Abstract

Traditional adaption of CAD geometry, which plays an important role in generating effective and fit-for-purpose finite element models, is usually carried out manually and optionally with excessive dependence on engineer’s experience. Automatic and efficient geometry modification before simulation evidently improves design efficiency and quality, and cuts down product life cycle. This paper represents an automatic approach to generate simplified and idealized geometry models for CAE simulation, which consists of hybrid model simplification criteria, feature-based model simplification, and simulation intent driven geometry modification. Hybrid adaption criteria takes detailed features geometric dimension, geometry topology, design intent into consideration synthetically. Simulation intent-driven modification with the help of virtual topology operators helps to deal with geometry at a higher level to get an ameliorative boundary for mesh without perturbing the original design model with constructing history for down-stream manufacture-oriented application, such as machining feature recognition and process planning. Development of plug-in toolkit guarantees automation of the simplification process and helps generate simulation-fitted geometry for subsequent analysis and simulation process. Prototype system and cases are implemented to demonstrate the result and efficiency of the proposed approach.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Computer aided design (CAD) and finite element analysis (FEA) have been considered independent activities and growing fast, respectively, for a long time. Computer systems’ extensive utilization facilitates the FEA performance more affordable and versatile in solving engineering problems with numerical methods. Models with large quantity of details in CAD commercial applications guarantee the accurate representation of components or assembly. However, too many small features like fillets, holes, bosses, will highly increase the complexity of simulation by expanding elements number and computing cost, even breakdown the progress under some extreme cases. Geometry adaption and simplification before simulation plays an important role in CAD/CAE integration and simulation realization process.

Enormous amounts of efforts have been implemented during the last decade and many researchers gave summary report on various techniques for fully automated or semi-automatic CAD model simplification. For example, Thakur [1], in 2009, classified related literature into four categories including techniques based on surface entity, volume entity, explicit features and dimension reduction. Kwon [2] pre-rendered quantitative evaluation metrics for simplification of feature-based 3D CAD assembly data of ship and offshore equipment. Nolan [3] proposed the concept of simulation intent to link geometry with boundary conditions to facilitate the automation of the simulation or optimization process. Foucault [4] also considered mesh generation method as well as geometry topology for simulation-oriented adaption of CAD model. Besides evaluation metrics and boundary conditions, inconsistency and unsynchronized change in CAD and FE model is another issue that needs to be improved. Common data model containing semantic parameters required for building design model, FE model and engineering analysis process, was presented by Gujarathi [5], to work as centralized data repository to facilitate the design process.

In this study, hybrid evaluation metric of each feature for simplification together with hybrid simplification operators is proposed and corresponding automation tool has been developed. Hybrid evaluation metrics take feature dimension, design intent and features relationship into consideration and calculate quantitative value for each feature. Feature-based simplification, together with topology-based modification and virtual topology adaption is utilized for simulation-oriented model simplification. Feature-based simplification is used to models with construction history using feature suppression operator. With hidden design intents and explicit geometry information in construction history, feature-based method can generate progressive and meaningful level of detail results. Topology-based modification here works as complement implemented after feature-based simplification and includes two operators naming split and wrap-round. Virtual topology-based topology adaption is specially utilized with the simulation intent considering mesh quality and loads constraints. It contains construct operator, split operator and merge operator. These three modification methods are sequential and complement each other which is more efficient than single limited simplification method. Compared to pure topology-based methodology, the proposed hybrid methodology can deal with geometry with complicated topology, easy to generate level of detailed model and is more robust in identifying hierarchical model elements including features, faces and vertices. Geometric information has been utilized for simplification criteria in previous studies [6], and only a few number studies have been implemented considering non-geometric information such as specific simulation information including load area and local mesh refinement. Synchronous consideration of geometric information, design intent and simulation-oriented information makes the proposed hybrid criteria more considerate in model simplification. An automated tool is designed to implement the proposed simplification methodology with hybrid criteria with the help of C + + and application programing interface of NX, which can export neutral format of simplified geometry for subsequent analysis and simulation and the tool can be easily migrated to other commercial CAD platforms with their respective automation tool.

Current adaption and simplification work rely heavily on engineers’ experience and needs repetitive manual work. That isolates CAD and CAE analysis process and hinders CAD/CAE seamless integration. Consequently, an automatic adaption system to facilitate adaption from delicate representation geometry to effective fidelity model for finite element simulation is of urgent need. The remainder of this paper is constructed to try to solve these problems as follows: Chap. 2 reviews the related different approaches for model simplification, CAD-CAE geometry mapping method is involved as well. Chapters 3–5 propose a hybrid and automatic approach to adapt geometry model including feature-based operators, topology-based operators, virtual topology-based operators. In the end, prototype system and case studies are implemented to demonstrate the efficiency of the proposed approach.

2 Related works

2.1 Explicit features removal

Feature is domain-dependent and application-driven [6]. For example, a small hole may be an important function, design or manufacturing feature, while CAE simulation usually ignores it. Therefore, creating a simplified model at different levels of details (LOD), which can be called multi-resolution modeling as well, is preferred to fit different downstream applications including but not limited to, product geometry design, engineering analysis, process planning and manufacturing. Works’ attention is focused on solving the problems in multi-resolution modeling like topology frameworks, criteria for LOD and effectiveness of models. Lee [7] came up with an algorithm based on the effective volumes of features with non-manifold topology and B-rep, to guarantee the unchangeable shape and the intermediate LOD models for arbitrary rearrangement of the features. To improve the quality of volume decomposition method, Kim [8] utilized a combined feature-based simplification method by sequentially and iteratively decomposing models into volumes through applying approach of fillet, round, and chamfer decomposition, wrap-around decomposition, volume split decomposition, and cell-based decomposition. Criterion for LOD based on geometry dimension, e.g., volume or area, is acceptable in preliminary analysis. Compared to size’s criterion method, hybrid method was preferred to be conducted for its precision in generating fit-for-purpose simulation model. Mounir [9] utilized hybrid method considering probable stress concentration besides size criteria. Mun [10, 11] provided multi-criteria decision-making technique based on weighting factors for part reuse to develop new product from existed ones. Kwon [12] proposed the concept of feature shape complexity for the generation of LOD models.

Features created by modeling macro command like blends, fillets, holes can be semantically identified through construction history and sequentially suppressed or deleted for simplification. However, many other situations such as blends constructed by sketch instead of “blends” macro command cannot be reached by suppress operation. Here, topology-based operation works well with appropriate criteria.

2.2 Topology modification

Cross-application or neutral format models may lose design intent such as feature trees and geometric constraints which increase difficulties in recognition and idealization with features. Dimension reduction is always utilized to idealize geometry for engineering analysis, especially for dealing with thin-walled parts, rotary and rod-shaped ones. Woo [13] proposed a divide and conquer approach for mid-surface abstraction. Boussuge [14, 15] modified the given B-rep model by extrusion and revolution operations to link the initial geometry and its idealization robustly, e.g., linkage of a block, created by “extrusion”, to its initial primitive shape plane helps to reach the goal of dimension reduction. B-rep model is adept at representing topology of geometry. But it has two drawbacks: (a) B-rep operation is computation-consuming and (b) B-rep model lacks semantic information. Cellular model with additional shape information was proposed by Bidarra [16] to solve the boundary overlapping and computation cost problem. To overcome time-consuming problem in face extension and intersection operations, Sun [17] put forward an approach for B-REP models simplification based on region suppression. To repair mesh surface, Chen [18] proposed a concept of hybrid surface B-rep to combine continuous and discrete representations of surfaces, that is, to map entities including faces, curves, points to their discrete counterparts including facets, edges and vertices.

Real topology operation will change the model tremendously. It is time-consuming but works successfully, for example, to fill up a hole or remove a non-significant boss as usually do, to create the CAE simulation model. If geometry has narrow faces or small edges, virtual topology operation will be utilized for geometry modification.

2.3 Virtual topology adaption

Feature-based and real topology modification operates geometry at a high level, which would lead to a direct and great modification and that may cause unpredictable results. Editing the geometry directly is ponderous, tedious and expensive. Virtual topology was pre-rendered by Sheffer [19] to change connectivity or high level of topology, which is relatively inexpensive and direct for mesh. Nolan [3] utilized virtual topology as a tool for partitioning and de-partitioning geometry. Partitioned or de-partitioned geometry would be applied with high-level analysis attributes, from which detailed analysis model could be generated. The concept of mesh constraint topology was proposed by Cuilliere [4, 20,21,22], utilizing operators of merging and splitting, to cluster narrow faces or adjacent vertices into area that is better fit for mesh generation. In addition, Chen [18] utilized merging operation to combine neighboring faces into a “virtual” one, with the whole topology of the geometry keeping intact synchronously. Tierney [23] put forward a hierarchical virtual structure for the partition or aggregation of virtual entities, providing users freedom to adapt, modify and simplify the model for mesh.

However, qualified mesh generation including hexahedral mesh and tetrahedral mesh, engineering complexity of the simulation type such as thermal analysis, structural optimization as well as the automation and efficiency of the process, still make modification of geometry by virtual topology operation a challenging work.

2.4 CAD/CAE geometry mapping

Integration of CAD and CAE is a historic challenge, by reason of design intent loss, data inconsistency, difference in mathematics description, etc. Initial design model usually contains construction history, tolerance information for manufacture, detailed features for downstream application, which are of redundancy in information for finite element simulation. Consequently, specific CAD-CAE geometry and information mapping is of great importance to be implemented. The common data model proposed by Gujarathi [5], acquiring geometry information, engineering rules and regulatory, works as a kernel data structure to facilitate generating CAD and FE model. Similarly, Xia [24, 25] pre-rendered a unified representation architecture for CAD display, FE analysis and simulation. Zhan [26] proposed a kind of new thought naming knowledge based ontology mapping method among engineering applications. Ontology represents product conceptualizations and semantic data, functional knowledge and engineering design intents. Hamri [27] tried to integrate CAD/CAE at level of software environment. It is impending for automatic integration to increase efficiency and effectiveness of down-stream optimization work, like structural optimization introduced in paper [28]. Louhichi [29] considered the reconstruction of CAD model from deformed mesh model. Wang [30] utilized the linkage of CAD/CAE to facilitate structural optimization process.

3 Proposed solution

Idealization of geometry model (simplification and modification) should be executed before mesh and simulation. Traditional sequential up-to-down design process is shown in Fig. 1, in which duplicate and tedious manual work must be implemented by designers or engineers.

Traditional onefold model simplification criteria seem insufficient with the increasing requirement of simulation. Apparently, none of any single simplification method can solve such a sophisticated problem.

3.1 Concept of SIMS

Based on that consideration, this paper proposes a conception of Super Inheritance Model for Simulation (SIMS), which is specialized simulation-oriented super model, and four fundamental factors will be considered: (a) geometry with detailed features, (b) real/virtual topology, (c) CAD-CAE consistency, (d) automation for the process of design, analysis and re-design.

As indicated in Fig. 2, SIMS inherits construction history from the original design (CAD) model and works as the model to be simplified or modified for meshing and simulation calculation, while keeping the original model intact. SIMS is essentially a kind of hybrid model containing geometry and simulation-oriented semantic/physical information. Geometry incorporates features construction information and interior topology. Physical information, such as model simplification and modification criteria for idealized model generation and other specification or rules about material, meshing and loads as well as boundary conditions, for subsequent CAE application, are stored in rule library and linked or applied to the feature or geometry instances to assess whether they need to be simplified or modified and by what kind of operators. Simplification and modification operators include feature-based retainment or suppression, topology-based split or wrap-around and virtual-topology-based Split, Merge or Construct.

To construct the instance of SIMS and execute model simplification and modification, sequential steps are addressed as follows:

-

1.

Construction of the hybrid model modification rule library considering both geometric and physical-oriented criteria;

-

2.

Hint and knowledge-based feature identification and classification;

-

3.

Construction of SIMS;

-

4.

Feature-based model simplification;

-

5.

Simulation intent driven geometry modification;

-

6.

Utilization of SIMS in subsequent process, such as exported in neutral format for specific analysis and optimization process.

3.2 Geometry–attribute–operator linkage

In this section, the geometry–attribute–operator linkage for automatic geometry detection and operator implementation is described to verify the efficiency of the designed plug-in. Unified and normative construction rule has been made and implemented to construct standard model which is consistently utilized in design process, analysis, simulation and optimization process as well as manufacture process. The interactive work done by users includes define constraints and loads for simulation and set criteria for model simplification with user interface. Automated simplification implementation comes after such configuration work.

3.2.1 Configuration of simplification criteria and simulation information

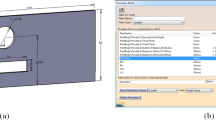

The work users need to do is to configure simplification criteria and assign simulation information with designed user interface. User interface shown in Fig. 3 has been developed with the help of API of NX and plug-in tools are offered for users to conveniently to add hierarchical attributes to geometry. For example, values set for blend and hole are utilized to depress blends and holes of which the radius is smaller than the threshold. Value set in ‘Threshold’ is the criteria considering geometry dimensions considering volume, area and length. It is a percentage value, which is mainly utilized to generate level of detailed geometry.

3.2.2 Attribute detection and operator implementation

In order to effectively manage the involved features and geometries through the simulation-oriented simplification and make the process consistent, a concept of attribute-based geometry–attribute–operator linkage is proposed and is utilized to be simulation specific and featuring with hierarchical semantic engineering information at different levels, which ensures the automatic recognition and the relation between the geometry and corresponding operators. Geometry–attribute–operator linkage can be represented by integration of hierarchical and heterogenous data format as follows:

where in this function, G stands for the hierarchical parametric geometry entity and dimensional parameters, A stands for data related to assembly constraints and S stands for data related to analysis including mesh and element size, boundary conditions and simulation information. The information geometry–attribute–operator linkage will be applied to hierarchical geometry according to the detection rules described in Sect. 3.3. Quantitative metrics for simplification criteria are introduced in Sect. 4.1.2. Hierarchical geometry includes features, bodies, faces, lines and points. The dimensional information includes volume of bodies, length of lines, the location of points, etc. Attributes, which were utilized to represent dimensional parameters, here are extended to represent conventional hierarchical structure, the dimensional information, the physical information as well as some logic information. The simulation information contains the constraints, the loads as well as thermal conditions of the products for simulation. Once simulation information has been marked and simplification criteria configured, automation tool will traverse the whole construction tree for feature and corresponding geometry item detection, to deploy attribute related to operator to detected geometry item. The geometry–attribute–operator linkage can be seen in Fig. 4.

The procedure of user configuration, attribute assignment, geometry–attribute–operator linkage and quantitative metrics calculation can be described as:

- Step 1::

-

configure the simplification criteria and simulation information with the help of automation tool;

- Step 2::

-

the tool traverses the construction tree considering configured information, calculated quantitative metrics for each feature to find geometry items that will be implemented on some operators.

- Step 3::

-

after the attribute assignment work, attribute detection will be implemented automatically to classify corresponding geometry item into different set.

- Step 4::

-

preview the simplification result, accept the result and return simplified geometry; if not satisfied, go to step 1, or go to further simplification work with simplification tool.

3.3 Idealization procedure

With the help of simplification criteria, quantitative metrics and geometry–attribute–operator linkage, models will be classified into different feature category by traversing the construction history. The proposed strategy of feature-based model simplification and simulation intent-driven modification is shown in Fig. 5, where three interdependent parts are involved: Part ① Establishing the hybrid Model simplification and modification rule library, Part ② Classification of Features and Construction of SIMS and Part ③ SIMS Simplification and Modification. The three types of simplification and modification operators, to wit, feature-based suppression or retainment, topology-based wrap-around or split, and virtual topology-based Merge, Split or Construct, will be implemented sequentially. After the implementation of all simplification operators, verification of the modified SIMS is carried out interactively to decide whether to mesh the SIMS model for simulation, or re-simplify the model by users or a reinforced simplification rule, or the worst case to re-recognize and re-classify the initial model.

Sections 4 and 5 elaborate the proposed approach on the sequential steps to implement the three types of operators.

4 Feature-based model simplification

Features, the meta-model with certain geometric shape created by modeling macro command provided by commercial CAD software and recorded on the model construction tree, are utilized to describe components at a higher level than entities like bodies, faces and points, so that the design intent or functional, technological and management information of a product can be represented and captured to facilitate the downstream applications such as hint-based feature recognition and knowledge-based model simplification for CAE simulation.

Different categories of features are recognized and classified by hybrid classification criteria and applied with different simplification operators. It is worth noting that there are difficulties in implementation of features detection, classification and simplification. First of all, the required LOD of geometry differs with respect to subsequent analysis procedures. Simplification tool should satisfy the requirement to obtain higher LOD of geometry to lower one. Second, from the perspective of assembly products in industrial application, the interconnection relationships among components are of greater priority than detail shapes of single geometry, which will conflict with the first points of LOD geometry. Third, CAD systems support geometry construction process and assembly process, but do not have capabilities to manage engineering information. Consequently, an important point can be concluded is that non-geometric information including assembly interface and engineering data should be taken into consideration in simplification procedure. Based on those considerations, this work proposed quantitative evaluation metrics that consist of feature dimension, feature assembly relationship and design intent.

Features constructed by commercial applications, such as NX, can be categorized into sketch feature, form feature, auxiliary features, and other features. Simple examples are shown in Fig. 6. Features can be recognized according to hint of construction history and classified by simplification rule including features dimension, design intent, assembly interface and features relationship.

4.1 Feature recognition and classification criteria

4.1.1 Simplification factors

-

1.

Feature dimension

During design process, usually a large base entity is always created first and then comes small additive or subtractive features. Every feature has its volume and it is reasonable to remove features from the smallest and proceeding to larger one. Feature dimension is utilized as simplification criteria which make the algorithm simple because feature dimension is fixed and easy to obtain. In this paper, volume criteria will be described as a percentage calculated by Eq. (2). SFj is the calculated simplification factor of the j th feature, \(\sum\nolimits_{{i=1}}^{j} {{V_{{\text{of}}}}}\) is the sum of volume of features of which the volume is smaller than the j th feature, \(\mathop \Sigma \nolimits_{{i=1}}^{n} {V_{{\text{of}}}}\) is the sum of all additive or subtractive features except the base entity. With the help of the SFj, small features will be detected and simplified first with appropriate operator introduced by 4.2:

Lower dimensional criteria, such as area, radius, length should be taken into consideration for better accuracy in simplification metrics. For example, radius for blends will be set by users so that blends with smaller radius will be deleted for avoidance of too small size of elements or resulting in chip surfaces. The ratio of area and thickness of a flat shape can be utilized to judge whether a dimension reduction operation may happen or not. In this way, dimensional information of features including volume, area and length is ranked and utilized as one of simplification criteria.

-

2.

Design intent

Design intent in this work refers to simulation information and assembly constraints, which are closely related to geometry items and components, serving as a bridge to link modeling, analysis and manufacture through the product life cycle. Considering simulation analysis, design intent plays an important role in generating a fit-for-purpose simulation geometry, for example, cooling hole should not be simplified whether its radius is smaller than threshold. From the perspective of assembly condition, the identification of design intent such as assembly interface, boundary conditions linked to geometry, guarantee that features related to design intent will not be disturbed during the process of model simplification and modification. An apparent example is screw bolt. The screw might be simplified for its dimension, but when it becomes an object of concern, the bolt hole should not be simplified even its radius is smaller than the set value.

-

3.

Features relationship

Feature relationship takes construction history and adjacent features into consideration. Features have relationship of “parent or children”. Once parent feature suppressed, the children features are suppressed as well. The character accelerates the modification process, but it may lead to troubles. Parent features should not be deleted if their children features should not be deleted. Relationship of features should be detected to guarantee that the modification will not affect features related to design intent. Adjacent features refer to features that are adjacent to features combined with assembly constraints or simulation information, which should not be simplified to keep structure intact.

Figure 7 shows the criteria adopted by the approach. Features dimension criteria are mostly utilized in model simplification. With design intent criterion taken into consideration, assembly holes and cooling water holes, as well as features related to boundary conditions, will be retained. For example, feature c should not be simplified because it is the parent feature of assembly features a and b. Implementation of the feature recognition and classification criteria will be introduced in 4.2.

4.1.2 Quantitative evaluation metric

The different LOD geometry obtained can reach different simulation precision which makes it important for users to easily get simplified geometry they require. On the basis of the three criteria introduced in Sect. 4.2, this work proposed quantitative evaluation metric in Eq. (3) to calculate specific importance for each feature,

where \({E_i}\) refers to importance evaluation of ith feature, \(C_{a}^{i}\) represents volume ranking of a feature equaling to SF calculated by Eq. (1), \(C_{b}^{i}\) represents whether or not a feature is adjacent or parent to assembly constraint feature, \(C_{b}^{i}=1\)(adjacent or parent), \(C_{b}^{i}=0\)(else) and \(C_{c}^{i}\) represents whether or not a feature is adjacent or parent to features related to simulation information, \(C_{c}^{i}=1\)(adjacent or parent) and \(C_{c}^{i}=0\)(else).

\(\omega\) is weighting factor of \(C\),

Initial values of \({\omega _a}\), \({\omega _b}\) and \({\omega _c}\) are set to 0.6, 0.2, 0.2.

The quantitative multi-criteria evaluation is based on decision making method introduced in Ref. [10].

4.2 Feature-based operators

4.2.1 Features suppression and retainment

As illustrated in Fig. 5, features are firstly obtained by traversing the construction tree, and classified into different categories shown in Fig. 6. Secondly, features are traversed, simplification factors and evaluation metrics are calculated according to hybrid rule library. Thirdly, features are reordered by their simplification factors. At the end, the marked features will be retained and the rest of the features will be suppressed or retained to get multi-resolution simplified model.

4.2.2 Topology operator for simplification

Topology operator comes into utilization when features cannot be simply suppressed, for example, the additive or subtractive pattern features shown in Fig. 8a, b. Feature recognition helps to locate local area. Topology operator here means wrap-around and split operator. Wrap-around operator adds material to some hollow region and split operator cuts some volume off a body. Different simplification results are shown in Fig. 9.

-

1.

Wrap-round operator

When dealing with additive features, warp-around operator can be utilized to add material. The algorithm and procedure for the given feature is described as follows: (1) detect the additive pattern features and the face (F1 in Fig. 9a) adjacent to Feature2 and instance1 (Figs. 8a, 9a); (2) find a boundary loop by help of F1 (Fig. 9b); (3) generate faces for wrap-around by co-surface loops (Fig. 9c); (4) wrap around the hollow region (Fig. 9d).

Detailed procedures for detection of the boundary loops and generation of co-surface loops can be seen in [17].

-

2.

Split operator

When dealing with subtractive features, split operator can be utilized to cut off volume. The algorithm and procedure for given feature is described as follows: (1) detect the subtractive features and the face adjacent both to Feature2 and instance1 (Figs. 8b, 10a); (2) find the boundary loops by the help of F1 (Fig. 10a) and generate split face (F2 in Fig. 10b) according to co-surface loops (Fig. 10b); (3) split the body by the split face and generate C1–C4, B1 and B2 (Fig. 10c); (4) unite B1 and B2 with the initial body (Fig. 10d, e); (5) delete C1–C4 and get simplified region (Fig. 10f).

As shown in Fig. 11, V1 is the volume of the entity \({\text{1}}\) and V2 is the volume of hollow region \({\text{2}}\).

-

1.

When \(\frac{{{V_1}}}{{{V_2}}}>1\), it means that the volume of entity is bigger than the volume of hollow region, and material should be added to get a more regular geometry (Fig. 11a, b).

-

2.

When \(\frac{{{V_1}}}{{{V_2}}}<1\), material will be cut off (Fig. 11c, d).

4.3 Implementation of feature-based simplification

The overall procedure for the proposed simplification of feature-based geometry is shown in Fig. 12. Designers are involved in configuration of simplification criteria and assigning design intent to corresponding features. Then, the simplification tool automatically traverses the construction tree and the geometry to calculate simplification factor for each feature. Operations will be applied to geometry items to obtain LOD geometry. The proposed method owns advantages in time saving compared to conventional simplification method where designers have to search features manually and evaluate whether or not remove the feature rely on experience.

A model simplification example is provided using simplification operators introduced in Sects. 4.1 and 4.2. Figure 13 shows the process and the result of feature-based model recognition and simplification.

Figure 14 shows the details of procedure of design intent detection, evaluation metric calculation and model simplification. Initial construction tree of the model to be simplified is shown in Fig. 14a. First, all features are acquired by traversing the construction tree. Second, design intents are detected and the SF is calculated, and consequently features are classified into different categories for different operators. For example, as shown in Fig. 14b, F2-Revolve is detected and marked because it is a design intent related feature, and, F1-Cylinder is detected for it is the parent feature of F2-Revolve. The evaluation metric is calculated for F4-Bosses, F5-Block and F6-Holes by Eq. (2) and Eq. (3) and then these features are sorted by the value of metrics. F7-Blends, or chamfer, fillet, are simplified according to length criteria. F3-Revolve is pattern feature and the detection and simplification method are introduced in 4.2.2. Third, simplification operators will be applied to features according to the classification. As shown in Fig. 14c, F2-Revolve and F1-Cylinder are retained. Multi-resolution simplified models can be obtained by setting different simplification threshold interactively. For example, if threshold equals to 0.78, F5-Block and F6-Holes will be suppressed; if threshold equals to 1, F4-Bosses will be suppressed as well. As to F7-Blends, it will be suppressed if its dimension is smaller than the threshold specially set for blends (Blends threshold, BT in Fig. 14b).

Figure 13d, g, h are multi-resolution simplified models with different levels of details.

Time spent on such geometry shown in Fig. 13 through proposed automated process is about 20 s, which is reduced sharply compared to conventional manual method. Compared to the existing feature-dimension-based simplification method, the hybrid simplification algorithm taking feature dimension, features relationships and design intent into consideration, together with corresponding operators, is more considerate for simulation-oriented simplification.

5 Simulation intent-driven geometry modification

Traditionally, geometry model can be described by both B-rep and CSG, the former focusing on the connectivity relationship between vertices, edges and faces, while the latter focusing on the boolean operation relationship and the space volume of the geometry entity. Virtual topology can be regarded as higher description of model uncoupling B-rep and geometry entity, which adapts the boundary for meshing without direct modifying the geometry entity. Simulation intent, the link between geometry and analysis parameters, are prone to be lost with even a slight change of geometry. The linkage of Virtual Topology and Design Intent with SIMS makes it easier to modify the topology connectivity directly for simulation process and keep consistency of simulation parameters. Principle, operation and construction of SIMS based on virtual topology will be introduced as follows.

In Sect. 5.1, general virtual topology operators including construct, split and merge operators, are described in detail. In Sect. 5.2, the automated tools for implementation which is designed for interaction with users are described, and application in simulation process are presented.

5.1 Virtual topology and operators

Virtual topology is available in popular CAE packages such as ANSYS and NX Simcenter. Virtual topology entities rely on real geometry entities and virtual topology technology refers to the modification of the topology connectivity for better meshing without directly changing geometry entities. There are three fundamental concepts in virtual topology technology naming merging, splitting and construction for topology modification, shown in Table 1.

-

Construct operator is utilized to generate dangling virtual topology without relying on real geometry entities.

-

Split operator is adopted to split ‘parasite’ entity from the initial geometry, providing convenience to apply boundary conditions.

-

Merge operator is utilized to generate larger area by combining more than one adjacent real entities, forming superset entities.

Here list virtual topology entities:

-

1.

Dangling entity: examples are shown in Fig. 15, naming dangling points (DP)and edges (DE).

-

2.

Subset Entity: subset entity is portion of single real geometry entity. Examples are shown in Fig. 16, subset face F1′, F2′ (Fig. 16b) generated by splitting F1 (Fig. 16a), and in Fig. 17, subset body (Fig. 17b) generated by splitting the initial body (Fig. 17a).

-

3.

Superset Entity: superset entity is the combination of several adjacent real geometry entities. Examples are shown in Fig. 18, superset edge E’ (Fig. 18b) generated by merging E1 and E2 (Fig. 18a).

5.2 Application of virtual topology for simulation

In this section, virtual topology operators, implemented by a designed plug-in tools written in C + + with the help of Application Programing Interface (API), are presented. The procedure is shown in Fig. 19. Firstly, user interface shown in Fig. 3 has been designed for criteria configuration. The automation system will traverse the geometry to search geometry items satisfying the criteria. Then, after geometry simplification with feature-based operator, topology-based split and wrap-round using hybrid criteria evaluation, virtual topology operators are implemented on such items to obtain virtual topologies to which simulation intent will be applied. The main functions of the plug-in tool are: (a) configure the criteria, (b) automated detection with criteria and (c) automated implementation for operators with the help of API and general virtual topology operators. The functions release designers or engineers from tedious, experienced-based and error-prone manual work to do real creative work.

Virtual topology application for simulation refers to virtual topology modified according to simulation intent. It has three main applications: (1) geometry topology modification considering small entities, (2) local mesh refinement considering simulation constraints, (3) direct linkage between simulation intent and virtual topology entities.

-

1.

Topology modification

Simplified model with feature-based criteria is usually full of small entities, e.g., narrow faces or sharp angles which are considered as geometry defect leading to unqualified mesh and extensive element number. That hinders automatic mesh generation procedure. The SIMS with virtual topology concentrates on (1) criteria for the automatic identification of narrow faces or sharp angles and small area with little edges; (2) automatic or semi-automatic virtual topology modification.

-

(a)

Pre-defined detection rules;

-

1.

Edges with its length smaller than element size;

-

2.

Faces with area smaller than a threshold, for example, 10 mm2;

-

3.

Edges with angles smaller than a threshold, for example, 15°.

Friendly user interface shown in Fig. 3 is offered for designers or engineers to conveniently set these detection rules. Once the rules are set, the program start to search the geometry and to find topology satisfying the rules and storing it with structure described in Sect. 5.1, which will be utilized for virtual topology modification subsequently.

-

(b)

Automated implementation

Virtual topology operations will be implemented after features-based geometry simplification and topology-based geometry modification. Narrow faces with small edges will be firstly detected and highlighted by detection rules and then be merged into its smallest adjacent face. As shown in Fig. 20, the initial geometry is shown in Fig. 20a, with the detection rules, small edges and narrow faces are detected in Fig. 20b, merge operation based on virtual topology described in Sect. 5.1 is implemented in Fig. 20e to topology detected. The results show that the mesh quality improves on comparing with Fig. 20c, f.

After hint-based feature recognition, feature-based simplification and virtual topology-based modification, ameliorative geometry and qualified mesh is generated for simulation.

-

1.

Local mesh refinement

Local mesh refinement is always applied to area where is of great concentration. Virtual topology operator SPLIT can divide larger entity into smaller ones with real geometry intact. Refinement applied to smaller volume (Fig. 21c, V2) instead of the initial whole volume (Fig. 21b V1), will largely decrease elements number.

-

3.

Direct linkage between virtual entities and simulation intent

The advantage of virtual topology lies in that: (1) virtual topology operators modify geometry directly for simulation intent without real topology change; (2) virtual topology guarantees virtual topology entity link closely to boundary conditions. Simulation intent is closely linked to mesh model including nodes and elements. A closed loop has to be constructed if a load is applied to a real geometry point (Fig. 22b). Dangling point can be directly applied with load because a node of mesh model can be linked right to it (Fig. 22c, d).

Thermal condition and the loads at different time and observation points are shown in Fig. 23. The loads and constraints are manually loaded at the geometry shown in Fig. 24 conventionally which is time-consuming and error-prone. With the proposed tool, topology is automatically detected and modified to fit the load conditions. The convenience that virtual topology offers is verified. Edges are merged or split at different thermal conditions and load constraints, which are shown in Fig. 24. The initial geometry and load or thermal condition is shown in Fig. 24a. As shown in Fig. 24b, with vertex V0, V1V2 and V3 deleted with Merge operator, and virtual point P0, P1, P2 and P3 inserted, edges E1, E2, E3 and E4 are split and merged into E1′, E2′, E3′ and E4′, which are appropriate for the load and thermal conditions.

To subdivide stress concentration area, subset body generated by split operator can be utilized to get hexahedral mesh for high analysis precision. Figure 25 shows the difference between initial geometry with its mesh and simulation intent topology with local hexagon mesh.

6 Case studys and discussion

6.1 Case studys

The efficiency and accuracy of the proposed SIMS is confirmed by applying to several models shown in Figs. 26 and 27. The procedure has been implemented as a C + + plug-in tool for NX. With sequential feature-based recognition and simplification operators introduced in Sect. 4 and successive simulation intent-driven modification operators in Sect. 5, the proposed SIMS is constructed and utilized for finite element analysis and simulation.

Feature recognition, classification and geometry modification can be implemented on initial model with construction history. Subsequent traverse of modified model will locate narrow faces and angles, short edges, pre-defined load constraints and some other simulation properties.

The implementation process of Fig. 26 lists as follows:

Configure the criteria with user interface;

Automatically traverse the whole construction tree and geometry shown in Fig. 26a to detect items that satisfy the criteria and set attributes;

Implement the corresponding feature-based operators shown in Fig. 26b;

Detect narrow faces, small edges and angles and implement virtual topology-based operators shown in Fig. 26c;

Obtain simplified model, export neutral format geometry and mesh the simplified model for subsequent analysis process; Fig. 26d is utilized to compared with the mesh of initial model and simplified model with statistical data shown in Table 2. Yellow lines in Fig. 26d indicate unsatisfying meshes.

Recommended size of mesh can be regarded as index of regularity of geometry. FE model with smaller element number costs less computation time and storage. Although complexity, time and computation cost of the method depends heavily on the complexity of the initial model, automation of the process and better qualified mesh model will help engineers with a prepared and specified simulation-oriented model. It is important to point out that the result shown with coarse mesh is for verification of the proposed method instead of real analysis.

Another model utilized in industrial applications is shown in Fig. 27. The main procedure is described as:

-

1.

Configure simplification criteria and assign assembly constraints and simulation intent with user interface, shown in Fig. 27a;

-

2.

Automatically traverse the construction tree and geometry to detect and classify features into different set, implement feature-based operators, detect small faces and edges, implement virtual topology operators, shown in Fig. 27c;

-

3.

Import thermal condition and location information shown in Fig. 23, and virtual operators has been implemented to link geometries to thermal condition, shown in Fig. 27c;

-

4.

Evaluate the simplified model. Mesh model of initial model is shown in Fig. 27b, where yellow lines indicate unsatisfying meshes, and mesh model of simplified model is shown in Fig. 27c, where the mesh shows better quality.

-

5.

Export neural format geometry and mesh for subsequent analysis and simulation.

After a series automatic operation, we get the final simplified model prepared for FEA with characters as:

-

1.

Features are simplified according to hybrid quantitative evaluation metrics and feature-based simplification operators and topology-based operators;

-

2.

Geometry defects are eliminated by virtual topology operators with pre-defined criteria;

-

3.

Area that may produce stress concentration is eliminated by virtual topology operation.

7 Discussion

-

1.

Advantages

Hybrid simplification rule: We first discuss the simplification rule of the designed plug-in tool, that is, the hybrid rule considering hierarchical geometry including features with construction tree, topology and virtual topology linked to physical constraints and loads.

Lightweight attribute representation For the proposed work, the geometry-attribute linkage plays a critical role in keeping automation of geometry detection and implementation of simplification operators. Attributes here in this paper are extended including dimensional information, physical information and logistic information. Attributes of dimensional information and logistic information can be calculated by traversing the construction tree and added automatically, while attributes of physical information are added or edited by users with the help of pre-defined user interface. Various attributes are added and linked to hierarchical geometry which is easy to implement subsequent operators. The management of context attributes is more convenient than dealing with the geometry directly and operators are conveniently implemented with closed geometry–attribute linkage. Attributes here in this paper are extended including dimensional information, physical information and logistic information. Attributes of dimensional information and logistic information can be calculated by traversing the construction tree and added automatically, while attributes of physical information are added or edited by users with the help of pre-defined user interface. Various attributes are added and linked to hierarchical geometry which is easy to implement subsequent operators. The management of context attributes is more convenient than dealing with the geometry directly and operators are conveniently implemented with closed geometry–attribute linkage.

8 Limitations and future work

A method that consider more general construction method and general range of geometry is still needed, which is a theme for future research. For example, construction methods of geometry are limited and normative where designers shall not use synchronous modeling approach unless conventional methods cannot be utilized to obtain the specified geometry shape. As an academic research, the work presented is a prototype which will be extended with much more test cases, more complicated features considered, and non-standardized construction methods. For further research or application in industry, several limitations of the proposed approach and the plug-in tool are listed for future development. Firstly, the proposed methodology is implemented on NX and consequently when it transforms to other platform, such as Pro/E and Catia, the code resources and the user interfaces must be redesigned with their corresponding API and development language. What’s more, the scope of features the plug-in tool can manage is limited to referred feature types and the proposed plug-in tool has no complete evaluation system to automatically implement iterative process for simplification. Secondly, another limitation lies in that when the design changes, the whole simplification process will start at the very beginning and the change of design is frequent. This limitation sometimes is acceptable because the simplification process is automated and saving time compared to manual work. Thirdly, there is no suitable quantitative evaluation for simplified geometry, which is a problem to be solved.

9 Conclusion

This work proposes a hybrid quantitative simplification criteria and automatic approach for simulation-oriented geometry simplification with the help of the concept of SIMS which is based on geometry-attribute-operator linkage, utilizing feature-based operators, topology-based operators and virtual topology-based operators, to automatically modify geometry model specially for FE analysis without changing manufactured-oriented model. Simplification criteria contains geometry dimensional information, simulation intent and features relationship. Topology operators are utilized to modify SIMS according to the criteria. Evaluation metrics are designed and calculated considering geometric information and non-geometric information, such as geometry volume, features relationships, assembly constraints and simulation intent. Corresponding operators for automatic implementation of simplification are introduced, including features suppression, topology operators containing split and wrap-round, and virtual topology operators containing construction, split and merge. The novelty of this work lies in that the evaluation metrics considering both geometric dimension, assembly constraints and simulation intent, where the hybrid metric helps generate simulation-oriented LOD geometry. There are very few of literatures have discussed hybrid quantitative metrics considering multiple criteria to the best of our knowledge. Simplified model can be utilized to generate neutral format for subsequent analysis and simulation work. Simplified mode with simulation information stored can be used to automatically derive mesh model with help of corresponding programming language, e.g., application programming design language (APDL) of ANSYS software. Automated toolkits are provided for users to enlarge the scope of the modification. Mesh-related geometry refinement, to wit, virtual topology operation, is employed to detect and eliminate probable stress concentration. The ability to increase the quality of mesh by modification of SIMS is verified through test cases.

More general methodology dealing with geometry is still needed to be developed, with many problems to be solved, such as quantitative evaluation of quality of simplified model, broader range of types of features and automation in simplification, generation of simulation model and optimization model. Further work will focus on integrating SIMS adaption into structure optimization work to help automatic CAD/CAE integration process.

References

Thakur A, Banerjee AG, Gupta SK (2009) A survey of CAD model simplification techniques for physics-based simulation applications. Comput Aided Des 41(2):65–80

Kwon S, Kim BC, Mun D, Han S (2015) Simplification of feature-based 3D CAD assembly data of ship and offshore equipment using quantitative evaluation metrics. Comput Aided Des 59:140–154

Nolan DC, Tierney CM, Armstrong CG, Robinson TT (2015) Defining simulation intent. Computer-Aided Design 59:50–63

Foucault G, Cuillière JC, François V, Léon JC, Maranzana R (2013) Generalizing the advancing front method to composite surfaces in the context of meshing constraints topology. Comput Aided Des 45(11):1408–1425

Gujarathi GP, Ma YS (2011) Parametric CAD/CAE integration using a common data model. J Manuf Syst 30(3):118–132

Sanfilippo EM, Borgo S (2016) What are features? An ontology-based review of the literature. Comput Aided Des 80:9–18

Lee SH, Lee K (2012) Simultaneous and incremental feature-based multiresolution modeling with feature operations in part design. Comput Aided Des 44(5):457–483

Kim BC, Mun D (2014) “Feature-based simplification of boundary representation models using sequential iterative volume decomposition. Comput Graph 38:97–107

Mounir H, Nizar A, Borhen L, Benamara A, Deneux D (2013) FEM simulation based on CAD model simplification: a comparison study between the hybrid method and the technique using a removing details. In: Haddar M, Romdhane L, Louati J, Ben Amara A (eds) Design and modeling of mechanical systems. Springer, Berlin, Heidelberg

Mun D, Ramani K (2011) Knowledge-based part similarity measurement utilizing ontology and multi-criteria decision making technique. Adv Eng Inform 25(2):119–130

Mun D, Kim BC (2017) Extended progressive simplification of feature-based CAD models. Int J Adv Manuf Technol 93:915–932

Kwon S, Mun D, Kim BC, Han S (2016) Feature shape complexity: a new criterion for the simplification of feature-based 3D CAD models. Int J Adv Manuf Technol 88:1831–1843

Woo Y (2014) Abstraction of mid-surfaces from solid models of thin-walled parts: a divide-and-conquer approach. Comput Aided Des 47:1–11

Boussuge F, Léon J-C, Hahmann S, Fine L (2014) Extraction of generative processes from B-Rep shapes and application to idealization transformations. Comput Aided Des 46:79–89

Boussuge F, Léon J-C, Hahmann S, Fine L (2014) Idealized models for FEA derived from generative modeling processes based on extrusion primitives. Eng Comput 31(3):513–527

Bidarra R, Madeira J, Neels WJ, Bronsvoort WF (2005) Efficiency of boundary evaluation for a cellular model. Comput Aided Des 37(12):1266–1284

Sun R, Gao S, Zhao W (2010) An approach to B-rep model simplification based on region suppression. Comput Graph 34(5):556–564

Chen J, Cao B, Zheng Y, Xie L, Li C, Xiao Z (2015) Automatic surface repairing, defeaturing and meshing algorithms based on an extended B-rep. Adv Eng Softw 86:55–69

Sheffer MBA (2000) Virtual topology operators for meshing. Int J Comput Geomet Appl 10(3):309–331

Foucault G, Cuillière J-C, François V (2008) Adaptation of CAD model topology for finite element analysis. Comput Aided Des 40(2):176–196

Cuillière J-C, Francois V, Drouet J-M, Automatic mesh generation and transformation for topology optimization methods. Computer-Aided Design 45:1489–1506

Cuillière J-C, François V, Lacroix R (2016) A new approach to automatic and a priori mesh adaptation around circular holes for finite element analysis. Comput Aided Des 77:18–45

Tierney CM, Sun L, Robinson TT, Armstrong CG (2015) Generating analysis topology using virtual topology operators. Proc Eng 124:226–238

Xia Z, Wang Q, Wang Y, Yu C (2015) A CAD/CAE incorporate software framework using a unified representation architecture. Adv Eng Softw 87:68–85

Xia Z, Wang Q, Liu Q, Wang Y, Liu J, Chen G (2016) A novel approach for automatic reconstruction of boundary condition in structure analysis. Adv Eng Softw 96:38–57

Zhan P, Jayaram U, Kim O, Zhu L (2010) Knowledge representation and ontology mapping methods for product data in engineering applications. J Comput Inf Sci Eng 10(2):021004

Hamri O, Léon JC, Giannini F, Falcidieno B (2010) Software environment for CAD/CAE integration. Adv Eng Softw 41:1211–1222

Park HS, Dang XP (2010) Structural optimization based on CAD–CAE integration and metamodeling techniques. Comput Aided Des 42(10):889–902

Louhichi B, Abenhaim GN, Tahan AS (2014) CAD/CAE integration: updating the CAD model after a FEM analysis. Int J Adv Manuf Technol 76:391–400

J Wang et al (2016) A CAD/CAE-integrated structural design framework for machine tools. Int JAdv Manuf Technol 91:545–568

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Feng, Q., Zhou, X. & Li, J. A hybrid and automated approach to adapt geometry model for CAD/CAE integration. Engineering with Computers 36, 543–563 (2020). https://doi.org/10.1007/s00366-019-00713-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-019-00713-4