Abstract

The aim of this study was to evaluate selected physical, morphological and thermal properties of durum wheat grain. Additionally, the parameters of control grain (grown without fertilizers or a growth retardant) were compared with the grain from treatments with different combinations of nitrogen fertilizer and growth retardant. The grain of durum wheat grown without nitrogen fertilizer or growth retardant was characterized by the lowest values of thousand-kernel weight (47.24 g for the sample collected in 2015 and 45.70 g for the sample collected in 2016), bulk density (814 kg m−3—2015 and 745 kg m−3—2016), length (7.62 mm—2015 and 7.54 mm—2016), width (3.35 mm—2015 and 3.32 mm—2016) and shape factors (specific perimeter of object boundary, Danielsson coefficient). The highest values of thousand-kernel weight, bulk density and width of durum wheat grain harvested in both years of the study were determined in the samples collected in the treatment with a total nitrogen rate of 80 kg ha−1 without the growth retardant. In the samples collected in 2015, the above combination produced grain with the greatest length, the highest specific perimeter of object boundary and the highest Danielsson coefficient. In 2016, these parameters were highest in grain from the treatment where a total nitrogen rate of 80 kg ha−1 was combined with a growth retardant. Different combinations of nitrogen fertilization and the growth retardant did not affect the true density or the thermal properties of wheat grain. Statistically significant differences between the experimental groups were not observed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Triticum durum Desf. is one of the most important agricultural crops which is grown mainly in the Mediterranean region. In Italy, the annual production of durum wheat is estimated at 1.5 m ha (Baldi 2012). This high yielding species is considerably influenced by environmental conditions. One of the key agronomic factors in the production of durum wheat is the rate of nitrogen fertilizer which determines plant growth and development as well as grain yield and quality (Ayadi et al. 2016; Żuk-Gołaszewska et al. 2016). Growth retardants are also important agricultural inputs which decrease the length of plant shoots and minimize lodging. Growth retardants enhance sprouting, in particular under unfavorable environmental conditions during maturation, accelerate harvest and improve the properties and quality of wheat durum grain (Rajala 2003). In the literature, the effect of different agronomic conditions on the properties of cereal grain has been described in several reports. However, the impact of different combinations of nitrogen fertilizer and growth retardant on the physical, morphological and thermal properties of durum wheat grain has not been comprehensively researched. Nitrogen’s effect on the physical parameters of durum wheat was investigated by Makowska et al. (2008). Pan et al. (2017) reported differences in the yield and yield components, including thousand-kernel weight, of rice subjected to nitrogen fertilization. Shekoofa and Emam (2008) found that nitrogen fertilization did not increase thousand-kernel weight. However, the evaluated parameter increased in response to a plant growth regulator (ethephon).

The quality and safety of food products are influenced by the thermal and physical properties of agricultural products. These parameters are important for modeling and optimizing food processing conditions (drying, heating, freezing, cooling, pumping) to obtain desirable food products and to reduce energy costs (Mercali et al. 2011). The thermal properties of a material can be measured with the use of different devices, methods and techniques, such as the KD2 Pro thermal properties analyzer and thermal analysis (TA). The KD2 Pro analyzer is useful for determining thermal conductivity, thermal resistivity, specific heat and thermal diffusivity of food products (Kadam et al. 2012; Barnwal et al. 2015; Perussello et al. 2015). TA techniques such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) are applied to determine the thermal parameters of foods. In the TGA technique, changes in the mass of the analyzed sample are measured as a function of temperature (Lever et al. 2014). The DSC method supports determinations of the specific heat of agricultural materials as a function of temperature (Barnwal et al. 2015). The physical properties of food products, including density, porosity, dimensions and shape, are essential for designing transport, separation, sorting processes and packaging equipment (Yıldız et al. 2015). The physical properties of grain also influence its quality, and they are determined by end-use requirements. For example, the physical properties of whole wheat grain, such as size and shape, affect milling yield and screening losses. Small and shriveled kernels decrease milling yield (proportion of flour extracted). Grain quality is also influenced by moisture content. Moisture content is very important for determining the physical and chemical properties of grain and the quality of grain products (Paquet-Durand et al. 2015). Butscher et al. (2016) reported that the storage of grain with moisture content below 13% is generally safe, but there is a risk of microbial survival in a dormant state. Therefore, the determination of the moisture content of grain is an important consideration. Infected grain should also be identified based on its textural and morphological features (Ropelewska and Zapotoczny 2018). Plants growing under unfavorable climatic conditions develop specific adaptive strategies, and these mechanisms also influence the quality of grain (Nuttall et al. 2017).

The aim of this study was to evaluate selected physical, morphological and thermal properties of durum wheat grain. Additionally, the parameters of control grain (grown without fertilizers or a growth retardant) were compared with the grain from treatments with different combinations of nitrogen fertilizer and growth retardant.

2 Materials and methods

2.1 Materials

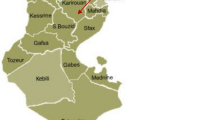

Spring wheat durum cv. SMH87 was grown in the Agricultural Experiment Station in Bałcyny (53°40′N, 19°50′E) in the Region of Warmia and Mazury, Poland, in 2015–2016. The experiment was established on class IVa soils (very good rye complex in the Polish soil classification system) with a slightly acidic pH. The experimental factors were: different rates of nitrogen fertilization and the application of the Medax Top 350 S.C. growth retardant (BASF South Africa (Pty) Ltd; active ingredients: mepiquat chloride and prohexadione calcium). In both years of the study, wheat was grown in treatments I, II, III, IV, V and VI with the following experimental design:

I—N0 (without nitrogen fertilization), R0 (without growth retardant)

II—N0 (without nitrogen fertilization), R1 (with growth retardant)

III—N80 (total nitrogen rate of 80 kg ha−1), R0 (without growth retardant)

IV—N80 (total nitrogen rate of 80 kg ha−1), R1 (with growth retardant)

V—N 120 (total nitrogen rate of 120 kg ha−1), R0 (without growth retardant)

VI—N 120 (total nitrogen rate of 120 kg ha−1), R1 (with growth retardant)

Nitrogen fertilizer was applied in the following stages of growth:

-

80 kg ha−1, split-apply: 50 kg ha−1 before sowing and 30 kg ha−1 in the 3rd node detectable stage (GS 33),

-

120 kg ha−1, split-apply: 50 kg ha−1 before sowing, 30 kg ha−1 in the 3rd node detectable stage (GS 33), and 40 kg ha−1 in the ear emergence stage (GS 51). Medax Top 350 SC retardant was applied in stage GS 37-39, according to the manufacturer’s instructions. After harvest, samples of spring wheat grain were transported to the laboratory. They were stored in a closed bag at a temperature of 23 °C until analysis.

2.2 Physical properties

Moisture content (%) was determined according to standard PN-EN ISO 712:2012 as the loss of grain mass after 3 h of drying at 130 °C. Moisture content was standardized to 12% by wetting grain or by storing grain under laboratory conditions at room temperature (23 °C). The analyzed physical, morphological and thermal properties were measured in grain with a moisture content of 12%. Thousand-kernel weight (TKW) was determined according to standard PN-68/R-74017. Bulk density was determined with the use of a 500 cm3 densimeter according to modified standard PN-EN ISO 7971-3:2010, and it was calculated as mass over volume (kg m−3).

True density was determined using a 100 cm3 glass pycnometer and a water-insoluble liquid according to standard PN-EN 1097-6:2013. True density (kg m−3) was calculated based on the following formula (1):

where ρt—true density; m0—grain mass in air; m1—grain mass in liquid; ρc—liquid density at a known temperature.

All measurements were carried out in 5 replicates.

2.3 Image analysis of morphological properties

Kernel images were acquired with the Epson Perfection 4490 Photo scanner (UK) and SilverFast Ai Studio Epson v6.6.1r6 scanning software (LaserSoft Imaging, Inc., USA). The images were obtained at a resolution of 2776 × 4222 pixels, 400 dpi, and saved in TIFF format. A caliper was applied for calibration. Images were processed and analyzed in the MaZda v. 4.6 application (Łódź University of Technology, Institute of Electronics, Poland) (Szczypiński et al. 2009). Approximately 60 geometric parameters, including linear dimensions, shape factors and moments of inertia (Zapotoczny 2011), and around 3000 textural features from color channels R, G, B, L, a, b, X, Y, Z were determined for each kernel in the MaZda program. All measurements were performed in 550 replicates.

2.4 Thermal properties

Thermal properties were determined in bulk samples of wheat grain placed in 100 cm3 beakers. The measurements were performed with the use of the KD2 Pro thermal properties analyzer (Decagon Devices) with the SH-1 dual-needle sensor, 30 mm in length, 1.3 mm in diameter and 6 mm spacing between needles. The values of thermal conductivity (λ), thermal resistivity (r), volumetric heat capacity (Ch) and thermal diffusivity (α) were determined (Ropelewska 2018). The measurements were carried out at ambient temperature of 23 °C. The results were displayed by the device. All measurements were carried out in five replicates.

2.5 Statistical analyses

The results of measurements were analyzed statistically using Statistica 12.0 (StatSoft Inc., Tulsa, USA) software. The differences in the physical, morphological and thermal properties of wheat grain from different treatments were determined at a significance level of p ≤ 0.05. The normality of data distribution was checked using Lilliefors, Shapiro–Wilk and Kolmogorov–Smirnov tests. Variables with normal distribution were processed by the Newman–Keuls parametric test, and variables with non-normal distribution were processed by the Kruskal–Wallis test.

The morphological properties of grain were also subjected to discriminant analysis. Grain samples were divided into six groups characterized by different rates of nitrogen fertilization and the presence or absence of the growth retardant (I, II, III, IV, V, VI) in WEKA 3.9 software (Machine Learning Group, University of Waikato) (Bouckaert et al. 2016). Selected Decision Tree (J48), Rules (JRip), Bayes (Bayes Net), Lazy (IBk) and Meta (Attribute Selected Classifier) classifiers were used. The models were tested by 10-fold cross-validation. Attributes were selected with the use of the Ranker method and the OneR attribute evaluator to reduce the number of variables and shorten analysis time. Ten features with the highest discriminative power were selected from each set of morphological and textural properties (from Lab, RGB and XYZ models) and were used in classification models. In the final step of the analysis, the selected morphological and textural features were incorporated into a single model. The evaluation criterion was the highest classification accuracy.

3 Results and discussion

The mean values and the results of one-way ANOVA for selected physical features (thousand-kernel weight, bulk density, true density) of wheat grain are presented in Table 1. TKW ranged from 47.24 to 51.33 g for the samples collected in 2015 and 45.70–51.93 g for the samples harvested in 2016. In both cases, TKW was lowest in grains with treatment I and highest in grains from treatment III. A similar trend was noted in bulk density. Wheat grain harvested in 2015 and 2016 from the treatment without nitrogen fertilization and without the growth retardant was characterized by the lowest bulk density of 814 kg m−3 and 745 kg m−3, respectively. The grain from treatment III had the highest bulk density of 822 kg m−3 in 2015 and 782 kg m−3 in 2016. The extreme values of TKW and bulk density differed significantly. The true density of grain did not differ significantly between the experimental groups. The mean values of the above parameter were determined at 1543–1567 kg m−3 in 2015 and 1431–1521 kg m−3 in 2016.

The values of selected linear dimensions (length, width) and shape factors (specific perimeter of object boundary, Danielsson coefficient) of durum wheat kernels, and the results of statistical analyses are presented in Table 2. The length (L) of grain harvested in 2015 ranged from 7.62 mm (treatment I) to 7.78 mm (treatment III). The grain from treatment I was also characterized by the smallest width (S) (3.35 mm), the lowest specific perimeter of object boundary (Ug) and the lowest Danielsson coefficient (RD). The values of S, Ug and RD were highest in the grain samples from treatment III. Similarly to the grain harvested in 2015, linear dimensions L (7.54 mm) and S (3.32 mm) and shape factors Ug and RD were also smallest in the grain harvested in 2016 from treatment I. The highest value of S (3.42 mm) was determined in the sample from treatment III, and the highest values of L (7.68 mm), Ug and RD were observed in the grain from treatment IV with a total nitrogen rate of 80 kg ha−1 and with the application of the growth retardant.

In a study by Tabatabaeefar (2003), the TKW of wheat ranged from 23.2 g to 39.7 g, bulk density—from 740 to 538.8 kg m−3, and true density—from 1240 to 847.2 kg m−3. According to Warechowska et al. (2013), the TKW of wheat was determined at 36.3 to 39.2 g and true density—at 1.250 to 1.281 kg m−3. In a study by El-Khayat et al. (2006), durum wheat was characterized by higher TKW than common wheat at 42.5–55.5 g, which is consistent with our findings. Tabatabaeefar (2003) analyzed the kernels of different wheat varieties and found that kernel length ranged from 6.64 to 7.36 mm and kernel width—from 2.51 to 3.95 mm. In a study by Warechowska et al. (2013), the length of wheat kernels ranged from 6.05 to 6.31 mm and their width—from 3.31 to 3.33 mm. According to literature data, nitrogen fertilizers and growth retardants can influence the properties of cereal grain. In a study by Makowska et al. (2008), a fertilizer rate of up to 100 kg N ha−1 increased TKW, hardness and virtuousness, and the corresponding regression coefficients (R2) were determined at 0.8508, 0.754 and 0.8292, respectively. Moreno et al. (2003) found that the TKW of barley peaked in response to a nitrogen fertilizer rate of 100 kg N ha−1. Harasim and Wesołowski (2013) observed that the bulk density of wheat grain increased from 100 to 150 kg N ha−1 with a rise in nitrogen rate from 76.2 to 76.3 kg hl−1. According to Schwerz et al. (2015), the application of a growth retardant (trinexapac-ethyl) increased the TKW of wheat.

The classification models based on selected morphological and textural variables with the highest discriminative power were built to discriminate the experimental groups (Table 3). The models based on selected morphological features were characterized by the lowest classification accuracy, which ranged from 27 to 34% for the samples harvested in 2015 and from 25 to 35% for the grain collected in 2016. In the next stage of the analysis, the models containing textural attributes from color spaces RGB, Lab and XYZ were used to discriminate the experimental groups. Classification accuracy reached 37–43% for the samples harvested in 2015 and 33–39% for the samples collected in 2016. Classification accuracy was highest in the models combining morphological and textural properties (57–62% for the samples collected in 2015 and 47–58% for the grain harvested in 2016). In this study, classification accuracy was low, which could imply that the experimental factors had a minor influence on the properties of grain harvested from various treatments. According to Zapotoczny et al. (2016), the seeds of plants subjected to various cultivation conditions can be distinguished based on their properties. In the cited study, fenugreek seeds harvested from plots with different seed inoculation treatments, sowing dates, row spacing, weed control and chemical protection treatments were discriminated with a total accuracy of 18–43% in a model containing morphological (geometric) properties, and with a total accuracy of 50–65% in a model based on textural parameters. Higher classification accuracies were obtained for different cultivars of seeds and grain. Ropelewska et al. (2017) reported that winter, spring, open-pollinated and hybrid rapeseed cultivars were discriminated with a total accuracy of 68–74% based on geometric parameters and 67–87% based on textural features. Similar results were noted in our study where classification accuracy was higher in the model based on textural properties than in the model containing geometric parameters. In several studies of barley grain, classification accuracy exceeded 96% in models based on morphological, optical and textural parameters, and in a model combining all features (Paliwal et al. 2003; Choudhary et al. 2008; Douik and Abdellaoui 2010; Zapotoczny 2012).

Different combinations of nitrogen fertilization and the growth retardant did not affect the thermal properties of wheat grain. None of the investigated parameters differed significantly between treatments (Table 4). Grain harvested in 2015 was characterized by thermal conductivity of 0.158 to 0.164 W m−1 K−1, thermal resistivity of 623.0 to 657.7 °C cm W−1, volumetric heat capacity of 1.493 to 1.587 MJ m−3 K−1, and thermal diffusivity of 0.100 to 0.104 mm2 s−1. In grain sampled in 2016, thermal conductivity was determined in the range of 0.140 to 0.149 W m−1 K−1, thermal resistivity − 670.8 to 728.9 °C cm W−1, volumetric heat capacity − 1.257 to 1.440 MJ m−3 K−1, and thermal diffusivity − 0.103 to 0.112 mm2 s−1. Similar values of selected thermal parameters of cereal and “pseudo-cereal” grain were found in the literature. The thermal conductivity of barley grain was determined at 0.124–0.155 W m−1 K−1 by Markowski and Białobrzewski (2013) and at 0.161–0.175 W m−1 K−1 by Jangi et al. (2011). According to Suleiman et al. (2015), thermal conductivity was 0.129 W m−1 K−1 for chia, 0.137 W m−1 K−1 for farro, 0.138 W m−1 K−1 for kañiwa and 0.170 W m−1 K−1 for triticale grain. The above authors determined thermal diffusivity at 0.093 mm2 s−1 for chia, 0.098 mm2 s−1 for farro, 0.092 mm2 s−1 for kañiwa and 0.102 mm2 s−1 for triticale. There is a general scarcity of published data regarding the combined effects of nitrogen fertilizer and growth retardant on the thermal properties of cereal grain. Gous et al. (2015) analyzed the thermal properties of starch extracted from barley grain grown with nitrogen fertilizer and found that different rates of fertilization exerted a minor influence on starch gelatinization temperature. The results of our study expand the existing knowledge about the properties of cereal grain subjected to nitrogen fertilization and a growth retardant.

4 Conclusions

Selected physical, morphological and thermal properties of durum wheat grain were determined. The effects of nitrogen fertilizer and a growth retardant were evaluated and compared with the control sample. The control samples of durum wheat grain grown without nitrogen fertilization and without a growth retardant were characterized by the lowest values of selected physical and morphological properties, including TKW, bulk density, linear dimensions (length, width) and shape factors (specific perimeter of object boundary, Danielsson coefficient). Different combinations of nitrogen fertilizer and the growth retardant increased the values of the analyzed parameters. However, nitrogen fertilization and the growth retardant did not induce significant changes in the true density and thermal properties of wheat grain. The determined properties of grain can be useful for designing grain transport, separation and sorting processes and packaging equipment, and for optimizing grain processing operations.

References

Ayadi S, Karmous C, Chamekh Z, Hammami Z, Baraket M, Esposito S, Rezgui S, Trifa Y (2016) Effects of nitrogen rates on grain yield and nitrogen agronomic efficiency of durum wheat genotypes under different environments. Ann Appl Biol 168:264–273

Baldi S (2012) Italian Grain and Feed Report. Gain Report Number: IT 1212. Global Agricultural Information Network

Barnwal P, Singh KK, Sharma A, Choudhary AK, Saxena SN (2015) Influence of pin and hammer mill on grinding characteristics, thermal and antioxidant properties of coriander powder. J Food Sci Technol 52(12):7783–7794

Bouckaert RR, Frank E, Hall M, Kirkby R, Reutemann P, Seewald A, Scuse D (2016) WEKA Manual for Version 3-9-1. The University of Waikato, Hamilton

Butscher D, Zimmermann D, Schuppler M, von Rohr PhR (2016) Plasma inactivation of bacterial endospores on wheat grains and polymeric model substrates in a dielectric barrier discharge. Food Control 60:636–645

Choudhary R, Paliwal J, Jayas DS (2008) Classification of cereal grains using wavelet, morphological, colour, and textural features of non-touching kernel images. Biosyst Eng 99:330–337

Douik A, Abdellaoui M (2010) Cereal grain classification by optimal features and intelligent classifiers. Int J Comput Commun 4:506–516

El-Khayat GH, Samaan J, Manthey FA, Fuller MP, Brennan ChS (2006) Durum wheat quality I: some physical and chemical characteristics of Syrian durum wheat genotypes. Int J Food Sci Technol 41(Supplement 2):22–29

Gous PW, Warren F, Mo OW, Gilbert RG, Fox GP (2015) The effects of variable nitrogen application on barley starch structure under drought stress. J Inst Brew 121:502–509

Harasim E, Wesołowski M (2013) Yield and some quality traits of winter wheat (Triticum aestivum L.) grain as influenced by the application of different rates of nitrogen. Acta Agrobot 66(3):67–72

Jangi AN, Mortazavi SA., Tavakoli M, Ghanbari A, Tavakolipour H, Haghayegh GH (2011) Comparison of Mechanical and thermal properties between two varieties of barley (Hordeum vulgare L.) grain. Aust J Agric Eng 2(5):132–139

Kadam DM, Kaushik P, Kumar R (2012) Evaluation of guava products quality. Int J Food Sci Nutr Eng 2(1):7–11

Lever T, Haines P, Rouquerol J, Charsley EL, Van Eckeren P, Burlett DJ (2014) ICTAC nomenclature of thermal analysis (IUPAC Recommendations 2014). Pure Appl Chem 86(4):545–553

Makowska A, Obuchowski W, Sulewska H, Koziara W, Paschke H (2008) Effect of nitrogen fertilization of durum wheat varieties on some characteristics important for pasta production. Acta Sci Pol Technol Aliment 7(1):29–39

Markowski M, Białobrzewski I (2013) Bulk thermal conductivity of malting barley. Ind Crop Prod 42:369–372

Mercali GD, Sarkis JR, Jaeschke DP, Tessaro IC, Marczak LDF (2011) Physical properties of acerola and blueberry pulps. J Food Eng 106:283–289

Moreno A, Moreno MM, Ribas F, Cabello MJ (2003) Influence of nitrogen fertilizer on grain yield of barley (Hordeum vulgare L.) under irrigated conditions. Span J Agric Res 1(1): 91–100

Nuttall JG, O’Leary GJ, Panozzo JF, Walker CK, Barlow KM, Fitzgerald GJ (2017) Models of grain quality in wheat—a review. Field Crop Res 202:136–145

Paliwal J, Visen NS, Jayas DS, White NDG (2003) Cereal grain and dockage identification using machine vision. Biosyst Eng 85(1):51–57

Pan S, Liu H, Mo Z, Patterson B, Duan M, Tian H, Hu S, Tang X (2017) Shading on root morphologies, nutrient accumulation, and photosynthetic parameters in different rice genotypes. Sci Rep 7:45611

Paquet-Durand O, Zettel V, Kohlus R, Hitzmann B (2015) Optimal design of experiments and measurements of the water sorption process of wheat grains using a modified Peleg model. J Food Eng 165:166–171

Perussello CA, Mariani VC, Masson ML, de Castilhos F (2015) Thermophysical properties of yacon (Smallanthus sonchifolius): experimental determination and effect of moisture content. Acta Sci-Technol 37:167–173

PN-68/R-74017 Cereal grain and edible legume seeds. Determination of the weight of 1000 grains

PN-EN 1097-6:2013 Tests for mechanical and physical properties of aggregates. Determination of particle density and water absorption

PN-EN ISO 7971-3:2010 Cereals—determination of bulk density, called mass per hectolitre—part 3: routine method

PN-EN ISO 712:2012 Cereals and cereal products—determination of moisture content—reference method

Rajala A (2003) Plant growth regulators to manipulate cereal growth in Northern growing conditions. University of Helsinki, Finland. Academic Dissertation. ISBN 952-10-0972-1, 53

Ropelewska E (2018) Relationship of thermal properties and ergosterol content of barley grains. J Cereal Sci 79:328–334

Ropelewska E, Zapotoczny P (2018) Classification of Fusarium-infected and healthy wheat kernels based on features from hyperspectral images and flatbed scanner images: a comparative analysis. Eur Food Res Technol 244:1453–1462

Ropelewska E, Zapotoczny P, Budzyński WS, Jankowski KJ (2017) Discriminating power of selected physical properties of seeds of various rapeseed (Brassica napus L.) cultivars. J Cereal Sci 73:62–67

Schwerz F, Caron BO, Shmidt D, de Oliveira DM, Elli EF, Eloy E, Rockenbach AP (2015) Growth retardant and nitrogen levels in wheat agronomic characteristics. Científica 43(2):93–100

Shekoofa A, Emam Y (2008) Effects of nitrogen fertilization and plant growth regulators (PGRs) on yield of wheat (Triticum aestivum L.) cv. Shiraz. J Agric Sci Technol 10:101–108

Suleiman R, Xie K, Rosentrater K (2015) Physical and thermal properties of chia, kańiwa, triticale and farro as a function of moisture content. ASABE annual international meeting, New Orleans, Louisiana, July 26-29, pp 1–38

Szczypiński PM, Strzelecki M, Materka A, Klepaczko A (2009) MaZda—a software package for image texture analysis. Comp Meth Prog Biol 94(1):66–76

Tabatabaeefar A (2003) Moisture-dependent physical properties of wheat. Int Agrophys 17:207–211

Warechowska M, Warechowski J, Markowska A (2013) Interrelations between selected physical and technological properties of wheat grain. Tech Sci 16(4):281–290

Yıldız G, İzli N, Ünal H, Uylaşer V (2015) Physical and chemical characteristics of goldenberry fruit (Physalis peruviana L.). J Food Sci Technol 52(4):2320–2327

Zapotoczny P (2011) Discrimination of wheat grain varieties using image analysis: morphological features. Eur Food Res Technol 233:769–779

Zapotoczny P (2012) Application of image texture analysis for varietal classification of barley. Int Agrophys 26:81–90

Zapotoczny P, Żuk-Gołaszewska K, Ropelewska E (2016) Discrimination based on changes in the physical properties of fenugreek (Trigonella foenum-graecum L.) seeds subjected to various cultivation conditions. Eur Food Res Technol 242(3):405–414

Żuk-Gołaszewska K, Żerańska A, Krukowska A, Bojarczuk J (2016) Biofortification of the nutritional value of foods from the grain of Triticum durum Desf. by an agrotechnical method: a scientific review. J Elementol 21(3):963–975

Funding

This study was conducted as part of a comprehensive research project financed by the University of Warmia and Mazury in Olsztyn (Grant no. 16.610.001-300) and by the National Science Centre in Poland (Grant no. 2015/17/B/NZ9/03601).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Ropelewska, E., Zapotoczny, P., Bożek, K.S. et al. Thermal, physical and morphological properties of durum wheat. J Consum Prot Food Saf 14, 131–137 (2019). https://doi.org/10.1007/s00003-018-1196-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00003-018-1196-3