Abstract

Nowadays, much attention is paid for developing lead-free ceramics, which can be utilized in the refrigeration domain. This communication provides a detailed description of the synthesis and characterization of a lead-free solid solution of BaTi0.91Sn0.09O3. The X-ray diffraction analysis showed that the compound exhibits a single phase of tetragonal symmetry (P4mm (99)). The average crystallite size estimated using Scherrer's technique was found to be 122 nm. The microstructure or surface morphology of the sintered sample was investigated by using scanning electron microscopy. Based on mapping image, the sensitivity and spatial resolution of the different elements in our sample were improved. Analytical and simulation data for the electrocaloric effect in our sample were reported. A good electrocaloric strength (ξ = ΔT/ΔE) of ξ = 0.171 K mm/kV near the ferroelectric-paraelectric phase transition temperature was obtained. These values are very interesting when compared to those for other materials and show the possibility of using such lead-free ceramics for refrigeration domain.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The refrigeration market has grown considerably because of the constant expansion of the industry, rising living standards, and climate change [1]. This has resulted in a lack of control over consumer energy expenditure. It should be noted that the extensive use of refrigeration is a major factor of excessive energy consumption resulting in the depletion of non-renewable energy resources, which exacerbates the effect of global warming. Nowadays, the open debate is mainly focused on the energy transition towards a green development focused on protecting the environment, preserving human health and reducing global warming [2,3,4]. The necessity to improve energy performance has become a major concern for industrial and scientific communities. This fragment of innovation has, therefore, become under great pressure to produce more sustainable technological solutions predicated on promising cooling technologies. A few successful techniques have been developed. For example, the thermoelectric technique (Thomson or Peltier, Seebeck effect), solar sorption [1], as well as magnetocaloric (MC) [5,6,7,8] and electrocaloric (EC) cooling [9,10,11,12,13]. Compared to MC cooling, EC cooling main advantage is that the high electric fields necessary for the refrigeration cycle are less costly and much easier to produce than the magnetic fields necessary for MC refrigeration [1]. The electrocaloric effect (ECE) could be defined in adiabatic conditions by the change of temperature when an electric field is applied. In 2006, Mischenko et al. found a giant ECE in thin films PbZr0.95Ti0.05O3 (PZT) [9]. The disadvantage of this type of material is that they are toxic and require high electric fields, which limits practical applications [14, 15]. So far, most inorganic materials with exceptional ECE are lead-based while lead-free ceramics, generally, have a lower ECE [1, 16]. Nevertheless, because of worldwide lead limitations, there is a pressing need to create environmentally-friendly materials [17,18,19,20,21,22]. This makes them attractive to further research in relation to widely used refrigeration technology based on gas compression. Among the lead-free EC materials are the prototypical BaTiO3 (BT), which has a maximum ECE at high temperatures [16, 23,24,25]. To enhance their ferroelectric performance and adjust their Curie temperature (TC), near room temperature, a transition strategy has been adopted by substitution at A (such as Ca2+and Sr2+), B (such as Sn4+and Zr4+) or in both sites [26,27,28,29,30]. It worth noting that the substitution of Ti4+ by Sn4+ in BT has also been an effective way to shift the TC close to room temperature and also to induce various interesting properties in the dielectric behavior and sensor applications [31,32,33]. Thus, it is important to continue research to achieve a giant ECE in a lead-free material in ceramic form by applying a relatively small electric field near room temperature.

In this work, we present a detailed study of the structural, morphology and EC properties of BaTi0.91Sn0.09O3 compound, which can be a suitable candidate as a working substance in refrigeration domain near room temperature. A phenomenological model for the simulation of the dependence of polarization on temperature variation under different applied electric fields is used for predicting the different EC parameters such as entropy (\(\Delta S^{{\text{E}}}\)), relative cooling power (RCP), heat capacity \((\Delta C_{{{\text{P}},{\text{E}}}} )\), temperature changes \((\Delta T)\) and electrocaloric strength ξ.

2 Experimental Details

BaTi0.91Sn0.09O3 polycrystalline sample was prepared by the solid-state reaction method. In this process, stoichiometric amounts of BaCO3 (99.9% purity, Aldrich), TiO2 (99.9% purity, Aldrich) and SnO2 (99.9% purity, Aldrich) precursors were taken in the appropriate molar ratio. The powders were weighed according to the stoichiometric proportion of the following equation:

The initial powder was prepared by grinding the starting materials in ethanol with an agate mortar for 2 h. Then, it was calcined in two stages: at 900 °C for 24 h and at 1200 °C for 12 h. The obtained powder was again ground for 2 h and pressed into pellets. Subsequently, these pellets were sintered at 1400 °C for 2 h to get dense ceramic. Hence, the experiment density of our sample was equal to 5.7 g/cm3. Figure 1 summarizes the schematic diagram of the synthesis procedure for BaTi0.91Sn0.09O3.

X-ray diffraction (XRD) pattern of our sample was recorded on a Philips diffractometer using CuKα radiation (λ = 1.54056 Å). The microstructure was characterized by scanning electron microscopy (SEM) using a TS QUATA 250. In order to predict the ECE properties, we determined the change in polarization as a function of the electric field for the selected temperature using a current Keithley 428 amplifier and a high voltage amplifier TREK Model 20/20C. The entropy change values, under different applied electric field, (experimental data) are calculated, using the Maxwell approach [34]:

where S, P, E, ρ and T are the entropy, polarization, applied electric field, mass density of the sample and the temperature of the system, respectively.

3 Results and discussion

3.1 Structural properties

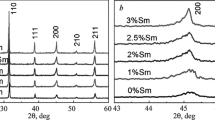

To describe the structural properties of our sample, we carried out XRD analysis, at room temperature. Figure 2 shows the dependence of XRD patterns of BST ceramic. It crystallized in the tetragonal structure with P4mm (99) space group with cell parameters: a = b = 4.0187(0) Å and c = 4.0199(9) Å; α = β = γ = 90°.

Based on Debye Scherer’s formula [35, 36] and Williamson–Hall (W–H) method [37, 38], the mean size of the crystallites of our ceramic was calculated, using the following equations:

where k (= 0.89), \(\lambda\), \(\beta\), \(\theta\), \(\varepsilon\) and D are, respectively, the shape factor, the wavelength of X-ray, the full width at half maximum (FWHM), the half of Bragg’s angle, the strain in the lattice and the crystallite size. The values of D obtained using Debye Scherrer's formula and W–H method (inset of Fig. 2) were 129 and 151 nm, respectively. The difference of D values between the two methods is due to the lattice stress correction term in the calculations.

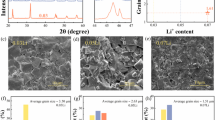

To better understand the morphology, the SEM image of our ceramic is shown in the inset (a′) of Fig. 3. The particles of our ceramic featured a relatively dense microstructure. Hence, the average particle size was estimated using ImageJ software. Then, we adjusted the data obtained with the log–normal function [35, 39]:

where σ and \(D_{0}\) are, respectively, the data dispersions and the median diameter. The inset (a″) of Fig. 3 shows the dispersion histogram. The mean diameter \(< D \ge D_{0} \exp \left( {\frac{{\sigma^{2} }}{2}} \right)\) and stand deviation \(\sigma_{D} = \left\langle D \right\rangle \left[ {\exp \sigma^{2} - 1} \right]^{\frac{1}{2}}\) were determined using the results obtained from the fit to Eq. (5). Therefore, the average grain size was found to be 0.6 µm. In order to confirm the existence of all elements present in our sample, the energy-dispersive X-ray (EDX) analysis was carried out. Figure 3a shows the appearance of characteristic peaks of these elements on the EDX spectrum, confirming the purity of our sample. In addition, Fig. 3b shows the composition dependence of element mapping. It was suggested that the distributions of the four elements are uniform, which improved the stability of the electrical properties.

3.2 ECE studies

3.2.1 Theoretical considerations

To determine EC properties, both the experimental and theoretical approaches were used. For the experimental evaluation, an approach based on polarization (P) data was applied (Eq. 2). However, for the theoretical investigation, a phenomenological model outlined in [40,41,42] is used. From this model, the variation of P versus temperature (T) and TC can be defined as:

where;

-

Pi/Pf are the initial/final values of P at ferroelectric (FE)–paraelectric (PE) transition, respectively, as shown in the inset (a) of Fig. 4.

$$A = \frac{{2B - \left. {\frac{{{\text{d}}P}}{{{\text{d}}T}}} \right|_{{T = T_{{\text{c}}} }} }}{{P_{{\text{i}}} - P_{{\text{f}}} }}$$ -

B is P sensitivity \(\frac{{{\text{d}}P}}{{{\text{d}}T}}\) at FE state before transition.

$$C = \frac{{P_{{\text{i}}} + P_{{\text{f}}} }}{2} - BT_{{\text{c}}}$$

Polarization versus temperature, under different electric field for BaTi0.91Sn0.09O3 sample. The red lines are modeled results by Eq. (6) and symbols represent experimental data. The inset a shows the temperature dependence of polarization for BaTi0.91Sn0.09O3 ceramic under constant electric field. The inset b is the plot of dP/dT versus T

From Eq. (6), the electrocaloric entropy change \(\Delta S^{{\text{E}}}\) (Eq. 2), caused by the variation of the external electric field (E) from E1 to E2, can be rewritten as follows:

where \(\rho\) is the mass density of the sample.

At T = TC, \(\Delta S^{{\text{E}}}\) becomes maximum. So Eq. (7) may be written as follows:

According to this model, a full width at half maximum can be calculated as follows:

Another very important parameter for refrigeration is the relative cooling power RCP, which presents the product of \(\Delta S_{{{\text{Max}}}}^{{\text{E}}}\) and \(\delta T_{{{\text{FWHM}}}}\). It is defined as:

A polarization-related change of heat capacity is given by:

According to this phenomenological model, a change of heat capacity is given by:

A temperature change of a polar system under adiabatic electric field variation from an initial value E1 to final value E2 can be written in the form:

CE is a heat capacity at constant electric field.

3.2.2 Simulation

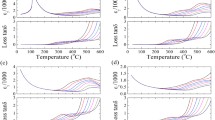

In order to apply the phenomenological model, numerical calculations were carried out with the parameters displayed in Table 1. The FE-PE transition temperature (TC) was determined from the inflection point of dP/dT versus T (°C), as shown in the inset (b) of Fig. 4. Figure 4 shows P versus T for our sample under different electric fields (5–30 kV cm−1). The symbols signify the experimental data and the red lines indicate the modeled data given by Eq. (6). It was found that these modeled data are consistent with the experimental data. Figure 5 shows the experimental entropy change data and their theoretical plot resulting from Eq. (7), at various applied electric fields. It appears that the results of the simulations agree well with the experimental data. It can also be noted that, for all applied electric fields and over the entire temperature range, the variation of \(\Delta S^{{\text{E}}}\) is positive, which confirms the FE character [43]. From Fig. 5, \(\Delta S^{{\text{E}}}\) increased sharply until reaching a peak near TC. Hence, the values of \(\Delta S_{{{\text{max}}}}^{{\text{E}}}\) are summarized in Table 2. Under an applied electric field E = 30 kV/cm, \(\Delta S_{{{\text{max}}}}^{{\text{E}}}\) of our sample reached a value of 0.56 J kg−1 K−1.

ΔSE as a function of temperature at different electric field, for BaTi0.91Sn0.09O3 sample. The red line curves represent the modeled data results by Eq. (7) and symbols are the experimental data

In the framework of EC refrigeration, it is essential to take into account two other parameters, having the same importance of \(\Delta S_{{{\text{max}}}}^{{\text{E}}}\), namely RCP and \(\delta T_{{{\text{FWHM}}}}\), which are defined in Eqs. 7 and 8, respectively. All EC parameters are recorded in Table 2, which are comparable to other works such as 0.75 PMN-0.25 PT [44] and Pb(Mg0.067Nb0.133Zr0.8)O3 [45]. Figure 6 shows the variation of \(\Delta C_{{{\text{P}},{\text{E}}}}\) as a function of the temperatures for different electric fields from 5 to 30 kV cm−1, based on Eq. (12). In this figure, we can see that \(\Delta C_{{{\text{P}},{\text{E}}}}\) changed strongly from a negative to a positive value around TC, which confirms FE behavior in our sample [40]. The obtained \(\Delta C_{{{\text{P}},{\text{E}}}}^{{{\text{min}}}}\) and \(\Delta C_{{{\text{P}},{\text{E}}}}^{{{\text{max}}}}\) values of our sample, under different electric fields, are listed in Table 2.

Heat capacity changes versus temperature for BaTi0.91Sn0.09O3 sample, obtained by Eq. (12) at different electric field

Using Eq. (13), Fig. 7a shows the experimental and theoretical curves of ΔT for our sample. It is obvious that the results of calculation are in good agreement with the experimental results. Also, it is clear that ΔT practically maintains the same behavior of \(\Delta S^{{\text{E}}}\). A maximum of ΔT was observed at around TC, which is due to the great change in P with increasing T [46].

a ΔT plotted as a function of temperature at different electric field, for BaTi0.91Sn0.09O3 sample. The red line curves represent the modeled data results by Eq. (13) and symbols are the experimental data. b The temperature dependence of the electrocaloric strength ξ at different electric fields in the BaTi0.91Sn0.09O3

Furthermore, the EC strength (ξ = ΔT/ΔE) is generally used to predict the heating/cooling capacity of a material [44, 47]. The influence of the electric field and temperature on ξ for our samples shown in Fig. 7b. The variation of ξ versus T, under different electric fields, is similar to that of ΔT (Fig. 7a). Around room temperature, ξ reached a maximum value (ξRT = 0.12 K mm/kV) under an applied electric field equal to 5 kV/cm, which is higher than that of pure PZT (ξRT = 0.02 K mm/kV) [16]. Around TC, the maximum of EC strength (ξmax = 0.171 K mm/kV) of BST ceramic is significantly higher than other lead-free ferroelectrics such as SBT (ξmax = 0.083) [48] and NBT (ξmax = 0.05) [49].

The different obtained EC parameters for our sample are summarized in Table 3. We can note that our sample can be considered as potential candidate in the field of refrigeration thanks to its important ΔT and ξ values, compared to those observed in other materials [48, 50,51,52,53,54,55,56,57,58,59,60,61,62].

In general, to determinate the nature of the magnetic phase transition, the plots of the magnetic entropy change (ΔSM) as function of T, under different applied magnetic fields, should collapse on a single curve with a second-order phase transition, which is suggested by Franco et al. [63, 64]. So by analogy with the MCE, the universal phenomenological \(\Delta S^{{\prime }}\) curve can be determined by the normalization of \(\Delta S^{{\text{E}}}\)[65, 66]:

Therefore, to construct the universal curve, it is important to resize the temperature axis, below and above TC, by a new parameter on two clearly separated reference temperatures, represented by the following equation:

where θ, Tr1 and Tr2 are, respectively, the rescaled temperature and the temperatures lower and higher than TC of each curve which should satisfy the relation \(\Delta S^{{\text{E}}} \left( {T_{{r_{1,2} }} } \right) = \Delta S_{\max }^{{\text{E}}} {/}2\).

The curves of ΔS′ (θ) for the different applied electric fields are shown in Fig. 8. It is worth noting that all the data are dispersed on a single universal curve, which indicates that the transition in our sample is of a second order [67].

4 Conclusion

To sum up, BaTi0.91Sn0.09O3 sample was prepared by solid-state method. XRD patterns showed that our sample crystallized in tetragonal structure with P4mm space group at room temperature. Based on mapping image, the sensitivity and spatial resolution of the different elements in our sample were improved. P versus T curves were adjusted at different electric fields and were used to calculate EC properties. Experimental and theoretical approaches were used to determine the EC properties. A good agreement of this model with the experimental data specifies the validity of this model under a variety of applied electric fields. Near room temperature, BaTi0.91Sn0.09O3 sample displayed an important entropy change. The relative cooling power RCP was also analyzed. In addition, the maximum of EC strength (ξmax) was found to be 0.171 K mm/kV around TC, which is comparable to those obtained in the literature. These make our sample potential non-toxic candidate for cooling systems. According to the universal curve, we confirmed that the PE–FE phase transition observed for our sample is of second order.

References

M. Valant, Electrocaloric materials for future solid-state refrigeration technologies. Prog. Mater. Sci. 57(6), 980–1009 (2012). https://doi.org/10.1016/j.pmatsci.2012.02.001

S.K. Patel, B. Kuriachen, N. Kumar, R. Nateriya, The slurry abrasive wear behaviour and microstructural analysis of A2024-SiC-ZrSiO4 metal matrix composite. Ceram. Int. 44(6), 6426–6432 (2018). https://doi.org/10.1016/j.ceramint.2018.01.037

N. Fortas, A. Belkahla, S. Ouyahia, J. Dhahri, E.K. Hlil, K. Taibi, Effect of Ni substitution on the structural, magnetic and magnetocaloric properties of Zn Ni Mg Fe O (x= 0, 0.125 and 0.250) manganite. Solid State Sciences, 101, 106137 (2020). https://doi.org/10.1016/j.solidstatesciences.2020.106137

X. Moya, S. Kar-Narayan, N.D. Mathur, Caloric materials near ferroic phase transitions. Nat. Mater. 13(5), 439–450 (2014). https://doi.org/10.1038/nmat3951

L. Shebanovs, K. Borman, W.N. Lawless, A. Kalvane, Electrocaloric effect in some perovskite ferroelectric ceramics and multilayer capacitors. Ferroelectrics 273(1), 137–142 (2002). https://doi.org/10.1080/00150190211761

M. Tishin, Y.I. Spichkin, The Magnetoelectric Effect and Its Applications (Institute of Physics Publishing, Philadelphia, 2003).

N. Kumar, A. Shukla, N. Kumar, R.N.P. Choudhary, Studies of structural, ferroelectric, magnetic and electrical characteristics of Bi (Fe1−xNdx) O3 (x= 0.05, 0.10, 0.15) multiferroics. J. Mater. Sci. Mater. Electron. 32(5), 5870–5885 (2021). https://doi.org/10.1007/s10854-021-05308-8

N. Kumar, A. Shukla, R.N.P. Choudhary, Structural, electrical and magnetic characteristics of Ni/Ti modified BiFeO3 lead free multiferroic material. J. Mater. Sci. Mater. Electron. 28(9), 6673–6684 (2017). https://doi.org/10.1007/s10854-017-6359-y

A.S. Mischenko, Q. Zhang, J.F. Scott, R.W. Whatmore, N.D. Mathur, Giant electrocaloric effect in thin-film PbZr0.95Ti0.05O3. Science 311(5765), 1270–1271 (2006). https://doi.org/10.1126/science.1123811

H.J. Ye, X.S. Qian, D.Y. Jeong, S. Zhang, Y. Zhou, W.Z. Shao, L. Zhen, Q.M. Zhang, Giant electrocaloric effect in BaZr0.2Ti0.8O3 thick film. Appl. Phys. Lett. 105(15), 152908 (2014). https://doi.org/10.1063/1.4898599

X.S. Qian, S.G. Lu, X. Li, H. Gu, L.C. Chien, Q. Zhang, Large electrocaloric effect in a dielectric liquid possessing a large dielectric anisotropy near the isotropic–nematic transition. Adv. Funct. Mater. 23(22), 2894–2898 (2013). https://doi.org/10.1002/adfm.201202686

D. Matsunami, A. Fujita, Electrocaloric effect of metal-insulator transition in VO2. Appl. Phys. Lett. 106(4), 042901 (2015). https://doi.org/10.1063/1.4906801

N. Kumar, A. Shukla, N. Kumar, S. Sahoo, S. Hajra, R.N.P. Choudhary, Structural, electrical and ferroelectric characteristics of Bi(Fe0.9La0.1)O3. Ceram. Int. 44(17), 21330–21337 (2018). https://doi.org/10.1016/j.ceramint.2018.08.185

S.G. Lu, B. Rožič, Q.M. Zhang, Z. Kutnjak, R. Pirc, M. Lin, X. Li, L. Gorny, Comparison of directly and indirectly measured electrocaloric effect in relaxor ferroelectric polymers. Appl. Phys. Lett. 97(20), 202901 (2010). https://doi.org/10.1063/1.3514255

T.M. Correia, J.S. Young, R.W. Whatmore, J.F. Scott, N.D. Mathur, Q. Zhang, Investigation of the electrocaloric effect in a PbMg2/3Nb1/3O3-PbTiO3 relaxor thin film. Appl. Phys. Lett. 95(18), 182904 (2009). https://doi.org/10.1063/1.3257695

G. Singh, V.S. Tiwari, P.K. Gupta, Electro-caloric effect in (Ba1−xCax)(Zr0.05Ti0.95)O3: a lead-free ferroelectric material. Appl. Phys. Lett. 103(20), 202903 (2013). https://doi.org/10.1063/1.4829635

N. Kumar, A. Shukla, R.N.P. Choudhary, Development of lead-free multifunctional materials Bi(Co0.45Ti0.45Fe0.10)O3. Prog. Nat. Sci. Mater. Int. 28(3), 308–314 (2018). https://doi.org/10.1016/j.pnsc.2018.01.012

N. Kumar, A. Shukla, N. Kumar, R.N.P. Choudhary, A. Kumar, Structural, electrical, and multiferroic characteristics of lead-free multiferroic: Bi(Co0.5Ti0.5)O3–BiFeO3 solid solution. RSC Adv. 8(64), 36939–36950 (2018). https://doi.org/10.1039/C8RA02306A

H. Tang, X.G. Tang, M.D. Li, Q.X. Liu, Y.P. Jiang, Pyroelectric energy harvesting capabilities and electrocaloric effect in lead-free SrxBa1-xNb2O6 ferroelectric ceramics. J. Alloys Compd. 791, 1038–1045 (2019). https://doi.org/10.1016/j.jallcom.2019.03.385

J. Koruza, B. Rožič, G. Cordoyiannis, B. Malič, Z. Kutnjak, Large electrocaloric effect in lead-free K0.5Na0.5NbO3-SrTiO3 ceramics. Appl. Phys. Lett. 106(20), 202905 (2015). https://doi.org/10.1063/1.4921744

X. Jiang, L. Luo, B. Wang, W. Li, H. Chen, Electrocaloric effect based on the depolarization transition in (1–x) Bi0.5Na0.5TiO3–xKNbO3 lead-free ceramics. Ceram. Int. 40(2), 2627–2634 (2014). https://doi.org/10.1016/j.ceramint.2013.10.066

N. Kumar, A. Shukla, Processing and characterization of Cd/Ti co-substituted BiFeO3 nanoceramics. Int. J. Mod. Phys. B 32(19), 1840069 (2018). https://doi.org/10.1142/S0217979218400696

Y. Liu, I.C. Infante, X. Lou, D.C. Lupascu, B. Dkhil, Giant mechanically-mediated electrocaloric effect in ultrathin ferroelectric capacitors at room temperature. Appl. Phys. Lett. 104(1), 012907 (2014). https://doi.org/10.1063/1.4861456

Y. Bai, G. Zheng, S. Shi, Direct measurement of giant electrocaloric effect in BaTiO3 multilayer thick film structure beyond theoretical prediction. Appl. Phys. Lett. 96(19), 192902 (2010). https://doi.org/10.1063/1.3430045

X. Moya, E. Stern-Taulats, S. Crossley, D. González-Alonso, S. Kar-Narayan, A. Planes, L. Mañosa, N.D. Mathur, Giant electrocaloric strength in single-crystal BaTiO3. Adv. Mater. 25(9), 1360–1365 (2013). https://doi.org/10.1002/adma.201203823

X.Q. Liu, T.T. Chen, M.S. Fu, Y.J. Wu, X.M. Chen, Electrocaloric effects in spark plasma sintered Ba0.7Sr0.3TiO3-based ceramics: effects of domain sizes and phase constitution. Ceram. Int. 40(7), 11269–11276 (2014). https://doi.org/10.1016/j.ceramint.2014.03.175

X.S. Qian, H.J. Ye, Y.T. Zhang, H. Gu, X. Li, C.A. Randall, Q.M. Zhang, Giant electrocaloric response over a broad temperature range in modified BaTiO3 ceramics. Adv. Funct. Mater. 24(9), 1300–1305 (2014). https://doi.org/10.1002/adfm.201302386

Y. Bai, X. Han, K. Ding, L.J. Qiao, Combined effects of diffuse phase transition and microstructure on the electrocaloric effect in Ba1−xSrxTiO3 ceramics. Appl. Phys. Lett. 103(16), 162902 (2013). https://doi.org/10.1063/1.4825266

L. Jin, R. Huo, R. Guo, F. Li, D. Wang, Y. Tian, Q. Hu, X. Wei, Z. He, Y. Yan, G. Liu, Diffuse phase transitions and giant electrostrictive coefficients in lead-free Fe3+-doped 0.5 Ba(Zr0.2Ti0.8)O3-0.5(Ba0.7Ca0.3) TiO3 ferroelectric ceramics. ACS Appl. Mater. Interfaces 8(45), 31109–31119 (2016). https://doi.org/10.1021/acsami.6b08879

K.N.D.K. Muhsen, R.A.M. Osman, M.S. Idris, The effects of Ca, Zr and Sn substitutions into a ternary system of BaTiO3–BaSnO3–BaZrO3 towards its dielectric and piezoelectric properties: a review. J. Mater. Sci. Mater. Electron. (2020). https://doi.org/10.1007/s10854-020-03756-2

K.N.D.K. Muhsen, R.A.M. Osman, M.S. Idris, M.H.H. Jumali, N.H.B. Jamil, Enhancing the dielectric properties of (Ba0.85Ca0.15)(SnxZr0.10−xTi0.90)O3 lead-free ceramics by stannum substitution. J. Mater. Sci. Mater. Electron. 30(23), 20654–20664 (2019). https://doi.org/10.1007/s10854-019-02431-5

H. Kaddoussi, Y. Gagou, A. Lahmar, J. Belhadi, B. Allouche, J.L. Dellis, M. Courty, H. Khemakhem, M. El Marssi, Room temperature electro-caloric effect in lead-free Ba(Zr0.1Ti0.9)1−xSnxO3 (x= 0, x= 0.075) ceramics. Solid State Commun. 201, 64–67 (2015). https://doi.org/10.1016/j.ssc.2014.10.003

N. Baskaran, H. Chang, Effect of Sn doping on the phase transformation properties of ferroelectric BaTiO3. J. Mater. Sci. Mater. Electron. 12(9), 527–531 (2001). https://doi.org/10.1023/A:1012453526652

J.F. Scott, Electrocaloric materials. Ann. Rev. Mater. Res. 41, 229–240 (2011). https://doi.org/10.1146/annurev-matsci-062910-100341

A. Dhahri, H. Kacem, J. Dhahri, Effect of La3+ substitution on the physical properties of CaTiO3–0.15KNbO3-based lead-free ceramics. Appl. Phys. A 126(8), 1–10 (2020). https://doi.org/10.1007/s00339-020-03789-8

N. Kumar, A. Shukla, R.N.P. Choudhary, Structural, dielectric, electrical and magnetic characteristics of lead-free multiferroic: Bi(Cd0.5Ti0.5)O3BiFeO3 solid solution. J. Alloys Compd. 747, 895–904 (2018). https://doi.org/10.1016/j.jallcom.2018.03.114

G.K. Williamson, W.H. Hall, X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1(1), 22–31 (1953). https://doi.org/10.1016/0001-6160(53)90006-6

N. Kumar, A. Shukla, R.N.P. Choudhary, Structural, electrical and magnetic properties of (Cd, Ti) modified BiFeO3. Phys. Lett. A 381(33), 2721–2730 (2017). https://doi.org/10.1016/j.physleta.2017.06.012

M.H. Ehsani, T. Raoufi, F.S. Razavi, Impact of Gd ion substitution on the magneto-caloric effect of La0.6-xGdxSr0.4MnO3 (x= 0, 0.0125, 0.05, 0.10) manganites. J. Magn. Magn. Mater. 475, 484–492 (2019). https://doi.org/10.1016/j.jmmm.2018.11.131

M.A. Hamad, Theoretical investigations on electrocaloric properties of (111)-oriented PbMg1/3Nb2/3O3 single crystal. J. Adv. Ceram. 2(4), 308–312 (2013). https://doi.org/10.1007/s40145-013-0076-7

M.A. Hamad, Electrocaloric properties of Zr-modified Pb (Mg1/3Nb2/3)O3 polycrystalline ceramics. J. Adv. Dielectr. 3(04), 1350029 (2013). https://doi.org/10.1142/S2010135X1350029X

M.A. Hamad, Room temperature giant electrocaloric properties of relaxor ferroelectric 0.93PMN-0.07PT thin film. AIP Adv. 3(3), 032115 (2013). https://doi.org/10.1063/1.4795156

Y. Bai, G.P. Zheng, S.Q. Shi, Mater. Res. Bull. 46, 1866–1869 (2011)

I. Kriaa, N. Abdelmoula, A. Maalej, H. Khemakhem, Study of the electrocaloric effect in the relaxor ferroelectric ceramic 0.75 PMN-0.25 PT. J. Electron. Mater. 44(12), 4852–4856 (2015). https://doi.org/10.1007/s11664-015-4051-7

M.A. Hamad, Investigations on electrocaloric properties of ferroelectric Pb(Mg0.067Nb0.133Zr0.8)O3. Appl. Phys. Lett. 102(14), 142908 (2013). https://doi.org/10.1063/1.4801868

S.G. Lu, Q. Zhang, Electrocaloric materials for solid-state refrigeration. Adv. Mater. 21(19), 1983–1987 (2009). https://doi.org/10.1002/adma.200802902

G. Akcay, S.P. Alpay, J.V. Mantese, G.A. Rossetti Jr., Magnitude of the intrinsic electrocaloric effect in ferroelectric perovskite thin films at high electric fields. Appl. Phys. Lett. 90(25), 252909 (2007). https://doi.org/10.1063/1.2750546

H. Chen, T.L. Ren, X.M. Wu, Y. Yang, L.T. Liu, Giant electrocaloric effect in lead-free thin film of strontium bismuth tantalite. Appl. Phys. Lett. 94(18), 182902 (2009). https://doi.org/10.1063/1.3123817

Y. Bai, G.P. Zheng, S.Q. Shi, Abnormal electrocaloric effect of Na0.5Bi0.5TiO3–BaTiO3 lead-free ferroelectric ceramics above room temperature. Mater. Res. Bull. 46(11), 1866–1869 (2011). https://doi.org/10.1016/j.materresbull.2011.07.038

B. Asbani, J.L. Dellis, A. Lahmar, M. Courty, M. Amjoud, Y. Gagou, K. Djellab, D. Mezzane, Z. Kutnjak, M. El Marssi, Lead-free Ba0.8Ca0.2(ZrxTi1−x) O3 ceramics with large electrocaloric effect. Appl. Phys. Lett. 106(4), 042902 (2015). https://doi.org/10.1063/1.4906864

Y. Zhang, Thermal hysteresis and electrocaloric effect in Ba1-xZrxTiO3. J. Phys. Chem. Solids 115, 326–331 (2018). https://doi.org/10.1016/j.jpcs.2017.12.043

Y. Bai, X. Han, L. Qiao, Optimized electrocaloric refrigeration capacity in lead-free (1–x) BaZr0.2Ti0.8O3-xBa0.7Ca0.3TiO3 ceramics. Appl. Phys. Lett. 102(25), 252904 (2013). https://doi.org/10.1063/1.4810916

B. Zhang, X. Lou, K. Zheng, X. Xie, P. Shi, M. Guo, X. Zhu, Y. Gao, Q. Liu, R. Kang, Enhanced electrocaloric effect in the Sm and Hf co-doped BaTiO3 ceramics. Ceram. Int. 47(1), 1101–1108 (2021). https://doi.org/10.1016/j.ceramint.2020.08.226

S. Liu, Q. Xie, L. Zhang, Y. Zhao, X. Wang, P. Mao, J. Wang, X. Lou, Tunable electrocaloric and energy storage behavior in the Ce, Mn hybrid doped BaTiO3 ceramics. J. Eur. Ceram. Soc. 38(14), 4664–4669 (2018). https://doi.org/10.1016/j.jeurceramsoc.2018.06.020

S. Patel, A. Chauhan, R. Vaish, Multiple caloric effects in (Ba0.865Ca0.135Zr0.1089Ti0.8811Fe0.01)O3 ferroelectric ceramic. Appl. Phys. Lett. 107(4), 042902 (2015). https://doi.org/10.1063/1.4927558

Y.S. Kim, J. Yoo, Electrocaloric effect of lead-free (Ba, Ca)(Zr, Ti)O3 ferroelectric ceramic. J. Electron. Mater. 44(8), 2555–2558 (2015). https://doi.org/10.1007/s11664-015-3732-6

P.D. Thacher, Electrocaloric effects in some ferroelectric and antiferroelectric Pb(Zr, Ti)O3 compounds. J. Appl. Phys. 39(4), 1996–2002 (1968). https://doi.org/10.1063/1.1656478

M.D. Li, X.G. Tang, S.M. Zeng, Q.X. Liu, Y.P. Jiang, W.H. Li, Giant electrocaloric effect in BaTiO3–Bi (Mg1/2Ti1/2) O3 lead-free ferroelectric ceramics. J. Alloys Compd. 747, 1053–1061 (2018). https://doi.org/10.1016/j.jallcom.2018.03.102

R. Chaim, Densification mechanisms in spark plasma sintering of nanocrystalline ceramics. Mater. Sci. Eng. A 443(1–2), 25–32 (2007). https://doi.org/10.1016/j.msea.2006.07.092

H. Kaddoussi, A. Lahmar, Y. Gagou, B. Asbani, J.L. Dellis, G. Cordoyiannis, B. Allouche, H. Khemakhem, Z. Kutnjak, M. El Marssi, Indirect and direct electrocaloric measurements of (Ba1−xCax)(Zr0.1Ti0.9)O3 ceramics (x=0.05, x=0.20). J. Alloys Compd. 667, 198–203 (2016). https://doi.org/10.1016/j.jallcom.2016.01.159

B. Neese, B. Chu, S.G. Lu, Y. Wang, E. Furman, Q.M. Zhang, Large electrocaloric effect in ferroelectric polymers near room temperature. Science 321(5890), 821–823 (2008). https://doi.org/10.1126/science.1159655

M. Zannen, A. Lahmar, Z. Kutnjak, J. Belhadi, H. Khemakhem, M. El Marssi, Electrocaloric effect and energy storage in lead free Gd0.02Na0.5Bi0.48TiO3 ceramic. Solid State Sci. 66, 31–37 (2017). https://doi.org/10.1016/j.solidstatesciences.2017.02.007

V. Franco, J.S. Blázquez, A. Conde, Field dependence of the magnetocaloric effect in materials with a second order phase transition: a master curve for the magnetic entropy change. Appl. Phys. Lett. 89(22), 222512 (2006). https://doi.org/10.1063/1.2399361

V. Franco, A. Conde, Scaling laws for the magnetocaloric effect in second order phase transitions: from physics to applications for the characterization of materials. Int. J. Refrig. 33(3), 465–473 (2010). https://doi.org/10.1016/j.ijrefrig.2009.12.019

M. Bourguiba, M.A. Gdaiem, M. Chafra, E.K. Hlil, H. Belmabrouk, A. Bajahzar, Effect of titanium substitution on the structural, magnetic and magnetocaloric properties of La0.67Ba0.25Ca0.08MnO3 perovskite manganites. Appl. Phys. A 125(6), 1–16 (2019). https://doi.org/10.1007/s00339-019-2665-y

S. Bouzidi, M.A. Gdaiem, J. Dhahri, E.K. Hlil, Large magnetocaloric entropy change at room temperature in soft ferromagnetic manganites. RSC Adv. 9(1), 65–76 (2019). https://doi.org/10.1039/C8RA09166H

L.J. Ding, Critical scaling analysis for displacive-type organic ferroelectrics around ferroelectric transition. Phys. A Stat. Mech. Appl. 471, 818–824 (2017). https://doi.org/10.1016/j.physa.2016.12.085

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kacem, H., Dhahri, A., Gdaiem, M.A. et al. Electrocaloric properties of lead-free ferroelectric ceramic near room temperature. Appl. Phys. A 127, 483 (2021). https://doi.org/10.1007/s00339-021-04604-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-04604-8