Abstract

New product design is inspired by the existing design. The clustering of similar design cases therefore enhances new product development (NPD). At the beginning of NPD, the success of creative design highly depends on the designers’ subjective judgments and try-and-error attempts due to its very obscure prospect. To facilitate an efficient approach for generating creative ideas, this paper proposes a new design method by integrating fuzzy relational analysis, case-based reasoning (CBR) and C-K theory. The proposed design method involves four specific sections: design criteria importance ranking; similarity measurement for design knowledge; knowledge clustering method for innovation and a step-by-step design algorithm. Moreover, a new battery buckling machinery is used as a empirical study to verify the workability of the proposed method. The contributed method shows its advantages to cultivate the inspirations from the existing design and generate creative design concepts from knowledge combination.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Nowadays, creative design has played a crucial role in the success of the companies [1]. Organizations need to innovate to maintain their competitive advantages in dynamic market [2, 3]. It is widely accepted that the innovations of NPD deeply rely on former design experience and knowledge, other than building total new products from scratch [4, 5]. Case-base reasoning (CBR) is a knowledge paradigm that solve new problems by applying the previous cases that are similar to the products in development [6]. Therefore, CBR has attracted widespread interests from the relevant domains and plays an important role in both conceptual synthesis [7] and engineering design [8].

The success of creative design based on CBR is closely reliant on feature selection and case organization in its case memory (library) [9]. Design ideation, especially at the beginning stage of NPD has obvious uncertainty, but it determines as much as 70–80% of the whole product development cost [10]. Sometimes the design requirements from customers are too ambiguous for designers [11] to conduct effective CBR processes since the absence of clear guidances for case retrieval and reusing of the existing design cases.

To deal with the uncertainty of the early stage in NPD, fuzzy rough number and grey relation analysis are widely used to manage the subjectivity in design concepts evaluation [3, 12]. The attempts to integrate the fuzzy cluster analysis and CBR are observed in feature selection [13], fabric advisory system [14], value engineering [15], cost estimation [2], feature clustering [9], just to name them a few.

With the help of fuzzy rough number based relation analysis (FRA) and the CBR, it is possible to facilitate the knowledge clustering of similar design cases at the very beginning of NPD. However, the traditional CBR has its well-defined limitation in resolution of inventive problems since its strong assumption that all the solutions already found are good enough to create the new design concepts. Therefore, the integration of other method is required to facilitate the application of CBR in innovations of NPD to make best of the existing cases in creative design. The C-K theory seems an ideal companion for CBR in inspiring the creative ideas for NPD. From the perspective of the C-K theory [16], the creation of innovative design concepts lies in the expanding of both concepts and knowledge spaces through the introducing the knowledge from outside domains. As the result of combination of CBR and C-K theory, CBR helps to build the knowledge spaces and enhances the knowledge reasoning process; meanwhile C-K theory proposes a framework through which the creative ideas are generalized by introducing the new design knowledge and expanding the concepts and knowledge spaces.

To the best of our knowledge, this paper is the first attempt to present a novel design approach by combining the FRA, CBR and C-K theory in forms of a variant C-K design algorithm to boost the creative ideations in NPD. To attain this objective, the rest of paper is organized as follows: Sect. 2 presents a brief review about CBR, fuzzy number based relation analysis, knowledge similarity measurement, C-K theory and knowledge-based creative design as the scientific foundation to this study. Section 3 explains the proposed method from four aspects involving design criteria ranking, function similarity measurement, knowledge clustering for innovation and design algorithm. Section 4 is an illustrative case to verify the feasibility of the proposed method. Section 5 highlights both the contributions and the limitations of the study.

2 Background

2.1 Case-based reasoning

Case-based reasoning (CBR) uses validate prior experience, or design cases, as solution to solve new problems [17]. CBR is built on the principles of analogical reasoning, through which design problem are resolved by adapting previously successful solutions to current problems [2].

The case is the central notion of CBR, which is usually represented as a pair formulated by problem and its solution [18]. To facilitate the case retrieval, a CBR system usually comprises four modules: case representation, case retrieval, case adaptation, case evaluation revision and learning [19]. Another important study [20] has regarded CBR as a cycle composing of four main subjects: Retrieving similar previously experienced cases; Reusing the retrieved cases; Revising the solutions for solving the new problem; Retaining the validated new solution.

The usage of CBR has several advantages, for instance, CBR employs the specific characteristics rather than general knowledge of problem domain, it is beneficial when the problems are not completely understood [18]. That may be the reason that CBR has numerous applications in various domain such as the medical diagnostics support [17] and risk management [21].

2.2 Fuzzy rough theory and triangular fuzzy number

Fuzzy logic helps to represent the characterization of imprecise and uncertain information in the cases of study [15]. Therefore, the theory of fuzzy set has been widely used to deal with the uncertainty associated with vagueness in a manner analogous to human thought [25], in which the most concerned issues involves the feature selection. Zhang et al. [22] and similarities measurement [15] to facilitate the case retrieval.

Fuzzy rough number is an important approach used by group decision making (GDM) [23] to aggregate individual judgments and priorities from group experts and manage the subjectivity among them [24]. The rough number [12] originated from rough set theory handles the subjective judgments regarding product design form the customers or experts.

Among the fuzzy rough numbers, the triangular fuzzy numbers (TFNs) are most commonly used [15] with the membership function [23] Q(x): R → [0, 1] is equal to

in which l and u denote the lower and upper limits of the fuzzy number Q, while its interval can be calculated as u-l. As the results of simplicity, the aforementioned fuzzy number is denoted as Q = (l, m, u). Operation laws for the TFNs are proposed by research [25] that involve addition “⊕”, subtraction “\(\otimes\)” and multiplication “\(\otimes\)”.

2.3 Grey relation analysis

At the beginning stages of NPD, there is limited information with high uncertainty for designers to make decisions concerning multiple criteria such as customers requirements, function analysis, technologies, design constraints [26]. In this respect, grey relation analysis [27] seems to be promising to provide the solution since it is a robust but simple and straightforward multi-criteria decision-making technique [12]. Grey relation analysis is able to calculate the correlation between the reference factor and the other compared factors of a system [11]. Therefore, most of previous works has successfully solved the multi-criteria decision making problems in different areas by integrating the grey relation analysis [28, 29].

The traditional grey relation analysis includes six steps [30] as the sections followed by in specific.

Step 1: constructing the initial decision matrix(X) involving n samples characterized by m criteria.

Step 2: Normalization based the characteristics of the criteria. Specifically for the criteria belonging to the larger -the-better:

For the smaller-the-better:

For the nominal-the-best with the xobj(j) is the target value for the jth criterion.

Step 3: Construction of normalized matrix by replacing each item in (5) with the calculation results of \(x_{i}^{\prime }(j)\) through the Eqs. (3)–(5), meanwhile the largest normalized value of each criterion works as the reference value in relation to the jth criterion.

Step 4: Calculate the difference between each normalized item and its reference value and build the difference matrix.

Step 5: Calculation of the grey relational coefficient for each item:

Step 6: Calculate the grey relational degree.

\({\Gamma _{oi}}\) is the grey relational degree that indicates the magnitude of the correlation, such as the similarity measured between the compared sequence and the reference sequence.

2.4 Knowledge clustering based on the similarity

Cluster analysis is a popular technique that has attracted a large amount of attentions among the data mining methods in CBR [31]. The main purpose of clustering is transferring the whole case library into several smaller ones in which the cases are more similar to each other. As the result, the most similar cluster would be retrieved with the comparison to the design target [9].

In product design, the design cases or patents that have the similar functions and technological structures usually play the roles of design heuristics [32] for inspiring the new ideas. In most cases, cosine similarity measurement [9, 33] is a widely used approach to screen out the potential design examples from the retrieval results. In similarity measurement, the patterns of the function and structure are two main indicators to classify the design knowledge. However, a comprehensive understanding about the knowledge in product is the premise for the reasonable knowledge cluster results.

The study on the systematic modeling of knowledge [34] in innovation has brought new inspiration for facilitating the knowledge clustering in product creative design from the multiple-facets nature of knowledge [35]. These various attributes found in definitions of knowledge can be divided into two groups: content and context. Firstly the attributes of content reflect the specific information about the domain such as the technological background of the knowledge [36]. While the contextual attributes of the knowledge mainly describes how the knowledge connect with its surroundings such as how a product meet the customers’ requirements [37]. For design ideation, it is wise to transform the knowledge into several clusters by their attributes of content and context dimensions through the similarity algorithm based on TFNs and grey relational analysis.

2.5 C-K theory

Creative design not only depends on the knowledge from the similar design cases in the same domain, but also requires knowledge from the other related domains, which beyond the realm of traditional CBR [17]. A generic consideration about the mechanism of innovation is the premise of applying the results of knowledge clustering to the generation of creative design ideas. C-K theory modeled design as the interplay between two independent spaces, namely, the space of concepts (C) and the space of knowledge (K) with different structures and logics [38]. In C-K theory, space K contains all the true propositions as the available knowledge, while space C contains all the concepts which are undecided propositions without the references in space K to prove their correctness [39].

C-K theory has developed the dynamic mapping process between required function and selected structures [40] to describe the generation of new objects and new knowledge which is the distinctive nature of design [39]. There are four operators [38]: C→C, C→K, K→K, K→C to explain the nature of creative design by expanding both the space C and the space K. These operators provide a general strategy to use the knowledge clustered by various attributes from both content and context dimensions. Figure 1, which is built on [41], illustrates how the four operators work in C-K theory to expand the regions of both concepts and knowledge that is related to the initial concept by introducing out-domains knowledge and building the concepts networks.

2.6 Knowledge-based creative design

Many researchers have investigated the correlations between knowledge creation and idea generation [42,43,44], while there is a study [45] argued that the innovation involves the transformations of knowledge into new products, services or business models. Knowledge plays a strategically important role in management of organizations’ success [46] as it speeds up the creation of new ideas in new and innovative ways [47].

As the cross-links in the creation of knowledge is often treated as the “creative leaps” for its producer [48], product innovation requires abundant scientific knowledge form different fields [49]. Accordingly, a designer holding a broader cross-discipline is more possible to produce more sound innovative ideas at the conceptual design stage of NPD since he or she can think out of the box, make up for his own knowledge. Nevertheless, if the designer only relays on his own knowledge or experience, his creativity will be restrained [49].

Application of new knowledge from other technological domains usually produces the design concepts with high level of innovation [50]. In current, novelty maybe the most recognized aspect of innovation. The degree of novelty is defined by the technological difference, in other words, how big is the leap from existing solutions [51].

From this viewpoint, knowledge from other technological domains can be observed in forms of technological means that are different from the existing solutions. Therefore, the technological difference seems an ideal proxy for the innovation of design concepts or at least the clue for searching the possible out-domain design knowledge.

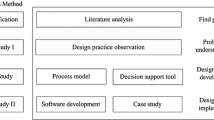

3 Proposed methods

This paper proposes a creative design method involving four specific sections: design criteria ranking, functional similarity measurement, knowledge clustering for innovation, and design algorithm. These sections are discussed as the following.

3.1 Design criteria ranking

At the beginning of design, designers determine the main function of product to meet the customers’ requirements. Due to the high uncertainty of design prospect, these function requirements are the main criteria for the following phases of design project. In most cases, designers give their subjective opinions on the importance of the function requirements based on their personal preference. Therefore, the fuzzy relational analysis is introduced to rank the importance of function requirements to deal with the uncertainty and the subjectivity of judgments made by the group of designers.

The ranking of design criteria based on TFNs relation analysis involves following steps:

Step 1: For a product design consists of n function requirements, a TFNs complementary matrix à = (ãij)n×n is used to represent the comparison results of importance between the i criteria and the j criteria. The fuzzy rough used by this paper for comparing the importance of criteria is shown in Table 1, for example if the ith function requirement is more essential than the jth function requirement, and its comparison result is 0.9, on the contrary the value is 0.1.

For ãij is a TFN and it is represented as \(\mathop {{a_{ij}}}\limits^{\sim } =[\mathop {{a_{ij}}}\limits^{L} ,\mathop {{a_{ij}}}\limits^{M} ,\mathop {{a_{ij}}}\limits^{U} ]\) where

Step 2: Calculate the weight vectors \(w={({w_1},{w_2}, \ldots ,{w_n})^T}\) in fuzzy ordered weighted averaging (FOWA) operator [52] through formula (11) and (12) where the operator Q is by its low and upper ends shown as Q(a, b), in which a indicates the lower end while the b is the upper end. In this study, a is set as 0.3 and b is 0.8 for representing the majority of the subjective judgments.

Step 3: Calculate the expected value \(\mathop {{a_{ij}}}\limits^{{\sim (\lambda )}}\) for each ãij in complementary matrix à through formula (13), in which λ is chosen as 0.5 for a normal preference. Subsequently, the ranks the order of ãij based on \(\mathop {{a_{ij}}}\limits^{{\sim (\lambda )}}\), in other words, the ãij with the largest \(\mathop {{a_{ij}}}\limits^{{\sim (\lambda )}}\) is ranked the first in each row of matrix. The result of ranking is represented as \(\mathop {{b_{ik}}}\limits^{\sim }\).

Step 4: Calculate the importance value \(\mathop {{d_i}}\limits^{\sim }\) for each criteria through formula (14) with the FOWA addition operator.

Step 5: The importance value \(\mathop {{d_i}}\limits^{\sim }\) is another TFN, so the expected value \(\mathop {{d_i}}\limits^{{\sim (\lambda )}}\) of each \(\mathop {{d_i}}\limits^{\sim }\) is calculated through (15) in which the λ is also usually chosen as 0.5.

Then the expected value \(\mathop {{d_i}}\limits^{{\sim (\lambda )}}\) is normalized through (15) to represent the final ranking weight value \(\omega ={({\omega _1},{\omega _2}, \cdots ,{\omega _n})^T}\) indicating the importance of every criteria.

Step 6: Calculate the overall weigh value \({\omega _O}={({\omega _{O1}},{\omega _{O2}}, \cdots ,{\omega _{On}})^T}\) for each design criteria based on judgments of all the designers in the rating group. If there are m raters in total recruited, the overall weigh value is calculated by (17) in which the weight value for each rater in the group denotes as \({v_j}\) that is decided by the role played by the rater.

3.2 Knowledge similarity measurement

The importance ranking of function requirements in design have provided the important criteria for measuring the similarity between the existing design cases and the target design. The measurement of their similarity involves several specific steps as following:

Step 1: Build the set of criteria and rank their importance.

For example, a product consists of n function requirements which denotes as F = [f1, f2,…, fn]. The ranking weight values of all these criteria can be calculated and normalized by the method in 3.1 with their ranking result denoting as ω = [ω1, ω2, …, ωn].

Step 2: Construct the comparison vectors.

The sum of design criteria from both design cases in comparison formulates the comparison vectors. For example, design case i has m function requirements as the criteria that denotes as Fi = [f1, f2, …, fm] and design case j has n criteria which denotes as Fj = [f1, f2, …, fn]. Their comparison vectors are denoted as \({F_A}={F_i} \cup {F_j}=[{f_{A1}},{f_{A2}}, \ldots ,{f_{Ak}}]\) where \(\hbox{max} (m,n) \le k \le m+n\).

Step 3: Define the importance weighted value of comparison vectors.

The aforementioned design criteria ranking has decided the importance value for each criteria in a normalized way. The comparison vectors with weighted value are decided by both the comparison vectors and their importance ranking. For example, in the comparison between design case i and design case j, the comparison vectors with weighted value for the design case i denotes as Fsi, where Fsi = [fsi1, fsi2, …, fsik], fsit = ωit when fsit∈Fi (1 ≤ t ≤ k) and fsit = 0 when fsit does not belong to Fi.

Step 4: Similarity calculation based on the law of cosine.

The similarity of two design cases comparison is measured by the law of cosine. For example, the similarity comparison vectors between design case i and design case j denote as Fsi and Fsj, respectively, and their similarity is calculated by (18) based on the law of cosine.

3.3 Knowledge clustering for creative ideation

Design case consists of knowledge involving both functional and structural aspects. Function similarity measurement shows the closeness of design cases regarding their contextual knowledge. The distance of their content knowledge is gauged by their technological means used to realize the function requirements.

There are several specific phases to facilitate knowledge clustering.

Phase 1: The similarity measurement of functional features.

In this paper, the first dimension of knowledge clustering is decided by the similarity of criteria belonging to functional characteristics. The similarity between design project and existing design case will be calculated by the methods in 3.1 and 3.2.

Phase 2: Analysis of technological characteristics of design cases.

As a technological system, a product usually involves four sub-systems [53, 54]: working unit, transmission, energy and control unit. Therefore, the technological characteristics of design cases are reflected in four sub-systems.

Phase 3: Calculate the potential novelty of knowledge by its technological difference.

As the most recognized innovation indicator, the novelty of conceptual ideas in NPD is measured by their differences in technological means involving the levels of principles, embodiments and details. The degree of difference in technological means can be measured by the genealogy tree that divides design solutions into four different hierarchies: physical principle, working principle, embodiment and design detail. The difference degree is quantitatively represented by set of numbers as 10, 6, 3, 1 [55] to respectively indicate the difference at level of physical principle, working principle, embodiment and design detail. To normalized the value of technological difference, the comparison vector denotes as C = [C1, C2, C3, C4] in which C1 denotes the difference of working unit, C2 for transmission, C3 for energy, C4 for control unit. In this paper, the difference value set is normalized as [1, 0.6, 0.3, 0.1, 0] to represent the difference on each hierarchy of genealogy tree. The overall value of technological difference DT is calculated trough (19) in which the weighted value ωT for each sub-systems are used to stress the importance different played by the different sub-systems.

An illustrative example shown in Fig. 2 is used to justify how to measure the technological difference in conceptual ideas. Refers to Fig. 2, the technological difference (TD) between broom and plastic broom is equal to 0.1 since they have difference at the level of detail yet sharing the same embodiment, while its TD = 0.3 when compared broom with hair removal broom since the later one holds a new embodiment for removing the hairs though applying the same working principle as the former. Accordingly, the TD between the electric broom and broom is equal to 0.6 as the electric one has implemented a different working principle as a electric driven automatic device though sharing the same physical principle by rubbing the surface of floor to do the cleaning. Vacuum cleaner has the highest TD = 1 from the other “brooms” since it uses a total different physical principle, i.e., vacuum absorption to clean the floor.

Phase 4: Knowledge clustering by two dimensions.

Based on the calculation results of functional similarity and technological difference, design knowledge such as the existing products and patents can be clustered by four quadrants shown in Fig. 3.

Refers to Fig. 3, knowledge has similar functional and technological characteristics as design target is grouped in the quadrant A. The most of the design cases in CBR usually belong to this zone since they come from the same and close technological domains with similar functional features as the design target. Quadrant B involves design knowledge that have the similar technological structures as the design target but their functional similarity are relatively low. Quadrant C has the most difference on both functional and technological aspects but its potential usage in NPD is obscure. Design knowledge belonging to quadrant D has the obviously functional similarity to design target but has applied different technological means since its TD value is high. This kind of design knowledge has positive impact on creative ideation in NPD by introducing the new principles from other domains to generate creative ideas. Knowledge clustering model acts better in creative design in NPD by explore the wider region of knowledge for innovation than the traditional CBR that seldom takes consideration of the design cases from other domain.

Phase 5: Knowledge combination for creative ideation.

Creative ideation in NPD requires the out-domain knowledge that can be obtained by searching the knowledge from quadrant C in knowledge clustering model. C-K theory has provided an efficient knowledge reasoning approach in which four operators are applied to expand both concept and knowledge spaces. With the help of the proposed knowledge clustering models, the region of searchable design knowledge has been expanded for having taking consideration of the design knowledge that has similar functional features, but different in its technological domain. Therefore, the C-K theory approach has been strengthen by applying the knowledge clustering model then makes the best of the design knowledge grouped in different quadrants. In knowledge reasoning process of C-K theory, the creative concepts is the final result after a series of knowledge combination during which the knowledge that is relevant to the initial concept integrates with the newly introduced knowledge that come from other technological domain brought about by the exploration of concepts. Creative ideas for NPD involve the application of cross-domain knowledge that is reflected in change of technological system compared with the existing solutions. Therefore, approaches involving FAR and CBR to facilitate the knowledge clustering as well as the C-K theory reasoning should be integrate as a new design algorithm that improve the efficiency of creative ideation in NPD by utilizing the knowledge from the extended searchable domains.

3.4 Design algorithm

A creative design algorithm for new product is formulated by combining CBR and C-K theory with its specific workflow shown in Fig. 4.

Step 1: Define design project (K0→C0).

The design project begins with the analysis of exploited knowledge (K0) such as customers’ needs and marketing to define the main function of new product. From the viewpoint of C-K theory, the main function (C0) for new design is proposed based on knowledge K0.

Step 2: Function analysis (C0→K1).

The main function of new product C0 evokes the thinking of designers. The process is a C→K operator in which the main function maps to the expert knowledge of the designers as K1.

Step 3: Function decompose (K1→C1).

The C space is expanded by C1 as the result of function decomposition based on the designers’ expert knowledge K1 in function analysis.

Step 4: Functional importance judgment (C1→K2).

The importance judgment of functional requirements (C1) requires the professional knowledge K2 from the designers that is reflected in their attitudes towards the importance of function requirements.

Step 5: Function importance ranking (K2→C2).

Based on the approach for design criteria ranking in 3.1, the C space is further expanded by C2 in which the normalized weighted value for each function requirement has been calculated based on the evaluators’ judgments.

Step 6: Design cases retrieval based on similarity (C2→K3).

The similarity of functions calculated by the method discussed in 3.2 is used for searching the relevant design cases from existing products or patent database as the design knowledge K3 for the target design.

Step 7: Define the technological prototype (K3→C3).

The technological solutions to fulfill the design requirements are proposed by reusing the design knowledge K3 in design cases. As a result of proposing the technological prototype, the C space is expanded.

Step 8: Knowledge clustering (C3→K4).

With the technological prototype C3, it is able to start the design knowledge clustering from two dimensions. The relevant design cases K4 are sorted into four quadrants in the clustering model.

Step 9: Creative ideation (K4→C5).

The creative idea for the design project is proposed and refined as the final solution C5 by the applying the new principles from design cases in knowledge clusters K4.

Step 10: Retain the design result as new design knowledge (C5→K5).

The new design result C5 can be stored as the new design knowledge K5 in the case library to inspire design in the future.

4 Case study

In this section, a new button battery buckling machinery is used as an illustrative example to verify the feasibility proposed design method. After the new design concept is generated, a comparing analysis between the ideality of new idea and the existing design is applied to validate the proposed design method.

4.1 Generation of the creative idea

By following the proposed design algorithm, the whole design process is explained as the following ten steps.

Step 1: Define design project.

The massive production of button battery requires the automatic approach to improve the productivity. The step to buckle the seal ring into the shell of the button battery is a labor-costing work for lacking of automatic machinery. However, there are many problems in the existing design for the bulking machinery. To be specific, these deficiencies involve low buckling speed but high cost in building and using. A new buckling machine will enjoy a marketing success if it is able to overcome these deficiencies. Therefore, this project is to provide a buckling device with high buckling speed and low cost in construction and operation.

Step 2: Function analysis.

There are three designers recruited to accomplish the new product design. At first they are suggested to give their professional comments on the function analysis of the design product. Their reflections are collected and then analyzed to facilitate the function decomposition.

Step 3: Function decompose.

Based on the remarking from the designers, the main function of buckling machinery is divided into three sub-functions: FR1: “Buckle” the “seal ring”, FR2: “Move” the “parts”, FR3: “Positioning” the “parts”.

Step 4: Functional importance judgment.

With the result of function decomposition, the designers are also required to give their judgments on the importance of these sub-functions and normalized them into a TFNs complementary matrix based on the fuzzy rough set in Table 1. For example, the rater 3 gave his comments on the importance ranking as (20). For instance, he though the FR1: “Buckle” is more important than the FR2: “Move” and used a TFN (0.7, 0.8, 0.9) to indicate the fuzzy degree of importance comparison between FR1 and FR2.

Step 5: Function importance ranking.

In this paper, a program is developed based on the MATLABE-GUI to make it convenient for designers to apply the ranking calculation algorithm in 3.1. The program and the calculation results of the function importance ranking are shown in Fig. 5 based on the designers’ opinions that are reflected in the TFNs complementary matrixes.

Refers to Fig. 5, FR1: “Buckle” ranks the first place with its normalized weight as 0.496, FR2: “Move” is the second important criteria weighted as 0.290, FR3: “Positioning” takes the third place and its scores is 0.214.

Step 6: Design cases retrieval based on similarity.

The designers are required to search the similar design cases from the patent database based on the set of defined function requirements. In this study, the database of Chinese patents is used to avoid the misunderstanding caused by the language. The designers have screened the useful design cases from the patent database in accordance with their professional knowledge and experience. The list of useful patents is in Appendix A1. Their similarities on functional requirements are measured by the algorithm in 3.2 and also shown in Appendix 1.

Step 7: Define the technological prototype.

The first design case in Appendix 1 is chosen as the existing technological prototype for the design project since it has the highest functional similarity to the design target. The composition of the technological prototype is divided into four sub-systems based on the research [53]. The genealogy tree of the technological prototype is illustrated in Fig. 6.

Step 8: Knowledge clustering.

The potential design cases are clustered by two dimensions: functional similarity and technological difference. The difference of four sub-systems on genealogy tree determines the value of technological difference. All the potential design cases are clustered and shown in Fig. 7. Based on Fig. 7, the result of knowledge clustering for the potential cases are in Table 2.

Step 9: Creative ideation.

In this design case, there are four cases in quadrant D. They are analyzed in-depth to find the innovative principles to realize the required functions. The seventh case has the most obvious priority than others with regard to increase the buckling speed and decrease the cost of building and usage. A new buckling part is designed based on the inspiration that comes from the seventh case and it is shown in Fig. 8a. Based on the rotating strategy and the spring-drive reciprocation part that is illustrated in Fig. 8b, the new part can work at high speed of buckling just like a machine gun firing at high speed.

New buckling part based on machine firing, (a). Buckling unit; (b) reciprocation part with the redesign of buckling part, the other parts of the machinery are adapted to this change, for example the feeding sub-system of the new design is represented in Fig. 9a and the coupling structure between buckling and feeding system is in Fig. 9b

All the adaption of the design finally formulates a new concept for this design project. The diagram for the structure of new design solution is in Fig. 10.

Step 10: Retain the design result as new design knowledge.

The new design solution is treated as new design knowledge for it has introduced new principles from other domains in button battery production machine and which in turns expanded the feasible solutions in this domain.

4.2 Comparing analysis of the proposed design solution

A comparing analysis between the proposed design solution and existing design (No. 1 case in Appendix) is conducted based on the ideality theory [53] that is firstly introduced in the field of value engineering. The ideal degree of a design solution is decided by three aspects: useful functions, harmful effects and costs and its specific computing formula is shown as (21).

Based on the (21), three categories of indexes involving useful functions, harmful effects, and costs are raised by two recruited raters and shown in detail in Table 3. The existing design solution has a physical prototype, some of its functional parameters are collected from the experimental data, two professional raters are recruited to assess the new proposed design concept and estimate some functional parameters to compare with the existing solution. The specific comparing results are shown in Table 3. Refers to Table 3, it is clear that the new proposed design concept has higher ideality than the existing solution, which is an important evidence to support the validation of the proposed design algorithm.

5 Conclusions

This paper has proposed a new creative design method by integrating the FRA, CBR and C-K theory. The feasibility of the proposed method is verified by designing a new battery buckling machine. The main contributions of this paper are summarized as four aspects:

-

1.

The proposed design criteria importance ranking method has applied TFNs analysis to deal with the uncertainty and subjectivity at the beginning of product development. The importance ranking can help the designers to determine the main characteristics of design project which is very important in subsequent design stages that depend on the importance weighted value of criteria.

-

2.

The knowledge similarity measurement can screen out the design knowledge that is related to the design target based on the design criteria importance ranking.

-

3.

The proposed approach for knowledge clustering classifies design knowledge by two dimensions: functional characteristics and technological structure. Knowledge clustering method is able to sort the design knowledge into four quadrants for inspiring the creative design ideas.

-

4.

The design algorithm has been developed from both CBR and C-K theory. On one hand, the design workflow makes up the shortages of CBR in supporting creative design by putting the design knowledge from other domains in knowledge clusters. On the other hand, this algorithm also improves the efficiency of the C-K theory in creative design by collecting the usable knowledge for designers.

The limitations of this study are also obvious that mainly involve two facets built on which future studies can start up.

A smart design cases database is required to improve the efficiency of the proposed method since both CBR and C-K theory largely depend on the appropriate knowledge. Therefore, for a product firm or organization, a database formulated by the certain kinds of design cases that have important influence on creative ideation of NPD.

Besides the functional requirements, it needs further consideration of ranking other design criteria such as the technological parameters, design constraints with the proposed method. The results of importance ranking are important to screen the suitable design cases at the latter parts of design project.

References

Zhang P, Essaid A, Zanni-Merk C, Cavallucci D (2017) Case-based reasoning for knowledge capitalization in inventive design using latent semantic analysis. Procedia Comput Sci 112:323–332

Relich M, Pawlewski P (2018) A case-based reasoning approach to cost estimation of new product development. Neurocomputing 272:40–45

Akay D, Kulak O, Henson B (2011) Computers in Industry Conceptual design evaluation using interval type-2 fuzzy information axiom. Comput Ind 62(2):138–146

De Mantaras RL et al (2005) Retrieval, reuse, revision and retention in case-based reasoning. Knowl Eng Rev 20(3):215–240

Xie SQ, Tu YL (2006) Rapid one-of-a-kind product development. Int J Adv Manuf Technol 27(5–6): 421–430

Kolodner J, Case-based reasoning. Morgan Kaufmann, Burlington, 1993

Han Y, Lee K, A case-based framework for reuse of previous design concepts in conceptual synthesis of mechanisms. 57:305–318, 2006

Guo Y, Peng Y, Hu J (2013) Computers in industry research on high creative application of case-based reasoning system on engineering design. Comput Ind 64(1):90–103

Zhu GN, Hu J, Qi J, Ma J, Peng YH (2015) An integrated feature selection and cluster analysis techniques for case-based reasoning. Eng Appl Artif Intell 39:14–22

Malekly H, Mousavi SM, Hashemi H (2010) A fuzzy integrated methodology for evaluating conceptual bridge design. Expert Syst Appl 37(7):4910–4920

Wang H, Ohsawa Y, Nishihara Y (2012) Innovation support system for creative product design based on chance discovery. Expert Syst Appl 39(5):4890–4897

Zhai LY, Khoo LP, Zhong ZW (2009) Design concept evaluation in product development using rough sets and grey relation analysis. Expert Syst Appl 36(3 PART 2):7072–7079

Sheeja TK, Kuriakose AS (2018) Computers in Industry A novel feature selection method using fuzzy rough sets. Comput Ind 97:111–116

Lau TW, Hui PCL, Ng FSF, Chan KCC A new fuzzy approach to improve fashion product development. 57:82–92, 2006

Fazel Zarandi MH, Razaee ZS, Karbasian M (2011) A fuzzy case based reasoning approach to value engineering. Expert Syst Appl 38(8):9334–9339

Hatchuel A, Weil B, A new approach of innovative design: an introduction to C-K theory. Int Conf Eng Des: 1–15, 2003

Rousselot F, Renaud J (2015) On TRIZ and case based reasoning synergies and oppositions. Procedia Eng 131:871–880

Avramenko Y, Kraslawski A (2006) Similarity concept for case-based design in process engineering. Comput Chem Eng 30(3):548–557

Richter MM, Weber RO, Case-based reasoning. Morgan Kaufmann, Burlington 2013

Agnar A, Plaza E (1994) Case-based reasoning: Foundational issues, methodological variations, and system approaches. AI Commun 7(1):39–59

Gouriveau R, Noyes D, Risk management—dependability tools and case-based reasoning integration using the object formalism. 55:255–267, 2004

Zhang X, Mei C, Chen D, Yang Y (2018) A fuzzy rough set-based feature selection method using representative instances. Knowl Based Syst 151:216–229

Liu F, Liu ZL, Wu YH (2018) A group decision making model based on triangular fuzzy additive reciprocal matrices with additive approximation-consistency. Appl Soft Comput J 65:349–359

Zhu GN, Hu J, Qi J, Gu CC, Peng YH (2015) An integrated AHP and VIKOR for design concept evaluation based on rough number. Adv Eng Inform 29(3):408–418

Kaufmann A, Gupta MM, Fuzzy mathematical models in engineering and management science. Springer, Heidelberg 1988

Ulrich KT, Eppinger SD (2012) Product design and development. Prod Des Dev 384:415

Ju-Long D (1982) Control problems of grey systems. Syst Control Lett 1(5):288–294

Kung CY, Wen KL (2007) Applying grey relational analysis and grey decision-making to evaluate the relationship between company attributes and its financial performance-a case study of venture capital enterprises in Taiwan. Decis Support Syst 43(3):842–852

Jayakrishna K, Vinodh S (2017) Application of grey relational analysis for material and end of life strategy selection with multiple criteria. Int J Mater Eng Innov 8:no. 3–4

Wu H-H (2002) A Comparative Study of using grey relational analysis in multiple attribute decision making problems. Qual Eng 15(2):209–217

Tseng HE, Chang CC, Chang SH (2005) Applying case-based reasoning for product configuration in mass customization environments. Expert Syst Appl 29(4):913–925

Hwang D, Park W, “Design heuristics set for X: a design aid for assistive product concept generation. Des Stud :1–38, 2018

Song K, Kim K, Lee S (October 2017) Identifying promising technologies using patents: a retrospective feature analysis and a prospective needs analysis on outlier patents. Technol Forecast Soc Change 128, no.:118–132, 2017

Xu J, Houssin R, Bernard A, Caillaud E (2013) Systemic modeling of knowledge for innovation in design. CIRP J Manuf Sci Technol 6(1):1–12

Holsapple CW, Joshi KD (2001) Organizational knowledge resources. Decis Support Syst 31(1):39–54

Li Z, Yang MC, Ramani K (2009) A methodology for engineering ontology acquisition and validation. Artif Intell Eng Des Anal Manuf AIEDAM 23(1):37–51

Xu J, Houssin R, Caillaud E, Gardoni M (2011) Fostering continuous innovation in design with an integrated knowledge management approach. Comput Ind 62(4):423–436

Hatchuel A, Weil B. A new approach of innovative Design: an introduction to CK theory. In: DS 31: proceedings of ICED 03, the 14th international conference on engineering design, Stockholm. 2003.

Hatchuel A, Weil B (2009) CK design theory: an advanced formulation. Res Eng Des 19(4):181–192

Pahl G, Beitz W (2013) Engineering design: a systematic approach. Eng Des A Syst Approach 11:544

Armand H, Benoît W (2007) Design as forcing: deepening the foundations of CK theory. In: International conference on engineering design, ICED’07/447, pp 1–12

Chou JR (2014) An ideation method for generating new product ideas using TRIZ, concept mapping, and fuzzy linguistic evaluation techniques. Adv Eng Inform 28(4):441–454

Popadiuk S, Choo CW (2006) Innovation and knowledge creation: How are these concepts related? Int J Inf Manage 26(4):302–312

Schulze A, Hoegl M (2008) Organizational knowledge creation and the generation of new product ideas: a behavioral approach. Res Policy 37(10):1742–1750

Bourke J, Roper S (2017) Innovation, quality management and learning: short-term and longer-term effects. Res Policy 46(8):1505–1518

Wijnhoven F (2006) Knowledge management: more than a buzzword. In: Jetter A, Schröder HH, Kraaijenbrink J, Wijnhoven F (eds) Knowledge integration: the practice of knowledge management in small and medium enterprises. Springer, Heidelberg, pp 1–16

Nasiri S, Ansari F, Fathi M (2013) Dynamics of knowledge assets and change management perspectives. In: 2013 IEEE international conference on electro/information technology (EIT). IEEE, pp 1–6

Novak JD, Cañas AJ. The theory underlying concept maps and how to construct them. Technical Report IHMC CmapTools 2006

Liu X, Li Y, Pan P, Li W (2011) Research on computer-aided creative design platform based on creativity model. Expert Syst Appl 38(8):9973–9990

Yang CJ, Chen JL (2011) Accelerating preliminary eco-innovation design for products that integrates case-based reasoning and TRIZ method. J Clean Prod 19(9–10):998–1006

Larsson L, Stahre J, Warrol C, Rönnbäck A (2018) An assessment model for production innovation: The Program Production2030. Procedia Manuf 25:134–141

Yager RR, Kacprzyk J, Beliakov G, Recent developments in the ordered weighted averaging operators: theory and practice, vol. 265. Springer, Heidelberg, 2011

Mann D, Hands on systematic innovation. CREAX Press, 2002

Huenteler J, Ossenbrink J, Schmidt TS, Hoffmann VH (2016) How a product’s design hierarchy shapes the evolution of technological knowledge—evidence from patent-citation networks in wind power. Res Policy 45(6):1195–1217

Shah JJ, Kulkarni SV, Vargas-Hernandez N (2000) Evaluation of idea generation methods for conceptual design: effectiveness metrics and design of experiments. J Mech Des 122(4):377

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1

Appendix 1

1.1 The list of potential cases that has functional similarity to design target

No. | Name | Serial number | Buckle (0.496) | Move (0.290) | Position (0.214) | Total similarity |

|---|---|---|---|---|---|---|

1 | One kind of button cell anode fastening ring means | CN201410213798.8 | Buckle | Move | Position | 0.999 |

0.520 | 0.280 | 0.200 | ||||

2 | New stamping die having one kind of intelligent positioning function | CN201711023359.0 | Buckle | Move | Position | 0.945 |

0.431 | 0.192 | 0.377 | ||||

3 | Cutting machine for battery pole plate | CN201720297745.8 | Buckle | Move | Position | 0.900 |

0.487 | 0.513 | 0 | ||||

4 | A high-frequency stamping punch | CN201720083552 0.2 | Buckle | Move | Position | 0.895 |

0.477 | 0.523 | 0 | ||||

5 | A rapid capping machine | CN201410173440.7 | Buckle | Move | Position | 0.922 |

0.538 | 0.462 | 0 | ||||

6 | Punching machine for automobile plastic parts | CN201710711406.4 | Buckle | Move | Position | 0.933 |

0.584 | 0/416 | 0 | ||||

7 | A circulating weapon firing device | CN201210079813.5 | Buckle | Move | Position | 0.913 |

0.762 | 0.238 | 0 | ||||

8 | A metal sheet rapid stamping device | CN201720329590.1 | Buckle | Move | Position | 0.872 |

0.789 | 0 | 0.211 | ||||

9 | A quick assembly system | CN201220364555.0 | Buckle | Move | Position | 0.932 |

0.448 | 0.160 | 0.392 | ||||

10 | A quick assembly machine | CN201620373877.X | Buckle | Move | Position | 0.850 |

0.556 | 0 | 0.444 | ||||

11 | A O-ring quick assembly mechanism | CN201620507013.2 | Buckle | Move | Position | 0.987 |

0.431 | 0.279 | 0.290 | ||||

12 | A battery pole cutting mechanism | CN201110229078.7 | Buckle | Move | Position | 0.878 |

0.654 | 0 | 0.346 | ||||

13 | A button type battery cathode automatic buckle device | CN201210580090.7 | Buckle | Move | Position | 0.977 |

0.391 | 0.320 | 0.289 | ||||

14 | A button battery pole shell buckle mechanism | CN201310738750.4 | Buckle | Move | Position | 0.973 |

0.473 | 0.402 | 0.125 |

Rights and permissions

About this article

Cite this article

Liu, W., Tan, R., Cao, G. et al. Creative design through knowledge clustering and case-based reasoning. Engineering with Computers 36, 527–541 (2020). https://doi.org/10.1007/s00366-019-00712-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-019-00712-5