Abstract

The effects of temperature on the bulk and surface properties of liquid Zn–Cd alloys have been theoretically investigated, using a combination of self association model, Darken’s thermodynamic equation for diffusion, empirical model for viscosity and a statistical mechanics model. The results from this study show that change in temperature resulted in cross-over effects in bulk and surface properties. We also found that with an increase in temperature, a pronounced asymmetry of viscosity isotherm is significantly reduced, and viscosity isotherm exhibited anomalous behaviour. Our results reveal that the homocoordination tendency in Zn–Cd liquid alloys is not strong and reduces with increasing temperature. The study further suggests a pronounced segregation of Cd-atoms at the surface of Zn–Cd liquid alloys and the extent of segregation reduces with temperature. We as well found that, in addition to the reported understanding that size-factor determines the compositional location of asymmetry of the viscosity isotherm, temperature is an operating parameter that has effect, not only on the composition of asymmetry, but also on the magnitude of asymmetry. In all the properties investigated, the most pronounced effect of temperature (52.9\(\%\)) is on the viscosity while the least effect (7.1\(\%\)) is on the surface tension.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Many researchers have shown interest in Zn–Cd liquid alloys for various reasons. These include the knowledge that Zn–Cd alloys are industrially useful in nanocrystals (CdZnS) and in optoelectronics (CdZnTe) [1, 2]. In addition, it has been reported that Zn–Cd liquid alloy system is one of the systems that has the potential for applications in bearing assemblies, ballasts, casting, step soldering and radiation shielding [3, 4]. Also, it is known that smaller cadmium content in Zn–Cd alloys exhibit lower melting point, improve both thermal and electrical conductivities and as well increase mechanical properties like wear resistance, tensile and fatigue strength [4].

Our interest in the study of temperature dependence of the bulk and surface properties of Zn–Cd liquid alloys is due to the fact that, although this liquid alloys have been studied for decades on the basis of their usefulness, literature search, to the best of our knowledge, indicates that the temperature dependence study on the aforementioned properties of Zn–Cd liquid alloys are yet to be undertaken. This is quite surprising, because it has been reported in [5] that, having a knowledge of the behaviours of various thermodynamic functions of liquid alloys, well above and well below the melting temperature, is necessary for a good understanding of the energetics of liquid alloys. Thus, the availability of needed experimental data of Zn–Cd liquid alloys at four different temperatures of 743, 780, 800 and 900 K [6, 7] (which are quite above the melting point of most Zn–Cd liquid alloys, reported to be around 265 \(^{\circ }\)C or 538 K [8]) serves as impetus for this study, which is aimed at complementing existing studies on Zn–Cd liquid alloys [1–4, 6, 7, 9, 10].

To investigate the temperature dependence of the bulk properties of Zn–Cd liquid alloys, we opted for the self association model (SAM) [11] reputed for being an excellent theoretical recipe for calculating the thermodynamic properties of demixing binary liquid alloys, knowing that Zn–Cd system belongs to this group [9, 11–15], as it indicates its simple, eutectic type phase diagram [16, 17]. A combination of the popular Darken’s equation [18] and an empirical formalism for viscosity and diffusion coefficient of Singh and Sommer in [19] are employed in our study of the effects of temperature on the transport or dynamic properties. The study of concentration dependence of the surface properties of Zn–Cd liquid alloys is based on the statistical mechanics model [20] commonly used in the literature [14, 21–23]. In the framework of the aforementioned model, the effects of temperature on these properties have also been analyzed.

In Sect. 2, we provided the theoretical formalism we employed in this work to determine the bulk, surface and transport properties of Zn–Cd liquid alloys. The results obtained when the essential theoretical equations obtained from the formalism for each of the properties are used to determine the properties profiles at temperatures of 743, 780, 800 and 900 K, are presented and discussed in Sect. 3. The paper is concluded in Sect. 4.

2 Theoretical formalism

2.1 Self association model for bulk properties

Self association model has been proposed by Singh and Sommer [18] for studying the properties of binary liquid alloys that exhibit positive deviation from Raoult’s law. Essentially, in SAM, Singh and Sommer assumed that a binary alloy consists of \(N_A = Nc_1\) atoms of A and \(N_B = Nc_2\) atoms of element B (where \(c_1\) is the concentration of element A, \(c_2\) is the concentration of element B and \(c_1+c_2=1\)). Also, it was assumed that all the atoms are positioned on a set of equivalent sites and the interaction is effective only between nearest neighbors (each of these atoms has z nearest neighbors). In addition, the components elements A and B in the alloy are considered to be in the form of polyatomic matrix which gives rise to the formation of like-atoms cluster, of the type \(A_\kappa\) and \(B_\nu\). Thus,

where \(\kappa\) is the number of atoms in the cluster of type A matrix while \(\nu\) is the number of atoms in the cluster of type B matrix.

On the premise of Flory’s approximation (i.e. \(z \rightarrow \infty\)), the following expression can be written for the Gibbs free energy:

where

In Eq. (2), R and T are universal gas constant and temperature, respectively, while in Eq. (3), w is the interchange energy or ordering energy, whose value indicates whether the atoms in the alloy are perfectly disordered or heterocoordinated (unlike atoms paired as nearest neighbours in preference to like atoms) or homocoordinated (like atoms paired as nearest neighbours in preference to unlike atoms); m and W which are both independent of composition but may depend on temperature, T, and pressure, P are the SAM parameters.

The following general expressions are usually used to obtain activity, \(a_t (t=A,B)\):

If we put Eq. (2) in Eq. (4) we shall obtain the following two expressions for activities in the SAM:

and

The relationship between the concentration fluctuations in the long-wavelength limit, \(S_{cc}\)(0) and the thermodynamic properties, i.e. Gibbs free energy of mixing and activities [24, 25] is given by:

If Eq. (2) is substituted in Eq. (7), we shall obtain the following expression for the concentration–concentration fluctuations in the SAM:

where in Eq. (8),

\(S_{cc}\)(0) elucidates the nature of mixing (ordering or demixing), while the Warren–Cowley short range order parameter, \({\alpha _1}\) is used to quantify the degree of chemical order/demixing in the liquid binary alloys. In the framework of the SAM it can be obtained by:

where in Eq. (10), Z is the coordination number (usually taken as 10, because in the liquid and amorphous states, the atoms are randomly distributed in a nearly close-packed structure and the coordination number of the nearest neighbours is about 10 [26]) and

It should be noted that the \(S_{cc}\)(0) in Eq. (11) is as defined in Eq. (8), and \(S_{cc}(0,id)\) is the ideal bulk concentration–concentration fluctuations at long wavelength, defined as \(S_{cc}(0,id)= c_1c_2\).

2.2 Darken’s equation for diffusion and empirical formalism for viscosity

According to [18],the link between Darken’s thermodynamic equation relating self- and interdiffusion with \(S_{cc}\)(0) is given by:

where in Eq. (12), \(D_\mathrm{M}\) is the mutual diffusion coefficient, \(D_\mathrm{S}\) is the self diffusion coefficient and \(S_{cc}\)(0) is the concentration–concentration fluctuations in the long wavelength limit (Eq. (8)).

In [19], Singh and Sommer showed that on the basis of the relationship between viscosity and the chemical diffusion coefficient of binary liquid alloys, the following two equations: Eq. (13) (this relates viscosity and the enthalpy of mixing), and Eq. (14) (this relates viscosity, enthalpic and entropic effects) are valid.

where \({\Delta \eta } ={\eta - \eta ^0}\) (\(\eta\) is the viscosity of the binary mixture while \(\eta ^0\) is the viscosity of pure components in the binary mixture) and \({H_\mathrm{M}\over RT}\) is the enthalpy of mixing of the binary alloy.

where g(m, W) is as defined by Eq. (9).

2.3 Surface properties model

Bhatia and Singh [20] proposed a simple model that relates the bulk and the surface properties of binary liquid alloys through the grand partition functions in the framework of statistical mechanical theory [27] in conjunction with the quasi-lattice theory (QLT) [28]. This led to the following equation which relates the surface (\(C_i^\mathrm{s}\)) and bulk (\(C_i\)) compositions:

where \(\sigma _i\) (\(i = 1\) or 2) is the surface tension of the pure components 1 and 2 or A and B of the \(A{-}B\) liquid alloy. In Eq. (15), the mean surface area of the alloy, \(\zeta\) is computed using:

where \(\zeta _i\) is computed from the relation:

where \(N_A\) is Avogadro’s number and \(V_i\) is the atomic volume.

Also, in Eq. (15), \(\gamma _i (= {a_i \over c_i})\) and \(\gamma _i^\mathrm{s} (= {a_i^\mathrm{s} \over c_i^\mathrm{s}})\) are the activity coefficients for the bulk and the surface phase, respectively. In agreement with the concept of layered atomic structure near the interface, the relationship between \(\gamma _i\) and \(\gamma _i^\mathrm{s}\) is assumed to be given by [23, 29–31]:

where r and t are the surface coordination fractions (these are fractions of total number of nearest neighbours made by an atom within the layer in which it lies and that in the adjoining layer respectively, such that \(r + 2t =1\). Thus, \(r = {1 \over 2}\) while \(t=\frac{1}{4}\) for closed packed structures); \(\gamma _i (C_i^\mathrm{s})\) means the expression for \(\gamma _i\) is used but with \(C_i\) replaced by \(C_i^\mathrm{s}\).

To compare the behaviour of \(S_{cc}\)(0) in the bulk and at the surface of liquid Cd–Zn alloys, the concentration fluctuations for the surface has to be determined. Once the surface composition is calculated (Eq. (15)), an expression for the concentration–concentration fluctuations in the long wavelength limit for the surface phase [32–35] can be obtained by:

where \(\beta ^\mathrm{s} = \sqrt{ 1+ 4C^\mathrm{s}_1C^\mathrm{s}_2 [ \exp (2W/Z^\mathrm{s}k_BT)-1]}\) and \(Z^\mathrm{s}\) is the coordination number of the surface atom expressed as \(Z^\mathrm{s} = (r + t)Z\). The ideal surface concentration–concentration fluctuations is given by

3 Results and discussion

A good understanding of the theoretical formulations presented in the last section, indicates that the two parameters needed to perform the present calculations are m (the size ratio) and W (the energy parameter). In our calculations, we have chosen at each temperature of interest, the values of these two parameters that gave an overall good fit to the computed and the experimental \(G_\mathrm{M}\) and \(S_{cc}\)(0). The experimental values of \(G_\mathrm{M}\) at temperatures of 743, 780 and 800 K are taken from [6], while the experimental values of \(G_\mathrm{M}\) at 900 K is taken from [7]. The experimental values of \(S_{cc}\)(0) at temperatures 743, 780 and 800 K are obtained from experimental activities in [6], using Eq. (7), while the experimental values of \(S_{cc}\)(0) at 900 K are obtained from experimental free energy of mixing in [7], using Eq. (7). Also, in line with the usual practice [32, 36] the same values of the fitting parameters employed in the computation of bulk properties are used in the computation of surface properties.

The values of m and W employed in our calculations following the procedure explained in the preceding paragraph are shown in Table 1. It should be noted that, in this table, the values of m and W at different temperatures are not the same. This seems to validate the assumption of Koirala et al. in [4], that, ordering energy is temperature dependent(on this premise, they successfully computed the entropy and enthalpy of mixing of Zn–Cd at 800 K). In addition, on the basis of the good fits of \(G_\mathrm{M}\) and \(S_{cc}\)(0) at all temperatures of interest (as seen in Figs. 1, 2), we computed the thermodynamic, transport and surface properties. The results obtained are shown in Figs. 1, 2, 3, 4, 5, 6, 7, 8 and 9 and are discussed below.

3.1 Temperature effects on the free energy of mixing, \(G_\mathrm{M} \over { RT}\) and concentration fluctuations, \(S_{cc}(0)\)

Equation (2) has been used to compute \(G_\mathrm{M} \over { RT}\) at four different temperatures of interest and the results obtained are shown in Fig.1. The figure shows that, at all temperatures, in the bulk concentration range 0.2 \(\le\) \(C_\mathrm{Zn}\) \(\le\) 0.5, there are obvious discrepancies or deviations between the computed and experimental data of \(G_\mathrm{M} \over { RT}\). These discrepancies or deviations, might be due to the formation of complex or complexes in Zn–Cd liquid alloys, which SAM formulation does not account for, as earlier reported in [4]. A perusal of Fig. 1 also shows that, generally speaking, at all bulk concentration, \(C_\mathrm{Zn}\), with the exceptions of \(C_\mathrm{Zn}\) = 0.30 and 0.42, as temperature increases, \(\vert { G_\mathrm{M} \over { RT}}\vert\) increases. This is an indication that, increase in temperature enhances the atomic interactions in Zn–Cd system. However, at \(C_\mathrm{Zn}\) = 0.30 and 0.42, and in the temperature range 743–800 K, the isotherm of \(G_\mathrm{M} \over { RT}\) shows cross-over effects. This implies that for all \(C_\mathrm{Zn}\) \(< 0.30\), all the values of \(G_\mathrm{M} \over { RT}\) at 780 K are smaller than at 800 K, while the reverse is the case when \(C_\mathrm{Zn}\) \(> 0.30\) and also,for all \(C_\mathrm{Zn}\) \(< 0.42\), all the values of \(G_\mathrm{M} \over { RT}\) at 780 K are greater than at 743 K, while the reverse is the case when \(C_\mathrm{Zn}\) \(> 0.42\).

Concentration dependence of free energy of mixing, \({G_\mathrm{M}\over RT}\) for Zn–Cd liquid alloys at 743 K (solid curve 1), at 780 K (dotted curve 2), at 800 K (solid curve 3) and at 900 K (dotted curve 4), using Eq. (2). The bulk concentration of Zn in Zn–Cd is represented by \(C_\mathrm{Zn}\). The squares, open circles, bullets and triangles are the experimental \({G_\mathrm{M}\over RT}\) for Zn–Cd at 743, 780, 800 and 900 K, respectively, taken from [6, 7]

A closer look at Fig. 1 as well reveal that the effect of temperature on the \(G_\mathrm{M} \over { RT}\) of Zn–Cd liquid alloys which appears to be indistinct, becomes more pronounced when \(C_\mathrm{Zn} \ge 0.41\). In this range of composition, the temperature increase from 743 K to 900 K led to as much as 14.7\(\%\) increase in \(\vert { G_\mathrm{M} \over { RT}}\vert\) (i.e.when \(C_\mathrm{Zn} = 0.75\), \(\vert { G_\mathrm{M} \over { RT}}\vert\) \(= 0.3332\) at 900 K, while \(\vert { G_\mathrm{M} \over { RT}}\vert =\) 0.2841 at 743 K). That, at all temperatures, the value of \(\vert { G_\mathrm{M} \over { RT}}\vert\) is far less than 3.0 is an indication that the energy of complex formation in Zn–Cd liquid alloys is small and hence, Zn–Cd liquid alloys are weakly interacting systems. This conclusion is in agreement with the report in [4] on the thermodynamic study of the properties of Zn–Cd liquid alloys at 800 K and the criteria established by Bhatia and Hargrove in [37], regarding complex formation in binary liquid systems and classification of binary liquid systems as weakly or strongly interacting systems.

Equations (8) and (11) were used to compute \(S_{cc}(0)\) (a thermodynamic quantity useful for the understanding of alloying behaviour in terms of compound formation and phase segregation [32]) and \(S_{cc}(0,id)\), respectively. The results of the computations are shown in Fig. 2. In the figure, we observed that at all temperatures, \(S_{cc}(0)\) > \(S_{cc}(0,id)\). This is an indication that Zn–Cd liquid alloys are homocoordinated (in agreement with the reports in [4, 7, 9]), and that the homocoordination which is weak is indicated by the relatively low peak at various temperatures, when compared with strongly homocoordinated alloys like Ga–Tl liquid alloys [9]. The figure also show that, when the temperature is increased, the position of maximum \(S_{cc}(0)\) shifts towards equiatomic composition, the values of \(S_{cc}(0)\) at all composition of Zn approach that of ideal solution (in agreement with the report in [7], from the study of experimental thermodynamic activity of Zn–Cd alloys at 800 and 900 K) and becomes nearly symmetrical about equiatomic composition (in agreement with the reports in [6, 7]). We observed that the maximum value of \(S_{cc}(0)\) reduces when the temperature increases, indicating that increase in temperature reduces the degree of homocoordination in Zn–Cd liquid alloys. Another effect of temperature on Zn–Cd liquid alloys as seen from the plots in Fig.2 is the cross-over in the variation of \(S_{cc}(0)\). This cross-over occurs when \(C_\mathrm{Zn}\) = 0.36, 0.44, and 0.48 at 800, 780 and 743 K, respectively, relative to \(S_{cc}(0)\) at 900 K. Thus, at all concentrations of Zn below these three concentrations, the \(S_{cc}(0)\) at 900 K is greater than that at the respective temperatures while at all concentrations of Zn above these three concentrations, the \(S_{cc}(0)\) at 900 K is smaller than that at the respective temperatures. Also, as a result of temperature increase, the magnitude of \(S_{cc}(0)\) decreased by as much as 35.7\(\%\) (i.e. when \(C_\mathrm{Zn}\) \(= 0.7\), \(S_{cc}(0)\) = 0.7092 at 743 K, while \(S_{cc}(0)\) = 0.4558 at 900 K).

Concentration dependence of the bulk concentration–concentration fluctuations, \(S_{cc}(0)\) for Zn–Cd liquid alloys at 743 K (solid curve 1), at 780 K (dotted curve 2), at 800 K (solid curve 3) and at 900 K (dotted curve 4), using Eq. (8). The computed (computed from Eq. (11)) ideal values of the bulk concentration–concentration fluctuations,\(S_{cc}(0,id)\) is represented by solid curve 5. \(C_\mathrm{Zn}\) is the bulk concentration of Zn in Zn–Cd. The squares, open circles, bullets and triangles are the experimental \(S_{cc}(0)\) for Zn–Cd at 743, 780, 800 and 900 K, respectively, taken from [6, 7]

3.2 Temperature effects on the thermodynamic activity, \(a_\mathrm{Zn}\) and short range order parameter, \(\alpha _1\)

Equations (5) and (10) were used to compute the thermodynamic activity, \(a_\mathrm{Zn}\) and Warren–Cowley short range order parameter, \({\alpha _1}\), respectively. The former is a thermodynamic quantity which is a measure of the minimum Gibbs energy needed to convert Zn atom from its state in the Zn–Cd solution to the pure state in any proposed extraction or refining process while the latter is an important microscopic function which is relevant for the prediction of the local arrangement of atoms in a liquid binary alloy [4, 38]. Figures 3 and 4 show the results of the respective computations of \(a_\mathrm{Zn}\) and \({\alpha _1}\) at the temperatures of interest. In Fig. 3, we observed that, although, at each of the temperatures, \(a_\mathrm{Zn}\) increases as \(C_\mathrm{Zn}\) increases, however, if each of the \(a_\mathrm{Zn}\) isotherms is closely compared with others, we found that:

-

1.

throughout the entire composition of Zn in the alloy, \(a_\mathrm{Zn}\) at 900 K is lower than at 743, 780 and 800 K.

-

2.

in the range \(C_\mathrm{Zn}\) \(\ge 0.23\), \(a_\mathrm{Zn}\) at 780 K though lower than \(a_\mathrm{Zn}\) at 743 K, yet is greater than \(a_\mathrm{Zn}\) at 800 and 900 K.

-

3.

cross-over effect occurs at \(C_\mathrm{Zn}= 0.23\), relative to \(a_\mathrm{Zn}\) at 743 K.

-

4.

the change in temperature of Zn–Cd liquid alloys resulted in as much as 8.4\(\%\) decrease in the magnitude of \(a_\mathrm{Zn}\) (i.e. when \(C_\mathrm{Zn} = 0.54\), \(a_\mathrm{Zn}\) \(= 0.7735\) at 743 K, while \(a_\mathrm{Zn}\) \(= 0.7083\) at 900 K).

In Fig. 4, the plots of \(\alpha _1\) at various temperatures show that:

-

1.

at each of the temperatures, the magnitude of \(\alpha _1\) increases up to a maximum, as the bulk concentration \(C_\mathrm{Zn}\) increases, and then, the magnitude reduces towards zero as \(C_\mathrm{Zn}\) increases.

-

2.

the bulk concentration of Zn at which the maximum magnitude of \(\alpha _1\) is attained depends on the temperature, and its position moves away from Zn-rich end towards equiatomic composition as the temperature increases.

-

3.

as temperature of Zn–Cd liquid alloys is increasing from 743 to 900 K, the maximum magnitude and asymmetry of \(\alpha _1\) are reducing.

-

4.

cross-over effects occur at \(C_\mathrm{Zn}=0.48\), 0.44, and 0.36 when the temperatures are 743, 780 and 800 K, respectively, relative to 900 K. This corroborates the cross-over we earlier observed in \(S_{cc}(0)\).

-

5.

the change in temperature led to as much as 35.2\(\%\) decrease in the magnitude of \(\alpha _1\) (i.e.when \(C_\mathrm{Zn}= 0.81\), \(\alpha _1=\) 0.0671 at 743 K, while \(\alpha _1=0.0435\) at 900 K).

-

6.

that at all temperatures, the maximum magnitude of \(\alpha _1\) is though positive, but much less than unity is an indication that Zn–Cd liquid alloys are weak homocoordinated alloys, and this is in agreement with the reports in [4, 9].

Concentration dependence of activity of zinc, \(a_\mathrm{Zn}\) for Zn–Cd liquid alloys at 743 K (solid curve 1), at 780 K (dotted curve 2), at 800 K (solid curve 3) and at 900 K (dotted curve 4), using Eq. (5). \(C_\mathrm{Zn}\) is the bulk concentration of Zn in Zn–Cd. The squares, open circles, bullets and triangles are the experimental \(a_\mathrm{Zn}\) for Zn–Cd at 743, 780, 800 and 900 K, respectively, taken from [6, 7]

Concentration dependence of Warren–Cowley short range order parameter, \({\alpha _1}\) for Zn–Cd liquid alloys at 743 K (solid curve 1), at 780 K (dotted curve 2), at 800 K (solid curve 3) and at 900 K (dotted curve 4), using Eq. (10). \(C_\mathrm{Zn}\) is the bulk concentration of Zn in Zn–Cd

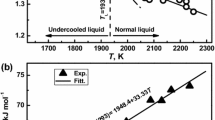

3.3 Temperature effects on the diffusion coefficients, \(D_\mathrm{M}\over D_\mathrm{S}\) and viscosity,\(\Delta \eta \over \eta ^0\)

It has been reported that transport properties such as diffusivities of metals in the liquid state are needed for many metallurgical processes and heterogeneous chemical reactions [4]. Also, from practical point of view, viscosity is reported to be one of the key parameters for design and optimisation of metallurgical processes [39]. In addition, Gruner et al. in [40] reported that, a study of viscosity of liquid alloys will contribute to the understanding of the relations between atomic structure and physical properties of alloys since properties like viscosity and diffusion are strongly sensitive to structural changes with respect to temperature and composition. Hence, we have extended our investigation of effects of temperature on the properties of Zn–Cd liquid alloys, to investigate effects of temperature on two of its transport properties, namely diffusivity and viscosity, using Eqs. (12) and (14), respectively. The results obtained are shown in Figs. 5 and 6. Although, in these figures, due to lack of experimental data, it is not possible to compare computed and experimental results, however, in Fig. 5, the results obtained at 800 and 900 K are in agreement with that reported in [4, 9] (where at 800 K, the tendency for phase separation is maximum around equiatomic composition, and at 900 K, minimum diffusivity is 0.4 at \(C_\mathrm{Zn} = 0.56\)). Thus, these agreements serve as evidence of the reliability of the following observations in Fig. 5:

-

1.

at all temperatures, the magnitude of diffusivity reduces from unity towards a minimum, and then increases towards unity as the composition of Zn in the alloy increases.

-

2.

the magnitude of the minimum diffusivity increases as the temperature increases.

-

3.

as temperature increases, the asymmetry in the diffusivity isotherms reduces and the composition of Zn corresponding to the asymmetry moves from Zn-rich end towards equiatomic composition. This implies that as temperature increases, the weak homocoordination tendency in Zn–Cd liquid alloys becomes weaker.

-

4.

cross-over effects occur at \(C_\mathrm{Zn}=0.55\), 0.53, and 0.48 when the temperatures are 780, 800 and 900 K, respectively, relative to 743 K. This is similar to the cross-over we observed in \(S_{cc}(0)\) and \(\alpha _1\).

-

5.

change in temperature resulted in as much as 35.5\(\%\) increase in the magnitude of the diffusivity of Zn–Cd liquid alloys (i.e. when \(C_\mathrm{Zn}=0.82\), diffusivity \(=0.5979\) at 900 K, while diffusivity \(=0.3854\) at 743 K).

In Fig. 6, we observed that the viscosity isotherm of Zn–Cd liquid alloys at various temperatures is in agreement with the expected pattern of negative deviation from additive rule of mixing for a typical homocoordinated alloy [19]. Hence, these isotherms corroborate the earlier observations that Zn–Cd liquid alloys are homocoordinated alloys. Also, in Fig. 6, it is significant to note the following about the relationship between the viscosity of liquid Zn–Cd alloys and temperature:

-

1.

generally, in the composition range 0\({\le }\) \(C_\mathrm{Zn}<0.36\), viscosity decreases as temperature increases from 743–900 K. This is in agreement with the known pattern of relationship between viscosity of liquids and temperature, as temperature increases, it is expected that the bonding between Zn and Cd atoms decreases, and thus, the velocity of the atoms decreases.

-

2.

in the composition range 0.36\({\le }\) \(C_\mathrm{Zn}\) \({\le }\) 0.49 and 0.50\({\le }\) \(C_\mathrm{Zn}\) \({\le }\) 0.54, viscosity decreases as temperature increases from 743 to 800 K and from 743 to 780 K, respectively. When the temperature is higher than 800 and 780 K in the composition ranges 0.36\({\le }\) \(C_\mathrm{Zn}\) \({\le }\) 0.49 and 0.50\({\le }\) \(C_\mathrm{Zn}\) \({\le }\) 0.54, respectively, anomalous behaviours occur, in which viscosity increases, as temperature increases. In the rest of the composition, 0.55\({\le }\) \(C_\mathrm{Zn}\) \({\le }\) 1.00, anomalous behaviour also occur when the temperature increases from 743 to 900 K.

-

3.

temperature has effect on both the magnitude of viscosity and the composition of asymmetry of the isotherm. In fact, we observed that as temperature increases, the magnitude of the minimum value of the viscosity increases and the composition of Zn corresponding to asymmetry move away from Zn-rich end towards equiatomic composition.

-

4.

cross-over effects occur at \(C_\mathrm{Zn}=0.48\),0.44, and 0.36 when the temperature is respectively, 743, 780 and 800 K, relative to 900 K. This cross-over is a direct opposite of the cross-over we observed in both \(S_{cc}(0)\) and \(\alpha _1\).

-

5.

change in temperature resulted in as much as 52.9\(\%\) increase in the magnitude of the viscosity of Zn–Cd liquid alloys (i.e. when \(C_\mathrm{Zn}=0.82\), viscosity \(=-0.4021\) at 900 K, while viscosity\(=-0.6146\) at 743 K).

The anomalous occurrences noted above, are so named because the pattern they exhibited is contrary to the usual pattern of viscosity decreasing when the temperature is increasing, and the anomalous is similar to that of the viscosity of In–Sb liquid alloys around 1073 K or between 1023 and 1073 K (where viscosity increases suddenly as temperature increases [41]). Furthermore, on the premise that viscosity of liquids depends, to a great extent on the movement of species (atoms or molecules or ions) and thus, on the bonding and the configuration of the species [41, 42], we conjectured that the highlighted anomalous in the viscosity Zn–Cd may be due to anomalous change in the structure of Zn–Cd liquid alloys.

Computed diffusivity or diffusion coefficients isotherms of Zn–Cd liquid alloys at 743 K (solid curve 1), at 780 K (dotted curve 2), at 800 K (solid curve 3) and at 900 K (dotted curve 4), using Eq. (12). \(C_\mathrm{Zn}\) is the bulk concentration of Zn in Zn–Cd

Computed viscosity isotherms of Zn–Cd liquid alloys at 743 K (solid curve 1), at 780 K (dotted curve 2), at 800 K (solid curve 3) and at 900 K (dotted curve 4), using Eq. (14). \(C_\mathrm{Zn}\) is the bulk concentration of Zn in Zn–Cd

3.4 Temperature effects on the surface tension, \(\sigma\), surface concentration, \(C^\mathrm{s}\) and surface concentration fluctuations, \(S^\mathrm{s}_{cc}(0)\)

It has been reported that the study of surface phenomenon in binary liquid alloys is an important adventure since knowledge of surface phenomenon is of great relevance from a metallurgical and catalytic point of view [28, 32, 43–45]. Hence, we included the study of temperature effects on three surface properties of Zn–Cd liquid alloys: surface tension, \(\sigma\), surface concentration, \(C^\mathrm{s}\) and surface concentration fluctuations, \(S^\mathrm{s}_{cc}(0)\). Equations (15), (19) and (20) were used to compute surface tension (surface concentration is also computed from the simultaneous solution of Eq. (15)), surface concentration fluctuations and ideal surface concentration fluctuations, respectively. The values of input parameters in these equations are given in Table 1.

The results of effects of temperature on the surface tension and the surface concentration are shown in Figs. 7 and 8, respectively. Also, it is worth noting that, as a result of lack of experimental data, which is the case with many metallic solutions (possibly due to reported experimental difficulties associated with measuring surface tension [4, 15]), we can not compare computed and experimental results (the only experimental surface properties data of Zn–Cd liquid alloys we found in literature [47] is at 730 K, which is outside the temperatures of interest). However, we are of the opinion that since the model we employed has been used by many researchers successfully to compute surface properties [4, 9, 14, 23, 30], the results obtained in Figs. 7 and 8 are reliable. In the two figures, we found the usual pattern of surface tension reducing with increasing concentration while surface concentration is increasing with increasing composition. This is a signature that the surface of Zn–Cd alloys has more of Cd atoms than Zn atoms or that Cd-atoms (having lower surface tension relative to Zn-atoms) segregate at the surface at all bulk concentrations, and it agrees with the reports in [4, 9]. This segregation is to minimize the system’s internal energy. Also, in Fig. 7, we observed that surface tension decreases with increasing temperature over the entire bulk concentration or that the temperature coefficient of surface tension, \({\mathrm{d}\sigma \over \mathrm{d}T}\) remains negative over the entire bulk composition. This is an indication that increasing temperature reduces the degree of segregation at the surface which may be as a result of retrogressive dissociation at the surface of Zn–Cd liquid alloys. A closer study of Fig. 7 shows that the change in temperature resulted in as much as 7.7\(\%\) decrease in the \(\sigma\) of Zn–Cd liquid alloys (i.e.when \(C_\mathrm{Zn}=1.00\), \(\sigma\) \(=0.5303\) at 743 K, while \(\sigma =0.4893\) at 900 K).

Computed surface tension isotherms of Zn–Cd liquid alloys at 743 K (solid curve 1), at 780 K (dotted curve 2), at 800 K (solid curve 3) and at 900 K (dotted curve 4), using Eq. (15). The dotted curve 5 represents the ideal values of the surface tension of the Zn–Cd, obtained from the relation: \({{\sigma }_i^{id}={\sigma }_A C_A+{\sigma }_B C_B}\) and \(\sigma _i\) (i = A or B). \(C_\mathrm{Cd}\) is the bulk concentration of Cd in Zn–Cd

In Fig. 8, we observed that the segregation of Cd atoms at the surface of Zn–Cd liquid alloys is so enormous that for bulk concentration,\(C_\mathrm{Cd}=0.1\)(10\(\%\)), the surface concentration of Cd is 0.6615 (66.15\(\%\)) at 743 K, 0.6525 (65.25\(\%\)) at 780 K, 0.6483 (64.83\(\%\)) at 800 K and 0.5968 (59.68\(\%\)) at 900 K. Also, this figure further shows that the extent of Cd segregation at the surface decreases with temperature (this is similar to the observation of Prasad and Mikula in [36] on the effect of temperature on the surface properties of Cu–Sn liquid alloys). A closer look at the various isotherms in Fig. 8 also reveals that change in temperature caused as much as 9.1\(\%\) decrease in the surface concentration of Cd in the Zn–Cd liquid alloys (when \(C_\mathrm{Cd}=0.13\), \(C^\mathrm{s}=0.7508\) at 743 K, while \(C^\mathrm{s}=0.6826\) at 900 K).

Computed values of the surface concentration, \({C^\mathrm{s}_\mathrm{Cd}}\) for Zn–Cd liquid alloys at 743 K (solid curve 1), at 780 K (dotted curve 2), at 800 K (solid curve 3) and at 900 K (dotted curve 4), using Eq. (15). The dotted curve 5 represents the ideal values of the surface concentration, \({C^\mathrm{s}_{id}}\) computed from: \({C^\mathrm{s}_{id}= C}\) (where C is the bulk concentration). The bulk concentration of Cd in Zn–Cd is represented by \(C_\mathrm{Cd}\)

Figure 9 shows the results of effect of temperature dependence on the surface concentration fluctuations of Zn–Cd liquid alloys. Although, not much has been known about this surface property up till date, hence, experimental data are not available for comparison, in the computed results, we observed that, at all temperatures, the computed \(S^\mathrm{s}_{cc}(0)\) is greater than the ideal \(S^\mathrm{s}_{cc}(0)\). This shows that Zn–Cd liquid alloys are homocoordinated alloys, as we have earlier observed in the bulk properties study. Additional notable effect of temperature on the surface concentration fluctuations are:

-

1.

cross-over effect occurs at \(C_\mathrm{Cd}=0.08\), relative to \(S^\mathrm{s}_{cc}(0)\) at 900 K. This is similar in behaviour to the cross-over we observed in \(a_\mathrm{Zn}\).

-

2.

change in temperature resulted in as much as 28.2\(\%\) increase in the magnitude of the surface concentration fluctuations of Zn–Cd liquid alloys (i.e. when \(C_\mathrm{Cd}=0.17\), \(S^\mathrm{s}_{cc}(0)\) \(=0.2187\) at 743 K, while \(S^\mathrm{s}_{cc}(0)=0.3048\) at 900 K).

Computed values of the surface concentration fluctuations, \(S^\mathrm{s}_{cc}(0)\) for Zn–Cd liquid alloys at 743 K (solid curve 1), at 780 K (dotted curve 2), at 800 K (solid curve 3) and at 900 K (dotted curve 4), using Eq. (19). The dotted curve 5 (computed from Eq. (20)) represents the ideal values of surface concentration fluctuations while the solid curve 6 (computed from Eq. (11)) represents the ideal bulk concentration fluctuations. \(C_\mathrm{Cd}\) is the bulk concentration of Cd in Zn–Cd

4 Conclusions

The theoretical study of the bulk and surface properties of liquid Zn–Cd alloys over a wide range of temperatures has shown that increase in temperature,

-

1.

resulted in the reduction in the degree of homocoordination in Zn–Cd liquid alloys.

-

2.

led to cross-over in both bulk (transport properties inclusive) and surface properties.

-

3.

caused anomalous behaviour in the viscosity of Zn–Cd liquid alloys.

-

4.

has effect on both the position and the magnitude of asymmetry in concentration fluctuations, short-range order parameter, diffusivity and viscosity.

-

5.

resulted in decrease in the magnitude of bulk properties quantities (with the exception of the transport properties, where it resulted in increase in the magnitude) while it caused increase in the magnitude of the surface properties quantities.

-

6.

has most pronounced effect on the viscosity (52.9\(\%\)) and least effect on the surface tension (7.1\(\%\)).

In addition, a comparison of the values of m obtained by fittings (1.680 at 743 K, 1.485 at 780 K, 1.310 at 800 K and 1.170 at 900 K, as shown in Table 1) and that computed at the melting points (1.430 at 743 K, 1.416 at 780 K, 1.426 at 800 K and 1.431 at 900 K, all obtained from [46]) shows that, within the limits of computational and experimental errors, as temperature is reducing, the value of m obtained by fitting is getting close and closer to that obtained at the melting point. This seems to suggest that the effect of size on the properties of Zn–Cd liquid alloys considered (bulk and surface properties) becomes more significant as the temperature is reducing or at lower temperature and vice versa.

The study also reveal that the characteristics behaviour of viscosity for a given binary liquid alloys known to be dependent on the coupled effects of energetic and size factor [19], as well depends on temperature. Thus, in addition to the reported understanding that size factor, W determines the composition of asymmetry of the viscosity isotherm in a typical alloy, our results indicate that temperature is another quantity that has effect on the composition of asymmetry [19].

Additionally, from Table 1, we observed that although all the W values at temperatures of interest are all positives (confirming that Zn–Cd liquid alloys are homocoordinated alloys), as temperature is increasing, the value of W is reducing. This is a signature of Zn–Cd liquid alloys losing their weak homocoordination tendency or an indication that the disassociation tendency in Zn–Cd liquid alloys is approaching ideality as temperature is increasing, and this agrees with the report in [7].

References

A. Kumar, D.P. Ojha, A first principle study of Cd–Zn binary alloy. Armen. J. Phys. 3(3), 203–217 (2010)

K. Nagamani, M.V. Reddy, Y. Lingappa, K.T.R. Reddy, R.W. Miles, Physical properties of Zn\(_x\)Cd\(_{1-x}\)S nanocrystalline layers synthesized by solution growth method. Int. J. Optoelectron. 2(2), 1–4 (2012)

I. Koirala, B.P. Singh, I.S. Jha, Transport and surface properties of molten Cd–Zn alloys. J. Inst. Sci. Tech. 19(1), 14–18 (2014)

R.P. Koirala, B.P. Singh, I.S. Jha, D. Adhikari, Thermodynamic, structural and surface properties of liquid Cd–Zn alloys. J. Mol. Liq. 179, 60–66 (2013)

R.N. Singh, F. Sommer, Temperature dependence of the thermodynamic functions of strongly interacting liquid alloys. J. Phys. Condens. Matter. 4, 5345–5358 (1992)

S. Chung, W. Jung, J. Pak, Activity measurement of Zn in liquid Zn–Cd alloy using EMF method. Korean J. Mater. Res. 12(4), 283–289 (2002)

I. Katayama, K. Maki, Y. Fukuda, A. Ebara, T. Iida, Thermodynamic activity of liquid Zn–Cd alloys studied by EMF method with zirconia solid electrolyte. Mater. T. Jim. 38(2), 119–122 (1997)

Solder Information. http://www.globalspec.com/learnmore/manufacturing_process_equipment/welding_equipment_supplies/solder. Accessed 29 April 2016

O. Akinlade, O.E. Awe, Bulk and surface properties of liquid Ga–Tl and Zn–Cd alloys. Int. J. Mater. Res. 97(4), 377–381 (2006)

B. Saatci, M. Ari, M. Gunduz, F. Meydaneri, M. Bozoklu, S. Durmus, Thermal and electrical conductivities of Zn–Cd alloys. J. Phys. Condens. Matter. 18(47), 10643–10653 (2006)

O. Akinlade, R.N. Singh, Surface segregation and surface tension in liquid Fe–Cu alloys. Z. Metallkd. 92(9), 1111–1113 (2001)

O. Akinlade, A.O. Boyo, B.R. Ijaduola, Demixing tendencies in some Sn-based liquid alloys. J. Alloy. Compd. 290, 191–196 (1999)

G. Wilde, R. Willnecker, R.N. Singh, F. Sommer, The metastable miscibility gap in the system Fe–Cu. Z. Metallkd. 88(10), 804–809 (1997)

Y.A. Odusote, A.I. Popoola, S.S. Oluyamo, Bulk and surface properties of demixing liquid Al–Sn and Sn–Tl alloys. Appl. Phys. A (2016). doi:10.1007/s00339-015-9591-4

I. Egry, E. Ricci, R. Novakovic, S. Ozawa, Surface tension of liquid metals and alloys—recent developments. Adv. Colloid. Interfac. 159(2), 198–212 (2010)

T.B. Massalski, P.R. Subramanian, H. Okamoto, L. Kacprzak (eds.), Binary Alloy Phase Diagrams, vol. 1–3, 2nd edn. (ASM, International Materials Park, OH, 1990)

L.A. Zabdyr, Phase equilibria in ternary Cd–Sb–Zn system. CALPHAD 21, 349–358 (1997)

R.N. Singh, F. Sommer, A Simple model for demixing binary liquid alloy. Z. Metallkd. 83(7), 533–540 (1992)

R.N. Singh, F. Sommer, Thermodynamic investigation of viscosity and diffusion in binary liquid alloys. Phys. Chem. Liq. 36, 17–28 (1998)

A.B. Bhatia, R.N. Singh, A quasi-lattice theory for compound forming molten alloys. Phys. Chem. Liq. 13, 177–190 (1984)

L.C. Prasad, R.N. Singh, Surface segregation and concentration fluctuations at the liquid-vapor interface of molten Cu–Ni alloys. Phys. Rev. B 44, 13768–13771 (1991)

L.C. Prasad, A. Mikula, Surface segregation and surface tension in Al–Sn–Zn liquid alloys. Phys. B 373, 142–149 (2006)

R. Novakovic, D. Zivkovic, Thermodynamics and surface properties of liquid Ga-X (X = Sn, Zn) alloys. J. Mater. Sci. 40, 2251–2257 (2005)

A.B. Bhatia, D.E. Thornton, Structural aspects of the electrical resistivity of binary alloys. Phys. Rev. B 2(8), 3004–3012 (1970)

O. Akinlade, R.N. Singh, F. Sommer, Thermodynamic investigation of viscosity in Cu–Bi and Bi–Zn liquid alloys. J. Alloy. Compd. 267, 195–198 (1998)

O.E. Awe, Y.A. Odusote, L.A. Hussain, O. Akinlade, Temperature dependence of thermodynamic properties of Si–Ti binary liquid alloys. Thermochim. Acta. 519, 1–5 (2011)

R.H. Fowler, E.A. Guggenheim, Statistical Thermodynamics (Cambridge University Press, Cambridge, 1960)

E.A. Guggenheim, Mixtures (Oxford University Press, London, 1952)

O. Akinlade, R.N. Singh, Bulk and surface properties of liquid In–Cu alloys. J. Alloy. Compd. 333, 84–90 (2002)

O.E. Awe, O. Akinlade, L.A. Hussain, Thermodynamic investigations of Bi–Cd, In–Pb and Ni–Pd liquid alloys. Z. Metallkd. 96, 89–93 (2005)

R. Novakovic, T. Tanaka, Bulk and surface properties of Al–Co and Co–Ni liquid alloys. Phys. B 371, 223–231 (2006)

L.C. Prasad, R.N. Singh, Surface segregation and concentration fluctuations at the liquid-vapor interface of molten Cu–Ni alloys. Phys. Rev. B. 44(24), 13768–13771 (1991)

R.N. Singh, I.K. Mishra, V.N. Singh, Local order in Cd-based liquid alloys. J. Phys. Condens. Matter. 2, 8457–8462 (1990)

R.N. Singh, I.K. Mishra, Conditional probabilities and thermodynamics of binary. Phys. Chem. Liq. 18(4), 303–319 (1988)

R. Novakovic, E. Ricci, D. Giuranno, F. Gnecco, Surface properties of Bi–Pb liquid alloys. Surf. Sci. 515, 377–389 (2002)

L.C. Prasad, A. Mikula, Effect of temperature on the surface properties of Cu–Sn liquid alloys. J. Alloy. Compd. 314, 193–197 (2001)

A.B. Bhatia, W.H. Hargrove, Concentration fluctuations and thermodynamic properties of some compound forming binary molten systems. Phys. Rev. B. 10(3), 3186–3196 (1974)

J. Tomiska, Thermodynamic activities of alloys. Thermochim. Acta. 314, 145–153 (1998)

A. Yakymovych, Y. Plevachuk, S. Mudry, J. Brillo, H. Kobataka, H. Ipser, Phys. Chem. Liq. (2014). doi:10.1080/00319104.2013.876639

S. Gruner, W. Hoyer, The dynamic viscosity of liquid Cu–Si alloys. J. Alloy. Compd. 460(1—-2), 496–499 (2008)

S.J. Cheng, X.F. Bian, X.B. Qin, P.C. Si, Temperature dependence of the viscosity of In–Sb alloy melts. Indian J. Eng. Mater. S. 11(60), 521–524 (2004)

M. Tan, B. Xiufang, X. Xianying, Z. Yanning, G. Jing, S. Baoan, Correlation between viscosity of molten CuSn alloys and phase diagram. Physica B 387(1), 1–5 (2007)

L.C. Prasad, R.N. Singh, V.N. Singh, G.P. Singh, Correlation between bulk and surface properties of AgSn liquid alloys. J. Phys. Chem. B 102, 921–926 (1998)

L.C. Prasad, R.N. Singh, G.P. Singh, The role of size effects on surface properties. J. Phys. Chem. Liq. 27(3), 179–185 (1994)

O.E. Awe, O. Akinlade, L.A. Hussain, Thermodynamic properties of liquid Te–Ga and Te–Tl alloys. J. Alloy. Compd. 361, 227–233 (2003)

T. IIda, R.I.L. Guthrie, The Physical Properties of Liquid Metals (Clarendon Press, Oxford, 1988)

W. Ptak, M. Kucharski, Surface tension of Zn–Cd and Cd–Bi alloys. Arch. Hutn. 19(3), 301–317 (1974)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Awe, O.E., Azeez, A.A. Temperature dependence of the bulk and surface properties of liquid Zn–Cd alloys. Appl. Phys. A 123, 363 (2017). https://doi.org/10.1007/s00339-017-0977-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-017-0977-3