Abstract

Three types of experiments were carried out. In the first series of experiments emmer wheat grains (Triticum dicoccum Schübl), var. AR, and peas (Pisum sativum L.), var. RE, were heated at temperatures ranging from 130–700 °C under controlled anoxic conditions for a maximum of 120 min. For each temperature a separate experiment was carried out in a pre-heated tube oven. Image acquisition was carried out on a flat bed scanner with a transparency adapter; for the analysis the image program IMAGE J 1.27 was used. Various size and shape factors are discussed and the definitions of the selected size and shape factors are given. The size and shape were measured and the mean calculated from thirty of the untreated specimens and the charred residues heated at each temperature. The results show a change of size and shape as a function of the temperature. The changes for wheat grains and peas are not identical. It is suggested that the presence of the pericarp enclosing the wheat grains causes this difference. In a second series of experiments it was shown that untreated grains of emmer wheat, bread wheat and macaroni wheat can be separated by measuring the shape, but size varies too much within each species, probably the result of different growing conditions, to be useful for separation purposes. As a result of heating at temperatures higher than 290 °C the shape of the three species becomes identical. This implies that the three species can no longer be separated after being heated, solely on the basis of size and shape. Finally, both emmer wheat grains enclosed by chaff and without chaff were heated under similar conditions. After removal of the chaff from the former, the size and shape of the grains were measured. The results show no significant difference in size and shape between both types.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Macrobotanical remains of fruits and seeds found in the archaeological record are of importance for our understanding of the way ancient people lived. One of the processes by which these remains may survive biological, physical and molecular decomposition in the soil is carbonization. This process is usually described as heating under anoxic conditions at a specific temperature. The physical and molecular properties of the fruits and seeds change as a function of the heating temperature and thus their chance for survival (Braadbaart et al. 2004a-c). Heating under anoxic conditions also causes distortions to the fruits and seeds (Hopf 1955; Van Zeist 1970; Kislev and Rosenzweig 1989; Smith and Jones 1990; Wright 1998). Usually the length, width and thickness of the fruits and seeds are measured and the ratios of length/width and thickness/width calculated, but measurement or calculation of the size was not possible.

Digital imaging analysis offers an objective and quantitative method for extracting digital images from fruits and seeds and their heated residues. These images can be used to measure the dimensions of individual specimens and mathematically extract size and shape related information. In the cereal industry several imaging systems have been developed for the characterization and classification of wheat varieties (Sapirstein 1995). In other fields of biology, digital imaging systems are also applied (Bannur et al. 1999). Most systems employ video cameras or CCD cameras for digitizing the images, but this has posed problems in the repeatability of the results (Shouche et al. 2001). In this study a digital scanner was used and the imaging was performed in transparency mode.

Differentiating species and varieties of the carbonized fruits and seeds retrieved from the archaeological record has been the subject of many studies (Van Zeist 1970; Jacomet 1987; Hubbard 1992; Hillman et al. 1993; Zohary and Hopf 2001). For grains of a species of wheat (Triticum L.), separation based solely on the measured dimensions poses problems, and the presence of carbonized parts of the chaff in the assemblage is usually necessary for identification. Also, additional characters of the grains are used to separate species, such as embryo angle, embryo roundness, cross section, apex bluntness, etc (Hillman et al. 1996). For the separation of varieties of pea (Pisum sativum L.) it is suggested that for example the length and the proportions of the hilum are used (Hubbard 1992).

This study assesses the extent and the possible causes for the change in size and shape of heated modern fruits and seeds as a function of the heating temperature. In addition the relationship between these morphological changes and the changes in physical and molecular parameters will be evaluated. The possibility of separating the three species of heated wheat grains based on size and shape is also investigated. Wheat grains and pea seeds were selected as they frequently occur in the archaeological record and because of the morphological differences between them. Wheat is a one-seeded fruit with the pericarp enclosing the seed, and pea is a seed with two cotyledons enclosed by a seed coat. It has been shown that the presence of the pericarp in wheat grains affects the morphology differently as a result of heating, when compared with peas (Braadbaart et al. 2004d). For each temperature a separate heating experiment was carried out. The dimensions were always extracted from the images with the fruit and seed or their heated residues in the same orientation and measured by digital image analysis.

Materials and methods

Samples

Four varieties of emmer wheat (Triticum dicoccum Schübl) were obtained from the Centre of Genetic Resources, Wageningen, The Netherlands (CGN): CGN 08340 (Germany), CGN 11482 (Germany), CGN 11485 (France) and CGN 11486 (Austria). Two varieties of emmer wheat are from the collection of the Faculty of Archaeology, Leiden University, The Netherlands: nrs. 4855 (Belgium) and 5801 (Switzerland). One variety of emmer wheat (AR) was grown at Archeon, Alphen a/d Rijn, The Netherlands. The two varieties of bread wheat (Triticum aestivum L.) are CGN 04263 (USSR) and 10417 (India). One variety was obtained from a harvest in the summer of 2003 in the Département of Aisne (France). One variety of bread wheat, Qualital (Q, a hard bread wheat) and one variety of macaroni wheat (Triticum durum Desf.), Ardente (A), were donated by the Unité de Technology des Céréales et des Agropolymères, ENSAM-INRA, Montpellier, France. Two varieties of macaroni wheat are from the collection of the Faculty of Archaeology: nr. 125 (Italy) and 1476 (The Netherlands). The peas used are the variety ‘Noord-Hollandse Rozijnerwt’ (RE; CGN 10293), obtained from CGN.

Heat treatment

Heating experiments were undertaken using a Carbolite tube oven (model MTF 12/38/250); the rate of heating was set at 2 ºC min-1. The wheat grains and peas were placed in the Pyrex vessel. The vessel was inserted into a 30 cm long Pyrex tube (Ø 2.3 cm) at 18 cm from the inlet and heated. Separate experiments were carried out at oven temperatures ranging from 130 up to 700 ºC. Reducing conditions were maintained under a constant flow (150 ml min-1) of nitrogen at atmospheric pressure. The peas were heated for 60 min and the wheat grains for 120 min. The oven was pre-heated and for each experiment the temperature was fixed. Gases and volatiles were vented and not further investigated.

Earlier investigations have shown that heat treatment up to a temperature of 250 °C causes wheat grains to swell and at higher temperatures the pericarp collapses with or without the formation of protrusions on the outside of the pericarp (Braadbaart et al. 2004d). The shape and size analysis took place after the protrusions were removed. In peas these features were not observed (Braadbaart et al. 2004a).

Imaging hardware and software

A flat bed scanner (Umax Mirage IIse) with transparency adapter and Umax majic scan software was used for image acquisition. ADOBE PHOTOSHOP 7.0 software was used to ensure an identical orientation of the specimens. The digital image analysis was carried out by the standalone version of IMAGE J 1.27, a program developed at the National Institute of Health of the USA. A standard personal computer was used for image analysis.

Image acquisition and analysis

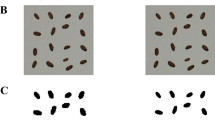

The wheat grains were placed on the scanner bed with the ventral side down with about one cm space between the specimens to avoid grain-to-grain contact. The grains were arranged in rows with the apical brush oriented upwards and the embryo downwards. The peas were placed in rows with hilum and chalaza oriented downwards (Fig. 1). Grey images of the specimens were acquired with the scanner software. The scanner resolution was set at 300 dpi and for all images identical settings of illumination were used. Images were stored in .tiff format and exported to the PHOTOSHOP program for possible corrections regarding the orientation. Subsequently the IMAGE J program was used for feature extraction. For the calculation of size- and shape-related features of individual specimens it is important to detect each specimen in the image. For this purpose thresholding (Binary Contrast Enhancement) is commonly used. A greyscale image is converted to binary by defining a greyscale cut-off point, the threshold. Greyscale values below the threshold become black and those above become white. The threshold value was set so that embryo and brush were still recognized in the image. It was kept constant for the analysis of all images.

Feature extraction

Geometric features of each specimen in the described position, including length and width, were measured from the binary images (Fig. 1). The size of the specimens can be characterized by the size factors of both area and perimeter. The area is measured as the surface (in mm2) of the longitudinal section at plane A of each specimen. This section is thus situated parallel to the scanner bed and can also be described as the space “seen” from above. The perimeter (in mm) is the length of the outer boundary of this section (Fig. 1). Area and perimeter are mathematically extracted from the geometric features, but in this study only the area was selected. The shape of the specimens can be expressed in a shape factor, calculated from the geometric features, which is determined by the morphology of the investigated fruits and seeds. In the cereal industry various shape factors are in use (Symons and Fulcher 1988). One is the compactness of a grain, which is calculated as (perimeter*perimeter)/(4*π*area). This factor can be compared with the slenderness of a grain or 100 Length/Width (100LW-1), a shape factor frequently used in archaeology (van Zeist 1970; Hubbard 1992). Both factors were calculated. Although the absolute numbers differ, the variation in shape as a function of variety or temperature is identical. In this study 100LW-1 is used as the shape factor. In archaeology the thickness of a specimen is often measured in addition to length and width. Additional measurements, with the specimens positioned on their side, showed that the variation of the width and the thickness are proportional. Thus measurements with wheat grains in the ventral side down position were considered sufficient. The peas were measured in an identical manner (Fig. 1).

Sample size

It was argued that for the determination of the changes in size and shape as a result of heating, the length, width and area of each untreated and heated specimen in a sample should be measured. In order to achieve this, the mean of each of these features of the specimens in a sample is calculated. The precision of the mean, based on independent measurements, depends upon its standard error, √(σ2n-1), in which σ2 is the variation of the population and n the sample size or in this case the number of measurements of each of the three features. The former is determined by the population and therefore fixed. An increase of n will reduce the standard error, but should not be increased unnecessarily. Therefore confidence intervals can be calculated for the mean of the features of the population with a 95% chance that the mean of the features of a random sample is situated within the calculated interval. The population of the grains of emmer wheat (var. AR) has a normal distribution with parameters mean (μ) and standard deviation (σ) as shown in Table 1. The 95% intervals for the mean of each feature are calculated from μ ± 1.96*σ*(√n)-1. The results show that for grains of emmer wheat a random sample of n= 30 is sufficient to fit the confidence interval of each feature. For peas (var. RE) the same procedure was followed and it shows that a sample of 10 peas will be sufficient (Table 2).

Results and discussion

Heating and the change of size and shape, as a function of temperature

Emmer wheat grains

Samples of 30 grains of the variety AR of emmer wheat, after removal of the chaff, were heated at 130, 160, 190, 220, 235, 250, 270, 290, 310, 340, 370, 400, 440, 500 and 600 °C for 120 min in separate experiments. Length, width and area of each specimen in the samples at each temperature were measured. The mean value of each feature at each temperature was calculated. The length was plotted versus the width (Fig. 2a) and the area versus the temperature (Fig. 2b). To obtain more insight into the changes of the shape, the shape factor, 100LW-1, has been plotted as a function of the area at the various temperatures (Fig. 2c). The results show that the grains become rounder (100LW-1 decreases) at increasing temperatures up to 250 °C, with an increase of the area. From 270 °C upwards the shape factor remains constant with a decreasing area. The samples of emmer wheat (var. AR) heated at 130 °C and 160 °C have the same area as the untreated grains, but the length is decreased and the width increased. This is the beginning of a swelling process, whereby only changes in shape are observed, resulting in a rounder grain. At 190 °C the area has increased and it continues to do so up to 250 °C. A reason for the swelling could be the actual swelling of the individual starch granules in the cells of the endosperm, being the bulk material of wheat grains. Swelling of starch occurs when it is heated in the presence of water and is called gelatinization (Singh et al. 2003). However, it has been shown through SEM microphotographs of the internal structure that as the result of heating whole wheat grains, the starch granules do not swell (Braadbaart et al. 2004c, d). The main process in these whole grains as a result of heating up to 250 °C is dehydration. Evidently the water vapour is not able to pass the pericarp directly causing an increase of the pressure inside resulting in the swelling of the grain. Simultaneously the molecular and /or physical properties of the pericarp change too and this suggests that from 190 °C the pericarp is able to stretch, resulting in a larger area. Heating at temperatures higher than 250 °C results in a gradual conversion of starch into aromatic compounds and from 310 °C starch is no longer present. This conversion results in the release of many volatiles and the pressure inside the grains increases in such a way that eventually the pericarp collapses. Hereafter no more swelling occurs and the size no longer increases, but decreases as the total weight decreases with increasing temperature (Braadbaart et al. 2004c). In this range of temperatures (270–310 °C) similar molecular reactions take place in the grains and the heated residues of 270, 290 and 310 °C have the same characteristic size and shape. The heated residues of 340 and 370 °C show the presence of exothermic reactions and thus the formation of secondary compounds (Braadbaart et al. 2004c). A further decrease of the size for both residues is observed, but the shape does not change. From 400 °C upwards a different type of conversion takes place, mainly because the heating rate has increased and no secondary reactions can occur as the volatiles are removed too fast from the reaction zone. Thus the residues at 400, 440 and 500 °C show the same size, however as the weight still continues to decrease the size becomes smaller compared with the residues heated at 340 and 370 °C. The shape does not change. Untreated grains and grains heated at 290, 340 and 440 °C are illustrated and show the differences in size and shape (Fig. 3).

Dimensional changes of emmer wheat grains (var. AR) as a result of heating for 120 min: (a) length (mm) as a function of width (mm) heated at the indicated temperatures (°C); (b) area (mm2) as a function of the oven temperature (°C) and (c) size (area) as a function of the shape (100LW-1) heated at the indicated temperatures. Sample size 30 grains

The physical and molecular changes that take place from 250 °C upwards can be divided into three stages as a function of the temperature, first the stage from 250–310 °C, then the stage from 310–400 °C and finally a stage at temperatures higher than 400 °C. These stages correspond well to the changes in size and shape.

Peas

Samples of 10 peas were heated at the same steps under similar conditions in separate experiments for each temperature. The mean values of width, length and area of the specimens in each sample of untreated peas and of the residues at each temperature were calculated. (i) The width as a function of the length (Fig. 4a), (ii) the area as a function of the oven temperature (Fig. 4b) and the size factor, represented by the area, as a function of the shape factor, 100 LW-1 (Fig. 4c) are shown. Until 190 °C no major changes in size and shape are observed. At higher temperatures up to 250 °C a decrease in the size is shown and the residues become rounder. The dehydration of the starch, being the bulk material of peas, is the main process at these temperatures (Braadbaart et al. 2004a, b). The resulting water vapour is freely removed from the seeds. The residues heated from 250 up to 340 °C do not show changes in size and shape. This implies that the physical and molecular changes that occur at 310 °C do not show their effects on the size and shape. Subsequently at 400 °C the size increases and the shape factor, 100LW-1, decreases resulting in rounder seeds. The physical and molecular properties change at this temperature, but no explanation of the changes in size and shape is possible. From 400 °C upwards the size gradually decreases, which corresponds to the gradual decrease of the weight (Braadbaart et al. 2004a). Simultaneously the seeds become less round.

Dimensional changes of pea seeds (var. RE) as a result of heating for 60 min; (a) length (mm) as a function of the width (mm) at the indicated temperatures (°C); (b) area (mm2) as a function of the oven temperature (°C) and (c) size (area) as a function of the shape (100LW-1) heated at the indicated temperature. Sample size 10 seeds

In the case of peas the stages, based on the physical and molecular changes, are from 270 – 310, from 310–400 and higher than 400 °C. The changes in size and shape, as a function of the temperature, show only two stages one stage from 250–370 °C and a second stage from 400 °C upwards.

Comparison between wheat grains and peas

The size and shape of wheat grains and peas as a function of the temperature change in a different way. The bulk material of both is starch and the same conversion reactions will take place as a result of heating. However, the morphology is different and the endosperm of wheat grains is enclosed by the pericarp, while the cotyledons of peas are surrounded by the seed coat. The volatiles are apparently freely removed through the seed coat of peas and no pressure builds up inside. In contrast, in wheat grains the pressure does build up and a swelling of the grains occurs. The changes in size and shape of both the wheat grains and the peas corresponds well to the changes in physical and molecular properties. There is one exception in the case of peas where at 310 °C no change in size and shape is observed.

Separation of three species of wheat

Untreated emmer, bread and macaroni wheat grains

The length, width and area of the specimens in the samples of untreated grains of seven varieties of emmer wheat, four varieties of bread wheat and three varieties of macaroni wheat were measured and their mean values calculated. The size factor, in this case the area (mm2) is plotted as a function of the calculated shape factor 100LW-1 (Fig. 5). It shows that the grains of each of the three species have a characteristic shape factor. For emmer wheat it varies between 265 and 290, for bread wheat between 215 and 230 and for macaroni wheat between 170 and 195. The area of the grains of the three species varies greatly, which can be explained by a variation in climate, local soil conditions, weather, position in the ear, etc. (Whitworth 2000). Nevertheless grains of the three species can be easily separated on the basis of the applied shape factor, 100LW-1.

Heated emmer, bread and macaroni wheat grains

The changes in area and shape of the grains of each of the three species as a result of heating were measured and calculated (Fig. 6). Samples of 100 grains of the species AR (emmer wheat), Q (bread wheat) and A (macaroni wheat) were heated at 290, 340 and 440 °C. These temperatures were chosen because each belongs to one of the three groups with similar changes of size and shape as explained in a previous section. The observed changes are basically identical for the three species. At 290 °C the area has increased and the grains have become rounder. From 290 °C upwards the shape does not change, but the size gradually decreases. The variety Q of bread wheat shows a different behaviour at 340 °C, in which its size does not decrease, but remains more or less similar to that of the grains heated at 290 °C. The grains of the three species heated at 440 °C show a size that is almost identical to that of the untreated grains. Thus at this temperature the differences in size of the treated grains between the three species remain, but the differences in shape observed in the untreated grains no longer exists in the heated ones. The change in shape of the three species is shown by one untreated grain and one heated at 440 °C of each species (Fig. 7). It shows that the shape of each grain is almost similar: AR440 is 148, A440 is 146 and Q440 is 142. When the grains of a species of wheat are heated, the change of the size as a function of the shape factors will follow a path that is similar for each investigated species, but the starting point of the path of each species is different. Three species have been investigated and three paths are thus distinguished (Fig. 6). Wheat grains exposed to heat and found in the archaeological record are difficult to separate as the heating has distorted the grains and this will have changed the size and shape (Hillman et al. 1996). As each species has its own characteristic starting point the original differences between the untreated species should be also present in the heated ones. The results show that this is only partly true (Fig. 6). The differences in size are generally still the same, however there are also considerable differences in size between the varieties of one species and thus the starting point of the conversion path (Fig. 5). Reasons for the difference in size could be variations in climate, soil, weather, etc. This implies that size poses problems when used for separation purposes. At temperatures higher than 290 °C the heated grains of the three species have all more or less the same shape (100LW-1 = 140–160). Thus shape is also not very useful for the separation of heated wheat grains. It explains and confirms the difficulties in separating heated grains of different wheat species without the presence of characteristic additional plant parts.

Size (area) as a function as function of the shape (100LW-1) of varieties of three species of wheat heated at the indicated temperatures (°C) for 120 min: (■) emmer wheat (var. AR); (●) bread wheat (var. Q) and (▲) macaroni wheat (var. A). Sample size 100 grains. Dotted lines added to aid the reader

Samples of one untreated grain of varieties of the following species of wheat: AR (emmer wheat), A (macaroni wheat) and Q (bread wheat) indicating variety and shape (100LW-1): AR (283), A (219) and Q (186), respectively and one grain of the same varieties heated at 440 °C: AR440 (148), A440 (146) and Q440 (142), respectively. Heating time: 120 min. Length of the untreated grain of AR is 7.5 mm

Heated emmer wheat grains enclosed by chaff

The presence of chaff on the change of the size and shape of wheat grains as a result of heating was investigated. For this purpose three samples of 100 emmer wheat grains without chaff were prepared and heated at 290, 340 and 440 °C, respectively. In this way a sample was heated in one of the three groups as described in a previous section. The area, as the size factor, was plotted as a function of the shape factor 100LW-1 (Fig. 8). Subsequently three samples of 100 emmer wheat grains, enclosed by chaff, were heated at these three temperatures. After removal of the chaff the heated grains were measured, the mean of the length, width and area calculated and plotted in the same way as the grains without chaff (Fig. 8). It shows that the presence of chaff has no effect on the size and a minimal effect on the shape of the heated grains at 290 and 340 °C. At 440 °C the grains heated with chaff have about 10% smaller shape, but the size remains unaffected.

Size (area) as a function of the shape (100LW-1) of emmer wheat grains (var. AR), with and without chaff, heated at the indicated temperatures (°C) for 120 min: (■) emmer wheat (var. AR) without chaff and (□) emmer wheat (var. AR) heated with chaff. Sample size 100 grains. Dotted line added to aid the reader

Conclusions

The obtained properties of wheat grains and peas can be divided into identical stages, as a function of the temperature, after heating under anoxic conditions. The division is based on their physical and molecular properties. In general these stages are also recognized in the changes of size and shape, as defined in this study. However, the changes of wheat grains and peas are different. It is suggested that the presence of the pericarp in wheat grains and the lack of it in peas is the reason for this difference.

The experiments with three species of wheat show that the size of the untreated grains varies too much between and within the species as a result of different growing conditions. Therefore size alone is not a suitable tool for the separation between the species of both untreated and heated wheat grains. Based on the shape, it is possible to separate untreated grains of the three species. However, as a result of heating at temperatures higher than 290 °C, the grains of the three investigated species attain an almost identical shape of 100LW-1 =140–160. This suggests that after heating of modern varieties of wheat under the present controlled conditions separation between the three species is hardly possible, when solely size and shape are known.

No significant difference in size and minimal changes in the shape are observed when wheat grains enclosed by chaff are heated and compared with grains heated without chaff.

This laboratory study shows why and how the size and shape of modern wheat grains and peas change as a result of heating. However, the conclusion that shape, under the present experimental conditions, is not a suitable tool for the separation of different species of wheat is not in accordance with the results obtained with carbonized wheat grains retrieved from the archaeological record. This poses a problem. A reason for this discrepancy might be that the heating conditions prevailing in the past were not in accordance with the conditions chosen for the present experiments. Thus to obtain more insight into this problem it is therefore necessary to carry out further experiments on the influence of the heating conditions on carbonized grains.

References

Bannur, S.V., Kulgod, S.V., Metkar, S.S., Mahajan, S.K., Sainis, J.K. (1999). Protein determination by Ponceau S using digital colour image analysis of protein spots on nitrocellulose membranes. Analytical Biochemistry, 267, 382–389

Braadbaart, F., Boon, J.J., Veld, H., David, P., Bergen, P.F. van (2004a). Studies on the heat treatment of peas: changes of their physical and bulk chemical properties. Journal of Archaeological Science, 31, 821–833

Braadbaart, F., Boon, J.J., Horst, J. van der, Bergen, P.F. van (2004b). Laboratory simulations of the transformation of peas as a result of heating: the change of the molecular properties by DTMS. Journal of Analytical and Applied Pyrolysis, 71, 997–1026

Braadbaart, F., Horst, J. van der, Boon, J.J., Bergen, P.F. van (2004c). Laboratory simulations of the transformation of emmer wheat as a result of heating. Journal of Thermal Analyses and Calorimetry, 77, 957–973

Braadbaart, F., Bakels, C.C., Boon, J.J., Bergen, P.F.van (2004d). Heating experiments under anoxic conditions on varieties of wheat. Archaeometry, 47, in press

Hillman, G.C., Wales, S., McLaren, F., Evans, J., Butler, A. (1993). Identifying problematic remains of ancient plant foods: a comparison of the role of chemical, histological and morphological criteria. World Archaeology, 25, 94–121

Hillman, G.C., Mason, S., Moulins, D. de, Nesbitt, M. (1996). Identification of archaeological remains of wheat: the 1992 London workshop. Circaea, 12, 195–209

Hopf, M. (1955). Formveränderungen von Getreidekörnern beim Verkohlen. Berichte der Deutschen Botanischen Gesellschaft, 68, 191–193

Hubbard, R.N.L.B. (1992). Dichotomous keys for the identification of the major Old World crops. Review of Palaeobotany and Palynology, 73, 105–115

Jacomet, S. (1987). Prähistorische Getreidefunde. Eine Anleitung zur Bestimmung prähistorischer Gersten- und Weizenfunde, Basel

Kislev, M.E., Rosenzweig, S. (1989). Influence of experimental charring on seed dimensions of pulses. Acta Interdisciplinaria Archaeologica, 7, 143–157

Sapirstein, H.D., (1995). Varietal identification by digital analysis. In: Wrigley C.W. (ed) Identification of food-grains varieties. American Association of Cereal Chemists Inc, St. Paul, MN, 91–130

Shouche, S.P., Rastogi, R., Bhagwat, S.G., Sainis, J.K. (2001). Shape analysis of grains of Indian wheat varieties. Computers and Electronics in Agriculture, 33, 55–76

Singh, N., Singh, J., Kaur, L., Singh Sodi, N., Singh Gill, B. (2003). Morphological, thermal and rheological properties of starches from different botanical sources. Food Chemistry, 81, 219–231

Smith, H., Jones, G. (1990). Experiments on the effects of charring on cultivated grape seeds. Journal of Archaeological Science, 17, 317–327

Symons, S.J., Fulcher, R.G. (1988). Determination of wheat kernel morphological variation by digital image analysis: I. Variation in Eastern Canadian milling quality wheats. Journal of Cereal Science, 8, 211–218

Whitworth, M. (2000). Heterogeneity of structure and grain composition. In: Workshop on Process Engineering of Cereals 1999, Montpellier

Wright, P.J. (1998). The making of the carbonized macrobotanical record. Dissertation Washington University, St. Louis, USA

Zeist, W. van (1970). Prehistoric and early historic food plants in the Netherlands. Palaeohistoria, 14, 41–173

Zohary, D., Hopf, M. (2001). The domestication of plants of the Old World. Oxford University Press, Oxford

Acknowledgements

The authors are grateful to B. Marino (FOM Institute for Atomic and Molecular Physics, Amsterdam, The Netherlands) for her suggestions regarding digital imaging analysis. Practical help with the microphotographs of wheat grains by E. Mulder (Faculty of Archaeology, Leiden University) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Braadbaart, F., van Bergen, P.F. Digital imaging analysis of size and shape of wheat and pea upon heating under anoxic conditions as a function of the temperature. Veget Hist Archaeobot 14, 67–75 (2005). https://doi.org/10.1007/s00334-004-0050-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00334-004-0050-y