model can be easily observed in Figs. 10, 11, 12, 13, and 14. Figure 10 indicates the proposed Sugeno model for the fuzzy system (for AISI 316 laser drilled samples), Fig. 11 shows the developed clustering rules for the membership functions and Fig. 12 indicates the developed adaptive network for the ANFIS model (for AISI 316 laser drilled samples). Figures 13 and 14 show the comparative graph plot between the predicted data (training and testing) and actual data (for AISI 316 laser drilled samples). Figures 12 and 13 also represent the obtained training and testing errors, respectively, for HAZ of AISI 316 laser drilled sample. Similarly, the analysis is performed for other performance measures for both the work pieces for each performance measures and they are depicted in Tables 6 and 7 for AISI 316 and Ti6Al4V samples, respectively.

4.2 Prediction of hole quality through MGGP

To predict the performance measures for laser beam drilling on AISI 316 and Ti6Al4V, multi-gene genetic programming (MGGP) has been used using MATLAB 2017b. The code is available in the open source [45]. The experimented data have been divided into two parts viz. training data and testing data. 70% experimental data (20 sets of data) is considered for training and remaining 30% (7 data) which not contributed in training of the network taken for testing of the proposed methodology. The control parameters and their settings are the predominant factor in instigating MGGP algorithm effectively. Trial and error methodology has been adapted to decide the parametric settings (Table 5). The function set consists of broader set of elements so as to evolve variety of non-linear forms of mathematical models. The values of population size and number of generations fairly depend on the complexity of the data. Based on literature review by Garg and Tai [17], the population size and number of generations should be fairly large for data of higher complexity so as to find the models with minimum error. Maximum number of genes and maximum depth of the gene influence the size and the number of models to be searched in the global space. The maximum number of genes and maximum depth of gene are chosen at eight and six, respectively. GPTIPS-2 [45] software is used for the implementation of MGGP algorithm. The preeminent multi gene genetic programming (MGGP) model is selected based on minimum root mean square error (RMSE) obtained from testing data trails as shown in Tables 8 and 9.

The detailed analysis for MGGP model has been presented through Figs. 15, 16, and 17. Figure 15 indicates the multi-gene regression model for the population size in proposed MGGP model. Figure 16 indicates the residual plots for the training and testing data for HAZ (AISI 316 sample). The residual plot suggests the adequacy of the proposed MGGP model. Figure 17 shows the comparative graph plots between the predicted data and experimental data in training and testing phase of the MGGP algorithm. The root mean square error (RMSE) of 0.06531 and comparative plot suggests the adequacy of the proposed model for the analysis. Similarly, the analysis is performed for other performance measures for both the work pieces depicted in Tables 6 and 7 for AISI 316 and Ti6Al4V samples, respectively.

To analyze the effectiveness of both the proposed predictive models, a comparative analysis is made in Tables 6 and 7 for stainless steel (AISI 316) and titanium alloy (Ti6Al4V) work pieces. From the study, it is observed that both the techniques are quite adequate in predicting the performance measures in training phase. To determine the adequacy of the models during testing phase, comparative graphs for testing data are shown in Figs. 18 and 19 for AISI 316 and Ti6Al4V, respectively. It is noted that MGGP model shows minimum root mean square error (RMSE) as compared to ANFIS model for the chosen performance measures (Tables 8 and 9). The results suggest that MGGP is potentially superior and adequate in predicting the performance measures for laser beam micro-drilling process.

5 Conclusion

In the present study, laser beam drilling on AISI 316 and Ti6Al4V of 0.45 mm thickness has been performed using millisecond pulsed Nd:YAG laser using Taguchi’s experimental plan to collect experimental data. The study is intended to propose a predictive model using artificial intelligence techniques. After extensive literature review, it is observed that ANFIS and MGGP are two potential competing artificial techniques for predicting the performance measures in laser material processing techniques [13, 16, 29]. A comparative study has been performed to analyze the adequacy of the ANFIS and MGGP models for predicting the performance measures of the laser drilled holes. Laser drilling on AISI 316 and Ti6Al4V has been performed under identical experimental conditions (same parametric settings). Following are the outcomes of the present investigation:

-

Laser beam micro-drilling on AISI 316 and Ti6Al4V is possible under identical experimental parametric settings.

-

Under identical machining conditions (for example experiment number 5), AISI 316 resists thermal shocks although micro-cracks are observed for few machining conditions. However, micro-cracks on the drilled surface for all the machining condition when Ti6Al4V work piece is used. The development of micro-cracks in Ti6Al4V work piece may be attributed to low thermal conductivity of the material and fracture toughness and development of high thermal stress in the machining zone exceeding the ultimate tensile strength.

-

While comparing the hole quality for both materials, AISI 316 has low circularity, high spatter area and development of surface erosion of the hole. This may be due to prolonged heating effect of the materials.

-

From the study, it can be concluded that both the artificial techniques such as ANFIS and MGGP are quite adequate in predicting the performance measures for laser drilling of AISI 316 and Ti6Al4V in training phase. To determine the superior prediction capability among the two proposed models, a comparative study for predicting the testing data has been performed.

-

It is noted that MGGP model shows minimum root mean square error (RMSE) as compared to ANFIS model for the performance measures. The results suggest that MGGP has more potentiality and adequacy in predicting the performance measures for laser beam micro-drilling process. It can be concluded that MGGP models have higher prediction accuracy as compared to ANFIS model.

References

Shen H, Jiang J, Feng D, Xing C, Zhao X, Xiao P (2019) Environmental Effect on the Crack Behavior of Yttria-Stabilized Zirconia during Laser Drilling. J Manuf Sci Eng 141(5):054501

Adelmann B, Hellmann R (2015) Rapid micro hole laser drilling in ceramic substrates using single mode fiber laser. J Mater Process Technol 221:80–86

Bharatish A, Murthy HN, Anand B, Madhusoodana CD, Praveena GS, Krishna M (2013) Characterization of hole circularity and heat affected zone in pulsed CO2 laser drilling of alumina ceramics. Opt Laser Technol 53:22–32

Dubey AK, Yadava V (2008) Experimental study of Nd: YAG laser beam machining-An overview. J Mater Process Technol 195(1–3):15–26

Casalino G (2018) Computational intelligence for smart laser materials processing. Opt Laser Technol 100:165–175

Hajihassani M, Kalatehjari R, Marto A, Mohamad H, Khosrotash M (2019) 3D prediction of tunneling-induced ground movements based on a hybrid ANN and empirical methods. Eng Comput. https://doi.org/10.1007/s00366-018-00699-5

Parandoush P, Hossain A (2014) A review of modeling and simulation of laser beam machining. Int J Mach Tools Manuf 85:135–145

Vijayaraghavan V, Garg A, Wong CH, Tai K, Mahapatra SS (2014) Measurement of properties of graphene sheets subjected to drilling operation using computer simulation. Measurement 50:50–62

Sibalija TV, Petronic SZ, Majstorovic VD, Prokic-Cvetkovic R, Milosavljevic A (2011) Multi-response design of Nd: YAG laser drilling of Ni-based superalloy sheets using Taguchi’s quality loss function, multivariate statistical methods and artificial intelligence. Int J Adv Manuf Technol 54(5–8):537–552

Bello O, Holzmann J, Yaqoob T, Teodoriu C (2015) Application of artificial intelligence methods in drilling system design and operations: a review of the state of the art. J Artif Intell Soft Comput Res 5(2):121–139

Gill SS, Singh J (2010) An Adaptive Neuro-Fuzzy Inference System modeling for material removal rate in stationary ultrasonic drilling of sillimanite ceramic. Expert Syst Appl 37(8):5590–5598

Pérez JA, González M, Dopico D (2010) Adaptive neurofuzzy ANFIS modeling of laser surface treatments. Neural Comput Appl 19(1):85–90

Garg A, Tai K, Vijayaraghavan V, Singru PM (2014) Mathematical modelling of burr height of the drilling process using a statistical-based multi-gene genetic programming approach. Int J Adv Manuf Technol 73(1–4):113–126

Abhishek K, Panda BN, Datta S, Mahapatra SS (2014) Comparing predictability of genetic programming and ANFIS on drilling performance modeling for GFRP composites. Procedia Mater Sci 6:544–550

Abidin NWZ, Ab Rashid MFF, Mohamed NMZN (2019) A review of multi-holes drilling path optimization using soft computing approaches. Arch Comput Methods Eng 26(1):107–118

Desai CK, Shaikh A (2012) Prediction of depth of cut for single-pass laser micro-milling process using semi-analytical, ANN and GP approaches. Int J Adv Manuf Technol 60(9–12):865–882

Garg A, Tai K (2014) Stepwise approach for the evolution of generalized genetic programming model in prediction of surface finish of the turning process. Adv Eng Softw 78:16–27

Arnaiz-González Á, Fernández-Valdivielso A, Bustillo A, de Lacalle LNL (2016) Using artificial neural networks for the prediction of dimensional error on inclined surfaces manufactured by ball-end milling. Int J Adv Manuf Technol 83(5–8):847–859

Khandelwal M, Faradonbeh RS, Monjezi M, Armaghani DJ, Majid MZBA, Yagiz S (2017) Function development for appraising brittleness of intact rocks using genetic programming and non-linear multiple regression models. Eng Comput 33(1):13–21

Asiltürk I, Çunkaş M (2011) Modeling and prediction of surface roughness in turning operations using artificial neural network and multiple regression method. Expert Syst Appl 38(5):5826–5832

Laouissi A, Yallese MA, Belbah A, Belhadi S, Haddad A (2019) Investigation, modeling, and optimization of cutting parameters in turning of gray cast iron using coated and uncoated silicon nitride ceramic tools. Based on ANN, RSM, and GA optimization. Int J Adv Manuf Technol 101(1–4):523–548

Bustillo A, Correa M (2012) Using artificial intelligence to predict surface roughness in deep drilling of steel components. J Intell Manuf 23(5):1893–1902

Gholami A, Bonakdari H, Ebtehaj I, Mohammadian M, Gharabaghi B, Khodashenas SR (2018) Uncertainty analysis of intelligent model of hybrid genetic algorithm and particle swarm optimization with ANFIS to predict threshold bank profile shape based on digital laser approach sensing. Measurement 121:294–303

Petković D, Nikolić V, Milovančević M, Lazov L (2016) Estimation of the most influential factors on the laser cutting process heat affected zone (HAZ) by adaptive neuro-fuzzy technique. Infrared Phys Technol 77:12–15

Abdulshahed AM, Longstaff AP, Fletcher S (2015) The application of ANFIS prediction models for thermal error compensation on CNC machine tools. Appl Soft Comput 27:158–168

Abdulshahed AM, Longstaff AP, Fletcher S, Myers A (2015) Thermal error modelling of machine tools based on ANFIS with fuzzy c-means clustering using a thermal imaging camera. Appl Math Model 39(7):1837–1852

Al-Ghamdi K, Taylan O (2015) A comparative study on modelling material removal rate by ANFIS and polynomial methods in electrical discharge machining process. Comput Ind Eng 79:27–41

Sohrabpoor H (2016) Analysis of laser powder deposition parameters: ANFIS modeling and ICA optimization. Optik-Int J Light Electron Opt 127(8):4031–4038

Sohrabpoor H (2017) Perspective of applying adaptive neuro fuzzy inference system (ANFIS) in laser cladding of graphene-metal alloys. J Nanotechnol 4:017

Sahu M, Khatua KK, Mahapatra SS (2011) A neural network approach for prediction of discharge in straight compound open channel flow. Flow Meas Instrum 22(5):438–446

Koza JR (1995) Survey of genetic algorithms and genetic programming. In: Wescon conference record. Western periodicals company, pp 589–594. https://doi.org/10.1109/WESCON.1995.485447

Koza JR (1994) Genetic programming II, vol 17. MIT press, Cambridge

Koza JR, Koza JR (1992) Genetic programming: on the programming of computers by means of natural selection, vol 1. MIT press, Cambridge

Kaydani H, Mohebbi A, Eftekhari M (2014) Permeability estimation in heterogeneous oil reservoirs by multi-gene genetic programming algorithm. J Petrol Sci Eng 123:201–206

Sharma N, Kumar K, Raj T, Kumar V (2019) Porosity exploration of SMA by Taguchi, regression analysis and genetic programming. J Intell Manuf 30(1):139–146

Panda B, Shankhwar K, Garg A, Savalani MM (2019) Evaluation of genetic programming-based models for simulating bead dimensions in wire and arc additive manufacturing. J Intell Manuf 30(2):809–820

Kök M, Kanca E, Eyercioğlu Ö (2011) Prediction of surface roughness in abrasive waterjet machining of particle reinforced MMCs using genetic expression programming. Int J Adv Manuf Technol 55(9–12):955–968

Garg A, Lam JSL (2015) Improving environmental sustainability by formulation of generalized power consumption models using an ensemble based multi-gene genetic programming approach. J Clean Prod 102:246–263

Brezocnik M, Kovacic M, Ficko M (2004) Prediction of surface roughness with genetic programming. J Mater Process Technol 157:28–36

Bandyopadhyay S, Sundar JS, Sundararajan G, Joshi SV (2002) Geometrical features and metallurgical characteristics of Nd: YAG laser drilled holes in thick IN718 and Ti–6Al–4V sheets. J Mater Process Technol 127(1):83–95

Bharatish A, Murthy HN, Anand B, Madhusoodana CD, Praveena GS, Krishna M (2013) Characterization of hole circularity and heat affected zone in pulsed CO2 laser drilling of alumina ceramics. Opt Laser Technol 53:22–32

Olsen FO, Alting L (1995) Pulsed laser materials processing, ND-YAG versus CO2 lasers. CIRP Ann 44(1):141–145

Ghany KA, Newishy M (2005) Cutting of 1.2 mm thick austenitic stainless steel sheet using pulsed and CW Nd: YAG laser. J Mater Process Technol 168(3):438–447

Chatterjee S, Mahapatra SS, Sahu AK, Bhardwaj VK, Choubey A, Upadhyay BN, Bindra KS (2017) Experimental and parametric evaluation of quality characteristics in Nd: YAG laser micro-drilling of Ti6Al4V and AISI 316. In: ASME 2017 gas turbine India conference. American Society of Mechanical Engineers Digital Collection. https://doi.org/10.1115/GTINDIA2017-4679

Searson DP (2015) GPTIPS 2: an open-source software platform for symbolic data mining. In: Gandomi A, Alavi A, Ryan C (eds) Handbook of genetic programming applications. Springer, Cham. https://doi.org/10.1007/978-3-319-20883-1_22

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chatterjee, S., Mahapatra, S.S., Bharadwaj, V. et al. Prediction of quality characteristics of laser drilled holes using artificial intelligence techniques. Engineering with Computers 37, 1181–1204 (2021). https://doi.org/10.1007/s00366-019-00878-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-019-00878-y