Abstract

This study includes the application of graft copolymer (polyacrylamide-grafted polyvinyl pyrrolidone—PVP-g-PAM) as wound healing agent. It is hypothesized that the branches of the graft copolymer adsorb at various colloidal components of blood plasma—thus assisting in formation of a networked structure, i.e. ‘blood clot’. Further, the adhesive property of graft copolymer supports in wound closure and immobilization of pathogens. Wound healing efficiency of PVP-g-PAM has been investigated ‘in vivo’ by excision and incision wound model. The 100% wound contraction has been shown by PVP-g-PAM after 13 days. This is superior to both in cases of standard drug and ungrafted polyvinyl pyrrolidone (PVP), which fails to achieve complete wound closure even after 21 days. Additionally, the graft copolymer-treated mice’s skin exhibited higher tensile strength than that of standard drug, PVP and stitched model.

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Fast recovery from a trauma is directly linked with accelerated healing of wound. Wound dressing/closure is essential to restore and repair the damaged epidermal and dermal tissues and for skin regeneration. Contemporary approaches discourage stitching and stapling for open wound closure as these are coupled with infection and granule formation (as a consequence of their degradation in the body) along with many other shortcomings, such as the related pain/trauma of the procedure [1]. Therefore, topical application of medical tissue adhesives is in forefront of wound management since they have several advantages over conventional methods of wound closure. Advantages include less traumatic, non requirement of anaesthesia, effective as haemostatic agent and may seal air leakages. Due to their effect on local cellular response, they work to sustain the moisture and oxygen at the wound, protect peri-wound skin, prevent microbial contamination, reduce pain, control the odours and eliminate dead spaces and nonviable cells.

From the last few years, the fabrication of biomimetic products has been found to be effective for wound healing [2]. Natural polysaccharides (such as chitin) [3] and proteins (like gelatine) [4, 5] are the largely used bioadhesives, but due to their lack of efficiency and microbial and water susceptibility, they have been replaced by synthetic one [6, 7]. Currently, fibrin-based adhesives [8, 9] and cyanoacrylates (owing to have high adhesion property) [10] are frequently applied as an alternative of natural bioadhesives, but these pose numerous troubles associated with immunogenicity and blood-borne disorders like HIV (human immunodeficiency virus) and BSE (bovine spongiform encephalopathy) [11, 12]. Moreover, cyanoacrylates release formaldehyde, a carcinogenic product [13] and have low biocompatibility [1].

Regardless of various prominent researches, none of the present bio-origin adhesives hold satisfactory controlled degradability and wet tissue adhesion strength for sutureless wound treatment [14]. Thus, scientists are continually trying to develop novel materials with controllable degradability, high wet adhesion strength, enhanced biocompatibility and significantly lower manufacturing expenditure.

A graft copolymer-based adhesive consists of long and flexible side chains. When the force is applied to such product (having customized architecture) to separate the adhesion bond, the developed network (links between wound cells and adhesive molecules) disperses the stress thus generated along the polymer bulk, without compromising the surface and hence defends the adhesion focal point. In case of synthetic polymers, it is feasible to incorporate the custom-built properties appropriate to the intended application by revising the chemical composition and orientation of distinct functional groups so that they can interact with biological cells. The product thus obtained has a strong affinity towards cells, therefore adheres to wound tissues without any difficulty and thus “mimic” in the final stage of the blood clotting process. However, there are several other physiological, chemical and mechanical processes involved in the course of wound healing.

It is supposed that the synthetic polymers having property to adhere to biological tissues cure the wound by overlapping evenly the incision edges. Some examples are polyacrylic acid derivatives, polyacrylate, poly(methacrylate) and some cellulose derivatives. Furthermore, the biological polymer such as fibrin and collagen has inherent haemostatic characteristic that supports in the coagulation process [15].

Natural polymers exhibit comparatively low mechanical strength than synthetic polymers. A number of polymeric materials have been investigated to study the cell-polymer interactions. Examples include polyacrylamide (PAM), polydimethylsiloxane (PDMS), alginate and agarose, etc. These materials necessitate surface modification (generally covalent modification viz. the surface is resistant to protein adsorption) to endorse cell adhesion. Indeed, the maximum studies evaluating the material mechanics affected on cell behaviour have been accomplished with polyacrylamide as it is simple and well-characterized macromolecules. Several studies exhibited that the acrylamide (a neurotoxin) does not discharge from polyacrylamide during degradation [16, 17]. Hence, it does not induce bio-toxicity and bioaccumulation.

By suitable modifications like grafting, cross-linking or blending with appropriate substances [18,19,20,21,22,23,24,25], the mechanical strength of preformed polymers can be enhanced; however, their biocompatibility may be affected up to some extent. The key advantages of these modified polymers include anti-haemorrhage effect along with tissue adhesion and wound healing activity. These properties are mainly due to the high water content and tissue-like consistency. The application of modified polymers may eradicate the threat of blood transmission diseases.

PVP is a functional, synthetic and biodegradable polymer. It is the most common compound used in pharmaceutical applications such as a tablet binder, as a lubricant in some ophthalmological solution and in contact lens solutions. Povidone–iodine complex is used as a disinfectant. It helps in enhancing the solubility of drugs and prevents its recrystallisation. It is also used in the preparation of membranes used in dialysis and water purification. It is used as food additive, as stabilizer and has E number—E1201. It is approved by US Food and Drug Administration for multiple applications and is generally regarded as safe [26].

PVP hydrogel membranes synthesized by radiation cross-linking have been studied earlier for skin regeneration and wound dressing by Darwis [27] and his coworkers and Himly [28] and his coworkers. They reported that the resilient and impermeable to bacteria membranes were fit only for healthy skin but not for wound dressing [29].

In the present study, the long, coiled side chains of polyacrylamide (PAM) have been incorporated onto the skeleton of preformed polymer—PVP, using acrylamide (as a monomer) and ceric ammonium nitrate (CAN) as the chemical-free radical initiator via microwave radiation resulting to the development of graft copolymer (PVP-g-PAM). Although the parent polymer (PVP) has some adhesive property, but the prime reason of structural modification of PVP is to enhance its bonding strength and to control its rate of degradation (growing with the increase in the grafted chains). The resultant product was then characterized by several techniques that included 13C NMR, XRD, FTIR, SEM, TGA, etc.

Wound healing activity of the synthesized graft copolymer has been evaluated ‘in vivo’ via incision and excision wound model using swiss albino mice, and it proved to be efficient to bind with the wet tissue precisely as well as it has wound healing property.

The increased tensile strength indicates improved wound healing stimulation. Thus, in the meticulous area of injured tissue healing, PVP-g-PAM may be considered as a sealant (bioadhesive), that is to say, as a suture adjuvant that supports healing of the injury.

Materials and methods

Materials

Male swiss albino mice (weight around 25 g) were procured from laboratory animal house of department of pharmaceutical sciences and technology (Birla Institute of Technology, Mesra, Ranchi, India). All animal experiments strictly comply with approval of institutional animal ethical committee (Protocol no. PROV/BIT/PH/IAEC/21/2016). Animals were given regularly with water and food during the entire period of study.

Microwave-assisted synthesis of polyacrylamide-grafted polyvinyl pyrrolidone (PVP-g-PAM)

This method involves the synergism of chemical-free radical initiator (CAN) and microwave radiation to develop the free radical sites on the polymer backbone (PVP) [30, 31]. The synthesis details and proposed mechanism have been well described in our earlier study [32]. In short, a uniform aqueous solution of PVP, monomer—acrylamide and free radical initiator—CAN have been prepared at about 50 °C. The mixture was then microwave irradiated until the gel has been formed (2 min). The product thus obtained was precipitated in an excess of acetone. Dried, fine powder of synthesized graft copolymer was prepared for further use. A series of five different grades of graft copolymer has been synthesized by varying the concentration of acrylamide and CAN. The composition of various grades is tabulated in Table 1 and mechanism of synthesis is proposed in Scheme 1.

Characterization of graft copolymer

The structural modification of synthesized graft copolymers was evident by various physico-chemical techniques and discussed earlier [32]. However, some more characterization techniques have been discussed further.

13C NMR spectra of PVP and PVP-g-PAM were recorded at 400 MHz with an NMR spectrophotometer (Model: 400 YH; Make: Jeol) using deuterium oxide (D2O) as a solvent. The spectra are illustrated in Fig. 1a, b.

Qualitative X-ray diffraction study of PVP and PVP-g-PAM has been evaluated by X-ray diffractometer (Make: Rigako, smart lab, 9 kV). The instrument was operated under the condition of 45 kV voltage and 200 mA current. The 10°/min scan rate was applied in fine-powdered samples. Scattering angle (2θ) was varied from 10 to 80°. The diffractogram is shown in Fig. 1c.

FTIR spectra of finely ground sample were recorded via KBr pellet method using FTIR spectrophotometer (Model IR-Prestige 21, Shimadzu Corporation, Japan). The spectral range was 4000–500 cm−1. The investigation has been accomplished at a resolution of 10 cm−1. The spectra are given in Fig. 2a, b.

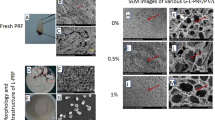

The surface morphological profile of the graft copolymers was obtained at various magnifications by scanning electron microscope (SEM) (Model: JSM-6390LV, Jeol, Japan). The finely ground samples were coated with platinum. Analysis has been carried out at a voltage of 5 kV. The microscopic images have been displayed and compared with that of PVP in Fig. 3a–d.

The concerned TGA data have been obtained from TGA instrument (Model: DTG-60; Shimadzu, Japan). The weight loss has been measured in the temperature range of 30–580 °C at a heating rate of 50 °C min−1 under nitrogen atmosphere. The thermogram is given in Fig. 4a, b.

Wound healing activity of synthesized graft copolymer

Excision wound model

The mice were anesthetized by open mask method with diethyl ether. After 30 min, a full thickness excision wound of the area of 10 mm diameter and 2 mm depth has been made by a surgical blade on the shaved back of the mice. The wounding day is regarded as day 0. The experimental animal groups were treated with topical application of the base gel, PVP, and all synthesized grades of graft copolymers of PVP and standard drug till the wound healed completely (i.e. 21 days) [33, 34]. The animals were divided into eight groups of six animals each.

Group 1–5: regarded as test group treated with five different grades of PVP-g-PAM for 21 days.

Group 6: regarded as test group treated with PVP.

Group 7: regarded as reference standard group treated with commercial antibiotic.

Group 8: regarded as control group treated with base gel.

A gradual reduction in the wound area has been observed periodically and measured on every alternate day viz. 3rd, 5th, 7th, 9th, 11th, 13th, 15th, 17th, 19th, 21st post-wounding days, and the mean percentage of wound contraction has been calculated [35, 36]. Wound area was measured by tracing the wound on a millimeter scale graph paper on every second day. The span of epithelialization has been measured as the number of days needed for filling of the dead tissue fragments devoid of whichever remaining unhealed wound. The granulation tissues have been seen on 13th, 15th, 17th and 21st post-wound days (after 100% wound contraction has been shown by the group of animals) and analysed for protein content (collagen). Photographical representation of excision wound healing is shown in Fig. 5a. The percentage wound healing was computed with the help of following formula [37], and the results are summarized in Table 2 and are graphically presented in Fig. 5b.

where n = number of days, i.e. 3rd, 5th, 7th, 9th, 11th, 13th, 15th, 17th, 19th, 21st post-wounding days.

Incision wound model

In the incision model [35, 38, 39], the mice have been anesthetized by open mask method using diethyl ether. One longitudinal peravertebral incision of about 2 mm length and 2 mm deep has been created through the skin and cutaneous muscle at a distance about 1.5 cm from the central-line on both side of the hairless back of the mice. The animals were divided into nine groups of six animals each.

Group 1–5: regarded as test group treated with five different grades of PVP-g-PAM for 21 days.

Group 6: regarded as test group treated with PVP.

Group 7: regarded as reference standard group treated with commercial antibiotic.

Group 8: regarded as control (treated with base gel).

Group 9: regarded as stitched model (untreated, only stitches given).

After the incision, the wounds have been treated by the same manner as that of the excision wound model, i.e. with topical application of the base gel, PVP, and all synthesized grades of graft copolymers of PVP and standard drug till the wound healed completely. The wounds have been observed regularly, and the tensile strength of newly formed skin has been measured on 10th day [40] (after complete healing of wound).

A tiny portion of healed wound (skin) was cut out. Four curved needles were pierced through the skin, two on each side. The one side two needles were fixed to a shaft, and the other side two needles were attached to a plastic bag, which hang up freely in the air (the each side of needles were kept at equal distance from the healed wound). Then, water was poured bit by bit to a plastic bag until the skin broken into two parts. The weight of water in the bag has been regarded as an indirect evaluation of tensile strength of the healed skin. Photographic representation of tensile strength measurement is given in Fig. 6a.

Stitched model

In this model, the incision was made in an anaesthetized animal as in case of incision wound model. In this case, the cleaved skin was kept jointly and stitched with the help of a curved needle (No. 11) and surgical thread (No. 000) at 0.5 cm intervals. The continuous threads were stitched on both wound ends for good closing of wound. The wound remained untreated. The sutures were separated on 9th day and tensile strength was analysed on 10th day (Fig. 6b).

Tensile strength measurement

The tensile strength of the healed skin corresponds to the extent of wound healing as wound healing agents enhance the tensile strength [41, 42]. The tensile strength of the graft copolymer-treated wounds was compared with that of control and standard drug-treated animals and with stitched model. The increased tensile strength signifies improved wound healing stimulation by the applied samples. The tensile strength has been computed by applying the equation given below:

The tensile strength of tissues treated with various grades of graft copolymer is graphically presented in Fig. 6c.

Statistical analysis

The readings were taken from six individual experiment, and results are expressed as mean ± SEM (n = 6). *P < 0.05, **P < 0.01, ***P < 0.0001, ns-not significant, when all synthesized grades compare to standard, PVP and control. One way ANOVA followed by Bonferroni’s comparison test (with 95% confidence level) has been done to calculate the percentage contraction in excision wound model. All values in Table 2 contain ***. The statistical computation and plotting of graphs were accomplished via GraphPad Prism software, version 7.03.

Result and discussion

Microwave-assisted synthesis of (PVP-g-PAM)

Five distinct grades of PVP-g-PAM have been synthesized by free radical mechanism using microwave radiation in synergism with CAN. In a polar solvent (water), PVP molecule undergoes keto–enol tautomerism [32] (Scheme 1) to generate reactive enol form which readily reacts with Ce(IV) leading to the formation of complex [43].

Microwave radiation rotates the small polar molecules (water) entirely resulting to the heat generation only. In such a condition, no bond undergoes cleavage and hence does not result in the generation of free radicals. While in case of macromolecules, only the polar bonds like –OH, –COOH in the functional groups of molecules (such as the ‘–OH’ group in ‘enol’ form of PVP) rotate in the presence of microwave radiation, whereas the not so polar bond (like C–C, –CH bonds of main polymeric structure) persists inactive under microwave conditions. This partial rotary motion of macromolecules consequences the cleavage of polar bonds, thus leads to the development of free radicals [44].

It is believed that ‘Ce’ reacts with the –OH bond of macromolecule and develops ‘–O–Ce’ bond. The microwave radiation can rotate ‘–O–Ce’ bond more forcefully as it is highly polar than –OH bond. This leads to the formation of free radicals onto the PVP backbone. These free radicals interact with acrylamide to produce graft copolymer via typical free radical reaction mechanism. The long, coiled chains of polyacrylamide were grown onto the backbone of PVP. The proposed microwave-assisted synthesis is depicted in Scheme 1.

Characterization of graft copolymer

13C NMR spectroscopy

13C NMR spectrum of PVP (Fig. 1a) has various peaks. The peaks in the range δ = 31–35 ppm belong to C1 and C5 of PVP molecule. The peaks in the range δ = 42–45 ppm may be attributed to the C2 and C3. A sharp peak at δ = 17 ppm corresponds to C4 of the ring. A small peaks in the range 177–181 ppm correspond to C=O (C6) of lactam group (cyclic amide) of PVP [45].

In addition to the peaks in the range δ = 33–41 ppm, the most significant trait in the NMR spectrum of graft copolymer (Fig. 1b) is the sharp, and intense peaks appeared in the range δ = 179 ppm correspond to the C=O group of grafted acrylamide (monomer). The presence and high intensity of this peak confirm the grafting of PAM chains onto the PVP backbone.

Qualitative analysis of XRD

The diffractogram of PVP and PVP-g-PAM is shown in Fig. 1c. There is significant modification in the intensity of the XRD peaks of the specimen. The diffractogram of pure PVP consists of two sharp peaks at around 2θ = 11.12° and 21.32°, exhibiting small crystallinity in its structure.

However, when PAM chains were incorporated into PVP, synthesizing graft copolymer, the intensity of the peaks reduces and become broader as shown in Fig. 1c, i.e. one broad peak at 2θ = 18.49° and a very small peak at 2θ = 37.62°. A reduction in intensity and an increase in width of the peak were observed indicating the transformation of crystal phase of the PVP into amorphous phase. The increase in amorphousness indicates disordered arrangement of molecules in the polymer structure due to the attachment of lengthy and dangling PAM chains [46].

FTIR spectroscopy

In the FTIR spectrum of PVP (Fig. 2a), a sharp peak at 3549 cm−1 may be attributed to the N–H stretching. The peaks at 2951 and 2873 cm−1 are associated with asymmetric C–H stretching vibrations. The peak at 1681 cm−1 belongs to C=O of lactam group. The peaks at 1438 and 1288 cm−1 may assign to C–C ring stretching and C–N stretching absorption, respectively.

Similarly, in the FTIR spectrum of PVP-g-PAM (Fig. 2b), the peaks at 2889 and 2769 cm−1 are attributed to C–H stretching vibrations. The most noteworthy change is the diminished intensity of the peak at 1689 cm−1 which corresponds to C=O group of amide molecule. Further, the intensity of the peaks at 1446 and 1215 cm−1 which belongs to CH2 bending vibration and CH2 twist, respectively, has been reduced in the spectrum of graft copolymer. The increased intensity of the peak at 987 cm−1 which belongs to C–O–C stretching vibrations indicates the new bond formation. These modifications in the spectra verify the occurrence of grafted PAM chains in the PVP structure.

SEM analysis

After grafting, the glaze, uniform surface of PVP (Fig. 3a, b) has been thoroughly modified to rough, coarse (fibrillar) structure as noticed from SEM micrographs (Fig. 3c, d). These changes may be attributed to the bonding of grafted monomer side chains (PAM) onto the structure of native PVP. These modifications verify the planned graft copolymerization and are similar with those observed in case of other graft copolymers [31].

Thermal analysis

The TGA thermogram of PVP (Fig. 4a) shows that the polymer is thermally stable up to 320 °C. On further increasing the temperature up to 500 °C, it readily degraded due to thermolysis of complete PVP backbone.

There is a gradual weight loss in case of graft copolymer in three different range of temperature (Fig. 4b). First range (30–320 °C) may be assigned to the dehydration and disintegration of grafted chains. The second range (320–400 °C) indicates the decomposition of graft copolymer into its organic components, and third range (400–580 °C) exhibits the steady and complete degradation of graft copolymer.

Wound healing activity of synthesized graft copolymer

Excision wound model

The results from excision model exhibited that all grades of synthesized graft copolymers have noteworthy wound healing property by reducing duration of epithelisation, by enhancing formation of granulation tissue, formation of collagen and have greater rate of wound contraction as compared to the control, standard drug and PVP-treated animals (Table 2 and Fig. 5b).

In this study, the various grades of synthesized graft copolymers showed much better wound healing property compared to that of control, standard and unmodified PVP in both parameters evaluated viz. wound contraction and epithelization period. From Table 2 and Fig. 5b, it is evident that for PVP-g-PAM 3 wound contraction was 100% by 13th day followed by 15th day for PVP-g-PAM 5, while for PVP-g-PAM 1, PVP-g-PAM 2 and PVP-g-PAM 4, it was by 17th day. On the other hand, for standard drug, it was by 19th day and 100% wound contraction has not been exhibited by the control (base gel) and PVP even after 21 day.

Incision, stitched wound model and tensile strength measurement

Tensile strength is the resistance to breaking under tension. It implies how much the healed tissue resists breaking under tension and may express the quality of the cured tissue. Usually, wound healing agents enhance the tensile strength. In incision model, the tensile strength of all synthesized grades of graft copolymer (except PVP-g-PAM 3) was found to be higher than that of control, standard drug and stitched model revealing the presence of good collagen formation (Fig. 6a–c).

The results obtained from our ‘in vivo’ experiments show that in accelerating wound healing process, all grades of synthesized PVP-g-PAM were more efficient than control (base gel), PVP and antibiotic used (standard drug). This superiority was supposed to occur from the stable physical cross-linked network of interchain hydrogen bonds formed around grafted PAM chains in the aqueous environment, which may work as a supporting structure for cell proliferation and migration during entire wound healing period. In other words, it mimics the mechanical support provided by extra-cellular matrix in promoting the growth and arrangement of cells during the restoration of injured tissue.

Further, it has already been well studied that graft copolymer acts as a flocculant in various other systems like wastewater treatment [22, 24], algal biomass harvesting [32], mineral ore beneficiation, etc. so it may be believed that it also takes part in haemostasis process during wound healing course. For instance, in the work reported here, it has been shown that the synthesized flocculant (PVP-g-PAM) encourages the local concentration (agglomeration) of RBCs, platelets and other coagulation factors and fasten the adhering of the blood component to its surface leaving behind the water (constituent of blood). Further, the colloid substance (floc) accumulated after blood flocculation can adhere the graft copolymer to the bleeding wound, push the wound vicinity and manage the uncontrolled haemorrhage effectively as a physical barrier. The accumulated colloid thus enhances blood viscosity and embellishes the conveyance of platelets to the vascular wall for the natural physiological haemostasis. The floc (clot) dries and develops a scab which in turn gives support and strength to the wounded tissue. Thus, haemostasis acts as a supporter as well as assists in prompt wound healing [47]. The wound healing properties of graft copolymer come from two aspects. Firstly, the branches of the graft copolymer adsorb at different colloidal components of blood plasma—thus assisting in formation of a networked structure, i.e. ‘blood clot’—that stops bleeding. Secondly, the adhesive property of graft copolymer leads to wound closure and immobilization of pathogens if any. Besides, as other structurally modified polymers used in tissue regeneration, PVP derivative (PVP-g-PAM) may also transform wound site inflammation and may take part in their ultimate interaction with particular receptors of the cells concerned in tissue rehabilitation mechanisms.

PVP-based graft copolymer acts positively throughout the healing period. Graft copolymer promotes surface-induced thrombosis and haemostasis instantly after skin damage that inhibits exsanguinations and develops a matrix to invade cells required for healing. Graft copolymer encourages natural blood coagulation by affecting platelets activity and clogs nerve endings and consequently decreases pain. Graft copolymer can regulate the activity of cells responsible for inflammation and growth factors thus develop a suitable inflammatory microenvironment favourable for healing. Grafted product may increases the various tissues repairing. Graft copolymer acts as a non-protein matrix for three-dimensional tissue growth and activates macrophages during proliferation phase. It induces fibroblast proliferation, angiogenesis, collagen deposition and remodelling thus supports prompt healing. Further, graft copolymer covers the wound area and thus inhibits pathogenic micro-organisms.

It is further evident from the results obtained from tensile strength measurement (incision model) that the new skin, developed after treating the wound with graft copolymer, has more tensile strength (load bearing capacity) than that of treated with control and unmodified PVP.

Statistical analysis

Wound contraction results exhibited by various grades of synthesized graft copolymers are highly significant, i.e. P value summary is *** and P value is < 0.0001.

Conclusion

Our study supports that the application of PVP-g-PAM as a bioadhesive is greatly beneficial and may have high impact on treatment where surgical bioadhesives, haemostatic agents, sealants, etc. are required.

The potential activity of synthesized graft copolymers in the therapeutic treatment of wound was examined via ‘in vivo’ experiments. The effect of graft copolymer on local cellular response has been revealed by enhancing moisture retention, wound collagen matrix, reducing exudates and improving the epithelialization process by adhesion and haemostatic property. The adhesive property of graft copolymer plays a key role in the wound healing process as mechanical support for cell proliferation and migration. Thus, based on the remarkable properties (graft copolymer exhibited a considerable enhancement in the wound closure rate), a significant use can be envisioned for this novel functional materials.

Since a generous awareness regarding the development of moist dressings which can replicate the characteristics of skin and which can reside in contact with the wound without trouble for entire period of healing is still going on, this graft copolymer may comprise an additional value in these biological applications.

References

Ghosh S, Cabral JD, Hanton LR, Moratti SC (2016) Strong poly(ethylene oxide) based gel adhesives via oxime cross-linking. Acta Biomate 29:206–214

Mogosanu GD, Grumezescu AM (2014) Natural and synthetic polymers for wounds and burns dressing. Int J Pharm 463:127–136

Han SS (2005) Topical formulations of water-soluble chitin as a wound healing assistant. Fiber Polym 6:219–223

Ulubayram K, Aksu E, Gurhan SID, Serbetci K, Hasirci N (2002) Cytotoxicity evaluation of gelatin sponges prepared with different cross-linking agents. J Biomater Sci Polym 13:1203–1219

Choi YS, Lee SB, Hong SR, Lee YM, Song KW, Park MH (2001) Studies on gelatin-based sponges. Part III: a comparative study of cross-linked gelatin/alginate, gelatin/hyaluronate and chitosan/hyaluronate sponges and their application as a wound dressing in full-thickness skin defect of rat. J Mater Sci Mater Med 12:67–73

Goh YF, Shakir I, Hussain R (2013) Electrospun fibers for tissue engineering, drug delivery, and wound dressing. J Mater Sci 48:3027–3054

Supaphol P, Suwantong O, Sangsanoh P, Srinivasan S, Jayakumar R, Nair SV (2012) Electrospinning of biocompatible polymers and their potentials in biomedical applications. Adv Polym Sci 246:213–240

Sierra DH (1993) Fibrin sealant adhesive systems: a review of their chemistry, material properties and clinical applications. J Biomater Appl 7:309–352

Spotnitz WD, Burks SG, Prabhu R (2005) Fibrin-based adhesives and hemostatic agents. In: Quinn JV, Decker BC (eds) Tissue adhesives in clinical medicine. Hamilton, Elliniko, pp 77–112

Quinn JV (2005) Tissue adhesives in clinical medicine. In: Quinn JV, Decker BC (eds) Tissue adhesives in clinical medicine. Hamilton, Elliniko, pp 27–76

Radosevich M, Goubran HI, Burnouf T (1997) Fibrin sealant: scientific rationale, production methods, properties, and current clinical use. Vox Sang 72:133–143

Joch C (2003) The safety of fibrin sealants. Cardiovasc Surg 11(1):23–28

Shalaby SW, Shalaby WSW (2004) Cyanoacrylate-based systems as tissue adhesives. In: Shalaby SW, Burg KJL (eds) Absorbable and biodegradable polymers. CRC Press, Boca Raton, pp 59–75

Mehdizadeh M, Weng H, Gyawali D, Tang L, Yang J (2012) Injectable citrate-based mussel-inspired tissue bioadhesives with high wet strength for sutureless wound closure. Biomaterials 33:7972–7983

Busuttil RWA (2003) Comparison of antifibrinolytic agents used in hemostatic fibrin sealants. J Am Coll Surg 197:1021–1028

Caulfield MJ, Qiao GG, Solomon DH (2002) Some aspects of the properties and degradation of polyacrylamides. Chem Rev 102:3067–3083

Vers LM (1999) Determination of acrylamide monomer in polyacrylamide degradation studies by high-performance liquid chromatography. J Chromatogr Sci 37:486–494

Sarkar AK, Mandre NR, Panda AB, Pal S (2013) Amylopectin grafted with poly (acrylic acid): development and application of a high performance flocculant. Carbohydr Polym 95:753–759

Sarkar AK, Pal A, Ghorai S, Mandre NR, Pal S (2014) Efficient removal of malachite green dye using biodegradable graft copolymer derived from amylopectin and poly(acrylic acid). Carbohydr Polym 111:108–115

Das R, Pal S (2013) Hydroxypropyl methyl cellulose grafted with polyacrylamide: application in controlled release of 5-amino salicylic acid. Colloids Surf B Biointerfaces 110:236–241

Das D, Das R, Mandal J, Ghosh A, Pal S (2014) Dextrin crosslinked with poly(lactic acid): a novel hydrogel for controlled drug release application. J Appl Polym Sci 40039:1–12

Pal S, Pal A (2012) Synthesis and characterizing a novel polymeric flocculant based on amylopectin-graft-polyacrylamidegraft-polyacrylic acid [(AP-g-PAM)-g-PAA]. Polym Bull 69:545–560

Das R, Panda AB, Pal S (2012) Synthesis and characterization of a novel polymeric hydrogel based on hydroxypropyl methyl cellulose grafted with polyacrylamide. Cellulose 19:933–945

Das R, Ghorai S, Pal S (2013) Flocculation characteristics of polyacrylamide grafted hydroxypropyl methyl cellulose: an efficient biodegradable flocculant. Chem Eng J 229:144–152

Krishnamoorthi S, Mal D, Singh RP (2007) Characterization of graft copolymer based on polyacrylamide and dextran. Carbohydr Polym 69:371–377

http://www.accessdata.fda.gov/scripts/cder/iig/index.cfm. Accessed April 7, 2010—search on povidone for list of approved items. Inactive Ingredients in FDA Approved Drugs

Darwis D, Hilmy N, Hardiningsih L, Erlinda T (1993) Poly(Nvinylpyrrolidone) hydrogels: 1. Radiation polymerization and crosslinking of N-vinylpyrrolidone. Radiat Phys Chem 42:907–910

Himly N, Darwis D, Hardiningsih L (1993) Poly(n-vinylpyrrolidone) hydrogels: 2. Hydrogel composites as wound dressing for tropical environment. Radiat Phys Chem 4:911–914

Kamoun EA, Chen X, Mohy EMS, Kenawy E-RS (2015) Crosslinked poly(vinyl alcohol) hydrogels, for wound dressing applications: a review of remarkably blended polymers. Arab J Chem 8:1–14

Ghosh S, Pal S (2013) Modified tamarind kernel polysaccharide: a novel matrix for control release of aspirin. Int J Biol Macromol 58:296–300

Pal S, Sen G, Ghosh S, Singh RP (2012) High performance polymeric flocculants based on modified polysaccharides-Microwave assisted synthesis. Carbohydr Polym 87:336–342

Pal P, Pandey JP, Sen G (2017) Sythesis of polyacrylamide grafted polyvinyl pyrollidone (PVP-g-PAM) and study of its application in algal biomass harvesting. Ecol Eng 100:19–27

Kokane DD, More RY, Kale MB, Nehete MN, Mehendale PC, Gadgoli CH (2009) Evaluation of wound healing activity of root of Mimosa pudica. J Ethnopharmacol 124:311–315

Vogel HG (2002) Drug discovery and evaluation-pharmacological assays. Springer, Berlin, pp 951–952

MacKay D, Miller L (2003) Nutritional support for wound healing. Altern Med Rev 8:359–377

Mokadas E, Rotimi VO, Sanyal SC (1998) In vitro activity of Piperacilin itazobactam versus other broad -spectrum antibiotics against nosocomial gram-negative pathogen isolated from burn patients. J Chemother 10:208–214

Kirtikar KR, Basu BD (2008) Indian medicinal plants. CBS Publishers and Distributors, New Delhi, pp 35–45

Khare CP (2007) Indian medicinal plants-an illustrated dictionary, 6th edn. Springer, Berlin, pp 104–105

Nema A, Gupta N, Jain UK (2012) Evaluation of wound healing activity of Tinospora cordifolia. Willd Der Pharm Sin 1:126–130

Houghton PJ, Hylands PJ, Mensah AY, Hensel A, Deters AM (2003) In vitro tests and ethnopharmacological investigations: wound healing as an example. J Ethnopharmacol 100:100–107

Morton JJ, Malone MH (1972) Evaluation of vulnerary activity by an open wound procedure in rats. Arch Int Pharmacodyn Ther 1:117–126

Erlich HP, Hunt TK (1968) Effects of cortisone and vitamin ‘A’ on wound healing. Ann Surg 3:324–328

Ram S, Fecht H-J (2011) Modulating up—energy transfer and violet- blue light emission in gold nanoparticles with surface adsorption of poly (vinyl pyrrolidone) molecules. J Phys Chem C 115:7817–7828

Kaity S, Isaac J, Kumar PM, Bose A, Wong TW, Ghosh A (2013) Microwave assisted synthesis of acrylamide grafted locust bean gum and its application in drug delivery. Carbohydr Polym 98:1083–1094

Oh T-J, Nam J-H, Jung YM (2009) Molecular miscible blend of poly(2-cyano-1-4-phenyleneterephthalamide) and polyvinylpyrrilidone characterized by two- dimensional correlation FTIR and solid state 13C NMR spectroscopy. Vib Spectrosc 51:15–21

Athawale VD, Rathi SC (1997) Synthesis and characterization of starch-poly(methacrylic acid) graft copolymers. J Appl Polym Sci 66:1399–1403

Chen Y, Zhang Y, Wang F, Meng W, Yang X, Li P, Jiang J, Tan H, Zheng Y (2016) Preparation of porous carboxymethyl chitosan grafted poly (acrylic acid) superabsorbent by solvent precipitation and its application as a hemostatic wound dressing. Mater Sci Eng C 63:18–29

Acknowledgement

The authors are grateful to Prof. S. Samanta, Head of the department of Pharmaceutical Sciences and Technology, Birla Institute of Technology, Mesra, Ranchi-835215, Jharkhand, India. This study has been carried out under his kind guidance. We are also thankful to CIF-BIT Mesra for its kind assistance.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pal, P., Rangra, N., Samanta, S. et al. Graft copolymer of PVP—A sutureless, haemostatic bioadhesive for wound healing application. Polym. Bull. 77, 5191–5212 (2020). https://doi.org/10.1007/s00289-019-03013-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-019-03013-5