Abstract

Predictive models have been widely used in different engineering fields, as well as in petroleum engineering. Due to the development of high-performance computer systems, the accuracy and complexity of predictive models have been increased significantly. One of the common methods for prediction is artificial neural network (ANN). ANN models in combination with optimization algorithms provide a powerful and fast tool for the prediction and optimization of processes which take a large amount of time if they are simulated using common simulation technics. In the present paper, to predict penetration rate during drilling process, several ANN models were developed based on the data obtained from drilling of a gas well located in south of Iran. Regarding the R2 and RMSE values of the developed models, the best model was selected for prediction of penetration rate. In the next step, artificial bee colony algorithm was used for optimization of the parameters which are effective on rate of penetration (ROP). Results showed that the model is accurate enough for being used in the prediction and optimization of ROP in drilling operations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Drilling operations leads to significant costs during the development of oil and gas fields. Therefore, drilling optimization can decrease the costs of a project and, hence, increase the profit earned from the oil and gas production. In most of the studies, rate of penetration (ROP) has been considered as the objective function of the optimization process. ROP depends on many factors including well depth, formation characteristics, mud properties, rotational speed of the drill string, etc. Several studies have been conducted to gain a profound insight into the effective parameters on ROP [1, 2]. Maurer [3] introduced an equation for ROP, in which it was accounted for rock cratering mechanisms of roller-cone bits. Galle and Woods [4] proposed a mathematical model for estimating ROP, where formation type, weight on bit, rotational speed of bit, and bit tooth wear were taken as input parameters. Mechem and Fullerton [5] proposed a model with input variables of formation drilling ability, well depth, weight on bit, bit rotational speed, mud pressure, and drilling hydraulics. Bourgoyne and Young [6] used multiple regression analysis to develop an analytical model, and also investigated the effects of depth, strength, and compaction of the formation, bit diameter, weight on bit, rotational speed of bit, bit wear, and hydraulic interactions associated with drilling. Bourgoyne and Young [6] introduced a technic for selection of optimum values for weight on bit, rotational speed, bit hydraulics, and calculation of formation pressure through multiple regression analysis of drilling data. Tanseu [7] developed a new method of ROP and bit life optimization based on the interaction of raw data, regression, and an optimization method, using the parameters of bit rotational speed, weight on bit, and hydraulic horsepower. Al-Betairi et al. [8] used multiple regression analysis for optimization of ROP as a function of controllable and uncontrollable variables. They also studied the correlation coefficients and multicollinearity sensitivity of the drilling parameters. Maidla and Ohara [9] introduced a computer software for optimum selection of roller-cone bit type, bit rotational speed, weight on bit, and bit wearing for minimizing drilling costs. Hemphill and Clark [10] studied the effect of mud chemistry on ROP through tests conducted with different types of PDC bits and drilling muds. Fear [11] conducted a series of studies using geological and mud logging data and bit properties to develop a correlation for estimating ROP. Ritto et al. [12] introduced a new approach for optimization of ROP as a function of rotational speed at the top and the initial reaction force at the bit, vibration, stress, and fatigue limit of the dynamical system. Alum and Egbon [13] conducted a series of studies which led to the conclusion that pressure losses in the annulus are the only parameter which affects ROP significantly, and finally, they proposed an analytical model for the estimation of ROP based on the model introduced by Bourgoyne and Young. Ping et al. [14] utilized shuffled frog-leaping algorithm to optimize ROP as a function of bit rotational velocity, weight on bit, and flow rate. Hankins et al. [15] optimized drilling process of already drilled wells with variables of weight on bit, rotational velocity, bit properties, and hydraulics to minimize drilling costs. Shishavan et al. [16] studied a preliminary managed pressure case to minimize the associated risk and decrease the drilling costs. Wang and Salehi [17] used artificial intelligence for the prediction of optimum mud hydraulics during drilling operations, and performed sensitivity analysis using forward regression. A variety of artificial intelligence works have recently been conducted in civil and oil engineering [18,19,20,21].

In the present paper, a new approach was used for prediction and optimization of ROP, based on artificial neural network (ANN). ANN technique is able to approximate almost all problems of science and engineering [22,23,24,25,26,27,28,29,30,31,32,33,34]. According to the authors’ knowledge, ANN application on ROP optimization has not been widely used by the previous studies. The variables used in this study were well depth (D), weight on bit (WOB), bit rotational velocity (N), the ratio of yield point to plastic viscosity (Yp/PV), and the ratio of 10 min gel strength to 10 s gel strength (10MGS/10SGS). Using ANN technic, several models were developed for prediction of ROP, and the best one was selected according to their performances. Then, an artificial bee colony (ABC) algorithm was used for optimization of ROP based on the selected ANN predictive model, and the drilling parameters were evaluated to determine their effects on ROP.

2 Methodology

2.1 General description of artificial neural network

Artificial neural network (ANN) is a branch of artificial intelligence (AI) technics, which was introduced by McCulloch and Pittsin [35]. ANNs have two important advantages. First, they can be used as a substitute for complex simulation software packages, which require a lot of time to run the model. ANNs can learn the behavior of the software and provide the output with less computational effort. Second, ANNs are powerful tools for obtaining a meaningful relationship between a large amount of data, and predict the output for an unexperienced case [36]. In fact, a group of training data and a group of testing data are used for developing an ANN. Training data are used for training the ANN, and modify its parameters, and test data are used for evaluation of the accuracy of predictive model [37, 38].

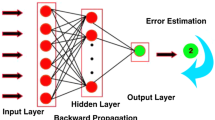

An ANN is composed of neurons distributed in different positions called layers. The layers between the first and last layer are called hidden layers [23, 39, 40]. By entering the data, each neuron imposes some mathematical calculations on the data and delivers it to the next neuron. There are different types of interaction between neurons in an ANN, and the most common type is feed-forward-back-propagation (FF-BP) method, which is reported to be efficient by the previous authors [26, 41, 42]. This method involves two stages. First, the input data are passed through the layers, and an output is obtained. During this stage, synaptic weights of the network are determined. Second, according to the difference between the real (measured) output and predicted value by the ANN, the weights are adjusted through back propagation of error signal. This process iterates until an acceptable value of accuracy is met. There are different indices for the evaluation of network performance [37]:

2.2 General description of artificial bee colony

This algorithm was developed by Karaboga [43] and mimics the behavior of bees when they search for nectar of flowers. In a hive of bees, there are three different types of bees: scouts, employed bees, and onlookers. The scout bees start a random search of the surrounding environment to find flowers which secrete nectar. After finding the flowers, they keep the location in their memory. Then, they return to the hive and share their information about their findings through a process called waggle dance. Next, the other group, called employed bees, starts finding the flowers based on the information obtained from the scouts to exploit the nectar of the flowers. The number of employed bees is equal to number of food sources. The third group of bees are called onlookers, which remain in the hive waiting for the return of the employed bees to exchange information and select the best source based on the dances (fitness of the candidates). In addition, the employed bees of an abandoned food site serve as a scout bee.

Considering an objective function, \(f(x)\), the probability of a food source to be chosen by ab onlooker can be expressed as follows [44]:

where \(S\) indicates the number of food sources and \(F(x)\) represents the amount of nectar at location \(x\). The intake efficiency is defined as \(F/\tau\), in which \(\tau\) represents the time consumed at the food source. If, in a predefined number of iterations, a food source is tried with no improvement, then the employed bees dedicated to this location become scout and hence start searching the new food sources in a random manner.

ABC algorithm has been used in different engineering problems including well-placement optimization of petroleum reservoirs [45], optimization of water discharge in dams [46], data classification [47], and machine scheduling [48]. More description on the ABC algorithm can be found in the other references [18, 43, 49, 50]. A typical flowchart of ABC algorithm is shown in Fig. 1.

3 Data collection

In the present study, a data set obtained from a drilling process in a gas field located in the south of Iran was used. The depth of the well was 4235, which was drilled with one run of roller-cone bit and three runs of PDC bit. The IADC code of the roller-cone bit was 435M, and PDC bits had codes of M332, M433, and M322. Roller-cone bit was used for about 20% and PDC bits for 80% of the drilled depth. In detail, roller-cone bit was used for the depth interval of 1016 to 1647 m, PDC (M332) was used for depth interval of 1647 to 2330 m, PDC (M433) was used for depth interval of 2330 to 3665 m, and finally, the depth between 3665 and 4235 m was drilled by PDC (M322).

The data sets consist of 3180 samples, which were taken every 1 m of penetration from 1016 to 4235 m. The recorded variables included well depth (D), rotation speed of bit (N), weight on bit (WOB), shut-in pipe pressure (SPP), fluid rate (Q), mud weight (MW), the ratio of yield point to plastic viscosity (Yp/PV), and the ratio of 10 min gel strength to 10 s gel strength (10MGS/10SGS). The statistical summary of the data points is gathered in Table 1.

4 Result and discussion

4.1 Prediction

In the present research, an ANN model was developed to predict the ROP as a function of effective parameters. To train the network, three training functions were used including Levenberg–Markvart (LM), scaled conjugate gradient (SCG), and one-step secant (OSS). The number of hidden layers in the network was one, since, according to Hornik et al. [51], one hidden layer is capable of solving any type of non-linear function. The number of neurons in the hidden layer was another parameter to be set. Several equations have been proposed by different authors to determine the optimum number of neurons in a hidden layer, which are represented in Table 2. Ni and No indicate the number of input and output variables, respectively.

Using the values obtained by the equations of Table 2, several ANN models were developed with neurons of 2–16. Then, the models were compared in terms of R2 and RMSE, and the best model was selected [59,60,61]. The comparison was done through the method proposed by Zorlu et al. [62]. In this method, the R2 and RMSE of each enveloped model are calculated. Next, the networks are assigned an integer number according to their R2 and RMSE values, in the way than the better result acquires higher number. For example, if the number of models is equal to 8, the model having the best (highest) R2 value acquires 8, and the model having the worst model acquires the value of 1. This procedure also is repeated based on RMSE comparison. Then, the two numbers of assigned to each model are summed up, and a total score is obtained for each model. Finally, the model acquiring the highest total value is determined as the best model for the problem of study.

In the present article, three types of learning functions were used for training the network, the results of which are presented in Tables 3, 4, and 5. According to the tables, LM, SCG, and OSS functions acquired the best results, respectively. To design an accurate model, the best model of each function was compared. The results of comparison are shown in Figs. 2 and 3. As can be seen, the best model of LM function yielded a better performance. Thus, this function was selected for designing an ANN for the prediction and optimization of ROP.

4.2 Optimization purpose

In the previous section, an ANN was developed for the prediction of ROP using the input data. As mentioned, selecting the most accurate predictive model can significantly affect the performance of optimization. In this section, the performance of the optimization algorithm is evaluated. Then, the ANN model obtained in the previous section is incorporated in the optimization algorithm to optimize the effective parameters for maximizing the penetration rate.

4.3 Evaluation of optimization algorithm

In this section, the best ANN model obtained in the previous section was selected for the optimization of ROP using ABC algorithm. To evaluate the performance of ABC, two functions were used for minimization by ABC:

The range of variations of x1 and x2 are (− 2, 2). In addition, the optimal value of this function at the point (1−, 0) is 3.

This function is plotted in Fig. 4. The ABC algorithm was used for finding minimum point of the above-mentioned function, and the values of − 0.33559 and − 0.52311 were obtained for Eq. 4. The performance of ABC in finding the minimum point is illustrated in Fig. 5.

Function of Eq. 4 plotted in Cartesian coordinates

Evaluation of ABC algorithm for Eq. 4

4.4 Optimization of ROP in petroleum wells

In this section, the ANN predictive model was used for the optimization of parameters effective on ROP. Since the well depth increases during drilling, it was not considered as a decision variable. Hence, the parameters of ROP were optimized in some specific depths. It makes sense in the way that the parameters cannot be optimized in each meter of penetration.

The ABC algorithm was used for the optimization of ROP effective parameters. After a series of sensitivity analysis, it was concluded that the efficient number of population and iterations are 40 and 500, respectively. Three depths on which optimization applied were 2000, 2500, and 3000. The results of optimization in the selected depths are provided in Tables 6, 7, and 8.

As can be seen, in each selected depth, value of ROP was increased by about 20–30%. Therefore, by combining artificial intelligence and optimization, it can create suitable patterns for ROP in an oil well to increase penetration and reduce costs.

5 Conclusions

In the present work, artificial intelligence method was used for prediction of rate of penetration in a gas well. The data were collected from a gas field located in south of Iran. Seven input parameters were selected as input data to develop a predictive ANN model. For this purpose, three learning functions were compared, and LM function was selected as the best function for designing the predictive model (R2 = 0.912 and R2 = 0.893 for training and testing section, respectively). Next, an ABC algorithm was employed to optimize the effective parameters of ROP for maximizing the penetration rate. Three scenarios were selected for considering the well depth in optimization process. Then, the best models for the depths 2000 m, 2500 m, and 3000 m were obtained, and the results showed 20–30% of improvement in penetration rate. Therefore, it was concluded that the proposed model can be used for prediction and optimization of penetration rate in drilling operations. The outputs of this study can be provided as a practical application to use by engineers and researchers. In addition, the developed intelligent methods can be considered as a good alternative for empirical or theoretical methods.

References

Zhao Y, Yang H, Chen Z, Chen X, Huang L, Liu S (2018) Effects of jointed rock mass and mixed ground conditions on the cutting efficiency and cutter wear of tunnel boring machine. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-018-1667-y

Yang HQ, Li Z, Jie TQ, Zhang ZQ (2018) Effects of joints on the cutting behavior of disc cutter running on the jointed rock mass. Tunn Undergr Space Technol 81:112–120

Maurer WC (1962) The “perfect-cleaning” theory of rotary drilling. J Pet Technol 14(11):1–270

Galle EM, Woods HB (1963) Best constant weight and rotary speed for rotary rock bits. In: Drilling and production practice. American Petroleum Institute, Washington, DC

Mechem OE, Fullerton HB Jr (1965) Computers invade the rig floor. Oil Gas J 14

Bourgoyne AT Jr, Young FS Jr (1974) A multiple regression approach to optimal drilling and abnormal pressure detection. Soc Pet Eng J 14(04):371–384

Tansev E (1975) A heuristic approach to drilling optimization. In Fall meeting of the society of petroleum engineers of AIME. Society of Petroleum Engineers

Al-Betairi EA, Moussa MM, Al-Otaibi S (1988) Multiple regression approach to optimize drilling operations in the Arabian Gulf area. SPE Drill Eng 3(01):83–88

Maidla EE, Ohara S (1991) Field verification of drilling models and computerized selection of drill bit, WOB, and drillstring rotation. SPE Drill Eng 6(03):189–195

Hemphill T, Clark RK (1994) The effects of pdc bit selection and mud chemistry on drilling rates in shale. SPE Drill Complet 9(03):176–184

Fear MJ (1999) How to improve rate of penetration in field operations. SPE Drill Complet 14(01):42–49

Ritto TG, Soize C, Sampaio R (2010) Robust optimization of the rate of penetration of a drill-string using a stochastic nonlinear dynamical model. Comput Mech 45(5):415–427

Alum MA, Egbon F (2011) Semi-analytical models on the effect of drilling fluid properties on rate of penetration (ROP). In: Nigeria annual international conference and exhibition. Society of Petroleum Engineers

Yi P, Kumar A, Samuel R (2015) Realtime rate of penetration optimization using the shuffled frog leaping algorithm. J Energy Res Technol 137(3):32902

Hankins D, Salehi S, Karbalaei Saleh F (2015) An integrated approach for drilling optimization using advanced drilling optimizer. J Pet Eng 2015:281276

Asgharzadeh Shishavan R, Hubbell C, Perez H, Hedengren J, Pixton D (2015) Combined rate of penetration and pressure regulation for drilling optimization by use of high-speed telemetry. SPE Drill Complet 30(01):17–26

Wang Y, Salehi S (2015) Application of real-time field data to optimize drilling hydraulics using neural network approach. J Energy Res Technol 137(6):62903

Koopialipoor M, Armaghani DJ, Hedayat A, Marto A, Gordan B (2018) Applying various hybrid intelligent systems to evaluate and predict slope stability under static and dynamic conditions. Soft Comput. https://doi.org/10.1007/s00500-018-3253-3

Koopialipoor M, Armaghani DJ, Haghighi M, Ghaleini EN (2017) A neuro-genetic predictive model to approximate overbreak induced by drilling and blasting operation in tunnels. Bull Eng Geol Environ. https://doi.org/10.1007/s10064-017-1116-2

Hasanipanah M, Armaghani DJ, Amnieh HB, Koopialipoor M, Arab H (2019) A risk-based technique to analyze flyrock results through rock engineering system. Geotech Geol Eng 36(4):2247–2260

Koopialipoor M, Nikouei SS, Marto A, Fahimifar A, Armaghani DJ, Mohamad ET (2018) Predicting tunnel boring machine performance through a new model based on the group method of data handling. Bull Eng Geol Environ 1–15

Shariat M, Shariati M, Madadi A, Wakil K (2018) Computational Lagrangian Multiplier Method by using for optimization and sensitivity analysis of rectangular reinforced concrete beams. Steel Compos Struct 29(2):243–256

Toghroli A, Mohammadhassani M, Suhatril M, Shariati M, Ibrahim Z (2014) Prediction of shear capacity of channel shear connectors using the ANFIS model. Steel Compos Struct 17(5):623–639

Armaghani DJ, Hasanipanah M, Mahdiyar A, Majid MZA, Amnieh HB, Tahir MMD et al (2016) Airblast prediction through a hybrid genetic algorithm-ANN model. Neural Comput Appl. https://doi.org/10.1007/s00521-016-2598-8

Hasanipanah M, Noorian-Bidgoli M, Armaghani DJ, Khamesi H (2016) Feasibility of PSO-ANN model for predicting surface settlement caused by tunneling. Eng Comput. https://doi.org/10.1007/s00366-016-0447-0

Toghroli A, Suhatril M, Ibrahim Z, Safa M, Shariati M, Shamshirband S (2016) Potential of soft computing approach for evaluating the factors affecting the capacity of steel–concrete composite beam. J Intell Manuf 1–9

Armaghani DJ, Mohamad ET, Momeni E, Monjezi M, Narayanasamy MS (2016) Prediction of the strength and elasticity modulus of granite through an expert artificial neural network. Arab J Geosci 9(1):48

Armaghani DJ, Hajihassani M, Sohaei H, Mohamad ET, Marto A, Motaghedi H, Moghaddam MR (2015) Neuro-fuzzy technique to predict air-overpressure induced by blasting. Arab J Geosci 8(12):10937–10950. https://doi.org/10.1007/s12517-015-1984-3

Armaghani DJ, Mohamad ET, Narayanasamy MS, Narita N, Yagiz S (2017) Development of hybrid intelligent models for predicting TBM penetration rate in hard rock condition. Tunn Undergr Space Technol 63:29–43. https://doi.org/10.1016/j.tust.2016.12.009

Mosallanezhad M, Moayedi H (2017) Developing hybrid artificial neural network model for predicting uplift resistance of screw piles. Arab J Geosci 10(22):479

Moayedi H, Jahed Armaghani D (2017) Optimizing an ANN model with ICA for estimating bearing capacity of driven pile in cohesionless soil. Eng Comput. https://doi.org/10.1007/s00366-017-0545-7

Moayedi H, Rezaei A (2017) An artificial neural network approach for under-reamed piles subjected to uplift forces in dry sand. Neural Comput Appl 1–10

Tonnizam Mohamad E, Jahed Armaghani D, Hasanipanah M, Murlidhar BR, Alel MNA (2016) Estimation of air-overpressure produced by blasting operation through a neuro-genetic technique. Environ Earth Sci. https://doi.org/10.1007/s12665-015-4983-5

Hasanipanah M, Jahed Armaghani D, Khamesi H, Amnieh BH, Ghoraba S (2016) Several non-linear models in estimating air-overpressure resulting from mine blasting. Eng Comput. https://doi.org/10.1007/s00366-015-0425-y

McCulloch WS, Pitts W (1943) A logical calculus of the ideas immanent in nervous activity. Bull Math Biophys 5(4):115–133

Garrett JH (1994) Where and why artificial neural networks are applicable in civil engineering. J Comput Civ Eng 8(2):129–130

Fausett L, Fausett L (1994) Fundamentals of neural networks: architectures, algorithms, and applications. Prentice-Hall, Upper Saddle River

Mansouri I, Shariati M, Safa M, Ibrahim Z, Tahir MM, Petković D (2017) Analysis of influential factors for predicting the shear strength of a V-shaped angle shear connector in composite beams using an adaptive neuro-fuzzy technique. J Intell Manuf 1–11

Haykin S, Network N (2004) A comprehensive foundation. Neural Netw 2(2004):41

Koopialipoor M, Fahimifar A, Ghaleini EN, Momenzadeh M, Armaghani DJ (2019) Development of a new hybrid ANN for solving a geotechnical problem related to tunnel boring machine performance. Eng Comput 1–13

Mohammadhassani M, Nezamabadi-Pour H, Suhatril M, Shariati M (2013) Identification of a suitable ANN architecture in predicting strain in tie section of concrete deep beams. Struct Eng Mech 46(6):853–868

Koopialipoor M, Fallah A, Armaghani DJ, Azizi A, Mohamad ET (2018) Three hybrid intelligent models in estimating flyrock distance resulting from blasting. Eng Comput. https://doi.org/10.1007/s00366-018-0596-4

Karaboga D (2005) An idea based on honey bee swarm for numerical optimization. Technical report-tr06, Erciyes University, Engineering Faculty, Computer Engineering Department

Koopialipoor M, Ghaleini EN, Haghighi M, Kanagarajan S, Maarefvand P, Mohamad ET (2018) Overbreak prediction and optimization in tunnel using neural network and bee colony techniques. Eng Comput 1–12

Nozohour-leilabady B, Fazelabdolabadi B (2016) On the application of artificial bee colony (ABC) algorithm for optimization of well placements in fractured reservoirs; efficiency comparison with the particle swarm optimization (PSO) methodology. Petroleum 2(1):79–89

Ahmad A, Razali SFM, Mohamed ZS, El-shafie A (2016) The application of artificial bee colony and gravitational search algorithm in reservoir optimization. Water Resour Manag 30(7):2497–2516

Zhang C, Ouyang D, Ning J (2010) An artificial bee colony approach for clustering. Expert Syst Appl 37(7):4761–4767

Rodriguez FJ, García-Martínez C, Blum C, Lozano M (2012) An artificial bee colony algorithm for the unrelated parallel machines scheduling problem. In: International conference on parallel problem solving from nature. Springer, pp 143–152

Karaboga D, Basturk B (2007) A powerful and efficient algorithm for numerical function optimization: artificial bee colony (ABC) algorithm. J Glob Optim 39(3):459–471

Ghaleini EN, Koopialipoor M, Momenzadeh M, Sarafraz ME, Mohamad ET, Gordan B (2018) A combination of artificial bee colony and neural network for approximating the safety factor of retaining walls. Eng Comput 1–12

Hornik K, Stinchcombe M, White H (1989) Multilayer feedforward networks are universal approximators. Neural Netw 2(5):359–366

Hecht-Nielsen R (1989) Kolmogorov’s mapping neural network existence theorem. In: Proceedings of the international joint conference in neural networks, vol 3, pp 11–14

Ripley BD (1993) Statistical aspects of neural networks. Netw Chaos Stat Probab Aspects 50:40–123

Paola JD (1994) Neural network classification of multispectral imagery. Master Tezi, The University of Arizona, USA

Wang C (1994) A theory of generalization in learning machines with neural applications. PhD thesis, The University of Pennsylvania, USA

Masters T (1993) Practical neural network recipes in C++. Morgan Kaufmann, Burlington

Kanellopoulos I, Wilkinson GG (1997) Strategies and best practice for neural network image classification. Int J Remote Sens 18(4):711–725

Kaastra I, Boyd M (1996) Designing a neural network for forecasting financial and economic time series. Neurocomputing 10(3):215–236

Gordan B, Koopialipoor M, Clementking A, Tootoonchi H, Mohamad ET (2018) Estimating and optimizing safety factors of retaining wall through neural network and bee colony techniques. Eng Comput 1–10

Koopialipoor M, Murlidhar BR, Hedayat A, Armaghani DJ, Gordan B, Mohamad ET (2019) The use of new intelligent techniques in designing retaining walls. Eng Comput 1–12

Safa M, Shariati M, Ibrahim Z, Toghroli A, Baharom SB, Nor NM, Petkovic D (2016) Potential of adaptive neuro fuzzy inference system for evaluating the factors affecting steel–concrete composite beam’s shear strength. Steel Compos Struct 21(3):679–688

Zorlu K, Gokceoglu C, Ocakoglu F, Nefeslioglu HA, Acikalin S (2008) Prediction of uniaxial compressive strength of sandstones using petrography-based models. Eng Geol 96(3):141–158

Acknowledgements

The authors would like to express their sincere appreciation to reviewers because of their valuable comments that increased the quality of our paper. Funding support from Shenzhen Science and Technology Innovation Commission (grant No. JCYJ 20160531192824598, JCYJ 20170811160740635) are greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, Y., Noorbakhsh, A., Koopialipoor, M. et al. A new methodology for optimization and prediction of rate of penetration during drilling operations. Engineering with Computers 36, 587–595 (2020). https://doi.org/10.1007/s00366-019-00715-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-019-00715-2