Abstract

In this study, polyethylene terephthalate (PET) nanofibers are dipped into the extraction of pomegranate leaves (Punica granatum) in aqueous solution operated as a reducing agent to fabricate PET nanofibers with CuO nanoparticles, which are used later for the photocatalytic degradation methylene blue (MB) in aqueous solution. Scanning electron microscopy analysis is used to study the surface nanofiber morphology. UV–visible spectrophotometry is used to determine the concentration of (MB) after photodegradation. Photodegradation of (MB) in this study has shown that the degradation efficiency is affected by many factors like time, pH, and concentration. The results have proved that PET nanofibers/CuO nanoparticles acquire high photodegradation efficiency in a short time.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Organic dye pollutants are produced by fabric, leather, and cosmetics production signaling a significant environmental concern [1]. The problem which the world is facing now is that organic dyes generally have a complex aromatic structure and can display anionic, cationic, and non-ionic properties [2]. These dyes are methylene blue (MB), crystal violet (CV), rhodamine B (RhB), methyl orange (MO), Congo red (CR), and Remazol Black-B (RB5) [3]. The colors of these organic dyes can be observed even at low concentration, making water highly unfavorable, which is risky to human health and the environment [4]. Over 10,000 different types of organic dyes and pigments, with an annual production of more than 0.7 million tons commercially exist, and 5–10% of the organic dye material is lost as industrial discharge [5].

There are various techniques for the removal of dyes from wastewater, such as membrane filtration, precipitation, flocculation [6], adsorption, and photocatalytic degradation [7].

Polymeric nanofibers have an appropriate platform for many applications due to their high porosity (approximately 90%), low basis weight, small pore size, well-interconnected pore structure, very high surface-to-volume ratio, and the ease for incorporating chemical functionalities. Due to these properties, the nanofiber-based membranes can be good alternatives to conventional membranes, thus providing high permeability for water filtration [1, 8]. Electrospinning has been known as one of the most universally used devices for the fabrication of composite nanomaterials and preparation of nanofiber [9].

Photocatalysis is a green technology which is regarded as a favorable technique for the degradation of organic pollutants in the polluted wastewater [10, 11].

Green synthesis of nanoparticles using plant extracts is a developing area of research and is advantageous over chemical or microbial synthesis as it reduces the elaborate process and can also meet large-scale production [12, 13]. There are numerous noteworthy applications of metal oxide nanoparticles such as cell line studies, anti-microbial, and dye degradation [14].

Copper oxide nanoparticles have superior properties, which have made them essential for various applications, such as sensors, catalysts, and super strong materials [15]. Despite the high presence and application of CuO-NPs in numerous organs/systems, few studies have been piloted to examine their immunotoxic effects; CuO-NPs poisonousness on human lymphocytes remains to be investigated [16]. However, so far, toxicity implications for most synthetic nanoparticles are reported to have been limited.

Plastic cups have been widely used for water drinking packaging everywhere. Polymer polyethylene terephthalate (PET) is used in the manufacture of these cups. Due to the overuse of plastic cups, the environmental problem of PET waste has become a serious issue as it is a non-degradable material [17].

In this research paper, a new method is proposed to prepare CuO nanoparticles by the green synthesis dispersed on PET nanofibers and its application to the photodegradation of dye. The degradation of methylene blue has been determined by UV–Vis spectrophotometer.

To the best of the researcher’s knowledge, the PET nanofibers/CuO nanoparticles have not been used before for the photodegradation of methylene blue (MB) in aqueous solution.

The choice to use nanofibers is outstanding, which is attributable to their large surface area, which may help better diffusion of CuO nanoparticles.

Materials and methods

Polymer (PET) as waste material is collected from a local company water packing. It is used after cleaning and removing the non-PET components and then being dried. Trifluoroacetic acid, dichloromethane, and copper chloride dihydrate are purchased from UNI-CHEM. In all the experiments, the chemicals are of analytical grade, and all the reagents are used as received without any further purification. Deionized water is used through all the procedures. The morphology of nanofibers is examined by using (TESCAN/MAIA3) ultra-high resolution scanning electron microscope.

Further, the images are analyzed by (Image J 1.48v) randomly counting 50 fiber diameters. The photodegradation study is performed using UV–visible spectrophotometer (Jenway, 7315, Spectrophotometer).

The preparation of electrospun solutions

The preparation of nanofibers from waste PET is done in our previous work by mixing dichloromethane and trifluoroacetic acid in a 3:1 ratio to make a simple solution. The solution is stirred at room temperature for 4 h and then placed in a glass syringe (500 µL, 22 ga) attached to a stainless-steel needle. The distance is 10 cm, 13 cm, and 15 cm between the tip and the collector. The syringe is connected to an injection pump to regulate the solution flow rate at the speed of 0.5 mL/h, 1 mL/h, and 2 mL/h. High voltage is applied to the tip of the needle and the collector using a high-voltage DC power supply (9, 12, 15 kV). The optimal electrospinning factors are determined as follows: 1 mL/h flow rate, 15 cm distance needle tip to collector, 5% PET concentration, and 9 kV for the applied voltage [17].

Green synthesis CuO nanoparticles

Pomegranate leaves have been collected from the pomegranate trees in Duhok city, then cleaned from dirt by distilled water and dried in room temperature. They have been ground and then sieved (250 µm). 5 g of pomegranate leaves are added to 50 mL of deionized water and heated at 80–90 °C for 60 minutes until the solution color changes to brown–yellow, and then the mixture is cooled to room temperature and filtered. The extract is stored at a room temperature to be used in the preparation of the copper nanoparticles. 0.1 g of copper chloride dihydrate (CuCl2·2H2O) is then dissolved in 50 mL of deionized water with continuous stirring. After that, 10 mL of the plant extract is added gradually with continuous stirring at room temperature so that the color changes from light blue to light green.

The adsorption copper oxide nanoparticles

The nanofibers mat is immersed into the solution of the extracted leaves with copper chloride, which is prepared earlier. After soaking the nanofibers mat for 24 h, its black color turns brown showing the reduction of the Cu2+ ions. Then, the mat is washed many times by the deionized water to remove any free ions and dried at oven 40 °C [18]. Figure 1 shows the process in detail.

Photodegradation of methylene blue

The dried PET nanofiber/CuO nanoparticles mat of 0.008 g and 10 mL of 10 ppm methylene blue solution were shaken for 30 min at 25 °C in the dark (covered from any source of light) in demand to allow the adsorption–desorption equilibrium to be touched. The mixture of the reaction was then irradiated beneath xenon lamp (100 W) as a function of time. Throughout illumination, 2 mL of the suspension was taken from the conical as organized. After the exact irradiation time, the PET nanofibers/CuO nanoparticles were separated by centrifugation, and then the UV–Vis absorption was measured [19].

The percent degradation of methylene blue in aqueous media was calculated by the following equation [20].

where C0 is the initial organic dye concentration (mg/L), C is the organic dye concentration after irradiation (mg/L), A0 is the initial absorbance, and A is the organic dye absorbance after irradiation.

Result and discussion

Morphological study

PET nanofibers were electrospun arranged on three factors of an L 9 orthogonal array with S/N ratios and ANOVA in Taguchi method, which discussed in our earlier work. Polymer concentration, feed rate, needle tip-to-collector distance, and applied voltage at three dissimilar levels were studied to examine the levels of the optimum factors for a thinner fiber diameter during electrospinning. The optimal electrospinning factors were determined to be as follows: 5% PET concentration, 1 mL/h feed rate, 15 cm distance between needle tip to collector, and 9 kV for the applied voltage.

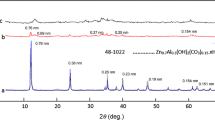

The morphological study of PET nanofiber after optimization is shown in Fig 2. Figure 3 confirmed the existence of CuO nanoparticles on the surface of PET nanofiber. SEM image also showed that the CuO nanoparticles are present in an agglomerated form on the surface of the nanofiber mat. Figure 4 indicates the frequency impact diagram for the SEM micrographs (evaluated by ImageJ 1.48v) in the diameter range of 50–200 nm. XRD pattern of this material displays the values of 2θ at [26.173º and 38.6855] with a big plane distance, which were 3.40204 and 2.32564, respectively. According to the Debye-Scherrer equation, the average crystallite size of this nanomaterial was calculated to be 2.97 nm, as shown in Fig. 5.

Photodegradation of methylene blue

CuO nanoparticle embedded in PET nanofibers was studied (photocatalytic properties) by degrading the MB under Xenon irradiation as a function of time. The photodegradation of MB was measured by the intensity of the UV–visible spectra, which gave the highest absorbance peak at 664 nm. The CuO nanoparticle embedded in PET nanofibers showed that the degradation of MB steadily increased with irradiation time. The CuO nanoparticle embedded in PET nanofibers degraded further than 88% of dye at 10 min, while the PET nanofibers degraded about 56% of MB beneath the similar experimental situation, and after 60 min the dye degradation was almost constant as shown in Figs. 6 and 7. Kinetic study of photodegradation of methylene blue in aqueous solution versus CuO nanoparticles-embedded PET nanofibers is shown in Figs. 8 and 9 [21].

where C0 is the initial concentration of methylene blue, C is the concentration of methylene blue at a specific time, and Ka is the rate constant of the pseudo-first-order model (min−1).

The high photodegradation of MB in aqueous media is due to the CuO nanoparticles on the surface of PET nanofibers.

The photodegradation of dye MB in solution is initiated by the photoexcitation of the CuO nanoparticles as semiconductor, followed by the production of electron–hole pair on the surface of (CuO) catalyst (Eq. 4). The high oxidative potential of the hole (h+VB) in the catalyst allows the immediate oxidation of the organic dye (MB) to reactive intermediates (Eq. 5).

Metal oxide

Hydroxyl radical (OH·) is another reactive intermediate which is accountable for the degradation. It is produced by the decomposition of water (Eq. 6) or via the reaction of the hole with OH− (Eq. 7). The hydroxyl radical (OH·) is an influential, non-selective oxidant (E° = +3.06 V), which leads to the fractional or complete mineralization of numerous organic chemicals [22].

Effect of pH on photodegradation

The influence of pH on photodegradation was studied because it is the critical factor which is essential through photodegradation organic materials [22].

The results in Fig. 10 show that the photodegradation of MB increases with the rise in pH. The results indicate that the photodegradation of MB is in basic solution.

The basic medium enhanced the creation of (OH) radicals. These radicals are robust oxidizing species, which might be responsible for upper pH values during the photodegradation.

The initial concentration of methylene blue effect

The effect of initial MB concentration on the photodegradation of MB onto PET nanofibers with CuO nanoparticles was studied at the initial MB concentration (10–40 mg/L). As shown in Fig. 11, the results indicate that the photodegradation decreases with increasing concentration from 10 to 40 mg/L. This result might be related to the saturated surface of the PET nanofibers with CuO nanoparticles, which are caused by the high concentration of the MB in solution [23].

Conclusion

In summary, CuO nanoparticles embedded in PET nanofibers were prepared by the green synthesis process, electrospinning, a dipping method, and environmentally friendly green chemical reduction that used plant extract as a reducing agent. XRD pattern of CuO nanoparticles displays the value of the average crystallite size of this nanomaterial which was calculated to be 2.97 nm. The characterization illustrates that the Cu nanoparticles with minor size were perfectly dispersed and embedded on the PET nanofibers. The SEM analysis exhibited that the morphology of PET nanofibers was not disturbed after treated with CuO nanoparticles.

PET nanofibers/CuO nanoparticles showed high photocatalytic activity for the removal of organic dye in aqueous solution. The results indicate that the photodegradation of Methylene blue( MB) more efficiency is in a basic solution and decreases with an increasing the initial concentration of (MB).

References

Haider S, Binagag FF, Haider A, Mahmood A, Shah N, Al-Masry WA, Khan SU, Ramay SM (2015) Adsorption kinetic and isotherm of methylene blue, safranin T and rhodamine B onto electrospun ethylenediamine-grafted-polyacrylonitrile nanofibers membrane. Desalination Water Treat 55(6):1609–1619

Voisin H, Bergström L, Liu P, Mathew A (2017) Nanocellulose-based materials for water purification. Nanomaterials 7(3):57

Nnaji C, Jeevanandam J, Chan Y, Danquah M, Pan S, Barhoum A (2018) Fundamentals of nanoparticles: classifications, synthesis methods, properties, and characterization. Elsevier, Amsterdam, pp 129–168

Mohamed A, El-Sayed R, Osman TA, Toprak MS, Muhammed M, Uheida A (2016) Composite nanofibers for highly efficient photocatalytic degradation of organic dyes from contaminated water. Environ Res 145:18–25

Acar I, Bal A, Güçlü G (2012) Adsorption of basic dyes from aqueous solutions by depolymerization products of post-consumer PET bottles. CLEAN Soil Air Water 40(3):325–333

Ghorai S, Sarkar A, Raoufi M, Panda AB, Schönherr H, Pal S (2014) Enhanced removal of methylene blue and methyl violet dyes from aqueous solution using a nanocomposite of hydrolyzed polyacrylamide grafted xanthan gum and incorporated nanosilica. ACS Appl Mater Interfaces 6(7):4766–4777

Özkahraman B, Bal A, Acar I, Güçlü G (2011) Adsorption of brilliant green from aqueous solutions onto crosslinked chitosan graft copolymers. CLEAN Soil Air Water 39(11):1001–1006

Vanangamudi A, Yang X, Duke MC, Dumee LF (2018) Nanofibers for membrane applications. In: Handbook of nanofibers, 1st edn. Springer International Publishing, pp 1–24

Jin S, Yu J, Zheng Y, Wang WY, Xin B, Kan CW (2018) Preparation and characterization of electrospun PAN/PSA carbonized nanofibers: experiment and simulation study. Nanomaterials 8(10):821

Bhatkhande DS, Pangarkar VG, Beenackers AA (2002) Photocatalytic degradation for environmental applications—a review. J Chem Technol Biotechnol 77(1):102–116

Rajaei P, Ranjbar M (2016) Synthesis and characterization of zinc oxide nanostructures by green capping agent and its photocatalytic degradation of methylene blue (MB). J Mater Sci Mater Electron 27(2):1708–1712

Kumar PV, Shameem U, Kollu P, Kalyani RL, Pammi SV (2015) Green synthesis of copper oxide nanoparticles using Aloe vera leaf extract and its antibacterial activity against fish bacterial pathogens. BioNanoScience 5(3):135–139

Naika HR, Lingaraju K, Manjunath K, Kumar D, Nagaraju G, Suresh D, Nagabhushana H (2015) Green synthesis of CuO nanoparticles using Gloriosa superba L. extract and their antibacterial activity. J Taibah Univ Sci 9(1):7–12

Al-Dhabi N, Valan Arasu M (2018) Environmentally-friendly green approach for the production of zinc oxide nanoparticles and their anti-fungal, ovicidal, and larvicidal properties. Nanomaterials 8(7):500

Kowalska E, Endo M, Wei Z, Wang K, Janczarek M (2019) Noble metal nanoparticles for water purification. In: Nanoscale materials in water purification, pp 553–579

Assadian E, Zarei M, Gilani A, Farshin M, Degampanah H, Pourahmad J (2018) Toxicity of copper oxide (CuO) nanoparticles on human blood lymphocytes. Biol Trace Elem Res 184(2):350–357

Jamal A, Ibtisam A, Manaf A. Mohamed, Suhad A, Zeravan A, Idrees H (2018) Electrospinning of polyethylene terephthalate (PET) nanofibers: optimization study using Taguchi design of experiment. In: Gill S (ed) IOP conference series: materials science and engineering, vol 454(1), IOP Publishing, Bristol, p 012130

Xu T, Li C, Li H, Bai J, Qin H, Sun W, Huang Y (2014) Synthesis and characterization of Cu nanoparticles embedded in PAN/β-cyclodextrin (β-CD) composite nanofiber films. Part Sci Technol 32(3):306–310

Mohamed A, Osman TA, Toprak MS, Muhammed M, Yilmaz E, Uheida A (2016) Visible light photocatalytic reduction of Cr(VI) by surface modified CNT/titanium dioxide composites nanofibers. J Mol Catal A Chem 424:45–53

Saeed K, Khan I, Park SY (2015) TiO2/amidoxime-modified polyacrylonitrile nanofibers and its application for the photodegradation of methyl blue in aqueous medium. Desalination Water Treat 54(11):3146–3151

Das DP, Parida K, De BR (2006) Photocatalytic reduction of hexavalent chromium in aqueous solution over titania pillared zirconium phosphate and titanium phosphate under solar radiation. J Mol Catal A Chem 245(1–2):217–224

Kansal S, Kaur N, Singh S (2009) Photocatalytic degradation of two commercial reactive dyes in aqueous phase using nanophotocatalysts. Nanoscale Res Lett 4(7):709

Salama A, Mohamed A, Aboamera NM, Osman TA, Khattab A (2018) Photocatalytic degradation of organic dyes using composite nanofibers under UV irradiation. Appl Nanosci 8(1–2):155–161

Acknowledgements

The authors are grateful for the financial supports by Partnerships for Enhanced Engagement in Research (PEER). It is administered by the U.S. National Academies of Sciences, Engineering, and Medicine (NASEM), PEER/Iraq project/cycle 6. Also, we thank Dr. Yasser S. Jameel for the graphic design.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yasin, S.A., Abbas, J.A., Saeed, I.A. et al. The application of green synthesis of metal oxide nanoparticles embedded in polyethylene terephthalate nanofibers in the study of the photocatalytic degradation of methylene blue. Polym. Bull. 77, 3473–3484 (2020). https://doi.org/10.1007/s00289-019-02919-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-019-02919-4