Abstract

Spinel ferrite having composition Ni0.5Mg0.3Cu0.2Fe2O4 was prepared by the sol–gel technique at 1473 K. The X-ray diffraction results indicate that the ferrite sample has a cubic spinel-type structure with \(Fd\bar{3}m\) space group. The electrical properties of the studied sample using complex impedance spectroscopy technique have been investigated in the frequency range 102–107 Hz and in the temperature range 300–500 K. The total conductivity curves for sample are found to obey Jonscher power law (σ(ω) = σ dc + Aω n) with an increase in the frequency exponent (n) as temperature increases. The activation energy deduced from the analysis of the conductivity curves matches very well with the value estimated from the relaxation time, indicating that relaxation process and electrical conductivity are attributed to the same defect. Nyquist plots of impedance show semicircle arcs for sample, and an electrical equivalent circuit has been proposed to explain the impedance results. The effect of frequency and temperature on dielectric constant (ε″) and dielectric loss (tanδ) has also been discussed in terms of hopping of charge carriers between Fe2+ and Fe3+ ions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Spinel ferrite materials with general formula of MFe2O4 where M is a divalent cation (Mn2+, Fe2+, Co2+, Ni2+, Cu2+, Zn2+, etc.) have become an important class of magnetic materials due to their rich electrical and magnetic properties which depend on several factors such as method of preparation, the difference in ionic radii, microstructure changes, and chemical compositions [1, 2]. Ferrite materials have attracted the attention of the scientific community for past few decades not only for the variety of their physical properties, but also for their potential applications such as microwave devices, computer memories, transformers, magnetic recordings and storage, multilayered chip inductors, magnetocaloric refrigeration, and other devices [1, 3–6].

A way to study the electrical properties of ferrites can be achieved by the complex impedance spectroscopy (CIS) technique. This technique offers several advantages such as the determination of relaxation frequency and separation of grain, grain boundary, and grain–electrode effects. The complex impedance spectroscopic studies involve measurement of real and imaginary parts of impedance for a wide range of temperature and frequency. In recent years, this technique has become a well-accepted fundamental tool for characterizing ionic conductors in terms of ionic conductivity, electrode polarization, and activation energy for ion migration. Along this line, several studies have been reported in the literature in order to understand the electrical and dielectric properties of ferrite materials [1, 2, 7–12].

Among spinel ferrites, Ni–Mg ferrites are among the most widely used soft magnetic materials because of their use in high-frequency applications as they possess high electrical resistivity and low losses [13]. The various compositions of Ni1−x Mg x Fe2O4 system have been widely investigated and reported in the literature [14–18]. Therefore, several substitutions were made on Ni–Mg ferrite system in order to improve its practical applications. For example, Hashim et al. [19] have studied the structural, electrical, and magnetic properties of Cr-doped Ni–Mg ferrite nanoparticle. For their part, Hossain et al. [20] have investigated the magnetic properties of Mn2+-substituted nanocrystalline Ni0.5−x Mn x Mg0.5Fe2O4 ferrites synthesized by a combustion technique. On the other hand, EI Hiti studied the effect of Zn substituted on the dielectric behavior and ac electrical conductivity of Ni–Mg ferrites [21]. However, the reports on electrical properties using CIS technique of Ni–Mg–Cu ferrite system with the specific composition Ni0.5Mg0.3Cu0.2Fe2O4 are not available in the literature. In this work, we choose to prepare this sample by sol–gel technique. Firstly, we presented the detailed synthesis process of our sample and then we studied its structural properties. We have also carried out complex impedance formalism and relaxation process of this sample in 300–500 K temperature range with varying frequency between 102 and 107 Hz.

2 Experimental

2.1 Synthesis process

Ni0.5Mg0.3Cu0.2Fe2O4 sample was prepared via the sol–gel method using stoichiometric amounts of Ni(NO3)2·6H2O, Mg(NO3)2·6H2O, Cu(NO3)2·3H2O, and Fe(NO3)3·9H2O precursors. Stoichiometric amounts of metal nitrates were first dissolved in distilled water to obtain a mixed solution. Subsequently, when these nitrates were completely dissolved in the solution, controlled amounts of citric acid were incorporated and dissolved with stirring. The molar ratio was fixed as 1:1 of nitrates to citric acid. A small amount of ammonia was added to the solution to adjust the pH value at about seven. The solution was heated on hot plate under regular stirring to 373 K followed by the addition of ethylene glycol which was used as a polymerization agent. Heating and stirring continued until obtaining a gel after about 4 h. The gel obtained was dried at 573 K to obtain a foamy dry which was ground in a mortar, followed by drying at 773 K for 12 h in air. A powder was then obtained after a subsequent heat treatment. The powder obtained was pressed into pellets with diameter of 10 mm and thickness of about 2 mm and then sintered at 973 K for 24 h. After grinding, the pellets were pressed again and then heated at 1173 K for 24 h. In order to obtain the desired crystalline phase, the obtained pellets undergo a third cycle of grinding and repelleting and finally sintered at 1473 K during a sufficiently long annealing period (48 h). Then, all the results found in the present investigation are presented for Ni0.5Mg0.3Cu0.2Fe2O4 ferrite nanoparticle sintered at 1473 K. The detailed synthesis process of our sample is represented in Fig. 1.

2.2 Characterization

Powder X-ray diffraction (XRD) data were collected in the 2θ range 15°–80° with a step size of 0.0167° and a counting time of 18 s per step using a “PANalytical X’Pert Pro” diffractometer with filtered (Ni filter) Cu radiation. Standard Si powder was used to obtain the instrumental resolution function. Morphology of the sample was analyzed using scanning electron microscopy (SEM; Philips XL30 microscope) under an accelerating voltage of 20 kV. For electrical measurements, pure silver is deposited on the surface of pellet to ensure ohmic contact. The frequency- and temperature-dependent electrical measurements were taken using a N4L-NumetriQ (model PSM1735) connected to a computer.

3 Results and discussion

3.1 Microstructural analysis

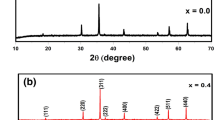

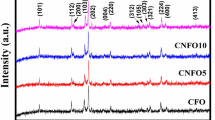

Figure 2 presents the X-ray diffraction patterns for Ni0.5Mg0.3Cu0.2Fe2O4 ferrite nanoparticle sintered at 1473 K. There are almost no diffraction peaks corresponding to impurity phases, suggesting that pure phase was obtained. Using “X’Pert HighScore Plus” software, the diffraction peaks are indexed with respect to the cubic spinel-type structure with the space group \(Fd\bar{3}m\). The presence of diffraction planes (111), (220), (311), (222), (400), (422), (511), (440), (620), (533), (622), and (444) in the diffraction pattern confirms the formation of a cubic spinel ferrite structure. The lattice constant was calculated from the XRD data using the following equation [22, 23]:

here λ is the wavelength, a is the lattice constant, and (h k l) are the corresponding Miller indices. The obtained lattice constant is a = 8.4185 Å that gives a cell volume of V = 596.63 Å3. The X-ray density for our sample was calculated according to the following equation [22]:

where 8 represents the number of molecules in a unit cell of spinel lattice, M is the molecular weight of the sample, a is the lattice constant of the ferrite, and N is the Avogadro’s number. The X-ray density of the sample is equal to 5.01 g/cm3. The obtained values of lattice constant (a) and X-ray density (ρ x ) for Ni0.5Mg0.3Cu0.2Fe2O4 ferrite sample are higher than those obtained for the parent Ni0.5Mg0.5Fe2O4 ferrite nanoparticle in Refs. [14, 15]. On the one hand, the increase in lattice constant may be attributed to the higher ionic radius of Cu2+ (0.73 Å) compared with that of Mg2+ (0.72 Å) [24]. On the other hand, the high-density value of X-ray density can be due to the higher density of copper (8.96 g/cm3) compared with that of magnesium (1.74 g/cm3). The inset of Fig. 2 shows the SEM micrograph for Ni0.5Mg0.3Cu0.2Fe2O4 ferrite nanoparticle. The image shows unique chemical contrast corresponding to the ferrite phase, uniform grain size distribution with negligible porosity, and average particle size of about 0.56 µm.

3.2 Electrical conductivity study

Frequency variation of the conductivity at different temperatures of Ni0.5Mg0.3Cu0.2Fe2O4 ferrite nanoparticle sintered at 1473 K is shown in Fig. 3. From this figure, it can be seen that the conductivity has two types of behaviors at two regions that is valid for all temperatures. The flat region with only electronic contribution at low frequencies represents the dc conductivity. Frequency-independent conductivity can be attributed to the long-range transport of charge carriers as a response to the applied external electric field. This is totally related to the insufficient magnitude of applied field at low frequencies to initiate hopping conductivity. Second region of conductivity which increases with frequency represents ac conductivity. As temperature rises, probability of electron hopping between Fe2+ and Fe3+ increases, resulting in an advancement of conductivity [25]. Therefore, ac conductivity increases with temperature as shown in the figure. Characteristic transition frequency between these two sites is around 105 Hz at 300 K and reaches to 106 Hz at 500 K. As seen from the figure, this frequency parameter shifts to higher values as temperature rises up. This behavior is due to the increment in the temperature of the sample by heat and a higher energy need of the mechanism which causes ac conductivity corresponding to higher frequencies. In such a case, total conductivity is expressed as the sum of conductivities in these two sites. Therefore, the frequency-dependent conductivity for the sample was analyzed using universal Jonscher’s power law [26]:

where the values of the dc conductivity (σ dc) are at 100 Hz of the sample.

In the low-frequency region, the curves indicate that our sample exhibits a semiconductor behavior in all temperature range. The experimental curve of dc conductivity is well fitted by the Arrhenius relation [1]:

where σ 0 is a pre-exponential factor, E a is the activation energy for the hopping mechanism, T is the absolute temperature, and k B is the Boltzmann constant. The plot of Ln(σ dc ) versus (1000/T) shown in Fig. 4 for Ni0.5Mg0.3Cu0.2Fe2O4 ferrite nanoparticle is linear in all the 300–500 K temperature range, confirming that conduction process is thermally activated. The E a value estimated from the slope of the linear fit plot is equal to 0.369 eV. This value is smaller than those of some spinel ferrite systems prepared by different methods for nanoparticles [1, 27–30], which suggest that the conduction mechanism in the sample of the present investigation may be due to hopping of electrons between Fe2+ and Fe3+ rather than polarons. On the other hand, the value of activation energy obtained for Ni0.5Mg0.3Cu0.2Fe2O4 ferrite sample is lower than those obtained for the Ni0.5Mg0.5Fe2O4 ferrite nanoparticle in Refs. [14, 17]. Then, we can conclude that the substitution of 20% of Cu in Ni0.5Mg0.5Fe2O4 ferrite system can improve its conductivity.

For high-frequency region, the ac conductivity (σ ac) can be described by the following power law:

where A is coefficient-dependent on temperature and n is the frequency exponent which depends on both frequency and temperature. According to Funke [31], the value of n has a physical meaning. n ≤ 1 means that the electron hopping involves a translational motion with a sudden hopping, whereas n > 1 means that the motion involves localized hopping between neighboring sites. The exponent n is frequency-independent, but it depends on both temperature and material kind.

The experimental data of total conductivity shown in Fig. 3 for Ni0.5Mg0.3Cu0.2Fe2O4 ferrite nanoparticle were well fitted using Eq. (3). Figure 5 depicts a typical example of this fitting at T = 300 K. In the fitting procedure, the (A) and (n) factors have been varied simultaneously to get the best fit. It can be seen that the fit matches well with the experimental values (red solid lines in Fig. 5). The goodness of the fit is usually evaluated by comparing the squared coefficient of linear correlation coefficient (R 2) obtained for each temperature (see Table 1). It is clear from Table 1 (see also the inset of Fig. 5) that n increases with increasing temperature. The change in n with temperature corresponds to a thermally activated process. The temperature dependence of n gives information to specify the suitable mechanism involved for ac conductivity. In our case, the n exponent is superior than 1 for all temperatures, indicating that the electron hopping between Fe2+ and Fe3+ occurs between neighboring sites.

Variation of the total conductivity versus frequency at T = 300 K for Ni0.5Mg0.3Cu0.2Fe2O4 ferrite nanoparticle sintered at 1473 K. Red solid lines represent the fitting to the experimental data using the universal Jonscher power law. The inset shows the variation of exponent n with respect to all temperatures

3.3 Complex impedance analysis

Figure 6 and its inset show the variation of the real part of impedance (Z′) with frequency at various temperatures for Ni0.5Mg0.3Cu0.2Fe2O4 ferrite nanoparticle sintered at 1473 K. Figure 6 shows that the magnitude of Z′ is typically higher in the low-frequency region and then it decreases gradually with increasing frequency. The value of Z′ appears to merge in the high-frequency region irrespective of temperature. This result may possibly be related to the release of space charge as a result of reduction in the barrier properties of material with rise in temperature, and may be a responsible factor for the enhancement of conductivity of the material with temperature at high frequencies. The merging of the value of Z′ for all temperatures at higher frequencies can be interpreted by the presence of space charge polarization. This interpretation was confirmed by the higher impedance values at lower frequencies. The behavior of Z′ observed for our sample at lower and higher frequencies is in good agreement with the reported results in the literature for several ferrite systems [8, 32, 33].

The variation of Z″ with frequency at different temperatures is depicted in Fig. 7. The spectra of Z″ are characterized by the appearance of peaks which shift to higher frequencies with increasing temperature. Such behavior indicates the existence of relaxation phenomenon in our material. The position of these peaks allows the determination of the relaxation frequency value (f max) and the relaxation time (τ) using the following relation:

Figure 8 shows the plot of Ln(τ) versus 1000/T. We observed that the value of τ decreases with the rise in temperature, which suggests the thermally activated process. The temperature-dependent characteristics of τ follow the Arrhenius relation as mentioned below [1]:

where E a is the activation energy. The E a value estimated from the slope of the linear fit plot (see Fig. 8) is equal to 0.351 eV. This value is in good agreement with those previously derived from the analysis of the dc conductivity. The small difference (0.018 eV) in the activation energy for the conduction and relaxation may be due to the fact that the relaxation process involves only the hopping energy of the carriers between the localized states, but the conduction mechanism involves hopping energy as well as disorder and binding energy of polarons [34]. From this, we can conclude that the same type of charge carrier is responsible for the conduction and relaxation process. This is in good agreement with the results found in Ref. [1].

If we plot the Z″(f, T) data in the scaled coordinates, i.e., Z″(f, T)/Z″ max and log(f/f max), where f max corresponds to the frequency of the peak value of Z″ in the Z″ versus log(f) plots, the entire data of imaginary part of impedance can collapse into one master curve as shown in Fig. 9. Thus, the scaling behavior of Z″ clearly indicates that the relaxation mechanism is nearly temperature-independent [1, 35, 36].

The complex-plane impendence plots (called Nyquist plots, i.e., Z″ vs. Z′ plot) for different temperatures for Ni0.5Mg0.3Cu0.2Fe2O4 ferrite nanoparticle sintered at 1473 K are illustrated in Fig. 10. One of the important factors, which influence the impedance properties of ferrites, is the microstructural effect [19]. The impedance measurement gives us information about the resistive (real part) and reactive (imaginary part) components of a material. A ferrite material is assumed to be consisting of piled-up crystalline plates. From the microstructural point of view, a sample is assumed as a microstructure made up of parallel conducting plates (grains) separated by resistive plates (grain boundaries). For all temperatures, as evident in Fig. 10, the impedance spectra show semicircle arcs (whose maxima and diameters decrease with increasing temperature) that are due to the conduction of the grain boundary, suggesting that a predominant conduction is through the grain boundary volume. Furthermore, contribution from the grain is not well resolved for all temperatures. It is therefore concluded that the conductivity for our sample is mainly due to the grain boundary contribution [19, 37]. To confirm this, it is necessary to modelize the sample. The appropriate equivalent circuit configuration for the impedance plane plots is of the type of (R g + R gb //C gb ) [38, 39], as shown in the inset of Fig. 10. R g and R gb modelize the grain and grain boundary resistances, respectively, and the capacitance (C gb ) modelizes the grain boundary capacitance. The intersection with real axis of the semicircle at low frequencies (right intersect) is ascribed to the total resistance (R T = R g + R gb ). On the other hand, the impedance response of grain dominates at high frequencies, so R g can be deduced from the left intersect of the semicircle with real axis. The grain boundary resistance values are then given as R gb = R T − R g . From the impedance spectra represented in Fig. 10, it is clear that the grain resistance R g is too weak and the grain boundary is approximately equal to R T . The expression of real (Z′) and imaginary (Z″) components of impedance related to the equivalent circuit is [40]:

The impedance data for all temperatures are fitted using Zview software [41]. It can be seen that the fit matches well with the experimental values (red solid lines in Fig. 10). The values of all fitted parameters are presented in Table 2. It can be seen from this table that the grain boundary resistance decreases with the increase in temperature, indicating a semiconducting behavior of our sample. The decrease in grain boundary resistance is due to the fact that the grain boundary effect has assisted in lowering the barrier to the motion of charge carriers paving the way for increased electrical transport with rise in temperature. Furthermore, it has been found that the values of R gb are larger than R g which indicates that the conductivity for our sample is mainly due to the grain boundary contribution as mentioned above.

Main panel: Nyquist plots (Z″ vs. Z′) in the temperature range 300–400 K for Ni0.5Mg0.3Cu0.2Fe2O4 ferrite nanoparticle sintered at 1473 K. The inset shows the Nyquist plots in the temperature range 420–500 K. Red solid lines represent the fitting to the experimental data according to the appropriate equivalent circuit (see the inset)

3.4 Dielectric properties

Figure 11a shows the frequency dependence of the imaginary part of dielectric constant (ε″) at different temperatures for Ni0.5Mg0.3Cu0.2Fe2O4 ferrite nanoparticle sintered at 1473 K. The values of ε″ were calculated from the conductivity data using the following relation:

where ω = 2πf is the angular frequency and ε 0 = 8.854 × 10−12 F/m is the permittivity of free space. It is observed from Fig. 11a that ε″ values decrease with increase in frequency. This type of dielectric behavior in the ferrite has been explained by the Maxwell–Wagner and Koop’s phenomenological theory [42]. Accordingly, the dielectric structure of ferrites is made up of well-conducting layer of grains followed by poorly conducting layer of grain boundaries, and the high value of dielectric constant arises from the space charge polarization produced at the grain boundary. The polarization mechanism involves the exchange of electrons between the ions of the same element, which are present in more than one valence states and are distributed randomly over crystallographic equivalent sites. Here the exchange of electrons mainly takes place between Fe3+ and Fe2+ ions present at octahedral sites (B-site). During this exchange mechanism, the electrons have to pass through the grains and grain boundary of the dielectric medium. Owing to high resistance of the grain boundary, the electrons accumulate at the grain boundary and produce space charge polarization. Figure 11a also shows that the dielectric constant (ε″) decreases rapidly in the low-frequency region and becomes frequency-independent in the high-frequency region. It is well known that the grain boundaries are more effective in low-frequency region and the grains are effective in the high-frequency region [42]. Therefore, due to the grain boundary effect, the dielectric constant decreases rapidly in the low-frequency region. In the high-frequency region, the grains come into action and also the hopping of electrons cannot follow the high-frequency ac field; therefore, the dielectric constant decreases and becomes frequency-independent. It is also observed from Fig. 11a that ε″ increases with increase in temperature because the hopping of charge carriers at the octahedral site is thermally activated.

The dielectric loss factor (tanδ) was calculated using the following relation:

This factor is a measure of dielectric loss within the ferrite, and it arises when the polarization lags behind the applied ac field. The variation of tanδ with frequency at different temperatures for Ni0.5Mg0.3Cu0.2Fe2O4 ferrite nanoparticle is shown in Fig. 11b. The dielectric loss tanδ decreases rapidly in the low-frequency region, and in the high-frequency region, it becomes almost frequency-independent. Such a behavior can be explained on the basis that in the low-frequency region, which corresponds to low conductivity of grain boundary, more energy is required for electron exchange between Fe2+ and Fe3+ ions; as a result, the loss is higher. In the high-frequency region, which corresponds to high conductivity of grain, a small energy is required for electron transfer between the Fe2+/Fe3+ ions at the octahedral site. Further, the loss increases with increasing temperature due to the increased conduction of thermally activated electrons (Fig. 11b).

4 Conclusion

Ni0.5Mg0.3Cu0.2Fe2O4 ferrite nanoparticle has been prepared by sol–gel technique. The XRD patterns reveal the spinel structure of the sintered ferrite. Conductivity is constant in the low-frequency region and shows dispersion in the high-frequency region. The linear variation of conductivity with temperature confirms the semiconducting nature of the studied sample. The curves of imaginary part of impedance (Z″) show the presence of electrical relaxation phenomenon in our sample with an activation energy close to that determined from dc conductance curve. The Nyquist representations (Z″ vs. Z′) revealed the appearance of semicircle arcs, well modelled in terms of electrical equivalent circuit of the type of (R g + R gb //C gb ). Dielectric constant (ε″) and dielectric loss (tanδ) decrease with the frequency of external electric field and increase with the increase in temperature. This has been explained in terms of hopping of charge carriers between Fe2+ and Fe3+ ions.

References

S.K. Mandal, S. Singh, P. Dey, J.N. Roy, P.R. Mandal, T.K. Nath, J. Alloys Compd. 656, 887–896 (2016)

M. Abdullah Dar, K. Majid, K.M. Batoo, R. Kotnala, J. Alloys Compd. 632, 307–320 (2015)

V. Jagdeesha Angadi, L. Choudhury, K. Sadhana, H.-S. Liu, R. Sandhya, S. Matteppanavar, B. Rudraswamy, V. Pattar, R.V. Anavekar, K. Praveen, J. Magn. Magn. Mater. 424, 1–11 (2017)

Z. Liu, Z. Peng, C. Lv, F. Xiuli, Ceram. Int. 43, 1449–1454 (2017)

R.K. Panda, R. Muduli, G. Jayarao, D. Sanyal, D. Behera, J. Alloys Compd. 669, 19–28 (2016)

E. Oumezzine, S. Hcini, M. Baazaoui, E.K. Hlil, M. Oumezzine, Powder Technol. 278, 189–195 (2015)

N. Sivakumar, A. Narayanasamy, K. Shinoda, C.N. Chinnasamy, B. Jeyadevan, J.M. Greneche, J. Appl. Phys. 102, 013916–013923 (2007)

M. Azizar, A.K.M. Rahman, A. Hossain, Phys. Scr. 89, 025803–025810 (2014)

B. Ünal, A. Baykal, J. Supercond. Nov. Magn. 27, 469–479 (2014)

Y. Köseoğlu, Ceram. Int. 39, 4221–4230 (2013)

Y. Köseoğlu, M. Bay, M. Tan, A. Baykal, H. Sözeri, R. Topkaya, N. Akdoğan, J. Nanopart. Res. 13, 2235–2244 (2011)

E. Şentürk, Y. Köseoğlu, T. Şaşmaz, F. Alan, M. Tan, J. Alloys Compd. 578, 90–95 (2013)

M. Hashim, Alimuddin, S. Kumar, S.E. Shirsath, R.K. Kotnala, H. Chung, R. Kumar, Powder Technol. 229, 37–44 (2012)

M. Naeem, N.A. Shahb, I.H. Gul, A. Maqsood, J. Alloys Compd. 487, 739–743 (2009)

H. Moradmard, S. Farjami Shayesteh, P. Tohidi, Z. Abbas, M. Khaleghi, J. Alloys Compd. 650, 116–122 (2015)

L. John Berchmans, R. Kalai Selvan, P.N. Selva Kumar, C.O. Augustin, J. Magn. Magn. Mater. 279, 103–110 (2004)

M.A. Gabal, Y.M. Al Angari, H.M. Zaki, J. Magn. Magn. Mater. 363, 6–12 (2014)

M.A. El Hiti, J. Phys. D Appl. Phys. 29, 501–505 (1996)

M. Hashim, S.S. Meena, R.K. Kotnala, S.E. Shirsath, A.S. Roy, A. Parveen, P. Bhatt, S. Kumar, R.B. Jotania, R. Kumar, Alimuddin, J. Alloys Compd. 602, 150–156 (2014)

A.K.M.A. Hossain, M.R. Amin, H. Tanaka, J. Magn. Magn. Mater. 334, 124 (2013)

M.A. El Hiti, J. Magn. Magn. Mater. 164, I87–196 (1996)

M.S. Anwar, F. Ahmed, B.H. Koo, Acta Mater. 71, 100–107 (2014)

Y. Köseoğlu, F. Alan, M. Tan, R. Yilgin, M. Öztürk, Ceram. Int. 38, 3625–3634 (2012)

R.D. Shannon, Acta Crystallogr. A 32, 751–767 (1976)

J.S. Ghodake, R.C. Kambale, S.V. Salvi, S.R. Sawant, S.S. Suryavanshi, J. Alloys Comp. 486, 830–834 (2009)

A.K. Jonscher, Universal Relaxation Law (Chelsea Dielectics Press, London, 1996)

M.S.R. Prasad, K.V. Ramesh, B.R. Babu, K. Trinath, J. Phys. 90, 417–428 (2016)

A. Humaira, M. Asghari, J. Phys: Conf. Ser. 439, 012014–012020 (2013)

S. Bhukal, S. Mor, S. Bansal, J. Singh, S. Singhal, J. Mol. Struct. 2014, 95–102 (1071)

S. Bhukal, T. Namgyal, S. Mor, S. Bansal, S. Singhal, J. Mol. Struct. 2012, 162–167 (1012)

K. Funke, Prog. Solid State Chem. 22, 111–195 (1993)

Z. Ahmad, S. Atiq, S.K. Abbas, S.M. Ramay, S. Riaz, S. Naseem, Ceram. Int. 42, 18271–18282 (2016)

M.-R. Syue, F.-J. Wei, C.-S. Chou, F. Chao-Ming, Thin Solid Films 519, 8303–8306 (2011)

M. Idrees, M. Nadeem, M.M. Hassan, J. Phys. D Appl. Phys. 43, 155401–155409 (2010)

V. Mohanty, R. Cheruku, L. Vijayan, G. Govindaraj, J. Mater. Sci. Technol. 30(4), 335–341 (2014)

A. Sinha, A. Dutta, RSC Adv 5, 100330–100338 (2015)

K.M. Batoo, Phys. B 406, 382–387 (2011)

M. Nadeem, M.J. Akhtar, A.Y. Khan, R. Shaheen, M.N. Hoqu, Chem. Phys. Lett. 366, 433 (2002)

M. Nadeem, M.J. Akhtar, A.Y. Khan, Solid State Commun. 134, 431 (2005)

H. Rahmouni, M. Nouiri, R. Jemai, N. Kallel, F. Rzigua, A. Selmi, K. Khirouni, S. Alaya, J. Magn. Magn. Mater. 316, 23–28 (2007)

D. Johnson, ZView: a Software Program for IES Analysis, Version 2.8, Scribner Associates, Inc. Southern Pines, NC (2008)

C.G. Koops, Phys. Rev. 83, 121–124 (1951)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dhaou, M.H., Hcini, S., Mallah, A. et al. Structural and complex impedance spectroscopic studies of Ni0.5Mg0.3Cu0.2Fe2O4 ferrite nanoparticle. Appl. Phys. A 123, 8 (2017). https://doi.org/10.1007/s00339-016-0652-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-0652-0