Abstract

The discrepancy of the existing literature data on the surface tension values of biopolymer solutions could be affected by the measurement technique. The aim of the study was to compare the surface tension values of biopolymer solutions, measured using the du Nouy ring method and the drop weight methods (Harkins–Brown correction factors method and the LCP coefficient method). Four biopolymers were chosen (sodium alginate, carboxymethyl cellulose, xanthan gum and pectin) and the surface tensions of the solutions were measured as a function of biopolymer concentration. The surface tension was found to increase with biopolymer concentration when measured using the du Nouy ring method. On the other hand, the drop weight methods gave an opposite trend. The results verified the discrepancy of the existing literature data. The error may be caused by the correction factors calculation and the solution viscosity when the du Nouy ring method was used. The LCP coefficient method which is independent of correction factors and liquid properties is proposed for measurement of the surface tension of viscous biopolymer solutions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Since the mid-twentieth century, many biopolymers of scientific and industrial interest have been discovered [1]. The production of biopolymer started in the end of 1920s and its production nowadays has increased to about 30,000 tonnes annually [2]. Out of the total production, 30 % is devoted to the food industry and the rest being used in pharmaceutical, medical, chemical and so on [2].

The unique physical properties of biopolymers enable these materials to be used as stabilizer, thickener and gelling agent in various applications [1, 3]. The knowledge of the physical properties of biopolymers solution is important because they should be readily controlled over a wide range to match the requirements of a particular application. For example, when the viscosity of diluted golden syrup was reduced to 2 Pa·s, a rapid and uniform heating of canned foodstuffs could be achieved during thermal preservation process [4]. Besides, it has been reported that the spreadability of alginate solution on garlic skin is improved by 3.6 times when the surface tension of alginate solution is reduced from 51.5 to 33.0 mN/m [5]. The density, viscosity and surface tension of biopolymers solution are commonly measured by commercially available instrument such as densitometer, viscometer, and surface tensiometer, respectively.

The density measurement of many biopolymer solutions is frequently conducted using the static densitometer such as pycnometer [6–8] and vibrating element digital densitometer [9, 10]. These densitometers are able to measure density of viscous liquid like biopolymer solutions accurately [11]. In general, the density of many biopolymer solutions is reported to be in the range of 1.00–1.02 g/ml [6, 8–10], which is close to that of water (i.e. 0.9970 g/ml) [12].

The viscosity of many biopolymer solutions can be easily measured using either rotational type viscometer [6, 8–10, 13–16] or capillary type viscometer [17, 18]. However, it has been reported that the viscosity of biopolymer solutions is significantly affected by the operating conditions of viscometer (e.g. shear rate, temperature and pressure) and the properties of biopolymer (e.g. molecular weight, grade, concentration, material source) [16, 19–21]. For example, the viscosity of sodium alginate solution with concentration of 1.0 w/v% at 20 °C is within the range of 20–400 cP [2] and the value depends on the grade and the biopolymer production process [2].

The surface tension of biopolymer solutions is most probably measured using simple experimental methods, namely the du Nouy ring method and the drop weight method. These methods are preferable due to their availability in most laboratories, low cost, easy and rapid measurement procedure [22]. In the past, the surface tension of many biopolymer solutions has been reported using these methods [5–7, 9, 23]. Based on the data compiled from literature for selected biopolymers, it shows that the surface tension value and trend were inconsistent. To our knowledge, there has been no attempt to determine the cause of the discrepancy. It is speculated that the discrepancy could be caused by different measurement techniques used. The main aim of this study was to measure surface tension of biopolymers solutions as a function of concentration using two simple and widely used methods, namely the du Nouy ring method and the Harkins–Brown (HB) drop weight method. In addition, a modified drop weight method (LCP coefficient method) was also used. The selected model biopolymers were sodium alginate, carboxymethyl cellulose (CMC), xanthan gum and pectin. The data from the experiments and literature were then compared and discussed.

Materials

Biopolymers: Sodium alginate (Manugel GHB) was provided by ISP Technologies Inc. (UK). CMC and xanthan gum were obtained from Fluka (USA). Pectin LM 35 was provided by TIC gum (USA). All the biopolymer solutions were prepared in deionised distilled water.

Methods

du Nouy ring method

The surface tension of all samples was tested using the du Nouy ring tensiometer (SEO DST 30 Surface tension metre, Korea). 50 ml of sample in 100 ml beaker was used for each test. The distance between the immersed ring and liquid surface was fixed at 4.5 mm to insure a clean break of the meniscus on the immersed platinum–iridium ring. The circumference (R) of the ring and the ring dimensions ratio (R/R′) were given by the manufacturer as 0.5960 cm and 53.3906, respectively. Based on the input parameters [ring dimension, density of sample and temperature (25 °C)], the calculation was made by the pre-programmed software in the tensiometer. The surface tension value was computed using Eq. 1 and the correction factor was computed according to the mathematical model proposed by Zuidema and Waters [24] (as shown in Eq. 2). The surface tension of the sample was recorded from the display.

Drop weight method

The surface tension of all samples was measured using the drop weight apparatus (see Fig. 1). Different sizes of hypodermic needle (Becton–Dickinson Medical (S) Pte Ltd, Singapore) were blunted first and then shortened to 3 mm. The diameter of the needles ranging from 0.55 to 1.65 mm was used in this study. The needle and the burette tip were mounted on a stand and set perpendicularly to the ground. The temperature of the samples was maintained at 25 °C using a water jacket. The weight of 30–100 drops of each samples were collected and measured using a 4 decimal digital analytical balance (Sartorious Co., Germany). The reproducibility of the drop weight data was evaluated by repeating a randomly selected experiments two to three times each. The standard error of the measurement was found to be <1 %. The drop weight results were analysed to determine the surface tension using the existing HB correction factors method [25] and the Lee–Chan–Pogaku (LCP) coefficient method [12]. In brief, the methods are described as follows.

HB correction factors method

The drop weight results together with density data of a sample were used to determine drop volumes. The density of each sample was measured using a digital density/specific gravity metre (Kyoto Electronics Manufacturing Co Ltd, Japan), where duplicate determination of data was conducted at 25 °C for each sample. The drop volume of a sample from a known dripping tip radius was used to determine the HB correction factor (\( \psi \left( {r/V^{1/3} } \right) \)). Instead of referring to the experimental curve and tables, a mathematical model known as the LCP model [26] was used to determine the HB correction factors, as shown in Eq. 3.

Then surface tension of the sample was calculated from the following equation:

LCP coefficient method

The drop weight results of a sample were first obtained from dripping tips of five different sizes. The data were then fitted into a quadratic regression equation (with regression R 2 > 0.99) in order to determine the linear coefficient (C 2) of the equation [12]. Finally, the surface tension is calculated through a linear semi-empirical equation as shown in Eq. 5.

Results

First of all, the surface tension of water was measured using three different methods. Table 1 shows the surface tension values of deionised distilled water. In general, the average values for all three methods were in good agreement with the reference value. Subsequently, the surface tension of water was used to compare with the surface tension of sodium alginate, CMC, xanthan gum and amidated low methoxyl pectin solutions.

Surface tension of sodium alginate solutions

The surface tensions of different concentrations of sodium alginate solutions, ranging from 0.5 to 5.0 w/v% were measured by the three methods. Surface tension data of the sodium alginate solutions were shown in Fig. 2. When the du Nouy ring method was used, the surface tension of sodium alginate solutions increased from 56.0 to 73.02 mN/m as the biopolymer concentration increased from 0.5 to 5.0 w/v%. In contrast, when the measurement was made by the HB correction factors method and the LCP coefficient method, the surface tension data were in decreasing trend, as presented in Fig. 2. At low concentrations, the surface tension of sodium alginate solutions was close to that of water and it remained relatively unchanged up until concentration of 2.0 w/v%. When the concentration increased from 2.0 to 5.0 w/v%, the surface tension of sodium alginate solutions decreased drastically from 68.0 to <63.0 mN/m. As a comparison, the result of the LCP coefficient method is more drastically decreased from 2.0 to 5.0 w/v% than the result of the HB correction factors method.

In the past, surface tension of sodium alginate solutions has been reported and the data are compiled in Table 2. Table 2 clearly illustrates that there are two different trends of the data; the surface tension is either increasing [5, 6] or decreasing [23] as the biopolymer concentration increases. The surface tension for 2.0 w/v% sodium alginate solution measured by the du Nouy ring method is reported by Zohar-Perez et al. [7] as 55.0 mN/m. The result coincides with the results measured by the du Nouy ring method in this study where the surface tensions for sodium alginate solutions of concentration <2.0 w/v% are within the 57.4–65.1 mN/m.

A comparison was made on the surface tension data measured by the HB correction factors method in this study with that from Watanabe et al. [6]. As shown in Fig. 2 and Table 2, the surface tensions of sodium alginate solutions in this study are lower than 73.0 mN/m when the concentration increases, in contradiction to the results obtained by Watanabe et al. [6] where the surface tension of sodium alginate solutions was found to be greater than that of water. On the other hand, the surface tension of 1.0 w/v% sodium alginate solution measured in this study is 70.9 mN/m and it is close to the value (i.e. 69.7 mN/m) reported by Van Santvliet and Ludwig [28].

It has been recommended to use the Wilhelmy plate method to measure surface tension of viscous liquids [29], whenever the instrument is available. This is to avoid systematical errors in the measurement made using surface detachment methods due to viscous force effect [29]. In reference to Table 2, inconsistent trend is also exhibited in the surface tensions of alginate solutions measured by the Wilhelmy plate method [5, 23]. According to Hershko and Nussinovitch [5], the surface tension of sodium alginate solutions increased from 60.9 to 62.0 mN/m when the concentration increased from 1.00 to 2.00 w/v%. However, in the study conducted by Babak et al. [23], the surface tensions of sodium alginate solutions decreased from 71.5 to 68.8 mN/m when the concentration increased from 0.10 to 2.25 w/v%. Nevertheless, the surface tensions of sodium alginate solutions determined in both studies were lower than that of water.

Surface tension of carboxylmethyl cellulose (CMC) solutions

The surface tensions of CMC solutions with concentration in the range of 0.5–2.0 w/v% were measured and the data are presented in Fig. 3. The surface tensions of CMC solutions measured by the du Nouy ring method at low concentrations (0.5–1.0 w/v%) were about 75.0 mN/m. However, the surface tension gradually increased from 75.1 to 78.2 mN/m as the concentration increased from 1.0 to 2.0 w/v%. On the other hand, the surface tension data trend determined using the drop weight methods are in the opposite trend of that determined using the du Nouy ring method. It is noted that the HB correction factors method gives higher surface tension value at high concentration compared to that measured by the LCP coefficient method. In this case, the HB correction factors method gives surface tension values which are 2.0 and 2.7 mN/m higher than the latter method for CMC concentrations of 1.5 and 2.0 w/v%, respectively.

The surface tension data of CMC solutions collected from literature are presented in Table 3. By comparing the surface tension of CMC solutions measured by the du Nouy ring method, the results determined in this study agree with that reported by Halard et al. [30] but disagree with that reported by Weber et al. [31]. The surface tension data from the previous studies [30, 31] are in contradicting trend as the polymer concentration increases. Nevertheless, the result reported by Tomanova et al. [32] matches the data presented by Weber et al. [31]. On the other hand, the surface tension data of Jomsurang and Sakamon [33] and of this study exhibit decreasing trend when drop weight method was used in the measurement (see Fig. 3; Table 3). However, they reported that the surface tensions of CMC solutions drastically decreased from 70.5 mN/m at concentration of 1.0 w/v% to below 65.0 mN/m at high concentrations (i.e. 1.5 and 2.0 w/v%). The results are in contradiction with the results of this study. Another data measured using the drop weight method from Watanabe et al. [6] is also shown in Table 3. They reported that the surface tension of 0.25 w/v% CMC solution was greater than that of water. In contrast, a lower value (i.e. 64.5 mN/m) was reported by Cao and Li [34] for 0.5 w/v% CMC solution when the measurement was made by the Wilhelmy plate method. In reference to Table 3, Guillot et al. [35] reported that the surface tension of CMC solutions is relatively constant at about that of water at low CMC concentrations (from 0.01 to 0.70 w/v%) when they measured using the Wilhelmy plate method. Furthermore, the surface tension of the CMC solutions at high concentrations (from 0.75 to 1.40 w/v%) was found to be lower than that of water and the data were in decreasing trend as the CMC concentration increased [35].

Surface tension of xanthan gum solutions

The surface tension of xanthan gum solutions was measured in this study. As presented in Fig. 4, the surface tension of xanthan gum solutions in this study increases from 74.0 to 83.2 mN/m as the biopolymer concentration increases from 0.1 to 0.5 w/v% when the du Nouy ring method was used in the measurement. The surface tensions measured by the ring method are clearly higher than that of water. However, this is not seen in the results obtained by the drop weight methods. The measured surface tensions are lower than that of water and they are in decreasing trend as the concentration increases from 0.1 to 0.5 w/v%. The results are in similar trend to that of the sodium alginate solutions and CMC solutions in this study. In addition, the surface tensions of xanthan gum solutions measured by the drop weight methods (i.e. the HB correction factors method and the LCP coefficient method) are insignificantly different (see Fig. 4).

Table 4 shows the surface tension data of xanthan gum solutions collected from literature. In general, the reported surface tension data are generally lower than that of water [5, 28, 36, 37]. Weber et al. [31] and Huang et al. [37] measured the surface tension of 0.5 w/v% xanthan gum solution using the du Nouy ring method but different results were determined. On the other hand, Garti et al. [36] and Hershko and Nussinovitch [5] both reported that the surface tension of 1.00 w/v% xanthan gum solution was 42.3 mN/m when measurement made by Wilhelmy plate method. In reference to Fig. 4 and Table 4, the data reported by Weber et al. [31] were in similar trend (i.e. increasing) as those measured in this study by the du Nouy ring method. Moreover, the surface tension of xanthan gum solution at low concentrations (i.e. 0.18 and 0.25 w/v%) was reported to be about 69.0 mN/m by Weber et al. [31] and Van Santvliet and Ludwig [28], which coincides with the data measured by the drop weight methods in this study.

Surface tension of pectin solutions

The surface tension of pectin solutions of different concentrations (ranging from 5.0 to 8.0 w/v%) was measured in this study and the results are presented in Fig. 5. Similar to the results of other biopolymer solutions, the surface tensions of the pectin solutions measured by the du Nouy ring method in this study shows increasing trend as its concentration increases. The surface tension of 5.0 and 6.0 w/v% pectin solution was approximately close to 64.0 mN/m but it gradually increased to 67.1 mN/m as the biopolymer concentration was increased to 8.0 w/v%. On the other hand, the surface tensions of the pectin solutions were found to decrease as the biopolymer concentration increases when the measurement was made by the drop weight methods in this study (see Fig. 5). The surface tension data determined by the HB correction factors method are relatively higher than that measured by the LCP coefficient method. In reference to Fig. 5, the surface tension of the pectin solutions is high (close to surface tension of water) at low concentrations (e.g. 5 and 6 w/v%) and then decreases to a lower value as the concentration increases.

The literature data on the surface tension of pectin solutions are shown in Table 5. In general, all the results measured by the du Nouy ring method, including those in this study, Weber et al. [31], and Huang et al. [37] are lower than that of water (see Fig. 5; Table 5). The data reported by Weber et al. [31], where the surface tension increases from 64.2 to 67.3 mN/m when the concentration increases from 0.25 to 0.50 w/v% (see Table 5). Similar data trend was determined in this study (see Fig. 5). In reference to Table 5, Jomsurang and Sakamon [33] showed that the surface tension gradient between 1.0 and 1.5 w/v% pectin solution is large, as much as 8.5 mN/m and this is not observed in the results obtained in this study (see Fig. 5).

Discussion

As presented in the above sections, the discrepancy of the surface tension of biopolymer solutions is apparently demonstrated in the results of this study and previous studies. As a whole, the results obtained from the du Nouy ring method in most cases (expect pectin solutions) showed that the tested biopolymers increase the surface tension of water as their concentration increases. However, the results obtained from the drop weight methods in this study demonstrate an opposite effect. The tested biopolymers reduce the surface tension of water as the biopolymers concentration increases. These results clearly showed that the measured and collected data are influenced by the measurement technique. Although the apparent surface tension value of the biopolymer solutions could be influenced by the chemical properties, grade, manufacture batch-to-batch variation of the biopolymers, the intention of this study was to investigate the data trend of the biopolymer solutions where the apparent surface tension of water is increased or reduced by the biopolymers.

Surface tension measurement of a sample by the du Nouy ring method is basically involved the measurement of maximum pull force (F max) that required to detach a circular ring from the liquid surface of the sample [38] or the maximum weight capable of being held up by the ring [39]. It has been well known that the measured F max could be in error of 30 % or even more because only a portion of the liquid raised by the ring that breaks away from the surface and attaches to the ring, while a smaller portion of it remains undetached from the surface. This problem has been resolved by multiplying the calculated surface tension value with a correction factor that can be obtained from a table developed by Harkins and Jordan [40]. The Harkins–Jordan (HJ) table is developed based on the fraction of the ideal F max, \( \psi = F_{\max } /F_{\max {\rm{Ideal}}} \), as a function of the dimensionless ring radius, R 3/V and the ring dimensions ratio R/R′. A mathematical model has been developed by Zuidema and Waters [24] (see Eq. 2) to determine the correction factors without referring to the HJ table. Nowadays, the Zuidema–Waters (ZW) model has been pre-programmed into the commercially available surface tensiometer to determine surface tension of a sample, which is similar to the one used in this study. However, based on the results of biopolymer solutions in this study, the applicability of the ZW model for wide range of liquid and different sizes of ring has raised the concern of the authors. This is because the model is initially developed based on two sizes of ring (i.e. 4 and 6 cm) with R/R′ of 30, 40, 50 and 60, and the studied range of F max/density covers from 50 to 850 N ml/g only [24].

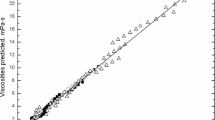

Figure 6 shows the plot of surface tension of water, benzene and bromobenzene against different ring dimensions ratios (R/R′). The surface tension data were computed using two approaches; first by the HJ table and second by the ZW model. In general, the surface tension data of liquid computed by the ZW model are randomly scattered around the reference value; where the data vary from 20 % lower to 20 % higher. In contrast, it was noted that the deviation of the results computed using HJ table from the reference value was <1.1 %. In order to evaluate the accuracy and reliability of the two approaches for determination of surface tension in comparison with the reference values, a statistical error analysis was conducted (Table 6). Two statistical indicators were used and they were average absolute deviation (AAD) and maximum absolute deviation (MAD). AAD analysis indicates the average deviation of the experimental data and MAD analysis reflects the degree of the deviation of the experimental data. The approach of using HJ table gives lower deviation if compared to ZW model approach when it used to compute the surface tension of liquid. Therefore, the inconsistency of the surface tension data of biopolymer solutions could be due to the error in the calculation of surface tension by the surface tensiometer. This is because the tensiometer computes the surface tension using the ZW model, which had been pre-programmed in the instrument.

Surface tension of few liquids against the ring dimensions ratio [R/R′]. The surface tension data were computed using the correction factors from HJ table [40] and ZW model [24]. All the experimental data [a water, b benzene, c bromobenzene] were collected from Harkins and Jordan [40]. The reference values [solid line] were measured by the capillary rise method and they were determined from Harkins and Jordan [40]

Over many decades, the HJ correction factors have been used to determine surface tension of many liquid and solutions. Despite the wide application of the correction factors, the issue on the applicability of the correction factors for various solutions has attracted the attention of researchers. Many studies have reported that the accuracy of the correction factors could be affected by solution conditions, ring wettability, liquid/solution viscosity, and solution types [29, 41–44]. In fact, these effects were not considered and tested during the development of the correction factors. The effect of viscous force on the measured F max of viscous liquid like biopolymer solutions could be significant.

The viscous force of the liquid could influence the measured F max in two scenarios. First, the viscous force of a liquid plays an important role in the surface detachment mechanism between the ring and the liquid/solution surface [45, 46]. It may influence the amount of liquid that breaks away from the liquid raised by the ring after the surface detachment occurs as well as the amount of undetached liquid. As a consequence, the amount of the liquid attached to the ring after the detachment (F max) could be higher or lower than its actual amount. Besides, an error may also incur in the correction factors determination due to deviation of the F max value from its actual value. Second, the viscous force may cause error in the detection of maximum pull force (F max). It has been reported that sometimes the measured F max is not necessarily the pull at which the liquid film breaks and the F max typically occurs just before the ring detaches from the surface [22, 42, 46]. Hence, the measured F max for viscous liquids (like biopolymers solutions) might not be the actual pull that caused the detachment of the ring from the interface. As a result, it is commonly recommended that the du Nouy ring method should be used with precautions especially when it is used for the surface tension measurement of viscous liquid [29, 44, 46]. Imaging system (e.g. high speed camera) could be used to monitor the surface detachment and hence the associated errors could be eliminated [46].

On the other hand, when surface tension measurement was made by the drop weight methods, it was noted that the surface tension decreases as the biopolymer concentration increases in all experiments conducted in this study. The trend is in good agreement with the theorem of surface thermodynamics (Gibbs adsorption isotherm). According to the theorem, the surface tension of biopolymer solutions at low concentration is expected to be close to the value of water (about 72 mN/m) [5, 36] because biopolymer solutions are typically containing about 98 % of water [5, 23, 36]. As the concentration of the biopolymer solutions is increased, the apparent surface tension of water is typically decreased by the solute (biopolymer). This is because substance like biopolymer will tend to accumulate at the surface in preference to remaining in the bulk when it is dissolve in water [44, 47, 48].

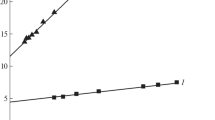

As a result, the drop weight methods could be a more suitable method to measure the surface tension of biopolymers solutions. However, when the classical drop weight method was used, HB correction factors were required to determine the surface tension. It has been reported that the correction factors are influenced by the liquid properties (i.e. density, surface tension and viscosity), sample delivery mode and tip geometry and size [12]. Hence, when HB correction factors were used for surface tension determination of biopolymer solutions could be associated with errors. Conversely, the errors can be minimised with the use of the LCP coefficient method. The method was developed to eliminate the influence of liquid properties on the drop weight method and it was found to be valid for a large variety of liquids and different experimental conditions [12]. The viscous force effect on HB correction factors is clearly illustrated in the results of sodium alginate, CMC and pectin solutions at high concentrations, when the viscosity of the solutions is high (see Figs. 2, 3, 5). This is because the results of these solutions (4.0 and 5.0 w/v% sodium alginate solutions, 1.5 and 2.0 w/v% CMC solutions and 6.0, 7.0 and 8.0 w/v% pectin solutions) determined by HB correction factors method are deviated from those determined by the LCP coefficient method. Therefore, the LCP coefficient method which is independent of correction factors and liquid properties is proposed for surface tension measurement of viscous biopolymer solutions.

Conclusions

The surface tension of four types of biopolymer (sodium alginate, CMC, xanthan gum and pectin) solutions in different concentrations was measured using the du Nouy ring method and the drop weight methods. The surface tension was measured as a function of the biopolymer concentration. In general, the surface tension determined using the du Nouy ring method was in an increasing trend but the drop weight method gave an opposite trend. The available literature data also showed inconsistent results and this verifies that the surface tension values of biopolymer solutions could be affected by the measurement technique. When surface tension measurement made by the du Nouy ring method, the error could be due to the correction factors determination using the ZW model. The error analysis shows that the ZW model gives surface tension values that vary from 20 % lower to 20 % higher, as compared to the reference value. In addition, the error of the du Nou ring method could be due to the solution viscosity. The solution viscosity was not considered during the development Harkins–Jordan (JW) correction factors for the du Nouy ring method. The viscous force of the biopolymer solutions has a significant effect on the detachment mechanism of the ring from the liquid surface and the detection of the actual maximum pull force (F max). Therefore, surface tension measurement of biopolymer solutions using the du Nouy ring method is to be conducted with extra precautions. On the other hand, the results of the drop weight methods are in good agreement with the theorem of surface thermodynamics. According to the theorem, the surface tension of biopolymer solutions is expected to be close to the value of water at low concentration and lower than the value of water as the biopolymer concentration increases. In conclusion, the LCP coefficient method which is independent of correction factors and liquid properties was identified to be the most accurate and suitable method to measure surface tension of biopolymers solutions.

Abbreviations

- Ψ :

-

Correction factor of ring method

- ρ :

-

Density (g/ml)

- Ψ(r/V 1/3 ) :

-

Drop weight correction factor in function of (r/V 1/3)

- G :

-

Gravitational force (981 cm/s2)

- C 2 :

-

Linear coefficients of quadratic equation between drop weight and dripping tip radius

- m :

-

Mass of falling drop (g)

- F max :

-

Maximum pull force (N)

- r :

-

Radius of dripping tip (cm)

- R′ :

-

Radius of du Nouy ring wire (cm)

- R :

-

Radius of du Nouy ring (cm)

- γ :

-

Surface tension (mN/m)

- V :

-

Volume of a detached drop (cm3)

References

Born K, Langendorft V, Boulenguer P (2002) Chapter 11 Xanthan. In: Vandomme EJ, De Baets S, Steinbuchel A (eds) Biopolymers, vol 5., Biology chemistry biotechnology application, polysaccharides i polysaccharides from prokaryotesWiley, Weinheim, pp 259–297

Shilpa A, Agrawal SS, Ray AR (2003) Controlled delivery of drugs from alginate matrix. J Macromol Sci C 43:187–221

Mammarella EJ, Rubiolo AC (2003) Cross linking kinetics of cation-hydrocolloid gels. Chem Eng J 94:73–77

Yang Z, Fan X, Bakalis S, Parker DJ, Fryer PJ (2008) Impact of solids fraction and fluid viscosity on solids flow in rotating cans. Food Res Int 41:658–666

Hershko V, Nussinovitch A (1998) The behavior of hydrocolloid coatings on vegetative materials. Biotechnol Prog 14:756–765

Watanabe H, Matsuyama T, Yamamoto H (2003) Experimental study on electrostatic atomization of highly viscous liquids. J Electrostat 57:183–197

Zohar-Perez C, Chet I, Nussinovitch A (2004) Irregular textural features of dried alginate-filler beads. Food Hydrocolloid 18:249–258

Del Gaudio P, Colombo P, Colombo G, Russo P, Sonvico F (2005) Mechanisms of formation and disintegration of alginate beads obtained by prilling. Int J Pharm 302:1–9

Brandenberger H, Widmer F (1998) A new multinozzle encapsulation immobilisation system to produce uniform beads of alginate. J Biotechnol 63:73–80

Chan ES, Lee BB, Ravindra P, Poncelet D (2009) Prediction models for shape and size of ca-alginate macrobeads produced through extrusion–dripping method. J Colloid Interface Sci 338:63–72

Eren H (1999) Chapter 21. Density measurement. In: Webster JG (ed) Measurement, instrumentation and sensors handbook. CRC Press, Boca Raton, pp 21-1–21-16

Lee BB, Ravindra P, Chan ES (2009) New drop weight analysis for surface tension determination of liquids. Colloid Surf A 332:112–120

Seifert DB, Philips JA (1997) Production of small, monodispersed alginate beads for cell immobilization. Biotechnol Prog 13:562–568

Al-Hajry HA, Al-Maskry SA, Al-Kharousi LA, El-Mardi O, Shayya WH, Goosen MFA (1999) Electrostatic encapsulation and growth of plant cell cultures in alginate. Biotechnol Prog 15:768–774

Rousseau I, Le Cerf D, Picton L, Argillier JF, Muller G (2004) Entrapment and release of sodium polystyrene sulfonate (SPS) from calcium alginate gel beads. Eur Polym J 40:2709–2715

Herrero EP, Del Valle EMM, Galan MA (2006) Development of a new technology for the production of microcapsules based in atomization processes. Chem Eng J 117:137–142

Fundueanu G, Esposito E, Mihai D, Carpov A, Desbrieres J, Rinaudo M, Nastruzzi C (1998) Preparation and characterization of Ca-alginate microspheres by a new emulsification method. Int J Pharm 170:11–21

Simcone M, Alfani A, Guido S (2004) Phase diagram, rheology and interfacial tension of aqueous mixtures of Na-caseinate and Na-alginate. Food Hydrocolloid 18:463–470

Day DF (1998) Chapter 5, Alginates. In: Kaplan DL (ed) Biopolymers from renewable resources. Springer, Berlin, pp 119–143

Sabra W, Deckwer W (1998) Alginate—a polysaccharide of industrial interest and diverse biological functions. In: Dumitriu S (ed) Polysaccharides. Structural diversity and functional versatility. Markel Dekkar, Inc., New York, pp 515–531

Marcotte M, Hoshahili ART, Ramaswamy HS (2001) Rheological properties of selected hydrocolloids as a function of concentration and temperature. Food Res Int 34:695–703

Thiessen DB, Man KF (1999) Surface tension measurement, In: Measurement, instrumentation and sensors handbook. CRC Press LLC, Boca Raton, pp 31-1–31-13

Babak VG, Skotnikova EA, Lukina LG, Pelletier S, Hubert P, Dellacherie E (2000) Hydrophobically associating alginate derivatives: surface tension properties of their mixed aqueous solutions with oppositely charged surfactants. J Colloid Interface Sci 225:505–510

Zuidema HH, Waters GW (1941) Ring method for the determination of interfacial tension. Ind Eng Chem Anal Ed 13:312–313

Harkins WD, Brown FE (1919) The determination of surface tension (free surface energy), and the weight of falling drops: the surface tension of water and benzene by the capillary height method. J Am Chem Soc 41:499–524

Lee BB, Ravindra P, Chan ES (2008) A critical review: surface and interfacial tension measurement using the drop weight method. Chem Eng Commun 195:889–924

Kawanishi T, Seimiya T, Sasaki T (1970) Correction for surface tension measured by Wilhelmy method. J Colloid Interface Sci 32:622–627

Van Santvliet L, Ludwig A (1999) Influence of the physico-chemical properties of ophthalmic viscolysers on the weight of drops dispensed from a flexible dropper bottle. Eur J Pharma Sci 7:339–345

Drelich J, Fang CH, White CL (2002) Measurement of interfacial tension in fluid–fluid systems. In: Hubbard AT (ed) Encyclopedia of surface and colloid science. Marcel Dekkar Inc, New York, pp 3152–3166

Halard B, Kawase Y, Moo-Young M (1989) Mass transfer in a pilot plant scale airlift column with non-Newtonian fluids. Ind Eng Chem Res 28:243–245

Weber FE, Taillie SA, Stauffer KR (1974) Functional characteristics of mustard mucilage. J Food Sci 39:461–466

Tomanova V, Pielichowski K, Srokova I, Zoldakova A, Sasinkova V, Ebringerova A (2008) Microwave-assisted synthesis of carboxymethylcellulose-based polymeric surfactants. Polym Bull 60:15–25

Jomsurang P, Sakamon D (2005) Evaluation of the effects of some additives and pH on surface tension of aqueous solutions using a drop-weight method. J Food Eng 70:219–226

Cao Y, Li H (2002) Interfacial activity of a novel family of polymeric surfactants. Eur Polym J 38:1457–1463

Guillot S, Delsanti M, Desert S, Langevin D (2003) Surfactant-induced collapse of polymer chains and monodisperse growth of aggregates near the precipitation boundary in carboxymethylcellulose–DTAB aqueous solutions. Langmuir 19:230–237

Garti N, Madar Z, Aserin A, Sternheim B (1997) Fenugreek galactomannans as food emulsifiers. Lebensm Wiss Technol 30:305–311

Huang X, Kakuda Y, Cui W (2001) Hydrocolloids in emulsions: particle size distribution and interfacial activity. Food Hydrocolloid 15:533–542

Huh C, Mason SG (1975) A rigorous theory of ring tensiometry. Colloid Polym Sci 253:566–580

Freud BB, Freud HZ (1930) A theory of the ring method for the determination of surface tension. J Am Chem Soc 52:1772–1782

Harkins WD, Jordan HF (1930) A method for the determination of surface and interfacial tension from the maximum pull on a ring. J Am Chem Soc 52:1751–1772

Paddy JF, Russell DR (1960) The measurement of the surface tension of pure liquids and solutions. J Colloid Interface Sci 15:503–511

Drost-Hansen W (1965) Precise measurements of surface & interfacial tension can provide clues to liquid structure. Ind Eng Chem 57:38–44

Lunkenheimer K, Wantke KD (1981) Determination of the surface tension of surfactant solutions applying the method of Lecomte du Nouy (ring tensiometer). Colloid Polym Sci 259:354–366

Morrison ID, Ross S (2002) Colloidal dispersions. Suspensions, emulsions and foams. Wiley, New York, pp 246–260

Hauser EA, Edgerton HE, Holt BM, Cox JT Jr (1936) The application of the high-speed motion picture camera to research on the surface tension of liquids. J Phys Chem 40:973–988

Lapham GS, Dowling DR, Schultz WW (1999) In situ force-balance tensiometry. Exp Fluids 27:157–166

Docoslis A, Giese RF, Van Oss CJ (2000) Influence of the water-air interface on the apparent surface tension of aqueous solutions of hydrophilic solutes. Colloid Surf B 19:147–162

Hunter RJ (2001) Foundations of colloid science, 2nd edn. Oxford University Press Inc, New York, pp 435–459

Acknowledgments

The authors thank the Faculty of Pharmacy, International Islamic University Malaysia (Kuantan, Malaysia) for providing the facility to use the du Nouy ring tensiometer.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, BB., Chan, ES., Ravindra, P. et al. Surface tension of viscous biopolymer solutions measured using the du Nouy ring method and the drop weight methods. Polym. Bull. 69, 471–489 (2012). https://doi.org/10.1007/s00289-012-0782-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-012-0782-2