Abstract

An effective method for determining the optical constants of Ta2O5 thin films deposited on crystal silicon (c-Si) using spectroscopic ellipsometry (SE) measurement with a two-film model (ambient–oxide–interlayer–substrate) was presented. Ta2O5 thin films with thickness range of 1–400 nm have been prepared by the electron beam evaporation (EBE) method. We find that the refractive indices of Ta2O5 ultrathin films less than 40 nm drop with the decreasing thickness, while the other ones are close to those of bulk Ta2O5. This phenomenon was due to the existence of an interfacial oxide region and the surface roughness of the film, which was confirmed by the measurement of atomic force microscopy (AFM). Optical properties of ultrathin film varying with the thickness are useful for the design and manufacture of nano-scaled thin-film devices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Recently, nanotechnology has advanced rapidly, and it is revolutionizing the microelectronic and optoelectronic applications. As traditional semiconductor technology encounters numerous scaling and economic challenges, smaller but more efficient devices with ultra thin films at the nanometer scale are created for information storage, processing, and display [1–3]. However, the optical properties and dielectric properties of thin films at nanometer scale are different from the bulk one’s due to the effect of surface and interface [4]. In order to get high performance of nano-scaled device, it is important to find how the optical properties of ultrathin films change with size shrinking. Up to date, this kind of study is not yet sufficient.

Owing to its large dielectric constant (high-k), high refractive index and good environment stability, tantalum pentoxide (Ta2O5) films have attracted great attention in both semiconductor sciences and optical sciences, and have found many applications such as antireflective layers [5], narrow-band interference filters [6], storage capacitors [7], gate dielectric [8], etc. Because of this wide field of applications, Ta2O5 films have been extensively studied both experimentally and theoretically. For device applications in microelectronics, ultrathin film with high dielectric constant can replace SiO2 as ultra-large-scale-integrated gate dielectric for its property equivalent to the one of a thinner SiO2 film [9, 10]. On the other hand, the dielectric constant of ultrathin film is dependent on the thickness [11]. Several researches indicate that the dielectric constants and refractive indices of Ta2O5 ultrathin films deposited on silicon drop because of the SiO2 layer at the Ta2O5/Si-substrate interface [5, 12]. However, some other results show that the interfacial region is not pure SiO2, but a complex depth-dependent ternary oxide of Si–Ta x –O y [13]. Therefore, it is worth further studying on this topic of clarifying the optical properties of Ta2O5 ultrathin films. Generally speaking, a sufficient understanding of the optical properties of diverse ultrathin films, including Ta2O5 ultrathin films, is very important for the development of related devices, and should be of wide interest in the field of nanotechnology.

Ellipsometry is now one of the popular tools for the characterization of ultrathin films for it can provide useful information about nanostructures [14, 15]. In this paper, we presented an effective method to get the optical constants of the transparent Ta2O5 thin films deposited on silicon using spectroscopic ellipsometry (SE), and the surface morphology of Ta2O5 thin films was studied by atomic force microscopy (AFM).

2 Experimental details

The Ta2O5 films with thickness range of 1–400 nm were deposited by electron beam evaporation (EBE) method at the same deposition conditions. Crystalline 〈100〉 n-type silicon with diameter of 2 inch, thickness of (350±20) μm and resistivity of 2–8 Ω cm, which was cleaned in an HF solution and de-ionized water to remove any native oxide material, was used as substrate. Over 30 samples have been prepared at the deposition rate of 0.2–0.4 nm/s. During deposition, the broadband optical monitoring (BOM) method was used to adjust the optical thickness and the deposition rate [16]. All the samples were characterized by a rotating-polarizer-analyzer ellipsometer (RPAE) [17, 18]. Ellipsometric parameters (Δ,Ψ) of each film were acquired over the wavelength range of 300–820 nm with an interval of 10 nm at three different incident angles of 65∘, 70∘, and 75∘, respectively. To attain high accuracy, each ellipsometric parameter (Δ,Ψ) was acquired with a total of 40 000 sets of raw data using the RPAE with the accuracy of Δ reaching 0.005∘ and the accuracy of Ψ reaching 0.01∘. A simple two-film model was used to determine the optical constants and thickness of the investigated films, which was found to show good agreement between the calculated curves and the experimental data obtained from ellipsometric measurement [19–21].

3 Results and discussions

In order to get the optical constants and physical thickness of Ta2O5 films, an analytical model should be chosen to fit the ellipsometry parameters both physically meaningful and best fit. In our work, a two-film model which is suited to calculate the optical constants of dielectric films deposited on silicon was adopted to fit the ellipsometry parameters [4]. For Ta2O5 was transparent dielectric material in the spectral range of 300–820 nm, the Sellmeier dispersion model was used to express the layer of Ta2O5, and it was given by [22, 23]

where B n is proportional to the density of effective electron states, C n represents a wavelength parameter corresponding to the effective electron energy level. However, only a sample ambient/oxide/substrate model could not fit the measured data well, especially in long wavelength band where the fitting error for the data becomes noticeably large for the ultrathin-film samples. So an interlayer with silicon-induced gap states (SIGS) was introduced between oxide layer and substrate, which expressed the breaking down of the Si–Si bond of the Si substrate [24]. According to Refs. [24, 25], the decay of the interface states was limited to about 0.12 nm close to the interface. Therefore, the thickness of the SIGS layer was assumed to be 0.12 nm. A Lorentz oscillator dispersion model was used to express the SIGS layer, and it is given by [26, 27]

where ε is the dielectric function, A is the amplitude of the oscillator, E center is the resonant energy, E is the photon energy, and Γ is the damping factor of the oscillator. In this model, E center is assumed to be close to the energy gap of silicon, i.e., E center=1.12 eV, and Γ is set to zero. Considering the two-film model, the calculated curve of tanΨ and cosΔ can fit the measured data well. Furthermore, the effective electron energy level of Ta2O5 films was assumed the same. After numerous fitting processes with samples of different oxide thickness, C n could be determined. The best-fit results show that C n has the value of 186 nm. Therefore, here are only three parameters unknown in this model, B n , A, and the oxide thickness d of Ta2O5 films. By fitting the measured data using this two-film model with the minimum root mean squared error (RMSE), these unknown parameters could be finally determined for each Ta2O5 thin films. The results are shown in Fig. 1. Apparently, the calculated curves are in good agreement with the measured ones, which means that the two-film model used in the above fitting process is reasonable and acceptable.

With this fitting process, parameter B n could be given by a function of the oxide thickness:

where A 0=3.19±0.03, d 0=1.94±0.12. Therefore, an empirical dispersion formula for the ultrathin Ta2O5 film was obtained by substituting (3) into (1), and was given by

Figure 2 shows the refractive index of the Ta2O5 thin films at wavelength of 550 nm with different thickness. In Fig. 2, the refractive index reduced sharply with decreasing thickness less than 40 nm, and the other ones remained constant when thickness was greater than 40 nm. The similar phenomenon is also observed at other wavelengths.

A simple inverse proportional function can be used to express the variation trend, which is given by

where n, d represent the refractive index and physical thickness of the Ta2O5 thin films, respectively, B=1.52±0.06.

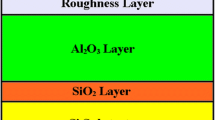

To explain this phenomenon, a roughness layer and an interfacial oxide region were introduced into the structure of the film system. The global dielectric constant of the roughness/Ta2O5/interfacial oxide system can be evaluated by using a simple model which supposes that the three dielectric layers are represented by three capacitors in series with the dielectric constants of three layers, respectively [5, 28]. The effective dielectric constant of the sandwich (ε eff) is then given by the following equation:

where d, d roughness, \(d_{\mathrm{Ta}_{2}\mathrm{O}_{5}}\), and d oxide are the physical thickness of the thin film, the roughness layer, the Ta2O5 layer, and the interfacial oxide layer, respectively, while ε eff, ε roughness, \(\varepsilon_{\mathrm{Ta}_{2}\mathrm{O}_{5}}\), and ε oxide are the dielectric constants of the thin film, the roughness layer, the Ta2O5 layer, and the interfacial oxide layer, respectively. Apparently, there is the relation

By substituting (7) into (6), it gives

where C is given by

The relation between the refractive index and the dielectric constant is given by the following equation, which is suitable for transparent material in the visible light region:

From (8) to (10), by using Taylor expansion, we get

While the refractive index of Ta2O5 \((n_{\mathrm {Ta}_{2}\mathrm{O}_{5}})\) has a value of 2.15 at wavelength of 550 nm. Finally we find that the equation has the same form as is used to express the trend of the refractive index versus thickness. Furthermore the parameter C can be acquired from (9). Here, we have assumed that C is a constant parameter in this approximate model for simplicity. The interfacial oxide layer is not pure SiO2, but is a complex depth-dependent ternary oxide of Si–Ta x –O y . Assuming the interfacial oxide layer mainly comes from contribution with oxidizing of the substrate, the refractive index and thickness can be determined by ellipsometry before deposition. The result showed the that the dielectric constant is 6.76, and the thickness is 2 nm, which accords with [5, 13]. So the values of the interfacial oxide layer acquired from ellipsometry are appropriate. The dielectric constant of roughness layer is given by effective medium approximation (EMA) model. It can be described as a mixture of Ta2O5 and air, with the following equation [29]:

where f is the volume fraction of Ta2O5, and the dielectric constant of air is assumed having the value of 1. Assuming the thickness of roughness layer is 5 nm, and f is 0.75, from (12), we find that the dielectric constant ε roughness is 3.09. According to (9) and (10), finally we estimate the value of C is 1.85, which approximates the experimental parameter B, which has a value of 1.52. This estimation has been confirmed by subsequent surface topography measurement on samples with thickness of 10 nm and 75 nm, respectively. The surface topography measurement was performed by AFM using non-contact head mode. The AFM images are shown in Fig. 3. According to former results, the Ta2O5 thin-film of 10 nm has a minor refractive index, but the refractive index of 75 nm-thick Ta2O5 film is close to those of bulk Ta2O5. However, from the AFM images, the formations of Ta2O5 films are both considered accumulating like “islands”, with the thickness difference between peaks and valleys less than 5 nm.

4 Conclusion

In summary, a series of Ta2O5 films deposited on Si substrate have been prepared by EBE method. The optical properties of the samples were obtained from SE measurement, and found to vary for the ultrathin films. The refractive indices of Ta2O5 films with thickness less than 40 nm reduce with the decreasing thickness, and those with thickness greater than 40 nm are close to the value of bulk Ta2O5. This phenomenon was attributed to the contribution of the interfacial oxide region and the roughness layer, and the AFM results confirmed this viewpoint. For detailed consideration in designing thin-film devices, the surface or interface effect must be considered in order to get high performance of devices, therefore, an ultrathin film for application cannot be considered as a single uniform layer but one usual layer together with two interface layers. The results are useful for the design and fabrication of optical thin-film devices, as well as microelectronic devices.

References

A. Chung, J. Deen, J.S. Lee, M. Meyyappan, Nanotechnology 21, 412001 (2010)

A. Redaelli, A. Pirovano, Nanotechnology 22, 254021 (2011)

W.M. Tolles, Nanotechnology 7, 59 (1996)

Q.Y. Cai, Y.X. Zheng, P.H. Mao, R.J. Zhang, D.X. Zhang, M.H. Liu, L.Y. Chen, J. Phys. D, Appl. Phys. 43, 445302 (2010)

C. Chaneliere, J.L. Autran, R.A.B. Devine, B. Balland, Mater. Sci. Eng., R Rep. 22, 269 (1998)

W.D. Gao, M.Q. Zhan, S.H. Fan, J.D. Shao, Z.X. Fan, Appl. Surf. Sci. 250, 195 (2005)

P.C. Joshi, M.W. Cole, J. Appl. Phys. 86, 871 (1999)

M. Houssa, M. Tuominen, M. Naili, V.V. Afanas’ev, A. Stesmans, S. Haukka, M.M. Heyns, J. Appl. Phys. 87, 8615 (2000)

J.Y. Zhang, I.W. Boyd, Appl. Phys. Lett. 77, 3574 (2000)

L.Q. Zhu, Q. Fang, G. He, M. Liu, L.D. Zhang, Nanotechnology 16, 2865 (2005)

G. He, L.D. Zhang, M. Liu, J.P. Zhang, X.J. Wang, C.M. Zhen, J. Appl. Phys. 105, 014109 (2009)

S. Seki, T. Unagami, O. Kogure, B. Tsujiyama, J. Vac. Sci. Technol., A, Vac. Surf. Films 5, 1771 (1987)

G.B. Alers, D.J. Werder, Y. Chabal, H.C. Lu, E.P. Gusev, E. Garfunkel, T. Gustafsson, R.S. Urdahl, Appl. Phys. Lett. 73, 1517 (1998)

M. Losurdo, Thin Solid Films 519, 2575 (2011)

M. Losurdo, M. Bergmair, G. Bruno, D. Cattelan, C. Cobet, A.D. Martino, K. Fleischer, Z. Dohcevic-Mitrovic, N. Esser, M. Galliet, R. Gajic, D. Hemzal, K. Hingerl, J. Humlicek, R. Ossikovski, Z.V. Popovic, O. Saxl, J. Nanopart. Res. 11, 1521 (2009)

Q.Y. Cai, Y.X. Zheng, D.X. Zhang, W.J. Lu, R.J. Zhang, W. Lin, H.B. Zhao, L.Y. Chen, Opt. Express 19, 12969 (2011)

L.Y. Chen, D.W. Lynch, Appl. Opt. 26, 5221 (1987)

L.Y. Chen, X.W. Feng, Y. Su, H.Z. Ma, Y.H. Qian, Appl. Opt. 33, 1299 (1994)

K. Vedam, Thin Solid Films 313, 1 (1998)

S. Colard, M. Mihailovic, Mater. Sci. Eng. B 66, 88 (1999)

E. Franke, C.L. Trimble, M.J. DeVries, J.A. Woollam, M. Schubert, F. Frost, J. Appl. Phys. 88, 5166 (2000)

M.J. Bergmann, U. Ozgur, H.C. Casey, H.O. Everitt, J.F. Muth, Appl. Phys. Lett. 75, 67 (1999)

G.E. Jellison, J. Appl. Phys. 69, 7627 (1991)

F. Giustino, A. Bongiorno, A. Pasquarello, J. Phys. Condens. Matter 17, S2065 (2005)

J.K. Tomfohr, O.F. Sankey, Phys. Status Solidi, B Basic Res. 233, 59 (2002)

H. Fujiwara, Spectroscopic Ellipsometry: Principles and Applications (Wiley, New York, 2007)

T.W.H. Oates, A. Mucklich, Nanotechnology 16, 2606 (2005)

R.A.B. Devine, Appl. Phys. Lett. 68, 1924 (1996)

L. Ding, T.P. Chen, Y. Liu, C.Y. Ng, S. Fung, Nanotechnology 16, 2657 (2005)

Acknowledgements

This work was supported by the National Science Foundation (NSF) project of China with the contract numbers 60778028, 60938004, 60908005, 11174058, by the No. 2 National Science and Technology Major Project of China under Contract No. 2011ZX02109-004, and by the STCSM project of China with the Grant No. 08DZ1204600.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, DX., Zheng, YX., Cai, QY. et al. Thickness-dependence of optical constants for Ta2O5 ultrathin films. Appl. Phys. A 108, 975–979 (2012). https://doi.org/10.1007/s00339-012-7007-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-012-7007-2