Abstract

The surface tension and specific heat for liquid ternary Ti–6Al–4V alloy were measured by the oscillating drop method and drop calorimetry, respectively, under containerless condition over broad temperature ranges. The solidification microstructures at different undercoolings appeared as the basket-weave morphology. The relationship between dendritic growth velocity of β phase and undercooling was determined as a power function, and the growth velocity attained 22.21 ms−1 at the maximum undercooling of 252 K (0.13 T L). The mechanical property of this alloy solidified at different undercoolings was determined through compression tests, while its thermal diffusivity in the solid state was measured by the laser flash method.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The substantial undercooling and characteristic properties of liquid alloys have attracted more and more interest in the past decade due to the significance for both experimental and computational materials science studies [1–17]. Up to now, the crystal growth and thermal properties research of liquid melts in substantial undercooled state such as crystal growth velocity [2], surface tension [6–10] and specific heat [12] are still limited owing to the difficulty of experiments. Fortunately, the substantial undercooling can be obtained by the electromagnetic levitation [6, 7, 12], and the oscillating drop method [6, 7, 9, 10] and drop calorimetry [12] under levitated condition can be used to determine the surface tension and specific heat of liquid melts, respectively. The electromagnetic levitation technique has also been applied to investigate the rapid crystal growth within undercooled liquid alloys [2]. Moreover, the mechanical property of small alloy samples is often determined by compression tests. In addition, the thermal diffusivity of solid alloys can be measured by the laser flash method effectively, which is the most frequently used technique [18].

Ti–6Al–4V alloy is the most commonly used Ti-based alloys owing to its excellent properties [10, 19–23]. The investigations on substantial undercooling and crystal growth characteristics are very important for the development of the alloy. The aim of the present work is to obtain the substantial undercooling of liquid Ti–6Al–4V alloy and the experimental data on the surface tension and specific heat measured by electromagnetic levitation technique. The solidification microstructure and dendritic growth velocity of β phase are also investigated. Meanwhile, the mechanical property of the alloy is obtained by compression test. Moreover, by using the laser flash method, the thermal diffusivity of solid Ti–6Al–4V alloy is measured over a wide temperature range.

2 Experimental method

The samples of Ti–6Al–4V (in wt%) alloy with the mass of about 0.65 g were prepared from high-purity metals, i.e., Ti (99.999 %), Al (99.9999 %) and V (99.8 %), to be used for the undercooling experiments. Electromagnetic levitation apparatus was employed to perform the undercooling experiments. The sample was levitated and melted in the apparatus. The surface oscillations were recorded to obtain the surface tension of liquid melts. The adiabatic copper calorimeter was used to measure the enthalpy change of the dropped liquid sample after recording the oscillation signal, and the specific heat can be determined from enthalpy change. The crystal growth velocity was measured by a high-speed photodiode device. The detail of these methods has been reported in references [2, 6, 12, 15].

The thermal diffusivity of solid Ti–6Al–4V alloy was determined by Linseis LFA 1000 laser flash diffusivity apparatus. The experimental sample with a diameter of 12.70 mm and thickness of 2.86 mm was prepared, and graphite was sprayed on the surface of the sample. Meanwhile, the engineering stress–strain curve of solidified sample was measured by INSTRON 5567 apparatus.

3 Results and discussion

3.1 Thermophysical properties of liquid Ti–6Al–4V alloy

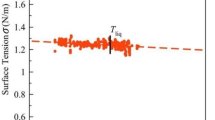

By means of the oscillating drop method, the experimental surface tension results of undercooled liquid ternary Ti–6Al–4V alloy were measured over the 1686 to 2250 K temperature range, and the maximum undercooling of 247 K (0.13 T L) was achieved. The experimental results are plotted in Fig. 1a. The experimental surface tension results of the alloy can be represented as a linear function of temperature, and the following equation can be fitted:

At the liquidus temperature (1933 K), the surface tension value is equal to 1.38 N m−1, and the temperature coefficient is determined as −3.13 × 10−4 Nm−1 K−1.

There are some relevant surface tension values of liquid ternary Ti–6Al–4V alloy in [10, 22, 23], as shown in Fig. 1a, where the Ti–6Al–4V (in at%) reported by Schneider [23] was transformed into Ti–3.5Al–4.4V (in wt%). The measured result of Ti–6Al–4V alloy at liquidus temperature is smaller than the value reported by Vinet [22], but similar to Ti–3.5Al–4.4V alloy [10, 23]. Furthermore, the temperature coefficients by Egry [10] and Schneider [23] are lower than that by this work. In addition, the measured surface tension value of liquid Ti–6Al–4V alloy at 1933 K is smaller than that of Ti [24] in liquid state, but higher than those of Ti80Al20 [6], Ti55Al45 [15] and Ti49Al51 [4] alloys in liquid state. Meanwhile, it is evident that the measured temperature coefficient of liquid Ti–6Al–4V alloy is also smaller than that of liquid Ti and these binary Ti–Al alloys.

The enthalpy change of the liquid Ti–6Al–4V alloy was determined by the levitation drop calorimeter method in the temperature range of 1713—2161 K, and the maximum undercooling obtained in the experiments was 220 K (0.11 T L), as shown in Fig. 1b. Clearly, the enthalpy change of the alloy presents a linear function of temperature as follows:

According to the equation, the measured specific heat value of liquid Ti–6Al–4V alloy is determined as 33.33 J mol−1 K−1.

The measured specific heat data for this alloy in undercooled liquid state are still limited in the literature. However, the specific heat results of liquid Ti [24], Al [24], V [24], Ti80Al20 [25] and Ti49Al51 [25] binary alloys can be found in several reports, which are, respectively, equal to 33.51, 29.14, 39.73, 33.01 and 31.27 J mol−1 K−1. Apparently, the specific heat data for the ternary alloy is smaller than those of Ti, V, but higher than those of Al and the binary alloys. Moreover, the specific heat value of the alloy is very close to that of Ti and Ti80Al20 alloy.

3.2 Dendritic growth and microstructures

To have more details on the crystal growth characteristics of substantially undercooled Ti–6Al–4V alloy, the dendritic growth, phase constitution and microstructure were further studied by electromagnetic levitation technique, XRD and optical microscope.

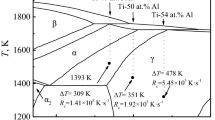

Figure 2 shows the solidification microstructures of Ti–6Al–4V alloy at different undercoolings in the electromagnetic levitation experiments. When the sample solidified at low undercooling state, the microstructure is characterized by the coarse grains, as shown in Fig. 2a. At the maximum undercooling of 252 K, the grain boundary has disappeared as shown in Fig. 2b. The microstructures of the samples at different undercoolings show the basket-weave morphology, and it is quite different from the other alloys solidified under electromagnetic levitation condition, such as Fe-based alloys [2]. The phase change from β to α phase in solid state at high temperature has remarkably changed solidification microstructures.

X-ray diffraction analysis was employed to obtain the phase constitution of Ti–6Al–4V alloy solidified at different undercoolings. Both of the diffraction patterns for the samples solidified at 32 and 252 K reveal α and β solid solution phases, as shown in Fig. 3a.

Moreover, the dendritic growth velocity of β phase in Ti–6Al–4V alloy was measured under electromagnetic levitation containerless condition, and the velocity attained 22.21 ms−1 at the maximum undercooling of 252 K (0.13 T L). Figure 3b presents the experimental dendritic growth velocity of β phase in Ti–6Al–4V alloy, which can be described as a power function of undercooling

3.3 Mechanical and thermal properties of solid Ti–6Al–4V alloy

The application of a material is usually determined by its characteristic properties, such as mechanical and thermal properties. In this work, these key properties are also investigated by using the relevant analysis equipment.

The engineering stress–strain curves of ternary Ti–6Al–4V alloy solidified at 19, 79 and 176 K were studied by INSTRON 5567 apparatus in order to reveal the relationship between mechanical property and undercooling, as shown in Fig. 4a. Obviously, the mechanical properties change significantly with the undercooling. In addition, the strength of ternary Ti–6Al–4V alloy rises at the cost of toughness. Figure 4b presents the elastic modulus and elastic limit of ternary Ti–6Al–4V alloy at these undercoolings. Both of the elastic modulus and elastic limit increase remarkably with the increase of undercooling. In this work, the microstructures of Ti–6Al–4V alloy have changed with the undercooling. The grain refinement is occurred with the increase of undercooling. Therefore, the elastic modulus and elastic limit of the ternary alloy are enhanced.

As one of the most important thermal properties, the thermal diffusivity of Ti–6Al–4V alloy in solid state was measured by Linseis LFA 1000 laser flash diffusivity apparatus. As shown in Fig. 5a, the measured result increased linearly with the temperature in the temperature range of 199–1080 K and can be described as follows:

In the experimental temperature range, there is no significant change for the measured thermal diffusivity results of this alloy.

The specific heat and density of solid ternary Ti–6Al–4V alloy have been determined by Boivineau [21] and Iida [24], respectively. Consequently, the thermal conductivity of ternary Ti–6Al–4V alloy in solid state can be obtained from these thermal properties as the following relationship

Figure 5b presents the thermal conductivity values for solid Ti–6Al–4V alloy found in the literature [21, 24]. Evidently, the computed value by this work is very close to those literature data.

4 Conclusions

The substantial undercooling and thermophysical properties of liquid ternary Ti–6Al–4V alloy were investigated by electromagnetic levitation. The surface tension data obtained for liquid Ti–6Al–4V alloy obey a linear relationship over the temperature range investigated, and the experimental value was equal to 1.38 Nm−1 at the liquidus temperature (1933 K). The specific heat of the liquid alloy was determined to be 33.33 J mol−1 K−1 over the 1713–2161 K temperature range. The solidification microstructures at different undercoolings were composed of α and β phases and displayed the basket-weave morphology. In addition, the power function relationship between dendritic growth velocity of β phase and undercooling was found, and its growth velocity attained 22.21 ms−1 at the maximum undercooling of 252 K (0.13 T L). Meanwhile, by using the laser flash method, the temperature dependence of thermal diffusivity for solid ternary Ti–6Al–4V alloy can be described by a linear function.

References

S. Akamatsu, S. Bottin-Rousseau, G. Faivre, E.A. Brener, Phys. Rev. Lett. 112, 105502 (2014)

S.B. Luo, W.L. Wang, J. Chang, Z.C. Xia, B. Wei, Acta Mater. 69, 355 (2014)

D.G. Quirinale, G.E. Rustan, A. Kreyssig, A.I. Goldman, Appl. Phys. Lett. 106, 241906 (2015)

K. Zhou, H.P. Wang, J. Chang, B. Wei, Philos. Mag. Lett. 90, 455 (2010)

T. Wang, T.E., Cullinan, and R.E. Napolitano. Acta Mater. 62, 188 (2014)

K. Zhou, H.P. Wang, B. Wei, Chem. Phys. Lett. 521, 52 (2012)

I. Egry, J. Brillo, D. Holland-Moritz, Y. Plevachuk, Mater. Sci. Eng. A 495, 14 (2008)

R. Novakovic, D. Giuranno, E. Ricci, A. Tuissi, R. Wunderlich, H. Fecht, I. Egry, Appl. Surf. Sci. 258(7), 3269 (2012)

R. Nowak, T. Lanata, N. Sobczak, E. Ricci, D. Giuranno, R. Novakovic, D. Holland-Moritz, I. Egry, J. Mater. Sci. 45, 1993 (2010)

I. Egry, D. Holland-Moritz, R. Novakovic, E. Ricci, R. Wunderlich, N. Sobczak, Int. J. Thermophys. 31, 949 (2010)

C.R. Clopet, R.F. Cochrane, A.M. Mullis, Appl. Phys. Lett. 102, 031906 (2013)

K. Zhou, H.P. Wang, B. Wei, Philos. Mag. Lett. 93, 138 (2013)

S. Ozawa, S. Suzuki, T. Hibiya, H. Fukuyama, J. Appl. Phys. 109, 014902 (2011)

W.K. Rhim, K. Ohsaka, J. Cryst. Growth 208, 313 (2010)

K. Zhou, H.P. Wang, J. Chang, B. Wei, Appl. Phys. A 105, 211 (2011)

S.M. Chathoth, B. Damaschke, K. Samwer, S. Schneider, Appl. Phys. Lett. 93, 071902 (2008)

P. -F. Paradis, T. Ishikawa, S. Yoda, J. Appl. Phys. 97, 053506 (2005)

B. Hay, J.R. Filtz, J. Hameury, L. Rongione, Int. J. Thermophys. 26, 6 (2005)

P. Vlcak, F. Cerny, J. Drahokoupil, J. Sepitka, Z. Tolde, J. Alloys Compd. 620, 48 (2015)

A.H. Liu, B.S. Li, D.G. Yan, J.J. Guo, Mater. Lett. 73, 40 (2012)

M. Boivineau, C. Cagran, D. Doytier, V. Eyraud, M.-H. Nadal, B. Wilthan, G. Pottlacher, Int. J. Thermophys. 27, 2 (2006)

B. Vinet, J.-P. Garandet, B. Marie, L. Domergue, B. Drevet, Int. J. Thermophys. 25, 3 (2004)

S. Schneider, I. Egry, I. Seyhan, Int. J. Thermophys. 23, 5 (2002)

T. Iida, R.I.L. Guthrie, The Physical Properties of Liquid Metals (Clarendon, Oxford, 1993)

K. Zhou, H.P. Wang, J. Chang, B. Wei, Appl. Phys. A 103, 135 (2011)

Acknowledgments

This work was supported financially by National Natural Science Foundation of China (Grant Nos. 51327901 and 51506182) and Fundamental Research Funds for the Central Universities (Grant No. 3102014JCQ01092). The authors are grateful to Dr. D. L. Geng, Dr. W. Zhai, Mr. P. Lü and Mr. X. Cai for their help with the experiments and discussion.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, K., Wei, B. Determination of the thermophysical properties of liquid and solid Ti–6Al–4V alloy. Appl. Phys. A 122, 248 (2016). https://doi.org/10.1007/s00339-016-9783-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-9783-6