Abstract

The wettability of solid surface is a very important property of materials, which depends on both surface chemical composition and the geometry of the solid surface. We herein report a simple and inexpensive method to fabricate superhydrophobic surfaces with the use of mullite whisks (MWs) for the first time. Binary micro-/nano-structural surfaces were created by the incorporation of hydrophilic needlelike MWs with poly(γ-methacryloxypropyltrimethoxysilane) to exhibit hydrophobic behavior, which further showed superhydrophobicity with water contact angle of 152.4±2∘ after modified with stearic acid. The wettability variation from hydrophilicity to hydrophobicity and superhydrophobicity during the assembly process are discussed based on the scanning electron microscopy, X-ray diffraction, thermogravimetric analysis, and contact-angle system. The superhydrophobicity of the surface could be attributed to the hierarchical microstructure of the rough surface induced by MWs and low surface energy of stearic acid.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Solid surfaces with special wettability have received considerable attention owing to their great merit in application. Specifically, superhydrophobic surfaces with water contact angle (WCA) higher than 150° and sliding angle (SA) lower than 10° have intrigued great interest over the last decade for their appealing applications in areas such as self-cleaning surface, oil/water separation, microfluidic devices, or stain-resistant textiles [1–4]. Recent studies show that superhydrophobicity can be achieved by the synergistic effect of the surface topography (i.e., surface roughness) and some surface chemistry (i.e., surface energy) [5, 6]. Correspondingly, two promising approaches have been proposed to fabricate superhydrophobic surfaces: creating hierarchical micro-/nano-structures on hydrophobic surfaces (WCA>90°) and chemical modification with materials of low surface energy. Up to now, a variety of elegant methods have been developed to increase the surface roughness, including lithography [7, 8], chemical vapor deposition [9], electrospinning [10], sol–gel processing [11], layer-by-layer method [12, 13], template method [14], electrochemical deposition [15], and so forth [16–19]. Polymers and long-alkyl-chain or fluorine-containing organic ligands have also been introduced to lower the free energy of the surfaces [20].

Recently, inorganic–organic assembly has presented bright prospect for the preparation of superhydrophobic surfaces with tailed structure, desired strength and promising steadiness [21]. In our previous works, we developed series of superhydrophobic surfaces with desirable performances via assembly of inorganic–organic nanocomposites, such as metal alkanethiolates [22], SiO2/polystyrene hybrids [11], nanosilica/polyurethane hybrids [2, 23], and dithiocarbamate-functionalized CdS nanocrystals [24]. Herein, we demonstrate the fabrication of superhydrophobic surface with the use of needlelike mullite whisks (MWs) for the first time. MW is an alumininosilicate material with wide industrial application owing to its good refractoriness, high creep resistance, low thermal expansion coefficient, and high chemical stability [25]. In this work, the incorporation of needlelike MWs with hydrophilic poly(γ-methacryloxypropyltrimethoxysilane) (PMPS) created binary micro-/nano-structural surfaces exhibiting hydrophobic behavior, which further showed superhydrophobicity after modified with commercial stearic acid (Fig. 1). This work contributes an available inexpensive way to the construction of superhydrophobic surfaces potentially usefully in various applications.

2 Experimental section

2.1 Materials

γ-methacryloxypropyltrimethoxysilane (MPS) (Nanjing Crompton Shuguang chemical Organosilicon Specialties Co.,Ltd) and stearic acid (Sinopharm Chemical Reagent Co., Ltd) were used as received. Mullite whisks (MWs) were prepared as described previously [26]. The initiator 2,2′-azobisisobutyronitrile (AIBN) (Fluka) was purified by recrystallization in hot ethanol (65 °C) twice. All other reagents were purchased from standard sources and used as received.

2.2 Synthesis of poly(γ-methacryloxypropyltrimethoxysilane) (PMPS)

PMPS was synthesized by free radical polymerization performed as follows. 125 g precursor solution containing 0.1 mol MPS and an amount of AIBN (0.5 wt% of MPS) was added into a three-neck flask (250 mL), which was equipped with a reflux condenser and a mechanical stirrer. Subsequently, nitrogen was introduced into this solution to expel oxygen for half an hour at room temperature prior to the polymerization of monomer. Finally, the solution saturated with nitrogen was placed in a controlled temperature water bath at 65 °C until thoroughly reacted was reached (about 5 h).

2.3 Preparation and surface modification of PMPS/MW hybrid surface

In a typical synthesis, a solution of 50 mL toluene, a solution of the above PMPS toluene mixed solution (7 g) and 0.8 g MWs (PMPS : MW= 3.5:2 wt/wt) were added into a four-neck flask (100 mL), which was equipped with a reflux condenser and a mechanical stirrer. After uniform dispersion, the reaction was started by immersing the whole reaction setting in an oil bath and then maintained at 120 °C for 8 h. Subsequently, the resulting product was distilled under reduced pressure to remove excessive toluene, directly spin-coated on a clean glass substrate, and then dried at 80 °C under reduced pressure conditions. The thickness of the dried PMPS/MW composite film was calculated to be ca. 0.5 mm. Finally, the as-prepared composite surface was immersed in a chloroform solution with stearic acid (10 wt%) at 50 °C for 30 s under sonication and then dried at room environment.

The PMPS/MW hybrids were also separated from the solution by centrifugation, washed with toluene for three times, and then dried under vacuum for further characterization.

3 Characterization

The morphology of the resulting film was determined by scanning electron microscopy (SEM) with a QUANTA 200 (Philips-FEI, Holland) instrument at 30.0 kV. The X-ray diffraction (XRD) patterns were conducted on Bruker-AXS D8 ADVANCE X-ray diffractometer with Cu Kα radiation (λ=0.1542 nm) at a scanning rate of 6° min−1 over 2θ range of 10° to 80°. Contact angles (CAs) of a 5 μL water droplet on the surface were measured with a KRÜSS DSA100 (KRÜSS, Germany) contact-angle system at ambient temperature. The mean value was calculated from at least three individual measurements. The weight-loss of PMPS and PMPS/MW composite on heating were studied by thermogravimetric analysis (TGA) using a thermogravimetric apparatus Shimadzu-TGA 50 under a nitrogen atmosphere. Measurements were taken with a heating rate of 10 °C/min from 38 to 700 °C.

4 Results and discussion

The fabrication procedure of the superhydrophobic surfaces is shown in Fig. 1. First, the free radical polymerization of MPS in the presence of AIBN at 65 °C afforded PMPS (Fig. 1a). Subsequently, PMPS was grafted to the surface of MWs by dealcoholization to yield PMPS/MW hybrids (Fig. 1b). TGA curves confirm the formation of PMPS/MW hybrids and the improvement in thermal stability after the introduction of MWs into PMPS matrix (Fig. 2). The solution of these hybrids was then spin-coated on a clean glass substrate, followed by the evaporation of the solvents to form a rough surface with thickness of about 0.5 mm. Finally, the hybrid surface was modified with stearic acid through dip coating process to exhibit superhydrophobicity with WCA of about 152° (Fig. 1c).

SEM and XRD measurements were performed to investigate the structure of MWs, as shown in Fig. 3. The SEM micrograph of MWs shows one-dimensional needlelike structures with diameters ranging from several tens of nanometers to microscale (Fig. 3a). The XRD pattern indicates that MWs are crystallized in the orthorhombic system (Fig. 3b), in good agreement with those fabrications in the previous works [26, 27].

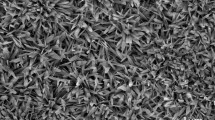

Figure 4 presents SEM images of the surfaces of PMPS and PMPS/MW hybrids, respectively. As shown in Fig. 4a, the pure PMPS surface prepared by spin-coating method is relatively smooth and hydrophilic with a WCA of 67°, whereas the surface of PMPS/MW hybrids displays hierarchical cluster microstructures (Fig. 4b). Via scrutiny of the microstructures, we find that the clusters are composed of numbers of rods with diameters ranging from several tens of nanometers to microscale (Fig. 4c). The formation of rod-like micro-/nano-structures should be related to the needlelike crystalline structure of MWs. Interestingly, the hybrid surface with hierarchical structure shows distinct hydrophobic properties, showing a WCA of 130°. Considering the hydrophilic nature of PMPS surface and inorganic salts MWs, the hydrophobicity of the hybrid surface should be derived from the cooperation of hierarchical micro- and nano-structures. The combination of the micro- and nano-structures increase the roughness of the surface, and air can be trapped into the interspaces of the rough surface, which can enhance the WCA according to the Cassie’s theory [28].

Obviously, the hydrophobicity of the PMPS/MW hybrid surface is superior to that of the pure PMPS surface, but it is still not qualified to be classified as superhydrophobic. Since PMPS is a relatively high-surface-energy material and MW is a hydrophilic material, the hydrophobicity of the hybrid surface should be further enhanced upon the surface modification of a hydrophobic material with low surface free energy. Stearic acid is a low-surface-energy material, and the water CA on the smooth surface of stearic acid can reach ∼100° (Fig. S1). We employed the chloroform solution of stearic acid to modify the as-prepared PMPS/MW hybrid surface at 50 °C for 30 s under sonication. The SEM images of the PMPS/MW hybrid surface modified with stearic acid are provided in Fig. 5a–c, which present the flowerlike microstructures. Compared to the unmodified hybrid surface, the diameters of flowerlike clusters after modified by stearic acid are almost doubled, which are in the range of 20–30 μm (Fig. 5a, b). Moreover, the shape of clusters demonstrates closely spherical morphology and relatively ordered structure. It is reasonable that the dried stearic acid can be adsorbed on the as-prepared hybrid clusters and deplete the nomadic MWs to form larger ones. In the high-magnification SEM image (Fig. 5c), petallike submicrostructures were observed. With hierarchical microstructures, the PMPS/MW hybrid surface modified with stearic acid shows an increase in the water repellency, with WCA of 152.4±2∘ and SA of 3° (Fig. 5d).

The structure and hence the wettability of the surface are also affected by the component ratio. When the proportion of PMPS to MW was adjusted from 3.5:2 to 3.5:1 (wt/wt), the roughness of the PMPS/MW hybrid surface decreased. As shown in Figs. 6a and 6b, the nanostructure is depleted by excessive PMPS, and the surface displays relative uniformity with lower WCA of 124°. After modified by stearic acid, the surface also shows relatively uniform microstructure, and the water CA on the surface is only about 135°. The results further confirm that the hierarchical binary structures are necessary to achieve superhydrophobicity for the PMPS/MW hybrid surface.

To further understand the superhydrophobicity of stearic acid-modified PMPS/MW hybrid surfaces, the trapped-air phenomenon between water and the rough surface was studied theoretically. The relationship between the CA of a smooth PMPS θ surface and that of a stearic acid-modified PMPS/MW rough surface θ r can be described by the Cassie–Baxter equation [28]

where f 1 and f 2 are the fractions of contact angle of water droplets with solid-versus-air pockets, respectively (f 1+f 2=1). We learn from the equation that the fraction of the air (f 2) increases with increase in θ r , and then the surface is more hydrophobic. Based on θ r =152° for stearic acid-modified PMPS/MW hybrid film prepared from PMPS : MWs=3.5:2 and θ r =135° for the other film from PMPS : MWs=3.5:1, the values of f 2 were calculated to be 0.92 and 0.79, respectively. This result indicates that the fraction of the air trapped in the rough surface plays a significant role in the superhydrophobic property, which minimizes the contact area between the rough surface and the water droplets.

5 Conclusions

In summary, a facile inexpensive approach for preparing superhydrophobic surfaces has been demonstrated by combining the use of needlelike crystalline MWs and low-surface-energy stearic acid. The arrangement of needlelike nanostructure of MWs into hierarchical micro-/nano-structure may greatly increase the water repellency, and superhydrophobic surfaces can be achieved by the synergistic effect of binary micro-/nano-structures and surface modification with stearic acid of low surface-free energy. We think that this work demonstrates a feasible way for building superhydrophobic surface, involving the cooperation of anisotropic crystalline inorganic materials and low-surface-energy organic/polymeric ligands.

References

X.F. Gao, L. Jiang, Nature 432, 36 (2003)

L.F. Wang, S.Y. Yang, J. Wang, C.F. Wang, L. Chen, Mater. Lett. 65, 869 (2011)

J. Ou, J.P. Rothstein, Phys. Fluids 17, 103606 (2005)

H. Zhou, H.X. Wang, T. Lin, Adv. Mater. 24, 2409 (2012)

T. Sun, L. Feng, X.F. Gao, L. Jiang, Acc. Chem. Res. 38, 8 (2004)

F. Xia, L. Jiang, Adv. Mater. 20, 2842 (2008)

J.Y. Shiu, C.W. Kuo, P. Chen, Chem. Mater. 16, 561 (2004)

T. Baldacchini, J.E. Carey, M. Zhou, Langmuir 22, 4917 (2006)

B. Balu, V. Breedveld, D.W. Hess, Langmuir 24, 4785 (2008)

H. Tang, H. Wang, J. He, J. Phys. Chem. C. 113, 14220 (2009)

S.Y. Yang, Y. Tian, L. Chen, S. Chen, Chem. Mater. 20, 1233 (2008)

J. Ji, J. Fu, J.C. Shen, Adv. Mater. 18, 1441 (2006)

N. Zhao, F. Shi, Z.Q. Wang, Langmuir 21, 4713 (2005)

X. Deng, L. Mammen, D. Vollmer, Science 335, 67 (2012)

H.M. Bok, S. Kim, S.H. Yoo, Langmuir 28, 4168 (2008)

Z. Wu, J. Walish, A. Nolte, Adv. Mater. 18, 2699 (2006)

J. Hiller, J.D. Mendelsohn, M.F. Rubner, Nat. Mater. 1, 59 (2002)

J.C. Hsu, P.W. Wang, Y.H. Lin, Opt. Rev. 17, 553 (2010)

F. Shi, X. Chen, L. Wang, Chem. Mater. 17, 6177 (2005)

Y. Liu, Z.Y. Lin, K.S. Moon, C.P. Wong, ACS Appl. Mater. Interfaces 4, 3959 (2012)

C.R. Crick, J.C. Bear, I.P. Parkin, Adv. Mater. 24, 3505 (2012)

S. Chen, C.H. Hu, N.P. Xu, Chem. Commun. 19, 1919 (2007)

S.Y. Yang, L.F. Wang, C.F. Wang, L. Chen, S. Chen, Langmuir 26, 1724 (2010)

L.R. Hou, C.F. Wang, L. Chen, S. Chen, J. Mater. Chem. 20, 3863 (2010)

T. Ramón, M.C. José, F. Gilbert, J. Eur. Ceram. Soc. 19, 2519 (1999)

B. Zhu, X. Li, R. Hao, H. Wang, Naihuo. Cailiao. 40, 165 (2006)

P. Peng, C. Sorrell, Mater. Lett. 58, 1288 (2004)

A.B.D. Cassie, S. Baxter, Trans. Faraday Soc. 40, 546 (1944)

Acknowledgements

This work was supported by the National High Technology Research and Development Program of China (863 Program) (2012AA030313), National Natural Science Foundation of China (21076103), and the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Deng, Z., Yin, Y., Yang, S. et al. Fabrication of superhydrophobic surface from binary micro-/nano-structure of mullite-whisk-based films. Appl. Phys. A 113, 591–596 (2013). https://doi.org/10.1007/s00339-013-7661-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-013-7661-z